Machine gun 45

| Machine gun 45 | |

|---|---|

| The further development of the MG 42 in the Museum of Munster | |

| general information | |

| Military designation: | MG 45 |

| Country of operation: | German Empire |

| Developer / Manufacturer: | Großfuß AG |

| Development year: | 1944 |

| Manufacturer country: | German Empire |

| Weapon Category: | Machine gun |

| Furnishing | |

| Weight: (unloaded) | 9 kg |

| Barrel length : | 600 mm |

| Technical specifications | |

| Caliber : | 7.92 × 57 mm (8 mm Mauser, 8 × 57 IS) |

| Cadence : | approx. 1800 rounds / min |

| Closure : | mass-supported roller lock |

| Charging principle: | Recoil loader |

| Lists on the subject | |

The machine gun 45 , MG 45 for short , also MG 42V , is a recoil loader with a delayed mass lock (or mass-assisted roller lock). It was intended as a successor to the MG 42 .

backgrounds

After the material-saving measures introduced in 1944, a simplified version of the MG 42 was required. The Mauser company then developed a simplified version of the MG 42, while at the same time the Großfuß company designed the MG 42V or MG 45 with a mass-supported roller lock. This weapon was already tested in June 1944. However, the further development dragged on, so that at the end of the war only ten weapons were made.

Structure, successor

Many parts were identical to those of the MG 42. So the ammunition feed, the trigger group and parts of the rifle butt were taken over. Only the closure was based on the principle of the delayed mass closure. The development was never fully completed, so that one has to speak of a prototype. The main advantage of the new weapon was a reduced production time, the weapons office assumed 60% of that of the MG 42. The housing was a simple stamped construction with a flash hider, since the recoil amplifier was omitted. The barrel was now a simple turned part without a locking piece with a service life of over 10,000 rounds. In contrast to the MG 42, the MG did not have a base, which is why the bolt had to be removed from the top. The locking principle of the MG 45 formed the basis for the MG710 manufactured by SIG and for a trial replica by Rheinmetall with the designation MG60. However, these weapons did not prove to be significantly better than the MG 42 and its immediate successor.

However, the locking principle made it possible to simplify the construction of lighter weapons and was further developed by some manufacturers. The G3 from Heckler and Koch is based on this breech, as are the weapons from CETME and the Swiss assault rifle 57 and its commercial version SIG-AMT. In addition to the SIG company, this weapon was also manufactured under license by Beretta . From 1961, the customer was Chile with 48,483 weapons delivered.

The closure principle

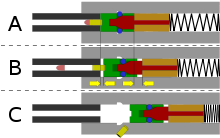

The bolt of the MG 45 has support rollers like the MG 42. In the MG 42, a recoil loader with a barrel return, the slide and barrel run back together until they are separated by inserting the rollers.

In contrast to the MG 42, the MG 45 is a recoil loader with a mass-supported roller lock and a fixed barrel. The locking principle of the MG 45 was adopted by SIG for the MG 710 and the assault rifle 57 and works as follows: The support rollers are mounted in the bolt head on both sides. During the advance, the bolt head is stopped at the end of the run, the control piece continues to run, presses the two rollers into the locking bearings with the wedge in front and strikes the firing pin. The shot breaks. As a result of the pressure of the bottom of the case on the bolt head, the support rollers are pressed from their bearings inwards onto the wedge of the control piece. This accelerates it backwards, at the same time the return speed of the bolt head is considerably delayed until the wedge releases the support rollers. The wedge shape is calculated so that this does not happen before the pressure in the barrel and sleeve has dropped. The accelerated control piece then pulls the bolt head, including the cartridge case, backwards with it. This is the classic function of the delayed ground connection, see also the functional description under G3 .

Since the bolt head is not blocked when the shot is fired, but continuously moves slightly backwards, the case must be prevented from being torn when the gas pressure is still high. For this purpose, pressure compensation grooves were milled into the front tapering part of the cartridge chamber in the SIG MG 710. The internal pressure on the sleeve cone is thus compensated. It is not known whether the MG 45 also has relief grooves; there are various reports about this. Werner Gruner stated that there were relief grooves , his colleague Hans-Joachim Kaltmann denied this.

Further technical data

| number of pieces | approx. 10 |

| Mass of the shutter | 0.845 kg |

literature

- Reiner Lidschun, Günter Wollert: Illustrated encyclopedia of infantry weapons. Siegler, Königswinter 2008, ISBN 978-3-87748-668-9 , pp. 197-201.

- DWJ Extra 10, ISSN 1610-7039