Cyclohexane

| Structural formula | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||

| Skeletal formula (left) and chair conformation (right) | |||||||||||||||||||

| General | |||||||||||||||||||

| Surname | Cyclohexane | ||||||||||||||||||

| other names |

|

||||||||||||||||||

| Molecular formula | C 6 H 12 | ||||||||||||||||||

| Brief description |

characteristic smelling, colorless liquid |

||||||||||||||||||

| External identifiers / databases | |||||||||||||||||||

|

|||||||||||||||||||

| properties | |||||||||||||||||||

| Molar mass | 84.16 g mol −1 | ||||||||||||||||||

| Physical state |

liquid |

||||||||||||||||||

| density |

0.78 g cm −3 |

||||||||||||||||||

| Melting point |

6.72 ° C |

||||||||||||||||||

| boiling point |

81 ° C |

||||||||||||||||||

| Vapor pressure |

|

||||||||||||||||||

| solubility |

almost insoluble in water (60 mg l −1 at 20 ° C) |

||||||||||||||||||

| Refractive index |

1.42623 |

||||||||||||||||||

| safety instructions | |||||||||||||||||||

|

|||||||||||||||||||

| MAK |

|

||||||||||||||||||

| Toxicological data | |||||||||||||||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . Refractive index: Na-D line , 20 ° C | |||||||||||||||||||

Cyclohexane (also hexahydrobenzene, hexamethylene, naphthene) is a colorless liquid. It is a cycloalkane with the molecular formula C 6 H 12 , which occurs in petroleum and is used as a solvent and raw material in synthesis .

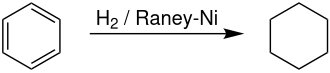

Extraction and presentation

The large-scale production of cyclohexane is carried out by catalytic hydrogenation of benzene at temperatures of 170-230 ° C and pressures of 20-50 bar over Raney nickel catalysts in the liquid phase.

Cascaded bubble column reactors or fixed bed reactors are suitable as reactors . In addition, the hydrogenation in the gas phase at 400-600 ° C and pressures of 20-50 bar on nickel , platinum or palladium - catalysts on alumina as a carrier feasible.

Furthermore, cyclohexane can also be isolated from raw gasoline cuttings by fractional distillation . However, this only leads to a purity of approx. 85%. The USA is the main producer of cyclohexane, around one million tons of cyclohexane are produced annually in the USA, which corresponds to around 34 percent of global production. The total production of cyclohexane in Europe is between 835,000 and 925,000 tons annually. Around 11.4% of the global benzene market in 2010 was accounted for by the production of cyclohexane.

The production capacities for cyclohexane in 1999 were around 5.5 million tons per year worldwide .

properties

Cyclohexane melts at 6.7 ° C and boils at 80.7 ° C under normal pressure . It smells like petrol, the odor threshold is 1.4 to 88 mg · m −3 , the liquid is highly volatile. Cyclohexane is insoluble in water, it is easily soluble in organic substances such as alcohols , hydrocarbons , ethers or chlorinated hydrocarbons , and cyclohexane itself is a solvent for many organic substances. The octane number of cyclohexane is 77. Cyclohexane is highly flammable and hazardous to water.

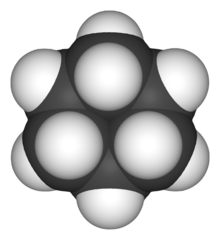

Conformations

Cyclohexane played a central role in the development of organic stereochemistry ( Hermann Sachse , Ernst Mohr , Sachse-Mohr theory ). The molecule can exist in two conformations , the chair and the twist conformation. At room temperature, about 99 percent of the cyclohexane molecules are in the chair conformation. A plane (planar) cyclohexane molecule would have a CCC valence angle of 120 ° and numerous ecliptic interactions of the C – H bonds, i.e. a high angular stress ( Baeyer stress ) and torsional stress . In the chair conformation , however, all C – H bonds can form a torsion angle of 60 °, and the valence angle approaches the tetrahedron angle (109.4 °). Therefore, this form is energetically more favorable and has long been considered to be stress-free (see article Stress Energy ). The chair conformation is also free from angular stress.

The twist conformation is achieved from the chair conformation when thermal energy is supplied; to do this, valence angles have to be distorted and an energy barrier has to be overcome. Your maximum is assigned to a "half armchair" arrangement. A relatively high amount of energy (approx. 45 kJ mol −1 ; 10–11 kcal mol −1 ) must be used for this.

The twist conformation is more flexible than the chair shape. The boat conformation discussed earlier - first called the Wannen conformation in German - is also free from angular stress; with it, however, ecliptic interactions of the C – H bonds occur on the “sides of the boat”, which creates torsional stress. The spatial proximity of two hydrogen atoms at the “bow” and “stern” of the boat also leads to considerable van der Waals stress . The twist conformation can easily change into a new twist shape via the boat arrangement (maximum potential energy) (energy barrier approx. 6.3 kJ mol −1 , 1.5 kcal mol −1 ). The twist shapes merge into one another through pseudorotation . According to current knowledge, the half-chair and boat arrangements are maxima of the potential energy, in other words not “stable” conformations. Finally, via the twist conformation, the chair-shaped cyclohexane ring can “snap” (“flip”) into another chair conformation; this is known as "inverting" the ring (ring inversion).

The interaction of the C – H bonds or hydrogen atoms is therefore of decisive importance for the energy of the various conformations. As for the most stable chair conformation, there are two sets of C – H bonds: six are parallel to the sixfold rotating mirror axis (S 6 ) of the molecule, three upwards and three downwards; the other six are aligned with an imaginary “equatorial plane” standing perpendicular to this axis. According to a suggestion by Derek HR Barton , these bonds are referred to as equatorial ( equatorial , abbreviated to "eq" or "e", blue in the picture), those as axial (ax or a, red in the picture). During the ring inversion, the two sets swap their places: Axial C – H bonds become equatorial and vice versa.

The structure determination by electron diffraction showed, however, that this model is somewhat simplified. Compared to the ideal chair conformation the molecule is somewhat flattened (Engl. Flattened ). The torsion angle is not 60 °, but 55 °, which means that the axial C – H bonds are not completely parallel, but are rotated "outwards" by approx. 7 °. The mean C – C bond length is 153.6 pm, the CCC valence angle 111.4 °, and the mean C – H bond length is 112.1 pm.

Thermodynamic properties

The vapor pressure function is obtained in the temperature range of 303 K to 343 K by Antoine corresponding

- log 10 (P) = A - B / (T + C)

with P in bar, T in K and A = 3.99200, B = 1216.930 and C = −48.621.

| property | Type | Value [unit] | Remarks |

|---|---|---|---|

| Standard enthalpy of formation | Δ f H 0 liquid Δ f H 0 gas |

−156.2 kJ mol −1 −123.1 kJ mol −1 |

as a liquid as a gas |

| Enthalpy of combustion | Δ c H 0 liquid | −3919.6 kJ mol −1 | as a liquid |

| Heat capacity | c p | 156.9 J mol −1 K −1 (25 ° C) | as a liquid |

| Critical temperature | T c | 553.8 K | |

| Critical pressure | p c | 40.8 bar | |

| Critical volume | V c | 0.308 l mol −1 | |

| Critical density | ρ c | 3.24 mol·l −1 | |

| Acentric factor | ω c | 0.20805 | |

| Enthalpy of fusion | Δ f H 0 | 2.732 kJ mol −1 | at the melting point |

| Enthalpy of evaporation | Δ V H 0 | 29.97 kJ mol −1 | at normal pressure boiling point |

The temperature dependence of the enthalpy of vaporization can be determined in the temperature range between 298 K and 380 K according to the equation

- Δ V H 0 = A exp (−αT r ) (1 - T r ) β

with Δ V H 0 in kJ / mol, T r = T / T c as reduced temperature and A = 43.42 kJ / mol, α = −0.1437, β = 0.4512 and T c = 553.4 K. describe.

Vapor pressure function of cyclohexane

Temperature dependence of the heat of vaporization of cyclohexane

Safety-related parameters

Cyclohexane forms highly flammable vapor-air mixtures. The compound has a flash point of −18 ° C. The explosion range is between 1.0% by volume (35 g / m 3 ) as the lower explosion limit (LEL) and 9.3% by volume (326 g / m 3 ) as the upper explosion limit (UEL). The explosion limits are pressure dependent. A decrease in pressure leads to a reduction in the explosion area. The lower explosion limit changes only slightly up to a pressure of 100 mbar and only increases at pressures below 100 mbar. The upper explosion limit decreases analogously with falling pressure.

| Explosion limits under reduced pressure (measured at 100 ° C) | ||||||||||||

| pressure | in mbar | 1013 | 800 | 600 | 400 | 300 | 250 | 200 | 150 | 100 | 50 | 25th |

| Lower explosion limit (LEL) | in% by volume | 0.9 | 0.9 | 0.9 | 1.0 | 1.0 | 1.1 | 1.1 | 1.1 | 1.3 | 1.7 | 3.3 |

| in g m −3 | 31 | 32 | 32 | 34 | 35 | 37 | 39 | 40 | 45 | 60 | 116 | |

| Upper explosion limit (UEL) | in% by volume | 9.3 | 8.8 | 8.4 | 8.0 | 7.8 | 7.6 | 7.5 | 7.5 | 7.4 | 6.2 | 4.0 |

| in g m −3 | 325 | 307 | 293 | 281 | 272 | 266 | 263 | 262 | 258 | 218 | 140 | |

The maximum explosion pressure and the limiting oxygen concentration are pressure and temperature dependent. The limit gap width was determined to be 0.94 mm. This results in an assignment to explosion group IIA. With a minimum ignition energy of 1.38 mJ, vapor-air mixtures are extremely ignitable. The ignition temperature is 260 ° C. The substance therefore falls into temperature class T3. The electrical conductivity is very low at 4.0 · 10 −15 S · m −1 .

|

Oxygen limit concentration and maximum explosion pressure under reduced pressure (measured at 20 ° C and 100 ° C) |

||||||||||||

| Pressure in mbar | 1013 | 600 | 400 | 300 | 200 | 150 | 100 | |||||

| Oxygen limit concentration (SGK) in vol% | 20 ° C | 9.3 | 9.3 | 10.0 | 10.5 | 14.0 | ||||||

| 100 ° C | 8.5 | 8.4 | 9.0 | 9.4 | 10.5 | |||||||

| Maximum explosion pressure (p max ) in bar | 20 ° C | 9.5 | 5.5 | 3.6 | 1.8 | 1.3 | 0.9 | |||||

| 100 ° C | 7.6 | 4.6 | 3.1 | 1.5 | 0.8 | |||||||

use

Cyclohexane is used to make synthetic fibers like nylon . It is also used as a solvent. Cyclohexane occurs in petroleum ; it is an important starting material for organic syntheses. Around 39 percent of the cyclohexane produced is consumed in Europe, Europe is the largest consumer of cyclohexane.

Health hazards

Inhalation and ingestion of the liquid lead to headaches, nausea and dizziness. The eyes and skin become red and there is irritation of the airways. A long-term exposure over cyclohexane can dermatitis result, an inflammatory reaction of the skin.

literature

- Siegfried Hauptmann: Organic Chemistry. 1st edition. Publisher Harri Deutsch, Thun-Frankfurt am Main 1985, ISBN 3-87144-902-4 .

- Hans Rudolf Christen, Fritz Vögtle: Organic chemistry. From the basics to research. 1st edition. Volume 1, Salle, Frankfurt am Main 1988, ISBN 3-7935-5397-3 , p. 92ff. (also: Sauerländer, Aarau 1988, ISBN 3-7941-3001-4 )

- Marye Anne Fox, James K. Whitesell: Organic Chemistry. 1st edition. Spectrum Academic Publishing House, Heidelberg u. a. O., 1995, ISBN 3-86025-249-6 , p. 193.

Web links

Individual evidence

- ↑ Entry on CYCLOHEXANE in the CosIng database of the EU Commission, accessed on May 24, 2020.

- ↑ a b c d e f g h i j k Entry on cyclohexane in the GESTIS substance database of the IFA , accessed on March 29, 2018(JavaScript required) .

- ^ A b R. H. Stokes, RP Tomlins: Thermodynamic functions of melting for cyclohexane. In: J. Chem. Thermodynamics. 6, 1974, pp. 379-386.

- ↑ CRC Handbook of Tables for Organic Compound Identification . 3. Edition. 1984, ISBN 0-8493-0303-6 .

- ↑ Entry on cyclohexane in the Classification and Labeling Inventory of the European Chemicals Agency (ECHA), accessed on February 1, 2016. Manufacturers or distributors can expand the harmonized classification and labeling .

- ↑ Swiss Accident Insurance Fund (Suva): Limit values - current MAK and BAT values (search for 110-82-7 or cyclohexane ), accessed on September 25, 2019.

- ↑ Entry on cyclohexane in the ChemIDplus database of the United States National Library of Medicine (NLM), accessed on July 31, 2018 or earlier.

- ↑ a b c Hans-Jürgen Arpe: Industrial organic chemistry - important preliminary and intermediate products . 6th edition. WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim 2007, ISBN 978-3-527-31540-6 , p. 384 f .

- ↑ a b Manfred Baerns, Arno Behr, Axel Brehm, Jürgen Gmehling, Kai-Olaf Hinrichsen, Hanns Hofmann, Regina Palkovits, Ulfert Onken, Albert Renken: Technische Chemie . 2nd Edition. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany 2013, ISBN 978-3-527-33072-0 , p. 605 .

- ↑ Benzene market study . on: Ceresana. July 2011.

- ↑ For the story see among others: Ernest L. Eliel, Samuel H. Wilen: Organic Stereochemistry. translated and edited by Henning Hopf . Wiley-VCH, Weinheim u. a. O., 1998.

- ↑ O. Bastiansen, L. Remote Holt, HM Seip, H. Kambara, K. Kuchitsu: Structure of cyclohexane deterministic mined by two independent gas-electron diffraction investigations. In: Journal of Molecular Structure. 18, 1973, p. 163.

- ^ WJ Gaw, FL Swinton: Thermodynamic Properties of Binary Systems Containing Hexafluorobenzene. Part 3: Excess Gibbs Free Energy of the System Hexafluorobenzene + Cyclohexane. In: Transactions of the Faraday Society . 64, 1968, pp. 637-647.

- ^ A b E. J. Prosen, WH Johnson, FD Rossini: Heats of formation and combustion of the normal alkylcyclopentanes and cyclohexanes and the increment per CH2 group for several homologous series of hydrocarbons. In: J. Res. NBS. 37, 1946, pp. 51-56.

- ↑ GE Moore, ML Renquist, GS Parks: Thermal data on organic compounds. XX. Modern combustion data for two methylnonanes, methyl ethyl ketones, thiophenes and six cycloparaffins. In: J. Am. Chem. Soc. 62, 1940, pp. 1505-1507.

- ↑ A. Lainez, MM Rodrigo, E. Wilhelm, J.-PE Grolier: Excess volumes and excess heat capacities of some mixtures with trans, trans, cis-1,5,9-cyclododecatriene at 298.15 K. In: J. Chem . Eng. Data . 34, 1989, pp. 332-335, doi: 10.1021 / je00057a021 .

- ↑ a b c d T. E. Daubert: Vapor-Liquid Critical Properties of Elements and Compounds. 5. Branched Alkanes and Cycloalkanes. In: J. Chem. Eng. Data . 41, 1996, pp. 365-372.

- ↑ J. Schmidt: Design of safety valves for multi-purpose systems according to ISO 4126-10. In: Chem. Ing. Techn. 83, 2011, pp. 796-812, doi: 10.1002 / cite.201000202 .

- ^ A b V. Majer, V. Svoboda: Enthalpies of Vaporization of Organic Compounds: A Critical Review and Data Compilation. Blackwell Scientific Publications, Oxford 1985, p. 300.

- ↑ a b c d E. Brandes, W. Möller: Safety-related parameters. Volume 1: Flammable Liquids and Gases. Wirtschaftsverlag NW - Verlag für neue Wissenschaft, Bremerhaven 2003.

- ↑ a b c d D. Pawel, E. Brandes: Final report on the research project, the dependence of safety parameters on the pressure below atmospheric pressure. ( Memento of December 2, 2013 in the Internet Archive ), Physikalisch-Technische Bundesanstalt (PTB), Braunschweig 1998.

- ↑ JB Fenn: Lean flammability limit and minimum spark ignition energy. In: Ind. Eng. Chem. 43, 1951, pp. 2865-2869.

- ↑ HF Calcote, CA Gregory, CM Barnett, RB Gilmer: Spark Ignition - Effect of Molecular Structure. In: Ind. Eng. Chem. 44, 1952, pp. 2656-2662.

- ↑ Technical rule for operational safety - TRBS 2153, BG RCI leaflet T033 Avoidance of ignition hazards due to electrostatic charges. As of April 2009, Jedermann-Verlag, Heidelberg.

- ↑ Bertram Philipp, Peter Stevens: Fundamentals of industrial chemistry. VCH Verlagsgesellschaft, 1987, ISBN 3-527-25991-0 , p. 179.