Arc welding sensors

The collective term sensors for arc welding refers to devices that, as part of a fully mechanized welding system, record information about the position and, if possible, the geometry of the seam to be welded on the workpiece and provide corresponding data in a suitable form to control the position of the welding torch and, if possible, the welding process variables.

introduction

The quality of a weld seam depends not only on the decisive welding parameters for the welding process (e.g. voltage , current , wire feed and welding speed) but also to a large extent on how the process energy and the filler material are introduced. The positioning of the torch has a direct effect on the material flow. The heat input for melting the component edges and the even heat flow are directly linked to the burner guidance and have a significant influence on the quality of the seam and the resulting internal stresses . In fully mechanized and automated inert gas welding , inaccuracies in the torch guidance, workpiece handling, joint preparation and heat distortion add up to deviations in the joint position and joint geometry. With fully mechanical welding , the information required for the required weld seam quality can be determined by sensors. Sensors are therefore used to determine the position of the component (seam start and seam end finding), for joint tracking and for adapting the process parameters to current joint changes. The sensors can be used both online (simultaneously with the welding process) and offline (in a separate work step before welding). The majority of sensor applications are in online joint tracking.

Operating principles

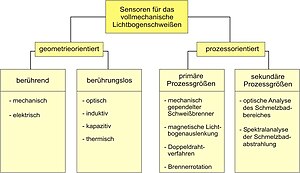

Every physical principle that can provide information about the position of an object can be used as a starting point for a sensor function. The ambient conditions prevailing during arc welding and the requirements that the fully mechanized system makes, however, lead to many restrictions. Figure 1 shows the system overview. The observation strategy of the sensor (process or geometry) was chosen as the overriding criterion, the further subdivision is based on the measuring principle . Another criterion that distinguishes sensor systems is the consideration of the design. Leading sensors are characterized by the fact that the measuring and joining points are not at the same location. In this case, the measuring and joining processes usually run sequentially. In order to be able to make position-relevant statements for the welding process, a calibration of the relative position is necessary in these systems . With process-oriented sensors, the measuring and joining points are identical. What all measuring principles have in common is the fact that by evaluating the sensor signals, geometric information about the joint and its position relative to the measuring head is obtained. The individual operating principles allow different processing speeds with which this information can be obtained.

Geometry-oriented sensors

Geometry-oriented sensors obtain their signals from the geometry of the joint or a defined edge or surface.

Tactile sensors

One type of tactile sensors are electrically touching sensors for seam detection or workpiece measurement. The sensor makes electrical contact with the workpiece; the electrically conductive workpiece is included in the measuring circuit of the sensor. The mechanically contacting sensors form the second category of tactile sensors. With them, the mechanical deflection of a probe element touching the workpiece is evaluated.

Electrically touching sensors

Electrically touching sensor systems, following a specific search strategy, feel the start of the seam or other points on the path by using components of the welding system (shielding gas nozzle , welding electrode , stylus, etc.) charged with voltage ( direct voltage from a few tens of volts to 1 KV depending on the material and surface ) . contact the workpiece. This means offline measurement of the start of the seam, the component position or geometry before welding. From the knowledge of the planned course of the path, a transformation of the path points is carried out according to the measured conditions. In this case, no corrective intervention takes place during the welding process.

Thermal sensors

With these sensors, the transferred heat flow is measured with the aid of two thermocouples arranged on the welding torch and used to control the lateral position and height of the torch. The alignment of the burner to the joint can be detected by comparing the sensor temperatures of the two thermocouples. With a symmetrical alignment of the burner, the difference between the radiated heat flows is zero, as are the temperature differences between the thermocouples. Depending on the lateral misalignment of the torch, the thermocouples are exposed to different heat flows , on the one hand due to the deformation of the arc and on the other hand due to the changed position of the weld pool.

Mechanically touching sensors

Systems with mechanical contact convert the deflection of a probe element directly into electrical control signals . A distinction is made between the following transducer principles :

- Microswitch

- Potentiometer

- Optical transducers (light barriers or similar)

- Inductive transducers

Due to the required distance between the switching points in one plane, transducers with microswitches result in a control hysteresis in the operating point and thus limited tracking accuracy. An electrical shift of the operating point is not possible. The other transducer systems mentioned (optical systems may be limited depending on the version) generate analog signals proportional to the probe element deflection and thus enable an error-proportional welding head tracking and an electrical shifting of the operating point by the higher-level control, e.g. B. in multi-layer welding. The output signals of the most common inductive transducer systems are 0 to 10 V DC depending on the deflection of the probe element (Fig. 2).

boundary conditions

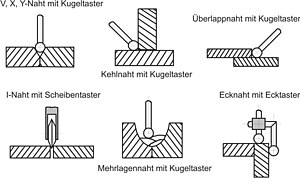

In the case of electrically touching systems, any impairment of the electrical contact between the sensor probe element and the workpiece is problematic, e.g. B. by welding spatter on the shielding gas nozzle, by a layer of scale and mill skin on the workpiece surface or by a spherically melted and slag-afflicted wire electrode end. In the case of mechanically contacting sensors, the probe elements must be adapted to the respective joint shapes. Butt welds with I-joint preparation should have a joint gap of more than 3 mm, with overlapping joints the thickness of the top sheet should be greater than 3 mm.

The sensor must be spatially separated from the welding torch mounted. This means that the joint scanning usually takes place in front of the burner. This arrangement does not pose a problem with predominantly straight seams. Probe element arrangements are also feasible (e.g. fork buttons or separate probe elements for height and side scanning) with which scanning in the torch plane and thus seam scanning can be carried out almost free of tracking errors. In addition to guiding the torch along a welding joint, mechanically contacting sensors can also be used to find the start of the seam and detect the end of the seam.

Optical sensors

Optical sensors are a type of non-contact, geometry-oriented sensors (Fig. 1). In the case of optical sensors, the welding joint is scanned to obtain information by means of a radiation detector that detects the emitted optical radiation of a measurement object . Semiconductor image recorders are used as radiation detectors. With the optical measurement principles, a distinction can be made between sensors with and without active structured lighting . Without active structured lighting means that a camera is used to obtain the signal , which observes the workpiece and extracts the information sought from the two-dimensional gray value image. Active structured lighting means the use of a light source for the targeted illumination of certain regions of the component. Depending on the design, individual photo elements , lines or arrays can be used to subsequently record these .

functionality

For optical measurement without active structured lighting, a camera is aimed at the area of the weld joint and the scene of interest is viewed directly. This is used, for example, in submerged welding processes to show the worker a live image of the weld joint on a monitor. Two semiconductor technologies are known as image recorders . The CCD camera (CCD: Charged Coupled Device) is the older, most widespread type of camera; it is also used in standard video cameras. When using a CMOS image recorder , it is possible to record a usable image of the weld joint even with a burning arc due to its high input dynamics. The method of optical measurement technology with active structured lighting, usually generated by a laser with a defined wavelength , is often used to automate welding processes. A distinction must be made between 1-, 2- and 3-dimensional measuring systems. Since it is not possible to measure directly in the arc itself, a certain distance (advance), which depends on the type and size of the arc itself, must be maintained.

With the one-dimensional measuring systems, the distance from the sensor to the workpiece surface is determined. This can be done by measuring the transit time. Another widely used method is laser triangulation (Fig. 4).

The distance between the workpiece can be determined from the known dimensions of the sensor and the triangulation angle α. Such one-dimensional, optical distance measuring systems are widely used in the field of industrial automation technology and are therefore offered by a large number of manufacturers. In automated welding, they are often used to detect the component and / or joint position before the welding process. In the case of the two-dimensionally measuring sensor systems, various designs are again known. The two-dimensional laser scanner can be derived directly from the 1D triangulation sensor by means of a pendulum movement . The geometry of the joint is recorded using a scanning movement across the joint (Figure 5). This is usually realized by a movable mirror unit integrated in the sensor head.

As an alternative to this, a pendulum movement of the entire sensor head can also be carried out, but this can only be viewed as a special application of a one-dimensional measuring system. One advantage of the laser scanner is that, given the appropriate processing speed, the exposure conditions can be readjusted for each individual point-like distance measurement, which results in a uniformly illuminated image. In addition, as a result of the point-like illumination, the laser point is better recognizable for the detection element by the concentrated laser power and by suitable optical filtering compared to the disruptive arc radiation. The light section sensor avoids the disadvantage of moving parts in the sensor head (Fig. 6). The surface is not scanned point by point, but the entire geometry is captured in one image. For this purpose, the punctiform laser beam is expanded into a line by optics, which is projected onto the surface of the workpiece at right angles to the joint according to the scan line of the scanner. The laser line is again recorded with a detector element, but now in two dimensions, using the same geometric principle of triangulation. CCD and CMOS cameras with the above properties can be used for acquisition.

The so-called height profile of the measured joint geometry is obtained from the laser scanner and light section sensor as the output signal after preprocessing the sensor signals. This represents the surface of the workpiece along the cut on the projected laser line. Three-dimensional measuring systems with active lighting mostly use the light section method in connection with the projection of several parallel laser lines. This gives you a height profile for each line. By arranging several lines along the welding joint, a further dimension is obtained, which shows the change in the height profile of the joint geometry. The number of lines increases the resolution in the longitudinal direction of the joint, but this in turn increases the data processing effort. Similar to the projection of several parallel lines, measurements can be made using a projected circle or other geometric figures on the workpiece surface.

boundary conditions

All optical measuring methods have in common that the determined joint points have to be transformed from the sensor coordinates of the cameras into machine or workpiece coordinates. For this purpose, these must be calibrated beforehand on test workpieces and calibration matrices must be stored. Furthermore, information about the joint profile must be stored in advance for the use of image processing algorithms. This can be done by teaching templates , entering geometric parameters or teaching in using test workpieces. More extensive image processing for 2 and 3-D sensor systems usually requires a PC system for evaluation, which is why the common PC interfaces are used for data exchange, but there is still no standardized sensor interface.

Problems with the use of optical sensors

Problems arise with optical sensor systems due to the principle of scattered light from the open arc. For this reason, measurement directly at the working point is not possible with most optical sensors; a certain amount of advance must be observed. Other disturbances also come from welding spatter, which can have a negative impact on the detection result. Shielding devices between the sensor and the burner help to a certain extent. An exception is the direct observation of the arc with special cameras for process monitoring. The lead in front of the arc requires limited access to corners in components. To reduce this problem, make sure that the structure is as compact as possible and that the lead-in distance is short. Furthermore, the specified orientation of the sensor means a restriction of the working space for the robot . For an undisturbed operation of the optical components, heavy soiling (due to dust and welding smoke particles) should be avoided as far as possible. This can be remedied by replaceable protective glasses and protective shields with compressed air curtains. The quality of the surface to be measured has a significant influence on the measurement result. If this is highly reflective, unwanted reflections and incorrect measurements can occur, matt surfaces cause fewer problems. Problems also arise with changing surface qualities. Since optical systems are equipped with semiconductor detectors and extensive electronics, good electromagnetic shielding must always be ensured. This applies to the sensor, the image processing unit and their connecting lines. Sensor systems with active laser lighting react particularly sensitively to strong temperature fluctuations, as the emitted light wavelength of the laser diodes used depends on the temperature of the laser. If the ambient temperature and thus the wavelength of the active lighting change, this light can no longer penetrate through the narrow-band optical filter to the photodetector. Appropriate shielding from the welding process or cooling of the sensor head must therefore be provided. Depending on the laser power used, particular caution is required when handling sensors with active lighting. The wavelengths of the systems used are often in the visible range. This means classification in hazard classes 3A and 3B . The corresponding accident prevention regulations must be observed. The following points must be taken into account when using optical sensors:

- Note the restriction of accessibility and work space

- Shield interfering light through the open arc and weld spatter

- Note the reflective properties of the measuring surface

- Avoid contamination of the optical components

- Provide electromagnetic shielding for electronic components

- Compensate for temperature fluctuations in the sensor

- Be careful when handling laser radiation

Inductive sensors

Inductive sensors evaluate the damping of a high-frequency electromagnetic field caused by eddy currents in the workpiece. A side or height correction is possible for single-coil designs. Multi-coil sensors allow a correction in two coordinate directions and also an influence on the welding torch orientation.

Capacitive sensors

Capacitive sensors measure the capacitance between the workpiece and an electrically conductive plate of small dimensions. They offer the possibility of distance measurement in media with constant dielectric constant .

Process-oriented sensors

Process-oriented sensors obtain their signals from the primary or secondary process variables.

Arc sensors use the primary process parameters (welding current and / or voltage) of a moving or two non-oscillating arcs to generate height and side correction signals. Of course, these sensors also require a scannable geometry of the joint, but compared to geometry-oriented sensors, the measuring and joining location coincide.

Arc sensors

Stable operating points in arc welding are established as the intersection between the process characteristic and the power source characteristic (Fig. 7). The process characteristic describes the relationship between a stable arc voltage and the associated current strength of the process under constant boundary conditions. A characteristic field is obtained by varying the arc length / the torch distance.

Arc sensors in TIG welding

The TIG welding is one of the welding process with non-consumable electrode. This is why the process characteristic is often referred to as the arc characteristic. A direct change in the working distance is compensated for by the length of the arc. As a result, the arc resistance changes. Short arcs have a lower electrical resistance than long arcs. In TIG welding, power sources with a steeply falling characteristic are typically used. A change in the arc length therefore leads directly to a change in the process voltage. A comparative measurement enables the distance to the workpiece to be determined.

Arc sensors for MSG welding

With MIG / MAG welding , a process characteristic in the voltage-current diagram results from the interaction of the electrical properties of the free wire end and the arc. In principle, stable operating points are obtained through the use of suitable current source characteristics or through superimposed control strategies.

At point 1 of Figure 8, there is a stable equilibrium in which the energy supplied to the process is sufficient to melt the continuously supplied wire electrode. In the event of a rapid change in distance, the arc compensates for the change in length, point 2.The lower resistance of the short arc causes an increase in the current strength, which leads to the faster melting of the free wire end until a stable working point is assumed again, point 3. This compensation process requires between 100 and 200 ms. The arc sensor evaluates the permanent change in current intensity between point 1 and point 3 in order to obtain a variable proportional to the distance. In principle, this evaluation concept can also be used for pulsed arc welding. The concept of distance measurement presented above is extended with most arc sensors with a transverse scan of the joint geometry. The deflection of the process on the joint flanks allows a comparative measurement of the burner distance. The lateral positioning of the burner can be evaluated by calculating the difference between the distance values. The mean value of the two distance values indicates the height of the burner above the joint. Various concepts are used for the deflection (Fig. 9). Mechanical oscillation is the most widespread and is used extensively in robots in particular. Basically, quickly deflected systems offer e.g. B. with magnetic or rotary deflection an improvement in the signal rate and the signal quality, but with these systems, a higher equipment cost must be accepted. With the double wire technology, both joint flanks can be scanned simultaneously with one wire each.

boundary conditions

Arc sensors evaluate the stable working points during arc welding. Disturbance variables in the process must be compensated for using suitable filtering and evaluation strategies that are not susceptible to failure. In the case of simultaneous height and lateral guidance, it must be ensured that only those joint geometries are suitable for the arc sensors that allow a lateral position determination from their geometry by comparative measurement of the joint flanks. V-seams and fillet welds are suitable without restriction. I-seams without a gap are not suitable for side guides. Up to now, industrially available arc sensors cannot be used on aluminum materials .

Systems evaluating secondary process variables

In the case of sensor types that monitor the weld pool, the area of application is restricted by the fact that the weld pool size and arc radiation are dependent on geometric factors such as material density or composition ( alloy components ).

Optical analysis of the weld pool area: An optical observation of the weld pool area detects changes in the weld pool contour. The deviation from a contour defined as ideal is interpreted as a misalignment or as a change in the process behavior and compensated for.

Spectral analysis of the process signals

During the spectral analysis of the process signals, emission spectra of the arc or the weld pool are compared with assumed ideal values. Deviations indicate a changed chemical composition or an energetic change in the process zone.

Other applicable technical rules

- DVS 0922-1 Industrial robot system for inert gas welding - definition of the terms and parameters

- DVS 0922-2 Industrial robot systems for inert gas welding - control and programming functions

- DVS 0922-3 Industrial robot systems for inert gas welding - Technical welding equipment for MIG / MAG welding

- DVS 0922-4 Industrial robot systems for inert gas welding - planning and installation

- DVS 0922-5 Industrial robot systems for inert gas welding - positioning systems for workpieces and industrial robots

- DVS 0927-2 sensors for fully mechanical arc welding; Influence of the workpiece geometry and the manufacturing conditions on the possible applications

- DVS 0939 Tolerances for fully mechanical MIG welding and welding with industrial robots

literature

- Ulrich Dilthey: Welding Manufacturing Process 1 : Welding and Cutting Technologies, Volume 1 of Welding Manufacturing Process , Verlag Birkhäuser, 2006, ISBN 3540216731

- Workshop and Operation, Volume 118 , 1985