Aircraft engine

An aircraft engine (also known as aircraft engine ) is an internal combustion engine (most commonly in the form of a reciprocating piston engine ) that has been specially designed for use in an aircraft . Special technical and legal requirements are placed on a certified aircraft engine. With a few exceptions, these requirements stand in the way of the use of comparatively less expensive large-scale series car or motorcycle engines .

Aero engines - unlike engines for road vehicles - are characterized, among other things, by the specification of take-off performance and continuous performance.

technical requirements

Due to the conditions of use, high performance with a favorable power-to-weight ratio and low-vibration engine operation are required from an aircraft engine. It should have a low specific fuel consumption and be absolutely reliable.

Likewise, the engine and its ancillary units should have a compact design and offer the smallest possible frontal area in order to enable flow-favorable installation in the airframe or engine nacelle.

These contradicting requirements, the small number of pieces, high development costs and statutory obligations to provide evidence ( certification ) mean that numerous aircraft engines have been built practically unchanged for decades. The current reciprocating piston engines, especially those from the two large US manufacturers Lycoming and Continental , still largely correspond to the technical standards of the early 1960s. In addition to carburetors , intake manifold injection is now also used. In the smallest power classes up to a maximum of 50 kW, two-stroke engines are common for microlight aircraft and motorized gliders .

Depending on the flight altitude, there are fluctuations in air density and temperature, which require suitable control devices for the mixture formation . (See also Leanen ). Aircraft engines remain efficient even at high altitudes thanks to engine charging .

Legal requirements

The failure of an aircraft engine can lead to an aircraft accident with fatal consequences for occupants and people on the ground and serious damage to property. Due to the resulting safety requirements, there are strict requirements for the approval of aircraft engines. The legislature requires extensive proof of reliability and, among other things, a double ignition system for approval as an aircraft engine. Furthermore, the maintenance of the engines is monitored very closely - the legislator prescribes a complete engine overhaul with replacement of the running gear after 2500 operating hours. The piston and its rings as well as the cylinders or cylinder liners are referred to as barrel sets.

Differences to internal combustion engines in road vehicles

In its basic principle, an aircraft engine, such as that used in light aircraft, is similar to that of a car . However, there are usually some special design features, some of which are prerequisites for certification.

For the choice of the engine configuration ( boxer engine , in- line engine , radial engine , V-engine ), special criteria are decisive for aircraft. An essential aspect of air-cooled engines is a good supply of all cylinders with cooling air.

In the case of single-engine propeller aircraft (see also light aircraft ), a further criterion is that the engine is arranged directly in front of the pilot and that the propeller or crankshaft should be installed in a high position due to the clearance of the propeller circle. All engine parts that are above the crankshaft therefore impair the pilot's view, so that almost exclusively boxer engines are used here. In the past, “hanging” V or in-line engines were also used, that is, the crankshafts were on top and the cylinder heads on the bottom.

In the case of engines of multi-engine aircraft arranged on the wings, the pilot's view is not impaired by the engine due to the design, so that the most powerful multi-engine propeller aircraft are also all equipped with radial engines with a large number of cylinders (such as the Lockheed Super Constellation ).

The main differences or deviations between aircraft engines and combustion engines in road vehicles are:

Double ignition

Two independent ignition systems are stipulated ( magneto ignition ), which are normally in parallel operation, but must be individually checkable during start preparations ("run-up"). In the event of failure of one of the ignition systems of this double ignition , the drop in performance of the engine must not exceed a certain percentage.

Use of light gasoline

Motor fuels are mixtures of different hydrocarbons. Those with a lot of hydrogen and little carbon (C5-C7) are firstly more energetic and secondly have a lower weight; both properties are important for aircraft.

Mixture formation and engine lubrication

Mixture formation must also be ensured in extreme flight positions and with strong acceleration ( aerobatics ) in order to avoid engine misfires. A position-independent mixture formation system is used for this. The engine lubrication must also be ensured regardless of the position, which is generally achieved with dry sump lubrication .

Mixture influence

It must be possible to adjust the fuel / air mixture - manually or automatically - to the decreasing air pressure in height (see Leanen ).

Valve control

The camshaft (s) or, in the case of a radial engine, the cam drum of the valve control must not be driven via toothed belts or timing chains . Spur gears or a vertical shaft are possible. Most of today's piston engines for aircraft have an OHV valve control , in which the valves are operated via tappets , push rods and rocker arms .

Air cooling

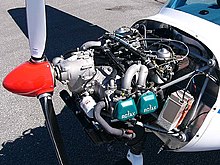

An air cooling is lighter than liquid cooling and can not fail due to loss of coolant, it is therefore customary for most aircraft engines. Modern aircraft engines have air-cooled cylinders and liquid-cooled cylinder heads (Rotax, Jabiru, Limbach, Sauer).

Larger displacements

Because of the operating limits of the propellers, aircraft engines have to provide high performance even at relatively low speeds (2500-2700 rpm). Therefore, relatively large displacements are common. The compression ratio is rather low. Modern aircraft engines have a reduction gear with vibration damper between the crankshaft and propeller hub with a correspondingly smaller displacement (Rotax 912 series: 1200 cm³ compared to the Lycoming O-235 with 3850 cm³ and direct drive of the same power).

Thrust bearings

Care must be taken to ensure that the considerable tensile forces transmitted from the propeller to the crankshaft are absorbed by an appropriate axial or tension bearing .

Screw locking

Almost all screw connections, including housing screw connections, are elaborately secured in a form-fitting manner in aircraft engines, mostly with wire locks or split pins .

Use in light aircraft

Air cooling is usually used in the engines used in light aircraft . The crankshaft can drive the propeller via a reduction gear or the propeller is bolted directly to the flange of the crankshaft. With direct drive , the maximum speed of the motor is limited to around 2700 rpm. This maximum speed results from the fact that the propeller tips almost reach the speed of sound at this speed , which is the physical-technical limit for the propeller drive .

In general, motors with a large displacement are used for directly driven propellers, typically gasoline engines with 360 cubic inches, i.e. around 5.9 liters displacement for 132 kW (180 PS) or 320 cubic inches, i.e. 5.25 l displacement, for 118 kW (160 PS) . The gasoline consumption of such an aircraft engine is around 35-40 liters AVGAS per hour, larger ones with 8.9 liters displacement, i.e. around 540 cubic inches and 265 kW (360 PS) consume up to 100 liters per hour.

In recent years, aircraft engines with a small displacement have also been manufactured in the lower power classes, which are completely or partially liquid-cooled. These include the Thielert - diesel engine (based on the Mercedes-Benz diesel engine is OM 668 of the A-class with 1.7 liter displacement, turbo charged, 100 kW (135 hp), consumption of 12 l / h kerosene or diesel ), the aluminum -Diesel EM-100 from Eco-Motors (with 1.4 liter displacement, 100 PS, also turbo-charged, consumption 10 l / h kerosene Jet A-1 ) and the gasoline engines from Bombardier- Rotax , the 912 and 914 series ( 1.4 liter displacement, up to 85 kW (115 PS), consumption 18 l / h MoGas ).

More recently, flat boxer engines are common, while earlier radial engines or often in-line engines (also hanging, i.e. with the cylinders down) were used, for example Hirth , Gipsy Major , Walter . In the area of the former Eastern Bloc, radial engines are used to drive light aircraft up to the present day ( Wedenejew M-14 ).

There is a general trend towards diesel engines, as these engines are now using direct injection and turbocharging to achieve a power-to-weight ratio that enables use in light aircraft. The biggest advantage is their low fuel consumption. For example, the consumption of a Robin DR 400 was reduced by around 35 percent by using a diesel engine with comparable performance. It should be noted, however, that currently diesel engines in light aircraft cannot be overhauled, but rather have to be completely replaced after a specified period of time due to the lack of replaceable liners. The costs for this are significantly higher than those of the general overhaul of classic aircraft engines.

history

First flights

Airship

Around the turn of the 19th to the 20th century, the native Brazilian Alberto Santos-Dumont built a number of impact airships in France . In 1894 he used the gasoline engine of his tricycle for the propeller of one of his airships.

First controlled flight of an airplane by the Wright brothers

The Wrights cut a high-efficiency propeller and, as a suitable engine was nowhere to be found, had one made by Taylor in the bicycle factory. Within a very short time, a water-cooled four-cylinder four-stroke gasoline engine weighing just 77 kg and delivering 12 hp was created. To compensate for the torques, the flying machine was given two propellers rotating in opposite directions, which were driven by roller chains that ran in tubes to avoid vibrations.

On the morning of December 17, 1903, Orville Wright lifted off the ground with the aircraft called the Flyer . He was in the air for twelve seconds and covered 37 meters (10.8 km / h). Wilbur immediately followed, each flying twice that day. Wilbur managed a flight of 59 seconds and a distance of 260 meters (19 km / h). Orville later said of it that it was the first time in history that “a machine with a human had raised itself in free flight by its own power, flown forward in a horizontal orbit, and finally landed without going to the wreck become". The flying machine measured 12.3 meters in wingspan, 6.4 meters in length and 2.8 meters in height; it was made of wood and a fabric covering, its flight weight was 340 kilograms, and the pilot was lying on the lower wing.

High point of development

During the Second World War and until the mid-1950s, reciprocating aero engines with over 3680 kW (5000 hp) takeoff power and more than 70 liters displacement were produced to power fighters , bombers and large passenger planes . For example, the Wright R-3350 and Pratt & Whitney R-4360 engines were outstanding . As a result of the technical developments after the Second World War with jet engines and turboprop engines, reciprocating piston engines with more than about 400 kW for flight applications have hardly been built since the 1960s.

Historical manufacturers (selection)

BMW

The most famous historical manufacturer of reciprocating piston aircraft engines today are the Bavarian Motor Works BMW , which today manufacture cars and motorcycles, but started out as a aircraft engine manufacturer.

BMW's predecessors were Rapp Motorenwerke GmbH, founded by Karl Rapp in 1913 . They changed their name in April 1917 first to BMW GmbH and a year later, after the conversion into a stock corporation, to BMW AG. The first managing director was Franz Josef Popp until 1942 . The aspiring engineer Max Friz quickly made a name for himself in the young company : in 1917 he developed an aircraft engine with overcompression. This reduced the power loss in altitude. This construction worked so well that BMW received an order for 2,000 engines from the Prussian Army Administration. On June 17, 1919, a BMW IIIa secretly set the world altitude record of 9,760 meters, but the end of the First World War seemed to be the end of the company: The Versailles Treaty forbade aircraft engines in the German Reich for five years ( the only product from BMW at the time). On December 30, 1921, a long-term flight record was flown with a BMW IIIa aircraft engine in the USA . A Junkers-Larsen 6 aircraft achieved a time of 26 h 19 min 35 s. In 1922 the main shareholder Camillo Castiglioni left the company and took the naming rights to BMW with him. He went to the Bayerische Flugzeugwerke (BFW).

These emerged from the Gustav Otto Flugmaschinenwerke registered on March 7, 1916, owned by Gustav Otto , a son of Nikolaus Otto , who was named after the Otto engine . This March 7, 1916 is considered to be the founding date of BMW in official company history. With the change from Castiglioni, the Bayerische Flugzeugwerke (BFW) became BMW.

As an example of aircraft engines by BMW in the interwar period was the BMW VI called a water-cooled twelve-cylinder - V engine , which among other things also in the flying boats Dornier Wal for the Arctic expedition of Roald Amundsen was used. In 1936 a test model of the BMW 114 diesel engine was also completed. Development stopped in 1937.

The BMW 801 , an air-cooled 14-cylinder double radial engine, developed from 1938 under the direction of Duckstein and built in series from 1940 , produced a total of around 21,000 engines in 22 variants, eleven of which went into series production.

Bristol

The Bristol Engine Company , a subsidiary of the Bristol Aircraft Company , has been producing aircraft engines since the 1920s. In the 1930s and 1940s, a number of notable valveless radial slide engines, such as the Bristol Hercules and Bristol Centaurus with the Burt-McCollum sleeve slide control, were manufactured and produced in large numbers. Bristol became part of the Rolls-Royce group in 1966 , after the Second World War, under the name Bristol Siddeley, mainly jet engines were manufactured, which displaced the powerful piston engines in the civil and military sectors.

Curtiss-Wright

The most important American manufacturer of aircraft engines was the Curtiss-Wright company . The company was formed on July 5, 1929 from the merger of the Wright Aeronautical Corporation of the Wright brothers and The Curtiss Airplane and Motor Company of aviation pioneer Glenn Curtiss and ten other subsidiaries.

The company became known for its advanced and powerful radial engines such as the Wright R-1820 , the Wright R-2600 , the Wright R-3350 and the Wright R-4090, as well as the associated propellers.

The Wright R-3350, the final point in the development of reciprocating engines, was still used in the 1950s on the Douglas DC-7 and the Lockheed Super Constellation , the last long-range piston-engine-powered passenger aircraft.

Daimler Benz

The Daimler-Benz AG produced high numbers of aircraft engines the top performance classes before and during the Second World War. These were primarily liquid-cooled twelve - cylinder engines in a hanging V-arrangement, such as the types DB 601 , DB603 and the DB 605 with over 42,000 units built. Aero engine production ended with the collapse of the Third Reich. More recently, aircraft engines have again been built by the Thielert and Ecofly companies on the technical basis of car engines from the Mercedes-Benz group (A-Class or Smart ) . These engines are turbocharged Otto (Ecofly) or diesel engines (Thielert / Centurion).

Henschel aircraft engine construction

The Henschel Flugmotorenbau GmbH was (1936-1957), a subsidiary of Henschel & Sohn for the manufacture and repair of aircraft engines. During the Second World War, the company developed into one of the top-selling and largest producers of military aircraft engines.

Hispano-Suiza

The Spanish luxury car manufacturer Hispano-Suiza began producing aircraft engines in its French plant Bois-Colombes ( Hispano France , from 1923 Société Française Hispano-Suiza ). The V8 engines from the HS 8 series were used in many military aircraft of the First World War, followed by the twelve-cylinder V engines from the HS 12 series in the 1920s . The last aircraft engine developed in-house was the Hispano-Suiza HS 12-Z89 V12 engine built after 1945 .

Porsche

In the 1980s, Porsche manufactured the PFM 3200 , which was based on the six-cylinder boxer engine of the Porsche 911 . In 1990 production was stopped.

Rolls Royce

The English company Rolls-Royce , founded in 1904 as a manufacturer of luxury cars, started building aircraft engines in 1914. In this field, the company became one of the largest manufacturers of engines for Allied aircraft during World War II.

Today Rolls-Royce only manufactures jet engines, turboprops and shaft engines, but no longer piston engines.

Current manufacturers

Lycoming

In general aviation , the units manufactured by the US manufacturer Lycoming are widely used. The numerous Cessna aircraft in particular fly with Lycoming, although both manufacturers have the same parent company with Textron . With the Lycoming R-680 , the company began manufacturing aircraft engines in 1929 and in 1944 developed the Lycoming XR-7755 (36 cylinders, 5000 hp), the most powerful reciprocating piston aircraft engine ever built.

Continental

Lycoming’s biggest competitor is the US manufacturer Teledyne Continental Motors , which has also been manufacturing aircraft engines for general aviation since 1929 (then still known as the Continental Aircraft Engine Company ). Some of these types of engines were also built under license by Rolls-Royce.

Société de Motorisations Aéronautiques

The Société de Motorisations Aéronautiques (SMA for short) is a French company that manufactures aircraft engines, especially diesel engines.

Between July 17 and 25, 2006, a Cessna 182 ( aircraft registration number: F-GJET) equipped with the SMA SR305-230 attracted international attention when the aircraft was flown in nine stages from Le Bourget to Oshkosh.

BRP Powertrain (Rotax)

Motors from BRP-Powertrain (mostly referred to as Rotax ) are widespread in the class of surface-controlled ultralight aircraft as well as in touring motor gliders and lighter propeller planes .

Limbach

The Limbach Flugmotoren company in Königswinter produces two and four-stroke boxer engines in the power range from 15 to 118 kW . These are mainly used in touring motor gliders and microlight aircraft. The program also included engines for unmanned aerial vehicles .

Angry

Sauer Flugmotorenbau in Ober-Olm manufactures - in addition to gearboxes, propellers and other aviation accessories - two- and four-stroke boxer and in-line engines in the power range from 20 to 80 kW. These are mainly used in ultralight aircraft, motor gliders and unmanned aerial vehicles.

Centurion / formerly Thielert

Centurion Aircraft Engines AG & Co. KG continues to produce and sell Thielert diesel aircraft engines as the successor company to the insolvent Thielert Aircraft Engines GmbH. Centurion builds and sells a 2.0-liter four-cylinder and a 4.0-liter eight-cylinder diesel engine that can be operated with Jet-A1 and conventional diesel fuel. The engines are offered as exchange units for conventional Lycoming and Continental Avgas engines, but are also installed in various models ex works (including Diamond DA-40, DA-42 Twin Star and Cessna 172 Skyhawk). Conversion kits with additional type certification are available for the Cessna 172, Piper PA28, Robin DA400 (all 2.0 l), Cessna 206 Stationair and Beechcraft Duke B60 (all 4.0 l).

Austro engine

Since the availability of the engines was unclear after the bankruptcy of the diesel aircraft engine supplier Thielert, the Austrian aircraft manufacturer Diamond Aircraft founded the aircraft engine manufacturer Austro Engine .

See also

literature

- Ernst Götsch: Aircraft technology. Introduction, basics, aircraft science. Motorbuch-Verlag, Stuttgart 2003, ISBN 3-613-02006-8 .

Web links

- The Development of the German Airplane Engine Industry (1883–1990)

- "World record achieved in long-term flight with a Bayern engine" - advertisement in the Allgemeine Automobil-Zeitung of July 9, 1922 (Austrian National Library)

Individual evidence

- ^ The Five First Flights on thewrightbrothers.org

- ↑ Ecofly website , accessed on February 1, 2015

- ^ Rotax Aircraft Engines website

- ↑ Motor overview on the Limbach Flugmotoren website , accessed on February 28, 2011

- ↑ Motor overview on the Sauer Flugmotorenbau website , accessed on February 28, 2011

- ↑ Company profile of Centurion Engines