Gothaer Waggonfabrik

The Gothaer Waggonfabrik was an important metal construction company for aircraft and tram construction in Gotha . It had existed since 1883 and went to new owners several times, the range changed from aircraft to vehicle parts and supplies.

1883-1918

Carousels, wagons

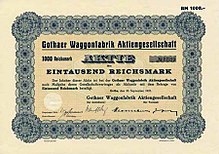

The roots of the Gothaer Waggonfabrik lie in a locksmith's shop founded in 1883 by the locksmith and later manufacturer Fritz Bothmann . In 1892 the businessman Louis Glück joined the company, which was now called Fritz Bothmann & Glück Maschinenfabrik & Carussellbau-Anstalt . At the beginning, a focus was on carousel construction , then the production of railway wagons, especially freight wagons, was added. The plant became known to the general public through the manufacture of tram cars , which began in 1898 and reached 57 units by 1913. In 1898 the legal form was converted into a stock corporation with the new name Gothaer Waggonfabrik, formerly Fritz Bothmann & Glück AG . After another seven years, the company's founders left in 1905. Albert Kandt (1866–1926) was appointed to the board and soon rose to general director due to his successful work. In 1909 he was appointed to the Council of Commerce and in 1917 to the Secret Commerce Council.

In 1910 it was renamed Gothaer Waggonfabrik AG (GWF). The company premises with a size of 110,000 square meters were located at Gothaer Ostbahnhof. Around 900 employees worked there. Companies that deal with vehicle construction are still located there today: a subsidiary of Schmitz Cargobull and the company "Gothaer Fahrzeugtechnik GmbH". The “Fliegerstrasse” there reminds of the history of the Gotha wagon factory.

Zeppelin airship port

The history of the airship port is closely linked to Albert Kandt. Kandt had already made a name for himself as a pioneer of aircraft construction in Gotha, where he found support from the Duke, the state government and the Gotha Aviation Association. Carl Eduard , the last ruling Duke of Saxe-Coburg and Gotha , was an avid supporter of airship travel. In 1909 he initiated the planning for an airship port on the outskirts of Gotha. On June 7, 1909, the Gotha Aviation Association was founded, it organized the construction of the first airship hangar in the Töpflebener Flur . The airship port was inaugurated on July 9, 1910 with the opening of the Carl Eduard airship hall , which could also be used by military airships. In the following years, numerous airships "in transit" arrived in Gotha. With the Thuringian Flight Week in spring 1911, several flight pioneers appeared in Gotha for the first time and showed their skills. In consultation with the Prussian War Ministry, the Duke then arranged for a flying school to be founded in Gotha. In March 1914, the army administration ordered the construction of the Gotha military aviation barracks with its own airfield on a piece of land next to the wagon factory , which began service on February 18, 1915.

Zeppelin-Versuchsbau-GmbH Gotha-Ost

The management of the Zeppelin factory in Friedrichshafen was forced to outsource areas of their development department due to lack of space. The choice fell, also because of the existing airship port, on the Gothaer Waggonbaufabrik, from which machines, workshops and experienced metal workers could be taken over. Alexander Baumann initially took over the management and the Gotha-Ost VGO I – III experimental buildings were built, which were then further developed into the Zeppelin-Staaken R VI long-range bomber . Later the engineer Adolf Rohrbach , an employee of Claude Dornier , took over the management of this branch, which continued to deal with the construction of giant aircraft .

Aircraft construction

In 1912 the Gothaer Waggonfabrik began experimentally with the construction of aircraft, initially monoplane with water-cooled engines of 70 hp. After the needs of the German Army for aircraft grew, an aircraft construction department was created in 1913 . A replica of the Etrich Taube was manufactured as the first aircraft under the name LE 1 .

The development department, which was founded in 1912, developed its own aircraft designs in quick succession. After the legendary "Gotha Taube" (also a design based on the Etrich Taube) had completed its test flight over the Krahnberg in April 1913 with the designation LE 2, the production of the aircraft could soon begin. The Gotha pigeon first flew over the English Channel to Dover in 1914 . Single and double deckers for school purposes as well as seaplanes were initially part of the product range.

With the First World War , aircraft construction became the most important branch of production. The wagon factory's planes quickly became generally known as “The Gothas” and during the First World War they achieved the dubious fame of being the “horrors of the enemy”. Towards the end of the First World War, the company was therefore looking for a new location to manufacture aircraft. The city of Fürth / Bay. provided an area on today's Hardhöhe , which continued to exist as an "industrial airport" until 1953. In 1938 this production site was sold to the newly founded company Bachmann, von Blumenthal & Co. Flugzeugbau (BBF).

A separate department was set up in Rostock-Warnemünde for testing seaplanes . From 1915 the large Gotha GI aircraft were built. The designer Hans Burkhard, who came from the Halberstädter Flugzeugwerke , designed the Gotha G.II to GV types . The twin-engined bombers from the royal seat of the English-born Duke Carl Eduard , known as The Gothas (The Gothas) through their missions against England , were one of the reasons for the renaming of the royal family of Coburg and Gotha to House Windsor in 1917 .

The Gotha G.IV was able to carry 500 kg bombs with a range of 800 km and was the first bomber to carry out attacks across the English Channel on London . The bomber Gotha GV had with a bomb load of 1000 kg already has a range of 840 km. More efficient further developments by the chief designer and technical manager Karl Rösner, the Gotha G.VII and Gotha G.VIII ( manufactured under license by Siemens-Schuckert ), reached 355 units by the end of the First World War in 1918.

From 1913 to 1918 the number of employees in the aircraft construction department of the Gothaer Waggonfabrik rose from 130 to 1250. According to the Versailles contract , aircraft production had to be discontinued and the machines dismantled in 1920.

| Aircraft type | use | built | constructor |

|---|---|---|---|

| LE 1 | Trainer aircraft | 10 | I. Etrich , E. Rumpler |

| LE 2 | spotter | 31 | F. Böhnisch; H. Bartl |

| LE 3 | spotter | 58 | Karl Grulich; H. Bartl |

| LE 4 | spotter | 1 | Karl Rösner |

| LD-4 | spotter | 20th | H. Schmieder |

| LD-5 | Cavalry plane | 13 | Hans Burkhard |

| LD-7 | spotter | 18th | H. Burkhard |

| GI | Remote reconnaissance | 18th | O. Ursinus ; H. Burkhard |

| G-II | Long-range scouts and bombers | 13 | H. Burkhard |

| G-III | bomber | 25th | H. Burkhard |

| G-IV | bomber | 52 | H. Burkhard |

| GV / G-Va | Long range bombers | 145 | H. Burkhard |

| G-Vb | Long range bombers | 80 | H. Burkhard |

| WD-1 | spotter | 6th | K. Rösner |

| WD-2 | Remote reconnaissance | 27 | K. Rösner |

| WD-7 | Torpedo training aircraft | 8th | K. Rösner; A. Klaube |

| WD-9 | Ranged Attack Aircraft (Navy) | 9 | K. Rösner; A. Klaube |

| WD-11 | Torpedo plane | 17th | K. Rösner; A. Klaube |

| WD-13 | spotter | 18th | K. Rösner; Hartwig |

| WD-14 | Long-range reconnaissance; Mine layers; Torpedo plane | 66 | K. Rösner; A. Klaube |

| WD-15 | Remote reconnaissance | 2 | K. Rösner |

| Legend: LE - landing monoplane, LD - land biplane, G - large aircraft, WD - water biplane. | |||

1919-1945

Reflection on the tradition of wagon building

After the end of the war in 1918, aircraft construction had to be stopped because of the Versailles Treaty. The production was converted to the construction of locomotive boilers, railcars and truck trailers. In 1923 the company employed 260 civil servants and 2,000 workers; when it was founded there were 17 civil servants and 166 workers. Under Kandt's leadership, the Bayerische Waggon- und Flugzeugfabrik (the branch with a factory airfield that was built in 1918–20 in Fürth / Bay) and the Eisenach vehicle factory were incorporated into the Gotha wagon factory.

Kandt was also long-time chairman of the Gotha Chamber of Commerce and a member of the German Railway Council. Since 1900 he lived in the villa designed by the Gotha architect Julius Krusewitz at Ernststraße 14. On July 24, 1926 Albert Kandt died of a heart attack while on a business trip at the age of 60.

Production in the 1920s again consisted of freight cars, streetcars (between 1923 and 1944 a total of 152 units) and railcars and truck trailers. In 1921, the company also became a car manufacturer by purchasing the Eisenach vehicle factory . This business area expanded through the merger with Cyklon Maschinenfabrik GmbH , Berlin-Tempelhof . During these years there were great financial losses. A “very severe renovation” was due, which led to the sale of both plants in 1928 in order to avert insolvency. The Eisenach vehicle factory was sold to Bayerische Motoren Werke AG , which thus laid the foundation for automobile production. The wagon construction division supplied, among other things, wagons for the CII series of the Berlin U-Bahn in 1929 . From 1931, the Gothaer Waggonfabrik AG belonged to the majority of the mechanical engineering company Orenstein & Koppel AG in Berlin, which also took over the Dessauer Waggonfabrik AG .

New aircraft construction

According to plans by Albert Kalkert (1902–1977), aircraft construction began again in Gotha in 1933 as part of the rearmament. The company increasingly became a licensee and supplier to other manufacturers ( Heinkel He 45 , Messerschmitt Bf 110 ), but a number of in-house designs were also developed.

One of the first developments was the Gotha Go 145 biplane , a single-engine training and training aircraft , largely made of wood, an important aircraft for beginners in the Luftwaffe , of which 1182 were made. The Go 146 , a twin-engine travel and courier aircraft, was built in small numbers from 1935.

Sample machines, some of which were manufactured, were the Gotha Go 147 , a single-engine, tailless aircraft , the Go 149 , a single-engine cabin single -seater , the Gotha Go 150 , a two-engine and two-seat sports and touring aircraft that set an altitude record in 1939 at 8048 m and the Go 241, a twin-engine, four-seat sports and touring aircraft.

On November 14, 1938, the newly founded Bachmann von Blumenthal & Co. Flugzeugbau (BBF) bought the branch in Fürth and continued to manufacture aircraft components there until the end of the war.

After the start of the war in 1939, cargo gliders were mainly developed and manufactured in Gotha . Engineer Kalkert designed the cargo glider Gotha Go 242 . This was made in the three series A to C, which differed mainly in the chassis, in about 1500 copies. The shoulder-wing deckers , mostly made of wood, were able to transport 23 fully equipped soldiers in addition to a two-man crew. The Gotha Go 244 was a variant of the Go 242 with two engines, of which only 42 machines are built. Further developments with sample machines were the Gotha Go 345 and Kalkert Ka 430 gliders .

1415 forced laborers were used in the factory during the final years of World War II . In 1944, about 80 percent of the factory was destroyed by an air raid. Nevertheless, in began Friedrichroda at war, the pre-production of the revolutionary flying wing - jet fighter Ho 229 (Ho IX) the brothers Horten .

Note: The production figures given come from different sources and can therefore differ.

| Aircraft type | use | built | constructor |

|---|---|---|---|

| Go 145 A / B | Multipurpose trainer aircraft | 1182 | A. Kalkert |

| Go 146 | Touring plane | 7th | A. Kalkert |

| Go 147 | brushless test aircraft | 1 | A. Kalkert |

| Go 149 | Trainer aircraft | 2 | |

| Go 150 | Private touring aircraft | 201 | A. Kalkert |

| DFS 230 | Glider | 1477 | H. Jacobs |

| Go 242 A / B | Glider | 1214 | A. Kalkert |

| Go 244 B / C | motorized cargo glider | 169 | A. Kalkert; Chicken hunter |

| Ka 430 | Glider | 12 | A. Kalkert |

| Go (Ho) 229 | Flying wing jet fighter | 3 | R. and W. Horten |

| He 45 | Scouts, bombers | ? | Heinkel (license) |

| Fw 58 | spotter | approx. 122 | Focke-Wulf (License) |

| Bf 110 | "Destroyer", night fighter | circa 2516 | Messerschmitt (license) |

1946-1990

Last aircraft construction

The Gothaer Waggon Fabrik AG was founded in 1946 in a Soviet corporation converted (SAG), but after completion of the dismantling provided in 1947 under German management. In 1949, Gothaer Waggonfabrik AG was nationalized as VEB Waggonbau Gotha , which belonged to the Association of Nationally Owned Locomotives and Waggon Manufacturers (VVB LOWA). From 1953 onwards again glider types from the pre-war period were built: 329 school gliders of type SG 38 and 68 school and exercise single-seaters of type Baby IIb . The two-seater training and training glider Go 530 (FES 530 / II) Lehrmeister was also developed until 1960 . This ended aircraft construction and production again concentrated on the construction of freight cars and trams.

Railway and tram construction

After the dissolution of VVB LOWA in 1954, the Waggonfabrik was the only tram manufacturer in the GDR and produced, among other things, Gotha and LOWA railcars. The three-line two-axle wagons of the standard type ET 57 / EB 57 and its successor types became known under the name Gothawagen . The open seating cars and articulated cars with a floating middle section were called Gotha open seating cars and Gotha articulated cars . Between 1946 and until production was discontinued in 1967, almost 3,000 tram cars were manufactured. The production profile still included the production of special freight wagons, for example for lignite transport, refrigerated vehicles with and without their own refrigeration units, and refrigerated containers.

Trailer construction

A production series of low-loader trailers such as the TL 12, TL 20 and TL 40, the heavy-duty trailer SL 40 and the 40 TGL 5912 road scooter built for the Deutsche Reichsbahn were also maintained until the 1960s.

Cooling systems and car parts

In 1967 the plant was renamed VEB Luft- und Kältetechnik Gotha . The employees developed and built fans, cooling systems and water purifiers. With effect from July 1, 1983, the company was restructured again and from then on belonged to the Kombinat Personenkraftwagen Karl-Marx-Stadt. The production of complete chassis, individual parts and assemblies for the Wartburg car now became the main task of the workforce. With this rededication, the majority of the track systems and halls that had remained from the pre-war period were cleared away; in addition to the press shop and turning shop, an assembly hall with a belt conveyor system with a planned capacity of 75,000 chassis per planned year was created. After an inspection, the finished chassis could be efficiently loaded using a remaining siding and distributed across the country by rail. In 1988 the required number of chassis was increased to 100,000, because the Eisenach automobile plant was to achieve a higher production capacity through restructuring and the introduction of the Wartburg 1.3. But the workforce was already fermenting, and dissatisfaction with the socialist mismanagement culminated in a letter of protest to the State Council Chairman Egon Krenz in October 1989 .

Collapse and privatizations

The discontinuation of car manufacturing in Eisenach also resulted in the temporary end for the supplier companies. In 1990 the 2300 employees were threatened with losing their jobs. Appropriate cooperation relationships and a lot of improvisation made it possible to initially keep 900 selected employees in work.

Since 1991

Trailer construction

On December 17, 1991, the Treuhandanstalt reported the company as capable of restructuring, and the company was initially part of the Lintra holding company. The economic survival ensured in 1996 the reorientation of the company towards truck trailer construction. After that, the cooperation with Schmitz Trailer Fahrzeugbau GmbH began until the company was finally taken over in 1997 by the Schmitz Group , vehicle construction division, and today manufactures trailers for trucks as Schmitz Cargobull Gotha GmbH . The core product are tipper trailers . With the production of about 4,000 vehicles in 2016 117 million euros have been implemented . In the 2016 financial year, the company employed 477 people.

Lattice masts and boom extensions

The second company, Gothaer Fahrzeugtechnik GmbH, was spun off in 1997 . The company mainly produces lattice masts and boom extensions for mobile and crawler cranes , but also troughs for construction vehicles and welded assemblies made of high-strength fine-grain steel and trains welders in a welding technology course in accordance with DVS guidelines. In the 2017 financial year, Gothaer Fahrzeugtechnik employed around 360 people.

literature

- Collective of authors: From the history of the company on the occasion of its 75th anniversary (1898–1973) . Ed .: VEB Luft- und Kältetechnik Gotha. Self-published, Gotha 1973, p. 88 .

- Jekaterina Vogel: The Gothaer Waggonfabrik - 100 years of a company . In: Gothaer museum booklet . Gotha 1998, p. 23-37 .

- Eberhard Hälbig: Gothaer Waggonfabrik A.-G. Gotha, Germany 1944-1945 . Rockstuhl, Bad Langensalza 2017, ISBN 978-3-95966-234-5 .

- Heiko Stasjulevics: Gotha, the city of flying . Rockstuhl, Bad Langensalza 2001, ISBN 3-934748-69-4 .

- Marion Siegmund: Gothaer Waggonfabrik, vorm. Fritz Bothmann & Glück Actien-Gesellschaft . In: Series of publications by the URANIA culture and education association Gotha eV on the company history of the city of Gotha. tape 13, 1-3 . URANIA Culture and Education Association Gotha, 2000, ZDB -ID 2382765-8 .

- GWF aircraft. Gothaer Waggonfabrik AG . In: Aviator book series. Row A: Work Chronicles. tape 9 . Luftfahrt-Verlag Walter Zuerl, 1968, ZDB -ID 595617-1 .

Web links

- Early documents and newspaper articles about Gothaer Waggonfabrik in the press kit 20th Century of the ZBW - Leibniz Information Center for Economics .

- gothawagen.de - Tram cars from Gothaer Waggonfabrik.

- Naumburg Tram Overview of the different tram cars

- Waggonfabrik share ( page no longer available )

Individual evidence

- ↑ The first visit by an airship, it was the Parsival , took place on the evening of November 14th, 1909. The approach in an approaching snowstorm forced the crew to make an emergency landing and subsequent dismantling of the aircraft.

- ↑ a b Heiko Stasjulevics: Gotha - the aviation city . In: Gothaer museum booklet. Contributions to regional history . 1992, p. 64-78 .

- ^ New renovation of Gothaer Waggon In: Vossische Zeitung of October 20, 1928.

- ↑ a b c Jekaterina Vogel: The Gothaer Waggonfabrik - 100 years of a company . In: Gothaer museum booklet. Contributions to regional history . Gotha 1998, p. 23-37 .