Opposed piston engine

The opposed piston engine - also known as counter-rotor motor , reciprocating engine or shortly expeller - is a reciprocating - engine in which two pistons in the same cylinder working against each other and a common combustion chamber split in the middle of the cylinder. Ferdinand Kindermann patented this type of engine in 1877 .

According to DIN 1940, March 1958 edition, the opposed piston engine is defined as a double piston engine with pistons moving in opposite directions.

So far it has almost always been implemented as a two-stroke engine . The inlet and outlet slots are located at opposite ends of the combustion chamber and are released by the pistons in the vicinity of their outer dead centers. This achieves longitudinal flushing and thus gas exchange that is practically just as complete as in the four-stroke cycle.

The engine can be designed as a diesel, gasoline or gas engine.

The two-stroke diesel opposed piston engine was used in ships, submarines, tanks and even aircraft in the 1930s to 1960s because of its high power density and is still used in isolated cases. However, it was largely replaced by the four-stroke turbodiesel.

Recently (2010, 2011) it has been taken up again by three US start-up companies - Ecomotors with the OPOC engine for trucks (150 kW per module from two cylinders with four pistons), Achates and Pinnacle - one of which, Pinnacle, developed a four-stroke version.

technology

Gas exchange (two-stroke variant)

The exchange of the burnt gas with fresh one requires an externally generated overpressure for every two-stroke engine. This can be delivered by

- Pre-compression in the crankcase

- external flushing fan (e.g. turbocharger , roots loader )

In order to achieve a charge, the inlet slot has to be open for a certain period of time while the outlet slot is already closed. As with the U-piston engine, this is achieved by advancing the exhaust piston by a value between 12 ° and 20 ° crank angle.

Engine versions

There are versions with one or two crankshafts .

- In the first case, one piston is connected to the crankshaft via a short connecting rod and the other via a yoke and a pair of long connecting rods.

- In the second case, the crankshafts must be connected to one another, for example by a spur gear cascade (as in the Junkers Jumo 205), a drive chain , a toothed belt or a vertical shaft .

There used to be other variants:

- Rocker arms were connected to the pistons and the crankshaft, which was arranged under the cylinders, via connecting rods.

- A shaft runs parallel to two opposed piston cylinders, with a swash plate or swash plate rotating at each end . These push the pistons inwards via plungers or are set in rotation by their pressure.

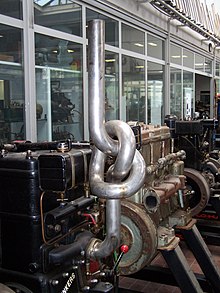

Structure and functionality using the example

An engine is shown similar to that of the DKW racing engine further developed by the designer Kurt Bang in the Prüssing office . It was available in a version with 250 cm³ and one with 350 cm³ displacement . It had two cylinders with four pistons, two crankshafts and a mechanical supercharger . The crankshafts were connected via a spur gear cascade. The mixture preparation was done by a carburetor , which resulted in high fuel consumption .

- Intake channel for the mixture prepared by the carburetor

- Mechanical loader . (here: vane loader; in the original Zentrix loader)

- Fresh gas chamber for storage and distribution to the cylinders

- Pressure relief valve (waste valve)

- Exhaust crank mechanism

- Inlet crank drive (runs to achieve an asymmetrical control diagram ) about 20 °

- Cylinder with inlet and outlet slots

- Outlet, connection for the exhaust system

- Water cooling jacket

- spark plug

The loader sucks in the mixture and pushes it into the fresh gas chamber. A pressure relief valve ensures the pressure limitation. From here the mixture reaches the crank chambers. On the outlet side, it is used to cool the piston, which is subject to high thermal loads. After ignition , both pistons run outwards and complete the working stroke . The outlet piston first opens the outlet slots, which allows the residual pressure to be reduced, which leads to an acceleration of the gas column in the exhaust system. Only then does the other piston open the inlet slits, which means that fresh gas driven by the boost pressure flows into the cylinder, which pushes out the old gas. If the inlet is still open, the outlet closes. Fresh gas continues to be pushed into the cylinder, which leads to charging . After the inlet slots have been covered by the piston again, compression begins.

Advantages and disadvantages of the opposed piston engine

Advantages compared to single-piston controlled two-stroke engines with the same number of pistons, displacement, speed and compression

- Significantly lower heat losses through the combustion chamber walls because they have a much smaller surface area. Particularly near top dead center, where the combustion gases are particularly hot, the free cylinder wall is only small; the combustion chamber surface is dominated by the pistons and cylinder heads. In opposed piston engines, the latter are omitted and the combustion chamber surface is approximately halved.

- More even torque curve over speed - the torque depends on the filling level. In the single-piston two-stroke engine, the filling level is very dependent on the engine speed - not in the opposed piston engine.

- Better purging - the longitudinal purging allows a complete gas exchange with low purging losses.

- The spatial separation of inlet and outlet slots means that they can be arranged over the entire circumference of the piston. This reduces an asymmetrical temperature distribution between the piston and cylinder wall, which benefits the accuracy of fit.

- The inflowing air can be given a swirl, which is good for mixing and the combustion process.

- Good mass balancing without additional measures.

Problems of the concept

- Particulate and hydrocarbon emissions through the discharge of lubricating oil from the outlet slots. This is very problematic with downstream catalysts. According to the company, newer developments (Achates, OPOC) have managed to get this problem so well under control through better oils and ensuring a sufficient lubricating film that all modern emission standards can be met without additional filters. Another proposed solution is to use self-lubricating graphite pistons (see Golle motor ).

- Oil consumption, it has essentially the same cause and solution as the particle emission and can therefore be regarded as solved.

- Service life problems due to the high thermal load on the outlet side, in particular the outlet piston. This problem is not so pronounced with the diesel version, since the exhaust gas temperature is lower here. It is understandable that all motors with high power density, i.e. high thermal-mechanical load, are potentially more affected by service life problems. One solution is the careful design of the cooling system and the use of suitable materials.

- Running a little less smoothly due to halving the number of cylinders.

- Only in engines with only one crankshaft (OPOC) slightly higher oscillating mass due to the tie rods.

- Lateral arrangement of the ignition / injection. However, the associated problems could be solved by improving the design of the piston surface.

History and commitment

Junkers

One of the first practical applications took place in 1892 by Wilhelm von Oechelhäuser jun. in his plant for gas engines, the Deutsche Continental Gasgesellschaft , in Dessau . The development was assisted by Hugo Junkers . The machine was operated with furnace gas . It was delivered to the Hörde blast furnace (Phoenix steelworks) in Dortmund in 1896 and had an output of 220 hp to drive a dynamo as an electricity generator.

Junkers further developed this type of prime mover in his factory. He built it first as a gasoline engine, later as a stationary and motor vehicle diesel with very low consumption.

Aircraft engines

The Junkers six-cylinder counter-rotating engine Jumo 205 with 880 hp at 2800 rpm was the only diesel aircraft engine built in larger numbers. In terms of its performance, it was relatively heavy, but aircraft equipped with it set several long-distance world records thanks to the very low specific fuel consumption . It took a long time to develop, especially because of the thermal stress on the outlet piston.

Stationary and vehicle engines

The diesel counter-rotors of the HK series by Junkers manufactured between 1930 and 1980 according to the so-called modular principle with a displacement of around 700 cm 3 per unit are primarily used as stationary and boat engines . They were available as 1-, 2- or 3-cylinder engines, which can produce between 8 and 38 hp. The vehicle engines were initially built under license by Krupp , but then replaced there because of the ejection and carbonization of oil at the outlet openings of two-stroke engines with outlet valves.

Up until 1945, opposed piston diesel engines were manufactured by the Gesellschaft für Junkers-Dieselkraftmaschinen mbH in Chemnitz . After the war, this company was transferred to the (district-run) state-owned company Diesel-Kraftmaschinenwerk Karl-Marx-Stadt and continued production of the HK 65 series under the type designation NZD 9/12 . The engines were used in shipbuilding as main and auxiliary machines. The drive of small working machines and tractors such as diesel rollers, excavators, concrete mixers, tractors or locomotives were also implemented with Junkers single-cylinder opposed piston engines. They were also used as drives for pump and compressor units and emergency power systems. The GDR industry produced opposed piston engines at the request of the Soviet Union. This type of construction was used comparatively rarely in Germany. After the production of the engines was stopped in 1980, spare parts were produced for the USSR until 1989.

DKW - Supercharged two-stroke engines in racing motorcycles

Before the Second World War, DKW experimented with a 250 cm³ two-stroke opposed piston engine with a Zoller compressor in a racing motorcycle . After the Second World War, a few remaining copies, whose designation was DKW GS250 , were assembled. The racing driver Kurt Kuhnke , in whose possession the parts came, drove as a private driver - the debut took place in 1950 - the machine now known as the KS1 . The engine had thermal problems, which is why Kuhnke retired in the first race. The performance of the 250 cc engine was about 45 horsepower at 7,000 min -1 . Germany's accession to the International Motorcyclists' Association ( FIM ) brought the end of the sporting career of the DKW opposed piston engine; the FIM had issued a compressor ban after the war.

In 1989, a team of engineers from the automotive engineering department at TU Darmstadt, led by restorers Herrmann Herz and Bert Breuer , set out to turn the legendary DKW opposed piston engine into a thermally stable machine. Two years and a diploma thesis later, the DKW counter-runner ran without thermal problems and produced 65 hp from 250 cm³, i.e. 20 hp more than was measured at the time of the DKW.

Napier Deltic

A special form of the opposed piston engine are the Deltic engines made by the British manufacturer Napier around 1950 ; These compact diesel engines, developed from the Junkers Napier-Culverin licensed engine and built for use in ships and locomotives, achieved outputs of around 3000 hp and consisted of three banks of opposed piston engines arranged in a triangle and connected by common crankshafts.

Other types of opposed piston engines

In 1898, Lucian Vogel started a diesel opposed piston engine ("5 HP horse-drawn carriage engine") at MAN in Nuremberg using the two-cylinder four-stroke process. But the version was not marketable.

In addition, Commer , Compagnie Lilleoise des Moteurs , Doxford , Fairbanks-Morse , Gobron-Brillié , British Leyland , Krupp , Napier , Rolls-Royce and Sulzer opposed piston engines developed and built, mostly for stationary operation, for ships, submarines and locomotives, but also for trucks , cars and motorcycles . Counter- rotating motors were also used in tanks . For example, the British Chieftain was equipped with a large six-cylinder counter-rotating engine for the main drive (type Leyland L60) and a small three-cylinder (Leyland H30) as an auxiliary unit. The Soviet T-64 was also powered by an opposed piston engine with five cylinders.

The opposed piston engine 10D100 (ten-cylinder, vertical arrangement of the cylinders, 3000 hp) was widely used in the Soviet diesel locomotive of the 2TE10 series of the Luhansk locomotive factory .

Current developments

Ecomotor's OPOC (Opposed Piston Opposed Cylinder) Engine

The OPOC concept has two special features:

- Two opposed piston units are in alignment with the common crankshaft between them (opposed cylinder) - a "two-cylinder, four-piston boxer engine".

- The power transmission of the external pistons takes place via longer connecting rods.

At the bearing points, the crankshaft is only loaded with the vector sum of the connecting rod pressure and tensile forces, which alternately partially cancel each other out. This keeps the forces on the bearings low so that they can be carried out more easily. The opposed cylinder arrangement has the advantage of a short crankshaft and very good mass balance.

Further properties are:

- Exhaust gas turbocharger with an additional electronically controlled electric drive, with which the boost pressure can be optimized at any speed, and

- an electronically controlled clutch allows an engine to be assembled from two (or more) modules on the crankshafts. In partial load operation, only one of them is active, which brings a considerable gain in efficiency. This is based on the fact that the heat, flow and friction losses of the decommissioned module are eliminated and the boost pressure and thus the thermodynamic efficiency in the active module is higher. This division into modules is not easily possible with a conventional four-cylinder engine, as this would then no longer have a mass balance and would vibrate too much.

- The problem of piston cooling is solved by jetting oil against the back of the piston.

The development was originally carried out by Advanced Propulsion Technologies Inc., which also holds the patent. The project was funded by DARPA because it can be used militarily for helicopters, tanks, trucks or generator units. Three variants were presented: 10 kW with 6 kg, 30 kW with 18 kg (from three coupled 10 kW units) and 242 kW with 204 kg.

For some years now, civil development has been carried out by Ecomotors International. The driving force behind the OPOC engine is Peter Hofbauer, long-standing Diesel Development Manager at Volkswagen .

Bill Gates invested $ 23.5 million early on in the work of Ecomotors International.

In February 2011 the truck and engine manufacturer Navistar International founded a joint venture with Ecomotors to develop a turbo diesel for trucks.

In April 2011, the Chinese auto supplier Zhongding announced its collaboration with Ecomotors and announced future series production of Opoc truck engines.

Achates power

Achates is a development company based in California. She developed an opposed piston engine with two crankshafts with gear coupling and an exhaust gas turbocharger.

According to Achates, the cheapest number of cylinders is three. This provides the most even pressure curve for the turbocharger and prevents the pressure pulse from flowing back from a cylinder that is just opening into one that has already been open for some time. However, a two-cylinder engine is also planned. Other numbers of cylinders are possible in principle.

By varying the row of gears, the speed of the output shaft can be adapted to the desired speed within certain limits.

A reduction in consumption of 15 to 20% compared to a state-of-the-art diesel engine has been demonstrated.

According to his own statements, Achates succeeded in lowering hydrocarbon emissions to values that are also low for four-stroke engines through a deep understanding of the oil transport processes and precise dosing of the oil.

The combustion chamber at the point of ignition resembles an ellipsoid of revolution with the injection nozzles at both ends. This is created by the corresponding bulging and hollowing of the piston surfaces. The effective combustion chamber surface and thus the heat losses are thereby reduced.

By using two injection nozzles, two different fuels can be injected with a slight delay. This allows the pressure and temperature profile of the combustion to be favorably influenced.

Pinnacle

Pinnacle develops a four-stroke opposed piston engine with two crankshafts. The problem with this is that inlet and outlet valves have to be in the middle, where there is very little space when the pistons are at inner dead center. Pinnacle's solution is to assemble the cylinder from two tubes, which are pressed gas-tight against an intermediate ring. During the intake stroke one cylinder tube is pulled outwards and during the exhaust stroke the other cylinder tube is pulled outwards, opening a slot that extends over the entire circumference of the cylinder. The advantage of better flushing and better control of the oil emission is opposed to the disadvantage of greater mass and mechanical complexity.

According to its own statements, Pinnacle wants to enter the Asian market with small engines. According to the company, there is also a cooperation with a large Asian manufacturer. A vehicle engine runs most of the time in the partial load range. That is why the Pinnacle motors are to be optimized for consumption, which results in lower peak efficiency levels.

Gemini 100/125 aviation diesel engine

The British company Powerplant Developments has developed a three-cylinder opposed piston aircraft engine. Its advantages are: light, compact, economical, longer overhaul intervals due to its simplicity and the possibility of using jet kerosene. The two variants produce 100 or 150 hp.

Golle engine

The so-called Golle engine is an opposed piston engine with two crankshafts connected via a spur gear cascade. The connecting rods are connected to the pistons via cross heads and piston rods. The crank chamber is sealed oil and airtight from the cylinder. The space between the cross head and the double-acting piston is used as an air charging pump with flutter valves. The piston runs oil-free. This has several advantages:

- fewer particles in the exhaust gas

- lower oil consumption, less aging of the oil ( lifetime lubrication possible)

- no external charger required, except to further increase performance.

The piston rings are made of fine-grain graphite, which is very light and self-lubricating and, thanks to its high temperature resistance, could solve the thermal problem on the exhaust piston. Its strength increases up to 2500 ° C.

The motor is easy to manufacture due to its symmetry and the small number of different parts. It is still in development (June 2009), with the focus being on the reliable control of the new types of pistons.

Laukötter GmbH, Diesel-Air GmbH, Carmag

An 80 kg 1.2-liter two-cylinder diesel engine with 85 to 100 hp was developed, which was originally intended for vehicles, but was used in 2004 for the motorization of the first flight of the ultralight Fläming Air "FA Smaragd". This first flight never happened because the engine was not able to run continuously.

A special feature is the use of toothed belts to couple the two crankshafts and the output shaft.

Like the Golle engine, it uses carbon pistons, which, however, are designed as a carbon-magnesium composite material according to a process patented by the Carmag company. Its further development was stopped around 2004, presumably due to a lack of customers. However, piston development continued and the pistons are used with success in motorsport.

Malyshev factory

The company Malyshev plant in Ukraine builds the opposed piston engine 6TD-2 for T-84 , the 1200 hp, 1.2 t weighs and consumes 218 g / kWh diesel. It is designed as a multi-fuel engine. Another motor is the 10D100 with an output of 3000 hp, which is used, for example, in the SŽD series 2TE10U .

Diesel Air Limited

The UK- based Diesel Air Limited has developed a 100 horsepower opposed piston aircraft diesel engine. Like the Junkers engine, it is provided with separate crankshafts and gear coupling. With a displacement of 1.8 l, it weighs 93 kg.

Web links

- Further information and diagrams on the topic

- Background to the OPOC engine from Ecomotors

- Patent application for the Junkers-Oechelhaeuser opposed piston engine

- Information on Junkers opposed piston engines ( Memento from April 14, 2008 in the Internet Archive )

- Two-stroke reloaded. Technology Review, Sep 20, 2010

Footnotes

Remarks

- ↑ The Leyland L 60, which was installed in the Chieftain battle tank, suffered from cracks in the housing and cylinder liners. (Stefan Zima: Unusual Motors. Vogel Buchverlag, 2005, p. 295.)

- ↑ See also: http://3d-meier.de/tut16/Jumo205/Seite1.html Jumo 205, animated principle illustration.

- ↑ For a description of how the motor works, see e.g. E.g .: two-stroke opposed piston diesel engine NZD 9/12 (Junkers HK 65). ( Memento of the original from March 4, 2016 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. From froehliche-doerte.de, accessed on October 16, 2016

- ↑ See also: List of well-known opposed piston diesels of the Junkers type. At forum.standmotor.de, accessed on October 16, 2016

- ↑ See also: dkw-rennmaschinen.de ( Memento of the original from April 5, 2013 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (accessed on May 10, 2013)

- ↑ See also: engineeringtv.com

- ↑ a b According to the developer, see: Interview with Prof. Hofbauer. On July 14, 2010 from youtube.com, accessed on October 16, 2016 (MP4; approx. 22.8 MB)

- ↑ See also: ecomotors.com ( Memento of the original from January 22, 2012 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ See also: news.cnet.com

- ↑ See also: achatespower.com

- ↑ a b c According to a statement by the CEO of Achates on talk show April 2013, [1]

- ↑ See also: pinnacle-engines.com

- ↑ See also: ppdgemini.com

- ↑ See also: youtube.com ( Memento from September 30, 2011 in the Internet Archive )

Individual evidence

- ↑ The Gobron Brillié aircraft engine in 1906 was a four-stroke engine. (Stefan Zima: Unusual Motors. Vogel Buchverlag, 2005, p. 136).

- ↑ Tank Power Pack with 6TD-2 Engine. morozov.com.ua, 2007, archived from the original on November 4, 2014 ; accessed on October 15, 2016 .

- ^ Peter Hofbauer, Diana D. Brehob: Opposed piston boxer engine for trucks . In: MTZ . Springer Vieweg / Springer Fachmedien, April 2012, ISSN 0024-8525 .

- ↑ Stefan Zima: Unusual engines. Vogel Buchverlag, 2005, p. 137.

- ↑ Stefan Zima: Unusual engines. Vogel Buchverlag, 2005, p. 200.

- ^ Stan Cornel: Alternative drives for automobiles. Springer-Verlag 2008, p. 135.

- ↑ Stefan Zima: crank drives. Vieweg Verlagsgesellschaft 1999, p. 123.

- ↑ a b http://achatespower.com/wp-content/uploads/2015/04/2014SAE-Congress-Paper.pdf

- ↑ Stefan Zima: Unusual engines. Vogel Buchverlag, 2005, p. 568.

- ↑ Stefan Zima: Unusual engines. Vogel Buchverlag, 2005, p. 122.

- ↑ http://www.deutsches-museum.de/sammlungen/maschinen/kraftmaschinen/verbrnung/dieselmotoren/fahrzeug-und-kleindiesel/flugmotor-gegenkolbenmotor-jumo-205-1932/ - technical data.

- ^ The Junkers Jumo 205 Diesel Engine ( Memento from February 2, 2011 in the Internet Archive ) - from Paul H. Wilkinson: Diesel Aviation Engines. 1940, for Jumo 205.

- ↑ Stefan Zima: Unusual engines. Vogel Buchverlag, 2005, p. 286.

- ↑ Junkers opposed piston two-stroke diesel engines type HK (bonnet piston). At standmotor.de, accessed on October 15, 2016

- ↑ Stefan Zima: Unusual engines. Vogel Buchverlag, 2005, p. 126.

- ↑ Motors and miscellaneous. From feldbahnseite.de, accessed on October 16, 2016

- ↑ Emergency power systems. On sachsenschiene.net, accessed on October 16, 2016

- ↑ Jürgen Stoffregen: Motorcycle technology. 7th edition. Vieweg + Teubner Verlag, 2010, ISBN 978-3-8348-0698-7 , p. 60.

- ↑ Klaus Mollenhauer, Helmut Tschöke: Manual Diesel Engines. 3rd edition 2007, section 1.1 History of the diesel engine. Springer-Verlag, Berlin Heidelberg, ISBN 978-3-540-72164-2 .

- ↑ greencarcongress.com

- ↑ The Patented OPOC ™ engine. Retrieved October 16, 2016 from propulsiontech.com

- ↑ greencarreports.com: bill-gates-backs-ecomotors-new-opoc-engine

- ^ Wirtschaftswoche: Bill Gates is involved in engine construction.

- ↑ US company makes revolutionary two-stroke engine ready for series production. Retrieved February 22, 2011 .

- ↑ Navistar Reaches Development Agreement with Ecomotors International on Groundbreaking Engine Design. (No longer available online.) Archived from the original on March 4, 2016 ; Retrieved February 22, 2011 . Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ EcoMotors International's Opposed-Piston, Opposed-Cylinder Engine Promises to Revolutionize Commercial Vehicle Design with Powerful, Lightweight, Fuel Efficient, Low Emissions Engines. ecomotors.com, February 22, 2011, archived from the original on November 10, 2013 ; accessed on October 15, 2016 .

- ↑ Anhui Ningguo, Allen Park: Zhongding and EcoMotors Announces Contract to Commercialize Revolutionary opoc® Engine. ecomotors.com, April 20, 2011, archived from the original on January 17, 2014 ; accessed on October 15, 2016 .

- ↑ Achates Power Opposed-Piston Engine Sets New Benchmark for Fuel Efficiency. (PDF; approx. 80 kB) achatespower.com, November 1, 2011, archived from the original on May 12, 2014 ; accessed on October 15, 2016 .

- ^ Brian J. Callahan et al .: Oil Consumption Measurements for a Modern Opposed-Piston Two-Stroke Diesel Engine. ASME 2011 International Combustion Engine Division Fall Technical Conference, Track 7, ICEF2011-60140 (abstract)

- ^ Michael Wahl: A Historical Look at Opposed-Piston Engines. achatespower.com, December 21, 2011, archived from the original on June 19, 2012 ; accessed on October 15, 2016 .

- ^ A b Klaus L. Schulte: Opposite piston flying diesel. e-Journ Tt-08, klspublishing.de, p. 7 ff.

- ↑ NET Journal. Vol. 14, No. 3/4, March / April 2009, borderlands.de (PDF; 1.1 MB)

- ↑ naumburger-tageblatt.de

- ↑ https://www.malyshevplant.com/en/content/6td

- ↑ dair.co.uk

- ↑ boxermotor.com