Ship engine

Ship engines are steam engines , steam turbines , diesel engines and gas turbines , which have been increasingly replacing the wind propulsion system using sails, which has been used for thousands of years for ships , since the beginning of the 19th century. The criteria for selecting the ship's engine are:

- Efficiency : The first steam engines achieved less than 1% efficiency and could hardly compete with sailing ships .

- Power density (kw / kg): Gas turbines are light and inexpensive, but have a higher consumption than diesel engines because of their lower efficiency.

- Fuel costs : Steam turbines run on anything that can heat water, including industrial waste

- Availability : A Flettner rotor works, like a sail, only in wind and fails in calm.

- Range : A nuclear powered icebreaker does not have to stop its journeys during the season to bunker.

history

In 1819 the Savannah crossed the Atlantic from New York to Liverpool partly under sail and partly with machine power. With this voyage of the Savannah, the proof of the usefulness of a propulsion engine for seagoing ships was provided - the machine age for ships began, even though large deep-water sailors were still being built after 1900. The paddle wheel initially served as the drive mechanism for the machine-driven ships, but it did not prove itself in the harsh North Atlantic. From 1860, the propeller prevailed. The ship's engine has brought about a fundamental change in shipbuilding and shipping in the short period of its existence . The construction of the ships, their speed and economy were influenced by it. Although today's commercial or naval ships without machinery are almost unthinkable, there are still individual commercially used sailing ships without a marine engine in individual regions of Southeast Asia and research continues on sails as an auxiliary drive for ships, as current developments by the Harburg company SkySails or Enercon show.

Steamships

Steam engines

It took nearly 200 years before the first idea of using a prime mover to propel a ship resulted in a viable solution and was used to propel a seagoing ship, the Savannah . The main purpose of the following 180 years was to improve the machines in terms of operational safety , economy and operation. During the first 100 years up to around 1910, the piston steam engine dominated the field almost exclusively in many different types and forms. First machines with oscillating cylinders , later cross-head machines with single and then with multiple steam expansion (triple or quadruple expansion machines ) were built.

In the first steamship built by Germans, Die Weser , the system produced 14 HP, had a specific coal consumption of around 8½ kg / PSh, corresponding to a thermal efficiency of around 1% and a power to weight ratio of around 1000 kg / PS. In the period between 1900 and 1910 - around 100 years after the first ship's steam engine was built - piston steam engines reached their peak as propulsion engines for seagoing ships.

The large express steamers were built with machine outputs of 2 × 20,000 hp. The coal consumption of these machines was only around 0.75 kg / WPSh, corresponding to a thermal efficiency of 13%. Each guard dragged 50 stokers and trimmers into the boiler room. Almost 30 quintals of coal was burned by each stoker per guard. The trimmers brought the coals and took care of the removal of the slag. This was probably the peak of the piston steam engine, but propulsion systems for ocean-going ships with steam engines were still being built into the 1950s.

Steam boiler

The boiler development had made very slow progress at first. The initially common suitcase boilers only permitted steam pressures of up to 2 bar. It was only with the development of the oval and later the cylinder boilers that higher steam pressures could be used. In the case of cylinder boilers , the simple and robust Scottish boiler became so popular that it was simply referred to as the “ship boiler” for several decades. The boilers were initially only heated with coal , the oil firing was first used in 1897 on a Russian naval ship. The fuels were not only used for economic and technical reasons. National self-sufficiency also played a role, and there was often a lack of sufficient heaters, even though coal was often cheaper.

The sensitive water-tube boiler with significantly higher steam pressure and temperatures, on the other hand, was initially unable to assert itself, although it was installed on board ships, especially naval vessels, on various occasions. The breakthrough for this type of boiler came primarily with oil firing and the installation of steam turbines . A particularly challenging and interesting development in ship boiler construction was the Benson boiler , which was first used on the Uckermark by HAPAG with a drive power of 6000 hp. With over 225 bar in the boiler and 70 bar and 460 ° C in front of the turbine, it was a so-called maximum pressure boiler that achieved a 17% higher degree of efficiency compared to comparable ship boilers.

Steam turbines

In merchant shipping, especially in the transatlantic voyage with express steamers and naval ships, ever higher ship speeds were required. For a ship, the power requirement increases with the 3rd power of the speed . The drives of the high-speed steamers with piston steam engines reached their technical limits at the turn of the century, as higher outputs could only be achieved by installing several steam piston engines. The individual outputs were between 15,000–17,000 hp, two or four steam engines were installed and a lot of space and weight was required for the boilers, machines and coal. The vibrations of these giant machines were difficult to control; the Schnelldampfer Deutschland , which won the Blue Ribbon in 1900 , was called the “Cocktail Shaker” by the international travel audience. The demand for higher performance in a small space and with lower weight led to the development and use of steam turbines . The steam turbine is a flow machine ; Steam flows in the turbine through an impeller and drives it like a water turbine - in contrast to the piston engine, in which the steam pressure on the piston surface generates a force which is converted into rotating mechanical energy via oscillating, vibration-causing piston movement and the engine via connecting rods and crank pins becomes. The first operational steam turbine was built by de Laval in 1883 . Just one year later, Parson presented a steam turbine in a different design.

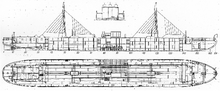

Turbines require high circumferential speeds, i.e. high speeds , so that good efficiencies can be achieved. For a propeller drive, however, low speeds are sought in order to achieve high degrees of efficiency. At the turn of the century no powerful reduction gears were available, so a compromise was necessary here. The first turbine systems were designed without a gearbox. The fast steamer Imperator of the Hamburg-America Line , built in 1912 (Vulcan Werke, Hamburg), received four turbines, each directly connected to a propeller shaft. The total output was 60,000 WPS at a speed of 175 rpm. 46 water-tube boilers, which were designed with a boiler pressure of 17 bar, were required to generate steam. Since turbines are only suitable for one direction of rotation, a further turbine, the reverse turbine, is necessary for reversing. Since the propulsion systems are only operated for a short time in port, reverse turbines are simple, low-efficiency turbines (mostly two-stage Curtis wheels) that can only generate around 40% of the advance power.

Due to the initially non-existent gearbox, turbo-electric drives were also built that could be reversed electrically for reverse travel. Another possibility was the installation of Föttinger transformers . It was not until the development of high-performance marine gear units and high-pressure vessels that the turbine drive made its breakthrough. These systems were designed for extremely high outputs, they had a lower power to weight ratio than steam engines or a corresponding number of diesel engines and required less space. Before the Second World War, they were the ideal drive for large, fast cargo ships and passenger ships , from 1950 also for large tankers and super tankers and from 1967 for large, fast container ships .

Turbine systems could not achieve the high efficiency of the diesel engine, but they were very reliable, had long maintenance intervals and caused only low repair costs. The higher fuel consumption was of less importance, since very heavy heating oil, which was cheap, was sufficient as fuel for the boilers. With the 1973 oil crisis , the price of heavy bunker oils rose sharply within a short period of time and the systems became uneconomical. Driving with reduced power in order to save fuel costs does not make much sense with turbine systems, since the efficiency of turbine systems deteriorates significantly with reduced power. The diesel engine offered an alternative; its performance had meanwhile been increased considerably and, with additional technical equipment, was also able to burn cheap heavy fuel oil.

Steam turbines were also replaced on fast naval ships during the 1960s and 1970s. ( F120 in Germany with construction start in 1957, Amazon class (1971) in Great Britain, Spruance class , Oliver Hazard Perry class in the USA.) Today, steam turbines are only installed in nuclear-powered naval ships. Also in supertankers and container ships of the 5th and 6th generation diesel engines are used today to drive. Gas tankers are one of the few remaining areas of application in shipping, along with naval vessels and nuclear icebreakers . Since a small part of the load, liquid gas, is constantly evaporating, this boil-off gas is used as boiler fuel ; its use on the move saves the otherwise necessary reliquefaction system. Since 2000, however, marine diesel engines have also been developed that can be operated with gaseous and liquid fuels.

Diesel engine

The steam engine had reached its peak around 1900, and steam turbines were increasingly being installed in naval vessels and fast merchant ships. At that time, another mechanical drive was used for shipping, the diesel engine. Whereas it took 200 years for the steam engine from its beginnings to installation in a seagoing ship, it was only 20 years for the diesel engine from the patent application to the commissioning of the world's first seagoing ship with a diesel engine drive. Development at MAN began with two test engines and a first operational engine. In February 1912, she took her to the Danish seagoing vessel Selandia at Burmeister & Wain in Copenhagen via a few Russian river vessels such as the Vandal and a small Dutch coastal tanker Vulcanus (1910) from Shell with diesel propulsion . The Christian X (ex Fionia ), a sister ship of the Selandia, is considered the first German ocean-going ship with a diesel engine . This cargo ship was bought by Albert Ballin of HAL in 1912 and used under the German flag. The first commercial ships with diesel engines built in Germany were the Monte Penedo (1912, Howaldtswerke shipyard) for Hamburg Süd and the Secundus (1913, Blohm & Voss shipyard ) for HAPAG .

The First World War encouraged the development of marine diesel engines, which were used as surface propulsion engines on submarines . MAN and Krupp received an order from the Navy to develop a double-acting 2-T diesel engine with a cylinder output of 2000 hp. After the war, some ships with small and medium outputs of up to around 6000 hp were initially equipped with diesel engines. The fuel consumption of the ship's diesel engines was 0.190 kg / PSh lower and the efficiency of 35% was considerably higher than with ship steam systems. However, the cost of the necessary ship auxiliary systems for operating the diesel engines is significantly greater. Shortly before the Second World War, the types of machines were distributed roughly as follows:

- small powers up to 1,500 hp: diesel engines or piston steam engines

- Medium power 1,500–5,000 hp: diesel engines

- higher outputs 5,000–15,000 hp: diesel engines or steam turbines

- great performance over 15,000 hp: steam turbines

After the Second World War, the situation shifted strongly in favor of the diesel engine. It was possible to burn cheap heavy fuel oil in the engines and to achieve very high cylinder outputs in the two-stroke diesel engines, from 2000 to 4000 HP per cylinder in 1970 to 7800 HP / cylinder today with a consumption of 0.128 kg / PSh, corresponding to an efficiency of 50%. The high efficiency of the engine and the low price of heavy oil have led to the fact that the diesel engine has now replaced the steam turbine from all power ranges, although additional ship auxiliary systems are necessary with a complex heavy oil processing system and increased maintenance work is required.

The diesel engine penetrates the area of greatest performance. The enlargement of the cylinder volume and the exhaust gas turbocharging made it possible for the large cylinder outputs to achieve an output of 93,400 hp or 68,700 kW with a 12-cylinder engine. These heavy oil engines are now reliable prime movers. This is evident from the fact that most ships today are only equipped with one main engine. However, their operation and maintenance requires trained personnel with special knowledge.

In addition to these slow-running two-stroke engines , medium -speed four-stroke diesel engines are increasingly being used in the medium power ranges. In the past, these motors were mainly used as generator drives for the on-board electrical system supply, these machines, which are now just as suitable for heavy oil, are also installed as the main drive. Connected via gearboxes , such multi-engine systems can cover large performance ranges. As they require less space and are lower, they are very well suited for passenger, ferry and RoRo ships .

Fast-running diesel engines were originally only installed in motor yachts and small naval vessels, but required a lot of maintenance. In the meantime, these motors have achieved a certain robustness with outputs of up to 7,500 kW or 10,000 hp. Because of their power density, such engines are therefore the main propulsion system for many marine, special and multihull ships today. Fast-running diesel engines are widely used on very fast, medium-sized passenger ferries with speeds of up to 40 knots, and some of them are used on the large high-speed ferries (and some are gas turbines).

Electric propeller drives

In addition to the operation of steam engines, the development of the steam turbine and the diesel engine, another propeller drive was developed from 1900 onwards. The starting point was both the steam turbine and the diesel engine. At the time of its introduction, the steam turbine had advantages and disadvantages (high speed, not reversible) compared to the steam engine, the latter also initially applied to diesel engines. In addition to other possibilities, the electric propeller drive was seen as a solution to these problems. The first thing that was implemented was the diesel-electric principle. Because the diesel engines could not be reversed, the combination of engine- generator set and electric propeller motor helped . The first ships with a diesel engine, the small river tankers Vandal and Ssarmat , received such systems in 1903/1904 (the Vandal a del Proposto drive that worked purely diesel engine forwards and diesel-electric backwards, the Ssarmat a purely diesel-electric drive) The advantage was that the motors were controlled directly from the bridge.

A turbo-electric propulsion system was first installed in Germany in 1907 in the submarine lifting ship Vulcan , but this ship remained the only one of its kind for almost thirty years. This principle was not used again until the turbo-electric ships in Scharnhorst and Potsdam back. Since the development of frequency converters , three-phase systems have increasingly been installed for propeller drives. The advantages of such systems are mainly used in special ships.

The advantages of these drives have also been recognized on cruise ships , where the space-saving, flexible design, the different power requirements and the low-vibration and low-noise operation play an important role. Cruise ships, for example, have diesel-electric systems with electric drive motors in their hulls that drive propellers. Alternatively, pod drives are used. In these, the electric traction motors are located under water in a nacelle that can be rotated through 360 °, drive the propellers directly and, comparable to an outboard motor, also serve as a rudder.

Gas turbines

Gas turbines for ship propulsion were mainly adopted as jet engines from the aviation industry, "navalized" (converted for use in ships) and mainly used on special ships and in the navy. In its basic form, consisting of a compressor, combustion chamber and gas turbine, the gas turbine unit is an impressively simple and compact machine. It has no reciprocating machine parts. The rotary movement required for the propeller drive is generated directly with a uniform torque and reduced to the required propeller speed via appropriate gears. In merchant shipping, gas turbines have seldom been able to establish themselves despite several attempts (fast ferries , low-vibration cruise ships). They have a significantly higher fuel consumption and usually require a higher quality and more expensive fuel. The advantages are a significantly lower power-to-weight ratio and a smaller space requirement compared to fast-running diesel engines. The first gas turbine used in shipping was used on a trial basis as part of a diesel-electric drive in 1951 on the Shell tanker Auris . The Auris had an electric propeller drive and four diesel generator sets; around a quarter of the drive energy could be generated by a gas turbine. After successful testing, the drive of the Auris was completely converted to a 4270 kW gas turbine in 1956, which allowed it to travel at around 13 knots.

The John Sergeant , a Liberty class ship (built in 1941), was retrofitted in 1956 with a gas turbine system and variable pitch propeller and is considered the first gas turbine merchant ship .

In 1958 the first German ship with a gas turbine drive, the stern catcher Sagitta , was delivered by Rickmers shipyard . In order to save the reverse turbine for maneuvering operations, the Sagitta was equipped with a controllable pitch propeller . The Fritz Heckert , a cruise ship delivered in 1961 by Mathias-Thesen-Werft , Wismar, was equipped with a gas turbine drive and controllable pitch propeller. A main reason for this drive was the low-vibration operation, which is still used today for the use of such drives on cruise ships. The success of both pioneers with gas turbine propulsion failed, the Sagitta later received a diesel engine propulsion; the Fritz Heckert was shut down after some time and became a hotel ship .

The first new construction of a gas turbine cargo ship was in 1967 by Adm.Wm.M.Callaghan, chartered by the US Navy for military sea transport . The two-screw ship was equipped with two Pratt & Whitney FT4 aircraft turbines, each with 18,375 kW, which had been converted for on-board operation . She reached a speed of 25.5 knots and thus held the speed record for cargo ships on the Atlantic for two years.

As the first ship built exclusively for regular freight traffic, the Seatrain Lines shipping company operated between 1971 and 1981 with four container ships powered by P&W gas turbines in regular trans-Atlantic freight traffic. The first to be launched on October 24, 1970 was the GTS Euroliner at the Rheinstahl Nordseewerke shipyard in Emden . It was powered by two Pratt & Whitney FT4 A-12 gas turbines with 22,700 kW each. She reached a speed of 26.5 knots and used about 300 tons of fuel a day. It also achieved the speed record for cargo ships on the Atlantic. Under the price pressure of the oil crisis of the 1970s, attempts were made to convert gas turbine ships to cheaper fuel quality. Since these attempts did not produce satisfactory results, the ships were converted to diesel engines in 1982.

The advantages of gas turbine drives are not decisive in merchant shipping. With the exception of a few fast container ships and ferries built before the second oil crisis (1978), they were rarely used. The fuel costs, which rose sharply after 1978, led to extremely high operating costs for these ships and to the conversion of the gas turbine container ships to medium-speed diesel engines. The Finnjet , a 30 knot fast ferry with gas turbine propulsion, has been equipped with additional diesel-electric propulsion, which enables economical operation outside the main season with a speed reduced to 17-19 knots and fewer departures.

For ships with high power concentration such as B. naval ships or fast ferries it looks different, here gas turbine drives are increasingly used. The high fuel consumption and the more expensive fuel quality play a subordinate role on these ships. Naval ships sometimes have combined diesel / gas turbine drives ( CODOG ). The diesel engines are used for economical cruising and the gas turbines for maximum travel. Some of the new cruise ships (Millennium class) received a combined system consisting of gas turbines and steam turbines (GUD) to drive electric generators . The electric drive motors for propeller drive are located in a nacelle outside the ship ( POD drive ). The high fuel consumption of the gas turbine is partially offset by the utilization of waste heat. The gas turbine is followed by an exhaust gas boiler for generating steam; the steam supplies a steam turbine to drive a generator. In the meantime, however, powerful diesel generators have been retrofitted on this series of ships.

Drive concepts

In many ships a prime mover acts on exactly one propeller. This has the advantage that the drive train has a very simple structure, which means that the design, operation, maintenance and servicing are inexpensive.

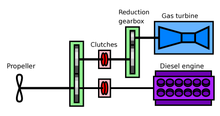

In order to achieve a higher overall efficiency under different load conditions and a higher failure safety of the drive train, different drive concepts have been developed which combine different drives so that the advantages of both drives can be used. The various drives work via clutches and gears on a common propeller, the clutches mostly being designed as self-synchronizing clutches .

Combined drives are more complicated, heavier and cost more compared to simple drives in which only one drive engine acts on the propeller.

CODAD drive

A CODAD drive (for Combined Diesel and Diesel ) is a ship drive concept in which two different diesel engines are switched to the drive shaft (s). The advantage of this type of drive, similar to the related COGAG drive , is the low fuel consumption, the disadvantage is the complicated differential gear .

CODAD drives are used in particular in yacht building. The first warships to receive this system were the Turkish Navy's MEKO-140 ships in the 1970s . The system turned out to be maintenance-intensive.

COGAG drive

A COGAG drive (for Combined Gas and Gas ) is a ship propulsion concept in which two different gas turbines are switched to the drive shaft (s). The advantage of this type of drive, similar to the related CODAG drive , is the low fuel consumption, the disadvantage is the complicated differential gear .

COGAG drives are used in particular in warship construction. The first warships to receive this system were the Amazon- class of the Royal Navy in the 1970s . The system proved to be maintenance-intensive and the complicated system proved extremely unstable in rough seas.

COGOG drive

A COGOG drive (for combined gas or gas ) is a ship drive concept in which two different gas turbines can be switched to the drive shafts. A highly efficient, less powerful turbine is used for cruising , while a more powerful turbine is used for high speeds.

As with the COGAG drive , the advantage is the reduced fuel consumption, since a small turbine at 100% power consumes less fuel than a twice as powerful one that is operated at 50% power. In contrast to the COGAG concept, the turbines for marching and high-speed travel are not used in parallel here, but always only used individually. This allows the differential gear of the COGAG drive to be replaced by a simple, inexpensive and low-maintenance spur gear . The disadvantage is a higher total weight of the drive with the same maximum power.

COGOG is mainly used on warships . Examples are the frigates of the Dutch Kortenaer class and the destroyer of the Canadian Iroquois class .

COSAG drive

A COSAG drive (for combined steam and gas ) combines a gas turbine with a classic steam turbine drive. The propeller can either be driven by the steam turbine only, only by the gas turbine or by both together via a gearbox. This drive concept offers the advantage of a classic, efficient and proven steam process and at the same time offers the advantage of using the high acceleration and the fast start-up time of a gas turbine. This system was mainly used on the first generation of gas turbine ships such as the British County class , the British and Indonesian frigates of the Tribal class and on the Spanish aircraft carrier Dédalo.

CODOG drive

A CODOG drive (for Combined Diesel Or Gas ) is a ship propulsion concept in which diesel engines for cruising or gas turbines for maximum speed can be switched to the drive shaft.

The advantage of the CODOG drive is the relatively simple design of the main gear. One disadvantage is the additional weight of the drive component that is not in operation. Earlier CODOG drives often suffered from being susceptible to failure when switching between diesel engine and turbine operation. This problem has been eliminated in modern drives of this type.

CODOG drives are used in particular in warship construction.

CODAG drive

A CODAG drive (for Combined Diesel And Gas ) is a drive concept in which diesel engines and gas turbines are switched together on the drive shaft (s). The first ships to be built with this system were the F120 -class frigates of the German Navy .

The advantage of a CODAG drive is the lower fuel consumption due to the drive diesel engines in conjunction with gas turbines that can be switched on at short notice for maximum speed. The disadvantage is the complicated design of the gearbox , since very different powers have to be processed at the same time (order of magnitude: diesel several thousand kW, gas turbines several ten thousand kW).

CODAG drives are often used in warship construction.

CODLAG drive

The CODLAG drive ( COmbined DieseleLectric And Gas ) is a type of drive in which diesel generators supply electricity for the electric drive motors and a gas turbine is switched on to achieve maximum speed . This system is to be installed in the new F125 frigate of the German Navy.

The advantage of this system is that only one type of diesel generator is installed for the entire power supply of the ship, which minimizes maintenance and repair work.

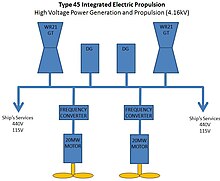

In contrast, a system of diesel engines and / or gas turbines that generate only electricity for the traction motors and have no mechanical connection with the propeller shafts, not as CODLAG but as integrated electric drive ( English Integrated electric propulsion [IEP] or Integrated full electric propulsion [IFEP] ).

CONAS drive

A CONAS drive (abbreviation for English combined nuclear and steam propulsion , Combined nuclear and steam drive ') is a marine propulsion concept is used in the nuclear and conventional steam generated for the drive.

When cruising , only the steam generated by nuclear reactors is used. Conventionally fired steam boilers are switched on to achieve maximum speed. Furthermore, if the nuclear reactors fail, the ship can only be propelled with conventionally generated steam.

The advantage of this configuration is the redundancy of the drive systems.

The only ships using this system are the Russian Kirov-class battlecruisers and the command and reconnaissance ship “Ural” (project 1941) based on a Kirov-class hull.

Only conventionally fired ships of the Kirow class can reach a maximum of 17 kn at a range of 1000 nm . Powered by nuclear power, they reach approx. 25 kn. When all steam generators are switched on, the maximum speed is 32 kn.

IEP drive

An integrated electric propulsion ( English Integrated electric propulsion [IEP] or Integrated full electric propulsion [IFEP] ) is a ship propulsion system in which ship diesel engines and / or gas turbines only generate electricity for the traction motors and have no mechanical connection with the propeller shafts . This drive system is z. B. used on many cruise ships and the guided missile destroyers of the Daring class (Type 45) of the British Royal Navy .

COGAS drive

A COGAS drive (for combined gas and steam ), like the COSAG drive, combines a gas turbine with a steam turbine drive. However, here the steam process is not heated by an oil burner; instead, the waste heat from the gas turbine is used for the steam process. As an alternative to the gas turbine, the waste heat from a diesel engine can also be used for the steam process. This procedure was first implemented on the ships of the Triple E class .

In both cases, the steam process serves to use the exergy contained in the exhaust gas for the drive and thus to reduce fuel consumption. In contrast to the other drive concepts presented, it would not be economical here to operate a drive concept separately.

literature

- Kurt Illies: Ship propulsion engines. In: 75 Years of the Shipbuilding Society 1899–1974. Hamburg 1974, DNB 780625900 .

- Harald Keil, Claus Wilde: Passion for shipbuilding. Book accompanying the special exhibition "Expo am Meer" in Wilhelmshaven as part of the Expo 2000. Koehler, Hamburg 2000, ISBN 3-7822-0791-2 .

- K. Bösche, Karl-Heiz high-rise, H. Pollem, J. Taggesell (Ed.): Steamers, diesel and turbines. The world of marine engineers. Convent-Verlag, Hamburg 2005, ISBN 3-934613-85-3 .

- Karl-Heinz Hochhaus, H. Keil (Ed.): Catalog for the exhibition “100 Years of Shipbuilding” in the VWS of the TU Berlin May 25 - July 18, 1999. Self-published by STG.

- H. Meyer-Peter, F. Bernhardt: Compendium Marine Engineering. Seehafen-Verlag, Hamburg 2009, ISBN 978-3-87743-822-0 .

- Günter Ackermann, Karl-Heinz Hochhaus: Electrical systems on ferry and cruise ships. In: Hansa . Issue 3/2012, pp. 42–48.

Individual evidence

- ↑ miramarshipindex.org.nz ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice. Miramar (English)

- ↑ a b c Rolf Schönknecht, Uwe Laue: Ocean freighters of world shipping. Volume 1, transpress VEB Verlag for Transport, Berlin 1987, ISBN 3-344-00182-5 .

- ↑ miramarshipindex.org.nz ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice. Miramar (English)

- ↑ miramarshipindex.org.nz ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice. Miramar (English)