Baker's yeast

| Baker's yeast | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Baker's yeast ( Saccharomyces cerevisiae ). The graduation marks each correspond to 1 µm. |

||||||||||||

| Systematics | ||||||||||||

|

||||||||||||

| Scientific name | ||||||||||||

| Saccharomyces cerevisiae | ||||||||||||

| Meyen ex EC Hansen |

Baker's yeast , also brewer's yeast , baker's yeast , Bärme (from Low German berme , 'Quellendes, Aufwallendes' ), North German Gest (cf. English yeast ), Bavarian Germ , Latin - scientific Saccharomyces cerevisiae , colloquially short yeast , belongs to the yeasts (single-celled mushrooms ) and is a budding yeast in ( english budding yeast ).

As can be seen from the Latin species name cerevisiae 'des beer', baker's yeast originates from top-fermented brewer's yeast . The Greco-Latin genus name Saccharomyces means 'sugar mushroom'.

The cells of Saccharomyces cerevisiae are round to oval, five to ten micrometers in diameter, and multiply through the process of budding . S. cerevisiae can also be in the hyphae form and form ascospores .

history

Pliny the Elder described the production or breeding of yeast ( ancient Greek ζύμη , Latin fermentum ) in his Naturalis historia .

A Hefner , in medieval brewing an independent profession, used and increased the yeast over brewing breaks away. The bakers received top-fermenting yeast from breweries . The yeasts enable the production of sweet-fermented breads such as the Kaisersemmel . With yeast as a leavening agent, bread with a finer taste can be made than with sourdough , in which not only yeast but also lactic acid bacteria are involved in fermentation. In the middle of the 19th century, more and more brewers switched from top-fermenting to bottom-fermenting yeasts . However, these are not suitable for making bread in the same way. As a result, the great demand led to the industrial production of baker's yeast outside the brewing process, first in 1846 using Mautner Markhof's “Viennese method” .

science

The eukaryote Saccharomyces cerevisiae is like the prokaryote Escherichia coli is a model organism in molecular biology and cell biology research. Due to the simple culture conditions and the relationship of the internal cell structure to other eukaryotic cells in the plant and animal world, it is used, for example, to study the cell cycle or protein breakdown .

Baker's yeast was the first eukaryotic organism whose nucleic acid base sequence was completely determined in the genome . The genome consists of 13 million base pairs (bp) and 6,275 genes in 16 chromosomes . Homologous genes can be found in the human genome for more than 23% of the genes in the yeast genome. There are now three major databases on the yeast genome.

Another pioneering scientific achievement was the complete synthesis of one of the 16 chromosomes of baker's yeast, which was announced in March 2014. Chromosome III, one of the shortest, was reproduced in seven years of work as part of an international project under the direction of geneticist Jef Boeke in the laboratory, and its functionality was demonstrated in living yeast cells. At 273,871 bp, it is significantly shorter than its natural counterpart at 316,667 bp, as the scientists omitted repetitions and other sequences that they deemed unnecessary. The work is the first step in a project to synthesize the entire yeast genome under the name “Sc2.0” (the “second version” of S. cerevisiae ).

A useful method in which baker's yeast does not act as a model organism, but rather as a tool for researching protein interactions, is the yeast two-hybrid system .

metabolism

Baker's yeast is considered to be facultatively anaerobic . This means that energy can be generated either aerobically (with oxygen) in the form of cellular respiration or through fermentation . Baker's yeast uses almost exclusively mono- or disaccharides (sugar) as starting materials for its energy metabolism. Long-chain carbohydrates (starch), on the other hand, cannot be used; the yeast lacks the necessary amylases . Excretion products are mainly carbon dioxide from breathing and ethanol (alcohol) from fermentation. The proportions of the products depend on whether the environment in which the yeast grows contains oxygen or not, as well as on the sugar concentration in the medium. When producing alcohol and using it as a leavening agent in baking, the anaerobic metabolism is crucial.

The designation of baker's yeast as facultative anaerobic is not entirely correct, since small amounts of elemental oxygen are required for the biosynthesis of ergosterol .

If larger amounts of easily usable organic substances (especially sugar) are present, these are fermented despite aerobic cultivation. This phenomenon is known as the Crabtree effect . The Crabtree effect reduces the yield (biomass per sugar used) and is therefore generally undesirable in yeast production. This can be minimized by supplying the appropriate substrate (see fed-batch process ).

If the baker's yeast is no longer available sugar, the oxidation of the self-produced ethanol with oxygen is used as an energy source under oxic conditions . In this way, the yeast can continue to multiply as long as there is no inhibition due to excessive ethanol concentrations or a limitation due to the lack of other nutrients ( phosphates , amino acids ).

The best temperature for fermentation (the "shoot") of the yeast is around 32 ° C. For the yeast to multiply, around 28 ° C is optimal. With a good supply of nutrients and oxygen (aerobic), the yeast mass in a brewer's yeast culture doubles in about two hours, so the increase is significantly slower than with many types of bacteria. In the case of anaerobic fermentation, the multiplication takes place considerably more slowly. At temperatures above 45 ° C, baker's yeast begins to die.

Baker's yeast is sensitive to pressure. When the pressure in the fermentation tank rises above 8 bar, the yeast stops fermenting. This effect is also used to control the fermentation process.

use

Yeasts of the Saccharomyces genus are used in many different areas. In addition to their use in baking, these yeasts are also involved in the fermentation of beer , cider , wine, and vinegar . They are also used today in the production of ethanol fuel and cellulosic ethanol . Baker's yeast is also used for the biosorption of heavy metals such as zinc , copper , cadmium and uranium from wastewater. The heavy metals accumulate inside and outside of the cells as crystals and can be chemically separated from the yeast.

In medicine, Saccharomyces cerevisiae , like the related species Saccharomyces boulardii, is used as a probiotic medicinal substance for the treatment of diarrheal diseases, to strengthen the general condition and to prevent hair loss.

Manufacturing

The basis for industrial baker's yeast production are two things:

- A yeast strain ( pure yeast ) that has been obtained for centuries by selection and breeding from sourdough yeast or from the brewer's yeast of top-fermented beers. Baker's yeasts are characterized by their high driving power and low levels of gluten- destroying enzymes. As a result of further breeding, the baker's yeast is stronger than the wild yeast in sourdough, but in contrast to sourdough yeast does not tolerate many other substances: acids, salts, fats and more.

- A culture medium with molasses serves as the main ingredient for the yeast to multiply.

While the yeast strain is the trade secret of the respective yeast producers, the technical process of yeast propagation is well known.

In order to produce masses of microorganisms in pure culture, they are usually produced in biotechnology in multi-stage culture processes. A one-step process in which a large volume of culture medium is inoculated with a small amount of the organisms is very disadvantageous for several reasons. If this were done, a large-volume system would need a relatively long time for propagation. That would have the following disadvantages:

- Technical: The larger a system, the more difficult it is to prevent foreign, undesirable microorganisms from entering. The phase of propagation in a large plant must therefore be kept as short as possible. This reduces the yield. Alternatively, the fermentation can be carried out longer with the addition of antibacterial auxiliaries.

- Economical: An expensive, large plant would take a long time to multiply a small amount of microorganisms, for whose production smaller, cheaper plants are sufficient.

- Biological: After their preparation, culture media are usually not optimal for the reproduction of microorganisms (among other things, too high redox potential, too low carbon dioxide concentration, too low concentration of specific growth stimulators). The organisms first have to create a more favorable environment through their metabolism. With a small amount of microorganisms in a large volume of culture medium, this takes a very long time and growth would be greatly retarded at the beginning.

In baker's yeast production, too, the propagation is carried out in several stages, for example from a test tube culture over liquid culture media with 50 ml, 1 l, 10 l, 40 l, 400 l, 4 m³, 10 m³ and 200 m³. The gradations can also be different.

An aqueous solution of eight to ten percent is used as the culture medium. Molasses contains around 50% sugar. The solution is brought to a pH of about 4.5 using acids, boiled (so that foreign microorganisms are killed) and filtered. Then nutritional salts (mainly ammonium salts and phosphates) and B group vitamins are added, as these are required for yeast growth and are not present in sufficient quantities in molasses. The cultures are aerobically , that is, with aeration, in order to obtain the highest possible biomass yield.

The first four stages up to about 40 l are carried out in the laboratory, with the culture facilities being sterilized, i.e. the yeast is propagated in pure culture. This takes about eight days. The next two to three stages up to about 10 m³ are carried out in a stationary technical system, the so-called pure breeding system, which is also sterilized (hot steam 120 ° C under 1 bar overpressure), duration about two days. Due to their size (200 m³), non-sterilized systems are used for the last two stages, but foreign microorganisms are largely excluded. These cultures only last a short time (10 to 20 hours each) and are started with a high yeast concentration so that any foreign organisms practically do not develop. In the example given, initially around 18 t of "yeast" is obtained in the 200 m³ stage. Sometimes yeast is also produced in two stages. In a final phase, also in a 200 m³ plant, the yeast is produced from the adjustable yeast in about ten hours, for example in four parallel cultures with 200 m³ of medium each about 65–70 t.

In about eleven days, almost ten billion times the yeast mass is produced from around 8 mg of starting mass with around 33 doubles.

The yeast is concentrated by means of separators (results in so-called "yeast milk" or "yeast cream") and further processed depending on the desired result:

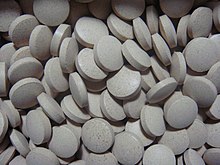

- Compressed yeast

- The yeast milk is concentrated to a dry matter content of around 30% using filter presses or vacuum rotary filters. The mass is then shaped and packaged using an extrusion press. One gram of compressed yeast contains about 10 10 (10 billion) yeast cells.

- Active dry yeast

- In the extruder compressed yeast is formed into small cylinders, then in the fluidized-bed process are dried.

- Dry yeast

- The remaining yeast milk is dried in a drum dryer or in a spray freeze-drying system, the enzymatic activity being completely lost, so that this yeast is mainly used as a feed additive or for dietetic and culinary purposes (so-called nutritional yeast ).

- Liquid yeast

- In liquid form, the yeast milk is adjusted to the driving force required by the customer.

Overall, larger amounts of organic and chemical substances as well as yeast water containing microorganisms are produced in the manufacture of molasses, which still represent a disposal problem.

An attempt is currently under development to use genetic engineering to induce yeast to form aromas (e.g. vanilla).

Dosage of the baker's yeast

Based on the amount of flour, about 3 to 6% of the yeast is added to the yeast dough . Doughs with a high fat content require up to 8%, as the lower water content has a negative effect on the yeast metabolism. With extremely long dough runs or pre-doughs , the yeast content used is around 1–2%. As an optimal Nährbasis using baking malt .

Commercial forms of baker's yeast and their shelf life

Yeast is offered as pressed fresh yeast (block yeast), as dry yeast (shelf life approx. 1 year) or liquid yeast. To produce the dry yeast, the majority of the water is gradually removed from the yeast that has been cleaned from the mash . Usually the emulsifier citrem ( ester of citric acid with monoglycerides ) is added. This is intended to prevent the yeast cells from drying out too much, so that the cells only become inactive, but do not die. Yeast inactivated in this way can be stored for a long time at room temperature. Nevertheless, one should take into account the expiry date printed on the package, as the ability of the yeast cells to reactivate is lost over time. A typical 7 g packet of dry yeast sold in retail stores has about the same fermentation power as half a 42 g cube of fresh yeast.

Ordinary fresh yeast retains its full power for ten to twelve days at a storage temperature of 2 to 8 ° C. A permanent breakdown of carbohydrate reserves and protein preserves the vital functions of the yeast. The more old or dead cells there are in a piece of yeast, the worse the driving force becomes. At the same time, substances such as glutathione leak from the cell. This leads to a softening of the glue ( gluten - grain protein) in the dough. Old fresh yeast is therefore practically useless, even at higher dosages.

Fresh baker's yeast can be recognized by its light, mostly yellowish color. It has a pleasant smell, a sweet, intense taste and a firm, shell-like break. Old yeast is brown-gray, cracked, crumbly, has an increasingly bitter taste and an unpleasant odor.

The shelf life of fresh baker's yeast can be extended by freezing. With a correspondingly small portioning, z. B. half a cube (approx. 21 g, usually sufficient for 500 g flour), direct processing from the freezer is possible.

An alternative to using baker's yeast is baking ferment .

Special types of baker's yeast

Special breeds are used for special tasks, such as osmotolerant yeasts, which - with very sweet doughs - are less sensitive to osmotic pressure . Organic yeasts ( sourdough yeasts ), which are grown on a cereal culture medium , are especially suitable for people with a yeast allergy, which usually only occurs with industrial yeasts (due to residues in the molasses substrate of yeast production).

Nutritional values

Compressed yeast

100 grams each:

- Energy value 439 kJ (105 kcal), water 73 g, protein 16.7 g, fat 1.18 g, carbohydrates 6.72 g of which: fiber 0.3 g

- Minerals : Potassium 649 mg, Phosphorus 605 mg, Calcium 28 mg, Sodium 34 mg, Iron 4.9 mg,

- Vitamins : niacin (B 3 ) 17.4 mg, pantothenic acid (B 5 ) 3.46 mg, thiamine (B 1 ) 1.43 mg, riboflavin (B 2 ) 2.31 mg, folic acid (B 9 ) 1.02 mg, biotin 0.033 mg

Active dry yeast

100 grams each:

- Energy value 1361 kJ (325 kcal), water 5.1 g, protein 40.4 g, fat 7.61 g, carbohydrates 41.2 g of which: fiber 26.9 g

- Minerals: potassium 955 mg, phosphorus 637 mg, magnesium 54 mg, calcium 30 mg, sodium 51 mg, zinc 7.94 mg, iron 2.17 mg, manganese 0.31 mg, copper 436 µg, selenium 7.9 µg

- Vitamins: niacin (B 3 ) 40.2 mg, pantothenic acid (B 5 ) 13.5 mg, thiamine (B 1 ) 10.99 mg, pyridoxine (B 6 ) 1.5 mg, riboflavin (B 2 ) 4 mg, Folic acid (B 9 ) 2.34 mg

Nutritional yeast (dried brewer's yeast, dry yeast)

100 grams each:

- Energy value 1440 kJ (344 kcal), water 6 g, protein 47.6 g, fat 1.3 g, carbohydrates 36.1 g of which: dietary fiber 0.8 g

- Minerals: potassium 1.41 g, phosphorus 1.9 g, iron 17.6 mg, manganese 0.53 mg

- Vitamins: niacin (B 3 ) 44.8 mg, pantothenic acid (B 5 ) 7.21 mg, thiamine (B 1 ) 12 mg, pyridoxine (B 6 ) 4.41 mg, riboflavin (B 2 ) 3.17 mg, Folic acid (B 9 ) 3.17 mg

See also

literature

- T. Satyanarayana, G. Kunze (Eds.): Yeast Biotechnology. Diversity and Applications . Springer, 2009, ISBN 978-1-4020-8291-7 (English, limited preview in Google book search).

Web links

- Entry on baker's yeast at DiArk

- hefefinder.de - Research project of the microbiology department of the Geisenheim research institute on yeasts

- Baker's yeast side

- DRYGIN (Data Repository of Yeast Genetic Interactions)

- Cell cycle and metabolic cycle regulated transcription in yeast

- Yeast Resource Center Public Data Repository

- BioPIXIE

- BioGRID: A General Repository for Saccharomyces cerevisiae Interactions

- YEASTRACT (Yeast Search for Transcriptional Regulators And Consensus Tracking)

- Website of the German Yeast Industry Association with consumer information on baker's yeast

- Country of origin Patagonia

- Magnetic baker's yeast

Individual evidence

- ↑ Peter H. Raven, Ray F. Evert, Susan E. Eichhorn: Biology of plants . Ed .: Thomas Friedl, University of Göttingen. 4th edition. De Gruyter , Berlin / New York 2006, ISBN 3-11-018531-8 , Chapter 14.8: Yeasts, p. 322 (942 pages, hardcover , American English: Biology of Plants, Seventh Edition . Translated by Uwe K. Simon, University of Tübingen (Chapter 14, Appendix)).

- ↑ AM Neiman: Ascospore Formation in the Yeast Saccharomyces cerevisiae . In: Microbiology and Molecular Biology Reviews . tape 69 , 2005, pp. 565 , doi : 10.1128 / MMBR.69.4.565-584.2005 , PMC 1306807 (free full text) - (English).

- ^ Max Nelson: Beer in Greco-Roman Antiquity. 2001, p. 149 ff. ( Digitized version ).

- ↑ Franz Meußdoerffer , Martin Zarnkow: The beer: A story of hops and malt. CH Beck Verlag, 2014, ISBN 978-3-406-66668-1 , p. 84.

- ↑ These include the Munich Information Center for Protein Sequences , the Saccharomyces Genome Database and the publication on the genome of Saccharomyces cerevisiae : A. Goffeau, BG Barrell, H. Bussey, RW Davis, B. Dujon, H. Feldmann, F. Galibert, JD Hoheisel, C. Jacq, M. Johnston, EJ Louis, HW Mewes, Y. Murakami, P. Philippsen, H. Tettelin, SG Oliver: Life with 6000 genes. In: Science. Volume 274, Number 5287, October 1996, pp. 546, 563-546, 567, PMID 8849441 .

- ↑ Narayana Annaluru et al .: Total Synthesis of a Functional Designer Eukaryotic Chromosome . In: Science . tape 344 , no. 6179 , 2014, pp. 55–58 , doi : 10.1126 / science.1249252 (English).

- ↑ Scientists Synthesize First Functional “Designer” Chromosomes in Yeast. Study reports major advance in synthetic biology. March 27, 2014, accessed April 3, 2014 (New York University press release).

- ↑ Otto Hoffmann-Ostenhof: Enzymology: A presentation for chemists, biologists and physicians. Springer 1954, p. 243.

- ↑ B. Volesky, HA May-Phillips: Biosorption of heavy metals by Saccharomyces cerevisiae . In: Applied Microbiology and Biotechnology , Vol. 42, No. 5, 1995, pp. 797-806.

- ↑ a b Waldemar Ternes , Alfred Täufel, Lieselotte Tunger, Martin Zobel (eds.): Food lexicon . 4th, comprehensively revised edition. Behr, Hamburg 2005, ISBN 3-89947-165-2 .

- ↑ Leavening agents, yeast, baker's, active dry ( Memento of the original dated May 30, 2015 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. nal.usda.gov