Composting

Composting (also called rotting ) refers to the part of the nutrient cycle in which organic material is broken down by soil organisms ( heterotrophic ) under the influence of air oxygen ( aerobic ) . In addition to carbon dioxide , water-soluble minerals such as nitrates , ammonium salts , phosphates , and potassium and magnesium compounds , which act as fertilizers, are released. A part of the intermediate products resulting from this degradation is converted into humus .

The word compost is derived from the Latin compositum , “what has been put together”, and describes both the collection site (also “compost heap” or “compost rent”) and the material stored there and the product created by the rotting (“finished compost”).

Today, hobby gardeners who compost themselves on a smaller scale, as well as waste management in large-scale composting processes, make use of the composting process to produce compost from kitchen and garden waste, organic waste and green waste .

Compost material is suitable for improving soil properties in gardening and agriculture, for the recultivation of areas, but also for the production of soil substrates and potting soil . Depending on the nutrient content, mature compost is a full-fledged fertilizer and can thus make the use of additional fertilizers superfluous.

The rotting process of composting is used to generate heat with a bio-pile .

history

The treatment of animal excrement through composting and recycling of organic matter has been known for thousands of years. In Europe, Homer described manure as fertilizer in the Odyssey ; Aristotle wrote it in 350 BC. The humus theory (according to which plants feed on humus ), Columella described composting in his books on agriculture around AD 60, and Pliny the Elder also described the technique of composting. Even Cato the Elder described the fertilization of his grapevines with compost, which he made lupines , straw, bean straw and leaves produced.

Modern papers on the systematic preparation of compost can be found from the middle of the 18th century. After the Austro-Hungarian botanist and microbiologist Raoul Heinrich Francé had researched the Edaphon , the entirety of the organisms living in the soil that play a role in the composting process, the first industrial application took place from 1921 in the Upper Austrian city of Wels in the natural fertilizer factory Wels , which operated until 1939.

The further development of composting methods for the production of organic fertilizer was carried out, for example, by the anthroposophist , garden and landscape architect Max Karl Schwarz on his gardener's farm, the Birkenhof in Worpswede . A propagation took place in particular through the biodynamic agriculture and the garden architect Alwin Seifert , who introduced it in the 1930s, among other things, in the construction of the Reichsautobahn . Seifert also put his thoughts on composting in writing, here in particular his book Gärtnern, Ackern ohne Poison should be mentioned. The permaculture relies on the recycling of nutrients as part of a surface composting.

Composting factors

General

Waste that is composted should, if possible, be composed of organic components and, if possible, contain no pollutants or contaminants. Contaminants are non-rotting or poorly biodegradable or usable materials such as glass, ceramics, plastics, plastic films and composites, rubber, wood, bones, table salt and metals.

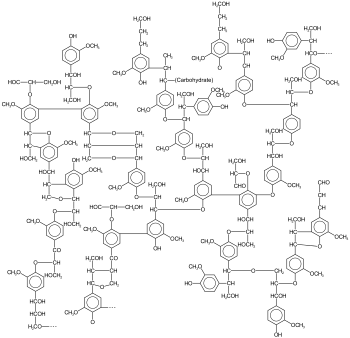

Carbon-hydrogen compounds can be broken down, i.e. mainly

- Carbohydrates that occur in plant material including the leaves, tubers, roots and seeds and e.g. B. in the form of sugar, starch, cellulose;

- Fats , oils , waxes , which are particularly contained in plant material, roots and seeds;

- Protein from vegetables;

- and to a small extent lignins , which are components of wood, leaves, bark, vegetables and plant fibers.

The composting microorganisms need oxygen and water to break down organic material. A good ratio of oxygen supply and water content is the decisive condition for the composting process. Four groups of microorganisms are important for composting:

In addition, snails , woodlice , beetles , worms and others take care of a large part of the composting.

Type of source material

Living or dead cells of plants and animals consist of an organic and a mineral part and water. The organic part is used by the aerobic microorganisms as an energy supplier. How well and how quickly a compost can be used by the microorganisms depends on how easily these nutrients are accessible to the microorganisms.

Composting involves a heterogeneous and solid starting material ( substrate ) with a limited water content. Microorganisms cannot use the solid substrate directly for nutrient supply. It must first be converted into smaller, low molecular weight substances ( hydrolysis ) before it can get into the cell to be supplied with nutrients. Therefore, during composting, the possibility of whether the microorganisms can hydrolytically break down the substrate enzymatically (e.g. can decompose cellulose ) decides on the availability of the substrate and thus the nutrient supply of the microorganisms. It is the factor that is responsible for the rate of degradation and thus the rate of composting.

The rate of breakdown of the organic matter is greatest in the first few weeks of the composting process. It slows down as the rotting time increases, and more and more remodeling processes occur towards the end. In the case of biowaste, a degradation rate of 40% to 70% can be expected within a period of twelve weeks, depending on the compost material and process management. Green waste, which contains a high proportion of poorly degradable lignocellulose , reaches degradation rates that can be below 30% in the same period.

ventilation

Oxygen is required to break down the organic material. One usually starts from two grams of O 2 per gram of degraded organic matter. If the exact composition of the starting material is known, it is possible to stoichiometrically calculate the amount of oxygen required for aerobic degradation . It should be noted, however, that the solubility of oxygen changes with temperature.

Water content

To start the rotting process more quickly, water is usually added. The water becomes a carrier for the numerous microorganisms and the dissolved nutrients that can penetrate the material through swelling . Water is also released through the breakdown of the organic matter. The solid components of the compost are surrounded by a film of water. The thickness of this water film is crucial for aerobic degradation. A water content of 40 to 60% in the composting material is ideal for degradation. Some of the water contained in the compost evaporates faster, mainly due to the self-heating of the compost.

In order to achieve an even distribution of the water and to bring in fresh oxygen, the material should be mixed well from time to time. If the water content is too low (<30%), the absorption and transport of nutrients are made more difficult and the composting process slowed down. If the water content is below 20%, the microbial degradation process comes to a complete standstill. If the water content is too high (> 70%), the microorganisms only have little oxygen available. Undesirable anaerobic conditions and putrefactive odor quickly emerge .

Air void volume

The volume in the compost material that is filled with water and gas is called the pore volume, gas space volume or air pore volume. The existing air pore volume is very important for the composting process. It determines the amount of oxygen and its distribution in the compost material. The heat generated by the breakdown of organic compounds causes both a heat flow and a draft of air through thermal convection ( rising heat ) , which transports the breakdown product carbon dioxide and supplies fresh oxygen. The better this draft, the faster the rotting will take place.

How the pores are distributed depends on the nature of the compost material. Coarser material such as small branches, straw or other structure-forming material allow air to flow through and form a good supporting structure. This can be particularly important in the case of high-level composts over 1.5 m in height, since the material's own weight can cause compression, which reduces the pore volume and thus the oxygen supply to the microorganisms. The type of rotting system chosen (static or dynamic) determines the optimum here. The minimum required air pore volume can be between 30% and 50%.

temperature

The breakdown process releases energy. The microorganisms only use 20% of the converted organic carbon for their building metabolism , while 80% is used for energy metabolism . The released energy occurs in the form of heat, the poor heat conduction or removal leads to self-heating of the compost material.

The composting process can be divided into several phases from the point of view of temperature. Depending on the temperature that results from the self-heating, one speaks of hot rot (at around 60 to 70 ° C) or below this temperature of cold rot . During composting, the temperature development can be controlled by adding water and adding or discharging nitrogenous (protein-containing) materials. Dripping water transports both heat and soluble warmth-giving substances in the extract ; in addition, cooling is mainly carried out by heat of evaporation . The temperature is directly related to the microorganism composition and the course of aerobic degradation and chemical oxidation processes .

In the start-up phase of composting, mesophilic organisms predominate. They are active in temperature ranges from 10 to 45 ° C and in the first twelve to 24 hours. With a self-warming above 45 ° C, their germ counts decrease again, and the number of thermophilic organisms increases sharply up to a temperature of 55 ° C. Above this temperature up to 75 ° C, the germ count of the thermophilic population continuously decreases. In most microorganisms, protein denaturation occurs above 75 ° C, but temperatures below 5 ° C also slow down their activity. If temperatures above 60 ° C can be maintained for several days, it can be assumed that the microorganisms and weed seeds in the compost material will be killed. In the cooling phase below 45 ° C, actinomycetes multiply more intensely. Their presence is a pointer to the compost maturity.

Higher temperatures than 70 ° C in the compost can only be traced back to purely chemical processes. The breakdown of pectins , protein and other compounds and direct oxidation of cellulose can cause the temperature to rise further. The absence of air flammable gases such as produced methane and vapors from fermentation - alcohols (see also Heuselbstentzündung # mechanism ).

PH value

The pH should be in a range between 7 and 9. At the beginning of the composting process, however, the pH value drops to values up to pH 6.5, as more organic acids are formed, carbon dioxide (CO 2 ) is formed and nitrogen is nitrified . The pH value rises again in the course of the degradation process.

C / N ratio

The ratio of carbon to nitrogen ( C / N ratio ) in the compost material is important for the reproduction of microorganisms and thus for the rate of degradation. Microorganisms need nitrogen for the formation of new cell matter. If there is an excess of nitrogen, ammonia (NH 3 ) can form, which also shifts the pH value unfavorably for degradation. Therefore, in such cases, for. B. straw or sawdust, which have a high carbon but low nitrogen content, added to the compost material. If the carbon content is too high (e.g. from wood chips), nitrogen-rich materials such as B. slammed grass clippings or sewage sludge to optimize the C / N ratio. A C / N ratio of 20: 1 to 25: 1 has been shown to be beneficial for the composting process.

Procedure

When it comes to composting, a distinction must be made between decentralized private composting and bringing compostable material to central (large) technical-commercial or municipal composting plants. The latter differ from composting in your own garden less in the process than in the quantities, the legal requirements associated with the plant operation and the degree of technology.

Self-composting

If the compost produced can be used sensibly and properly in your own garden, composting yourself is a variant for recycling garden and kitchen waste. One advantage of this is that there is no need for transports to a recycling plant with the associated energy consumption as well as CO 2 and other emissions.

Please note the possibility of a possible odor nuisance from neighbors; However, a well-kept compost will usually not smell unpleasant or at most for a very short time. In contrast to vegetable residues, residual animal material usually only rots with an attack of smell and can also attract animals such as rats, foxes and martens, just like storing larger quantities of cooked material. Brown rats also use compost heaps as quarters, as loose, easily digible soil, a warm burrow due to the heat of rotting, protein in the form of the numerous self-adjusting worms, moist plant remains and occasionally old bread and other human food remains provide them with an ideal habitat.

In general, freshly introduced material should be crushed as much as possible, because this increases the surface area for the “attack” of the decomposing organisms considerably. It is an advantage, dampens any odor formation and accelerates the rotting process, to temporarily store a (thin) layer of mother earth or mature compost from time to time. Fresh compost should be turned over once after three to six months so that it can then rot for a few more months. After about a year, depending on the raw material, the compost can be considered ripe or ready and, after sieving, it can be incorporated into the garden soil.

Which composting method is used for personal use depends on the local conditions and your own wishes. A distinction is made between the following procedures:

Open composting

Compost heap

The compost heap is a composting process for organic waste and green waste in the household (self-composting) derived from the farm manure heap .

A classic compost heap, also known as a compost heap, is suitable for every private garden. The compostable raw materials are piled up in shreds as much as possible. The pile should not be higher than 1 to 1.5 m. The space requirement is larger than with the procedures mentioned below. However, it is advantageous that if there is enough space, the compost heap can be expanded without problems, e.g. B. when seasonal larger amounts of garden waste are generated.

Chamber system (compost management)

Open chamber systems consist of two or more chambers or containers and are usually made of wooden slats. These are filled in such a way that loose, coarse materials such as branches are introduced in the lower area and only then are the (shredded) garden and kitchen waste layered. This is to ensure that the compost material can be ventilated from below. The principle of multiple chambers is based on the principle that the compost should be shifted from the first to the second chamber after a few months. As a result, it is mixed and can continue to mature in the second chamber, while the first chamber is again filled with new, fresh compost material. After six to twelve months, the finished compost can then be worked into the garden. The advantage of several chambers is that, on the one hand, space is reserved for the mixing and the more mature compost and, on the other hand, this is not constantly mixed with fresh material. In this way, a good quality compost can be achieved.

A variant of this process, the compost economy, works according to the same principle, only that instead of being repositioned after several months, a new chamber is put into operation, thus preventing the different stages of degradation of the compost from being mixed up. If you have three compost chambers, you can fill the first with fresh material, the contents of the second ripen, while the third can be successively emptied for the use of the completely ripened compost.

Closed composting

Thermal composters and quick composters are closed containers that are suitable for small gardens or for households that mainly compost kitchen waste.

Quick composter

Closed small compost silos ("Schnellkomposter") made of metal or plastic with removable lids are available in stores. In the case of galvanized composters, zinc can get into the compost as an undesirable metallic contamination due to the possible corrosion of the casing .

So that soil organisms can colonize the compost from below, the base plate of some high-speed composters is provided with holes or slots. With closed compost bins, the rotting process can hardly be influenced. A thorough mixing of fine and coarse composting material is therefore particularly important from the start.

Thermal composter

A special variant here are so-called “thermal composters”, which are lined with a heat-insulating layer. It is intended to ensure that temperatures are reached within the compost material at which the rotting organisms work well, even when the outside temperature is colder. However, this is only of interest at lower quantities of compost: Here the self is due to the lower volume of thermal insulation of the compost not guaranteed outward. The compost should not be compacted here; this would reduce the ventilation required for successful rotting and hinder the rotting process. When buying a closed compost container, care should be taken to ensure that the finished compost can be easily removed and that there are good ventilation options.

Rolling composter

Composters with curves have been offered since 2013. They have the advantage that, on the one hand, they can be easily rolled to those places in the garden where the green waste accumulates. On the other hand, the content is constantly moving and circulating. Frequent stirring and shifting are not necessary.

Two versions are currently on the market: a spherical composter with a diameter of around 80 cm, which is made of hard plastic and has flaps on the side that can be opened. A basic device ensures that the ball does not move uncontrollably in a storm. There is also a roller composter in the form of a roll or barrel with a length of about 1.30 meters and a diameter of 70 cm. It consists of sturdy, thick plastic film and has an opening that is closed with the help of a Velcro fastener. The whole thing can easily be rolled through the garden to sunny or shady places, depending on the requirements.

Worm composting

Earthworms are found in every compost heap. The red dung worm, also known as the compost worm ( Eisenia fetida ), can eat one and a half times its own weight every day. In good conditions, i. H. if there is sufficient moisture and food, it multiplies quickly. The earthworm's activity creates a crumb structure in the compost material, which means that water and oxygen can be better distributed in the compost. These worms are used in a targeted manner in worm composting. They can be purchased in stores or taken from an existing compost heap to inoculate the first compost material. The latter is cheaper. Two- or multi-chamber systems have also proven themselves in worm composting.

Technical composting processes

In 2006, around 65% of all residents in the Federal Republic of Germany were connected to the organic waste bin . If you compare the collection rates with other separate collection systems such as B. in the waste paper and waste glass collection, where values are achieved around 80%, it becomes clear that there is a high development or optimization potential in the organic waste collection. Higher coverage rates could e.g. B. with the help of organizational measures (including statutes) and through targeted public relations. Proof of this are bio-waste collection rates between 70 and 81%, as achieved in various administrative units. Despite the potential for optimization described, in 2006 (similar to 2008, see above) around 8.6 million tonnes of organic and green waste from households were collected and recycled for material and / or energy purposes. This corresponds to almost 20% of the total German municipal waste volume of over 46 million tonnes in 2006. Which biowaste and green waste are basically suitable and permitted for recycling is listed in the Biowaste Ordinance (BioAbfV).

In 2008, according to the Federal Statistical Office, there were around 289 bio-waste composting plants available in Germany with a nominal capacity of 5.5 million tons and a waste volume of 4.6 million tons; also 665 green waste composting plants with a nominal capacity of 4.5 million tons and a recycled amount of waste of 3.1 million tons. There were also 969 biogas and fermentation plants for organic waste, 100 sewage sludge composting plants and 18 plants for other biological treatment. In total, around 13 million tons of waste were processed in 2041 biological treatment plants in Germany in 2008. Of this, 8.7 million tons were separately collected organic waste from household waste , i.e. from the so-called “bio bins”, as well as biodegradable garden and park waste.

Basic structure of composting plants

The main work steps in technical composting differ only slightly depending on the method used; they are therefore summarized below:

processing

Biowaste and green waste are weighed when they are received in the composting plant and / or documented in an operating diary according to quantity, type and origin. The compost raw materials are subjected to a control. Are substances unsuitable, e.g. B. with high levels of contaminants, they are rejected. The delivered compost can be temporarily stored in a so-called flat bunker.

The preparation of the compost raw materials serves to pre-treat the material to improve the composting process. The content of existing contaminants and foreign substances is reduced. The organic waste is sorted into coarse-grained and fine-grained fractions through sieving. Depending on the degree of contamination, further processing can be carried out using suitable sieve cross-sections, decompacting (loosening) and shredding units. Iron components are removed by magnetic separators.

Much of the foreign matter accumulates in the coarse-grained fraction. It is therefore usually sufficient to eliminate the foreign matter from this fraction. In order to obtain a sufficient air pore volume in a compost body, structural material should be added to organic waste with little structure. Shredded tree and shrub cuttings as well as sieve overflows from the packaging of the finished products are suitable as structural material .

Pre, main, intensive rotting

The first phase of composting is known as preliminary rotting , main rotting or intensive rotting . It is characterized by high temperatures and high rates of degradation of the easily degradable organic substances.

In contrast to domestic composting, the composting process in intensive rotting is largely controlled. By encapsulating the rotting material, ventilation and humidification can be controlled in such a way that the process takes place as quickly as possible and at the end pathogenic germs (animal diseases) and weed seeds can be killed by intentional self-heating of over 60 ° C. Good technical equipment and skilful management can prevent anaerobic rot zones in intensive rotting. These are not only undesirable because of the delay in the aerobic rotting process, but also because of the formation of methane and hydrogen sulfide ( risk of explosion, global warming potential , odor). The odorous substances produced during aerobic rotting, including in the form of organic acids, can be broken down in downstream biofilters .

Post-rotting

The subsequent multi-week phase of composting is called post-rotting. During this time, the temperature in the compost body drops and the biological activity slowly decreases. Products of the previous degradation are converted into humus and humus-forming substances. The final rotting serves to biologically stabilize the compost. This phase is the maturation phase in which fresh compost is turned into finished compost. The final rotting takes place in open, covered or also closed heaps .

Assembly

During packaging, also known as fine processing, the end product is produced by sieving. Depending on the intended grain size of the finished product, fine-grain sieves (up to twelve millimeters hole diameter), medium-grain sieves (up to 25 millimeters) or coarse-grain sieves (up to 40 millimeters) are used. The sieve overflow can be reused as a structural material for composting. Finally, air separators and FE separators for ferrous metals or eddy current separators for non-ferrous metals can be used to reduce potentially still existing light-weight contamination .

Rotting systems

Various composting systems are used in large-scale composting. They are subdivided according to whether the compost material is continuously moved during composting (dynamic systems), is converted from time to time (quasi-static or also called semi-dynamic systems), or remains statically in one place for the duration of the composting.

Static, quasi-static systems

Rent

Rent is one of the oldest forms of composting. If the pile is not systematically forced ventilated, it can be layered up to a maximum of two meters, as otherwise an adequate oxygen supply cannot be ensured due to the load (see above). With ventilated heaps it is possible to build up to five meters high. Classic shapes are triangular, trapezoidal or table rents. Hiking rents, tunnel rents are semi-open, but technically enclosed systems.

Triangular, trapezoidal or table rentals

In the case of smaller systems, these rents are managed with freely movable moving devices. In larger halls, self-propelled devices are mostly used, or permanently installed moving devices are used. The heaps can be operated via slotted base plates with pressure or suction ventilation. In the case of unventilated heaps, ventilation takes place solely through thermal or diffusion.

Hiking rentals

Table rents are trapezoidal rents. If they are used continuously during composting, they are referred to as hiking heaps. The rents are being removed, loosened, homogenized and re-stacked. The hiking rental system is one of the quasi-dynamic processes.

Tunnel composting

When renting a tunnel, the rotting material is poured between reinforced concrete walls. The tunnels are two to four meters wide and 25 to 50 meters long. A moving device on rails ensures the mixing. The tunnels are ventilated from below. The individual tracks are encapsulated or closed at the top.

Volume composting

Rotting boxes

Rotting boxes are closed boxes with a usable volume of approx. 50 to 60 cubic meters. Rotting boxes are pressurized . They are used for pre-rotting.

Rotting container

Rotting containers usually have a smaller usable volume of around 20 cubic meters and are made of metal. In contrast to the boxes, they are not stationary and can be transported back and forth between the loading area and the rotting area.

Dynamic systems

Rotteturm

The rotting tower is a vertical container with a usable volume of more than 1000 cubic meters and is used for pre-rotting. The rotting material runs through the container from top to bottom and is discharged with screw conveyors. It is ventilated with compressed air using the counterflow principle.

Rotting drum

The rotting drum is also used in the main rotting process. It is a horizontal, slightly inclined rotary tube that is ventilated with compressed air. The rotting material is constantly moved and driven through the pipe.

Emissions

The operation of composting plants creates odors and other emissions such as noise, dust, bioaerosols and liquid emissions such as seepage and condensation water. These are minimized through structural and procedural measures as well as operational management based on good professional practice. Plants with a throughput of more than ten tons of waste per day are subject to approval.

As part of the approval of plants, these legal provisions for minimizing undesired emissions and for occupational safety apply:

- Technical instructions for keeping the air clean (TA Luft)

- Technical instructions for protection against noise (TA Lärm)

- Thirtieth ordinance for the implementation of the Federal Immission Control Act (30th BImSchV) - ordinance on facilities for the biological treatment of waste

- Health and safety regulations

There are special requirements for the areas of waste delivery and interim storage, waste processing and pre-rotting. The external impact of plants for biological waste treatment is mainly determined by their emissions. Public acceptance of the systems stands or falls with them. Therefore, when planning possible emissions, special attention should be paid.

Compost quality

There are several uses for compost. Depending on the application, different quality conditions must therefore be met. Quality criteria such as hygiene, degree of rotting , plant compatibility and overall visual impression are primarily dependent on the process technology. The ingredients, on the other hand, only depend on the material composition of the starting material.

In principle, every compost must be safe from an epidemiological point of view when it is disposed of. Ready-made compost should e.g. B. meet the following quality requirements set by the Federal Compost Quality Association :

- Degree of rotting IV – V

- high plant tolerance (in the cress test )

- Content of organic matter ( loss on ignition ) at least 20% (based on the dry matter ), content of interfering substances or fiber <0.5% by weight (based on the dry matter)

- Heavy metal content (in milligrams / kilogram dry matter): zinc (Zn) ≤ 400, lead (Pb) ≤ 150, chromium (Cr) ≤ 100, copper (Cu) ≤ 100, nickel (Ni) ≤ 50, mercury (Hg) ≤ 1, cadmium (Cd) ≤ 1.5

Degree of rotting

The degree of rotting is determined using the self-heating test. The material is incubated for 72 hours in a thermally sealed 1 liter Dewar vessel with sufficient air. The maximum temperature reached determines the degree of rotting.

Compost quality assurance (RAL-GZ 251)

The Bundesgütegemeinschaft Kompost states that in 2010 in Germany 434 composting plants with a plant capacity of 7.4 million tons (74%) were subject to the RAL compost quality assurance system . (Bundesgütegemeinschaft Kompost eV, as of March 2010). The compost quality assurance (RAL-GZ 251) guarantees regular quality monitoring of fresh, finished and substrate compost by the Bundesgütegemeinschaft Kompost e. V. or by approved test laboratories. The principles and requirements of quality assurance are laid down in the "Quality and test provisions". Quality assured composts are identified with a quality mark. In quality assurance not only the end product is examined, but the entire production facility. The raw materials, the production facilities, the hygiene, the process quality, the end product quality, the goods declaration and the application recommendations are checked and certified.

literature

- Heribert Insam , Nuntavun Riddech, Susanne Klammer (Eds.): Microbiology of Composting. Springer, Berlin 2002, ISBN 3-540-67568-X .

- Federal Office for the Environment (Hrsg.): Compost and digestate in Switzerland. Study 1: Organic pollutants in compost and digestate. Study 2: Effects of compost and digestate on the environment, soil fertility and plant health. In: environmental knowledge. No. 43, 2007.

- Alwin Seifert : gardening, farming - without poison. Biederstein, Munich 1980, ISBN 3-7642-0150-9 .

- Charlotte Reitsam: Reichsautobahn in the field of tension between nature and technology. VDM, Saarbrücken 2008, ISBN 978-3-639-08556-3 (also habilitation thesis at the Technical University of Munich , Faculty of Architecture, 2004).

Web links

- Ministry of Agriculture, Nature Conservation and Environment (Ed.): Thuringian Compost Guide. (PDF, 949 kB).

- Klaus Strotmann: Whole foods for soil life. (PDF; 162 kB) In: dlz special issue “Perspective Bio”. (Interview with Sepp Braun Bodenfrucht about compost in arable farming).

- Bundesgütegemeinschaft Kompost e. V.

- Composting: hygienic aspects. (PDF; 2.1 MB), Bavarian State Office for the Environment.

- Biowaste Ordinance. (PDF; 52 kB).

- Florian Amlinger, Stefan Peyr, Urs Hildebrandt, Joachim Müsken, Carsten Cuhls, Joachim Clemens: PDF: Guideline on the state of the art in composting. (2005), basic study at Lebensministerium.at

- Composter and composting. Garden Gnome Weblog.

Individual evidence

- ↑ Duden: dictionary of origin. P. 433.

- ↑ Kluge: Etymological Dictionary. P. 516.

- ^ Pfeifer: Etymological dictionary. P. 700.

- ^ A b Sebastian Hedel: The composting of pig excrement in the province of Can Tho (Vietnam). Diploma thesis, 2005, ISBN 978-3-638-70692-6 , excerpt from Google Books p. 8, possibly citing other authors.

- ↑ M.Andratschke: fertilizer - a curse or a blessing. Lecture notes at the University of Regensburg, p. 2.

- ^ Karl-Wilhelm Weeber: The wine culture of the Romans . Verlag Artemis & Winkler, 1993, ISBN 978-3-7608-1093-5 , pp. 24 .

- ↑ Winfried Titze: Fresh vegetables from the garden. Ulmer, Stuttgart 1987, ISBN 3-8001-6293-8 , p. 10.

- ↑ Welser Anzeiger of January 5, 1921, Volume 67, No. 2, p. 4

- ↑ Werner Bidlingmaier, Ralf Gottschall: Biological waste recycling. 96 tables. Ulmer, Stuttgart (Hohenheim) 2000.

- ↑ Martin Kranert: Introduction to waste management. 4th, fully updated and expanded edition. With the collaboration of Klaus Cord-Landwehr. Vieweg + Teubner, Wiesbaden 2010.

- ^ Hans Dieter Janke: Environmental biotechnology. Basics and procedures. 99 tables, 92 formulas. 2nd, updated and exp. Edition. With the collaboration of Alexander P. Herrmann and Thilo Britz. Ulmer, Stuttgart 2008.

- ↑ P. Präve, U. Faust, W. Sittig, DA Sukatsch (eds.): Handbook of biotechnology. 4th edition. Oldenbourg-Verlag, Munich / Vienna 1994, ISBN 3-486-26223-8 ( limited preview on Google Books ).

- ↑ Bernd Bilitewski: waste management. Manual for practice and teaching. With 130 tables. 3., rework. Edition. With the collaboration of Georg W. Härdtle and Klaus A. Marek. Springer, Berlin 2000.

- ^ Liebing, Alexandra (2009): Ecologically sensible recycling of biowaste. Suggestions for local decision makers . 1st edition. Berlin: BMU.

- ↑ Fricke, Klaus et al .: The separate collection and recycling of biowaste - inventory 2003 (PDF, 319 kB); In: The future of separate collection of organic waste. ANS 44 series of publications, Orbitverlag, Weimar 2003, pp. 11–64; Section 3.1.1.

- ↑ Federal Statistical Office: Waste disposal. Technical series 19, series 1 - 2008, item number 2190100087004, Wiesbaden 2010.

- ↑ Fourth ordinance for the implementation of the Federal Immission Control Act (ordinance on plants requiring approval - 4th BImSchV) , in the version of the announcement of May 31, 2017, Appendix I, No. 8.5.2