Liquid crystal display

A liquid crystal display or a liquid crystal screen ( English liquid crystal display , in short, LCD or LCD ) is a display or a screen (engl. Display ), the function based on the fact that liquid crystals , the polarization direction of light affect when a certain degree of electrical Voltage is applied.

LCDs consist of segments that can change their transparency independently of one another. For this purpose, the alignment of the liquid crystals is controlled with an electrical voltage in each segment. This changes the permeability for polarized light. Polarized light is generated by means of polarization filters , which either filter incident ambient light for reflective displays or light from a backlight for displays in transmission mode. If a display is to be able to show any content, the segments are arranged in a uniform grid (see pixels ). In devices that are only supposed to display certain characters, the segments often have a specially adapted shape, as is the case with the seven-segment display for displaying numbers (see also matrix display ). A further development is the active-matrix liquid-crystal display , which for driving a matrix of thin film transistors (engl. Thin-film transistor includes, TFT). In flat panel displays , this technique has dominated for about of 2005.

In advertising, LED televisions have been used a lot since around 2009 . These are often liquid crystal screens (LCDs) for image display, in which LEDs are used for background lighting ( LED backlight ). Screens with organic light-emitting diodes ( OLEDs ) as display elements instead of LCDs have been available for large-area televisions since the mid-2010s.

LCDs are used in many electronic devices such as consumer electronics, measuring devices, cell phones, digital watches and pocket calculators. Certain head-up displays and video projectors also work with this technology.

history

In 1888, while analyzing cholesteryl benzoate , the botanist Friedrich Reinitzer discovered a previously unknown phenomenon: When the substance changed from the solid to the liquid state, it was initially a cloudy, relatively viscous liquid, which only changed to a clear liquid when the temperature was further increased at the clearing point . Since Reinitzer could not find an explanation for this anomaly, he turned to the physicist Otto Lehmann , who later gave this type of substance the term flowing crystals . In 1904 Lehmann published his main work Liquid Crystals .

In 1911 Charles Mauguin described the structure and properties of liquid crystals . In 1917 Yngve Björnståhl studied the optical properties of liquid crystals under the action of an electric field. In 1936 the British Marconis Wireless Telegraph Co. Ltd. a patent for the first practical application of the technology as a liquid crystal light valve. In 1962 the first important English-language publication on the molecular structure and properties of liquid crystals (Original: Molecular Structure and Properties of Liquid Crystals ) by George William Gray appeared.

Liquid crystals were pioneered by the UK Radar Research Establishment in Malvern in the late 1960s . The team there supported the ongoing work of George William Gray, who with his team at the University of Hull in Kingston upon Hull ( England ) finally synthesized liquid-crystalline cyanobiphenyl compounds that met the requirements for stability and temperature behavior for LCDs.

The first working LCD based on the dynamic scattering mode (Engl. Dynamic scattering mode , DSM ) and was 1968 in the United States by a group at the Radio Corporation of America (RCA) under the direction of George H. Heil Meier introduced. The company Optel , a spin-off from RCA, developed some LCDs based on this principle.

On December 4, 1970, Martin Schadt and Wolfgang Helfrich , at that time working in the Central Research Laboratory of Hoffmann-LaRoche, reported the first patent for the "nematic rotary cell" (also TN cell , Schadt-Helfrich cell , twisted nematic field effect ) in Switzerland. The patent was granted in 21 countries, but not in Germany.

On April 22, 1971, James Fergason from Kent State University in the USA filed his patent application for the twisted nematic field effect in liquid crystals and in 1971 manufactured LCDs with this technology in his company ILIXCO , which has been called LXD Incorporated since 2005 . They quickly replaced the inferior DSM types.

Considerations, which are used in active matrix displays , arose during the conception of liquid crystal bar graph displays . In 1971 an LC matrix display for bar displays was developed by Brown, Boveri & Cie , Baden, Switzerland, with a diode (non-linear element) connected upstream of each LC segment and an additional capacitor connected in parallel as a storage element. On June 28, 1973, a patent application was made in the USA for an arrangement for the bar display, in which interdigital electrodes are attached to only one glass plate in order to generate an electric field parallel to the glass plate and to reorient the liquid crystals in a plane ( in-plane switching , IPS, see display types ).

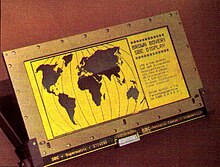

On July 7, 1983 with an amendment dated October 28, 1983, H. Amstutz and his co-inventors of the research center of Brown, Boveri & Cie, Baden, Switzerland, filed a patent application which formed the basis for Super-Twisted Nematic STN-LCD (see display types ). With STN-LCD it was possible for the first time to realize monochrome, passive matrix displays with sufficient resolution for simple image displays (see display of a world map under electronic control ). This patent has been granted in many countries. Asian manufacturers in particular became licensees (over 60 worldwide).

On January 9, 1990, G. Baur and his co-inventors reported to the Fraunhofer Society in Freiburg i. Br. A patent in Germany, which formed the concrete basis for optimized in-plane switching in matrix displays (IPS-LCDs). This patent was granted in many countries , taken over by Merck KGaA Darmstadt, the world's largest manufacturer of liquid crystal substances, and licensed to many companies.

On September 18, 1992 with an addendum of January 20, 1993, K. Kondo and his co-inventors filed a patent application with Hitachi in Japan, which presented a specifically suitable connection technology for thin-film transistors in matrix form as a further essential element of in-plane switching . Another Hitachi patent application followed later which improved the viewing angle dependence of this type of LC display.

In Germany in 2003, more LCD than CRT screens were sold for the first time in the field of computer monitors ;

Display types

Twisted Nematic (TN)

Liquid crystals used in liquid crystal displays are organic compounds that have the properties of both liquids and solids. On the one hand they are more or less fluid than a liquid, on the other hand they show properties such as birefringence .

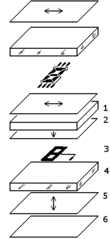

A simple liquid crystal display element can be realized with the Schadt-Helfrich cell ( nematic rotary cell, English twisted nematic , TN cell). In the illustration opposite , only the components of the lower half of such a rotary cell are numbered. The reference numbers (x) are inserted in this description. The insides of two very thin glass plates (substrates) (4) are coated with a transparent electrode layer ( indium tin oxide , ITO) (3), with the liquid crystal layer (1) between them, less than 10 micrometers thick. The liquid crystal molecules are arranged in a predetermined direction, namely parallel to the surface coated, for example, with a polyimide (2) and brushed in a preferred direction. The preferred directions of the two substrate plates are rotated by 90 ° to each other. When making hand-made prototypes, you can brush with polystyrene foam or use rollers coated with velvety textiles.

In addition, the two substrate plates (4 ) are coated with polarization filters (5) rotated by 90 ° to one another . On the back of this arrangement there can be a mirror (6) (reflector or transreflector ) that reflects the incident light (reflective operating mode). In the transmissive operating mode, a lighting unit is located behind the display element instead of the reflector.

A helical structure in the liquid crystal results from the mutually twisted substrate plates; a screw rotated by 90 ° is called TN. Incident light is thus linearly polarized before it enters the liquid crystal layer . The twisting of the molecules results in a rotation of the polarization direction of the light, whereby the light can pass the second polarizer and the cell is translucent (transparent). Since the display is transparent in the idle state, this operating mode is referred to as normally white mode . If an electrical voltage is applied to the electrodes, the liquid crystal molecules rotate under the influence of the electrical field and align themselves parallel to the electrical field. The twist is increasingly canceled, the direction of polarization of the light is no longer rotated and it can no longer pass through the second polarization filter.

If the polarization filters are arranged parallel to one another, the cell is dark without voltage and only becomes transparent with increasing voltage. One then speaks of the normally black mode . The Schadt-Helfrich cell is (like other liquid crystal displays) a voltage-controlled light valve . A screen can consist of any number of such cells (picture elements, pixels). In the pocket calculator, a simple 7-segment display shows one digit each; in a color screen, three sub-picture elements ( subpixels ) are used for the primary colors red, green and blue per picture element (pixel) .

Super-Twisted Nematic (STN)

With ( monochrome ) STN displays ( super-twisted nematic ), the twist angle of the molecules is increased to 180 ° to 270 °. As a result, a steeper electro-optical characteristic and thus improved multiplexability can be achieved than with TN displays. Due to various technical limitations, it is only possible with some effort (double cell = DSTN cell, compensation with birefringent retarder sheets ) to make the display color-neutral (i.e. only to generate gray levels between black and white). Instead, the light states are yellowish and the dark states are dark blue (with a purple hue). A further development is CSTN (color super-twist nematic) by the company Sharp , in which filters in the three basic colors red , green and blue are used in front of the pixels to display colors.

Double Super-Twisted Nematic (DSTN)

An attempt was made with different techniques, a black and white display on the passive matrix display to reach: with the guest-host technology , the OMI method of Martin Schadt ( "Optical Mode Interference" ) and the Double-Super -Twisted technique . The latter has established itself as the DSTN technology.

The construction principle of this DSTN cell can be seen in the picture. There are now two STN layers. In the active cell - that is, the one to which an electric field can be applied - the liquid crystal is rotated 240 ° counter-clockwise. The passive cell also contains nematic material, but here it is rotated by 240 ° clockwise. Both cells are rotated towards each other so that the orientation of the rods on the input side is perpendicular to that on the output side. The polarization foils are also rotated by 90 ° against each other.

In the conventional TN or STN cell, when linearly polarized light has passed through, one does not simply get linearly polarized light with a twisted oscillation plane, but elliptically (or circularly) polarized light. The tip of the electric field vector describes an ellipse or a circle. Such light passes through the polarizer, with the color splitting caused by the dichroism - depending on the polarization and the film orientation at the beam exit - leads to colored light.

The picture shows how DSTN-LCD works: White light falls on the rear polarizer (in the picture below) and is linearly polarized there. Then it gets into the active STN cell, which (without a field) now generates circularly polarized light from it. As with the conventional STN cell, this light is changed by dichroism . The path through the subsequent passive cell (which contains the same liquid crystal material as the first - active - cell, but twisted in the opposite direction) compensates for the color splitting (the phase difference becomes zero). The result is linearly polarized light that has the same plane of oscillation as before after passing through the rear polarization film. But because the front polarizer is rotated by 90 °, it does not let any light through: the screen is black at this point.

If an electric field is applied to the active cell, the linearly polarized light from the rear polarizer passes through smoothly without being changed. Circular polarization only occurs in the passive cell. Because circularly polarized light is not retained by polarizers, the screen is bright at this point. By carefully adjusting both the material used and the cell dimensions, the light that passes through becomes white. In this way, displays have been created that offer clean black and white with a contrast ratio of up to 15: 1.

Triple Super-Twisted Nematic (TSTN; referred to as TN or Film-TN)

The complex structure of a DSTN liquid crystal cell requires a relatively high level of effort in its manufacture. A new process has therefore been developed which leads to flatter displays with less weight. This new solution is called "Triple Super-Twisted Nematic" LCD ( TSTN ). The picture shows the construction principle of such a TSTN display.

There is only one STN-LC cell here. The color disturbances of the normal STN technology are balanced out by two special foils that are attached in front of and behind the cell - between the polarizer and the glass. These foils are responsible for another name of this technology: FST , for "Film-Super-Twisted" (occasionally displays in which only one compensation foil is used are referred to as FST-, those with two or more foils as TST-LCD. The term FSTN for film STN is also common. The improved contrast (up to 18: 1), the lower weight and the flatter and less complex design have helped TSTN LC displays to achieve a breakthrough. Such displays were first implemented in notebook computers as “VGA screens”.

Vertical alignment (PVA and MVA)

The patterned vertical alignment technology, also known as PVA for short , is a further development of the multi-domain vertical alignment technology ( MVA ) from a manufacturer. Both techniques are based on a similar procedure. The advantages of MVA / PVA screens are that they have a higher contrast (> 1000: 1 is common) than a TN screen (<800: 1). In addition, MVA / PVA screens offer a large viewing angle independence. The disadvantage of MVA / PVA screens is that they are slower than TN screens and are therefore less suitable for moving images such as games and videos. In addition, the price is higher than that of TN screens.

In-Plane Switching (IPS)

With in-plane switching technology ( IPS , English for in-plane switching ), the electrodes are located next to each other in a plane parallel to the display surface. When voltage is applied, the molecules rotate in the plane of the screen; the screw shape typical for TN displays is not applicable. IPS increases the viewing angle stability of the contrast.

Subtypes are divided between S-IPS ( Super IPS ), AS-IPS ( Advanced Super IPS ), A-TW-IPS ( Advanced True White IPS ), H-IPS (Horizontal IPS), and since 2009 E-IPS ( Enhanced IPS ) as well as AH-IPS ( Advanced High Performance IPS ) since 2011 . With the exception of the H-IPS type, the other IPS types can be recognized by the fact that, viewed from the side and in contrast to VA panels, they have a light purple hue. The E-IPS technology, which came onto the market in 2009, offers an even larger viewing angle and shorter switching times of 5 milliseconds.

The further development PLS ( Plane-to-Line Switching ) was developed by Samsung and offers, among other things, higher transparency (lower power consumption with the same brightness) and the elimination of the glitter effect typical of IPS panels. The first screens with PLS panels came on the market in 2011.

Electronic control

With the first prototype LCDs at the beginning of the 1970s, it was recognized that direct current operation can cause irreversible electrochemical processes in the liquid crystal layer and thus limit the service life of the display. Although, in contrast to LCDs based on the dynamic scattering mode (DSM), TN cells are about an electrical field effect, i.e. no current flow is necessary, the problems mentioned did exist when applying a direct voltage. Therefore, for a long time, all commercially used LCDs were operated with AC voltage. Essentially, an LCD element is a small electrical capacitance that is periodically recharged by a pulsed electrical voltage . The electronic complementary MOS circuits (CMOS ICs) that were already available at that time were ideally suited for this purpose, both in terms of adjustable voltage swing and symmetry of properties. One of the advantages of TN cells is the low operating voltage and thus the low power consumption. Liquid crystal substances for TN-LCDs were synthesized, which gave a good contrast in 3-volt operation and had a useful operating temperature range.

The operation of passive matrix displays depends on how pronounced an electro-optical threshold voltage is present. Because the control of the individual picture elements has to be repeated periodically in order to control not just one line but all pixels of a matrix, the lines of a matrix, for example, are controlled sequentially in the form of a pulse. In the case of the columns, the image information is entered in such a way that there is as great a voltage difference as possible to the line pulses for the activated picture elements and a voltage difference below the threshold value at the non-activated picture elements. The decisive factor for optimization was Peter J. Wild's finding that with pulsed, periodically repeated control, the root mean square (RMS) of the voltage differences is decisive. Detailed information on the best possible control techniques for passive matrix displays can be found in further literature.

An electro-optical characteristic curve with a pronounced threshold value and then a steep rise at higher voltage is a prerequisite for realizing passive matrix displays with many rows and columns. This is the only way to achieve a sufficient contrast even with matrices with many pixels. The tedious optimization of the voltage-contrast characteristic by the choice of liquid crystal substance and the cell structure of TN cells did not produce the desired results. It took more than ten years until the breakthrough came in 1983 with the discovery of super-twisted nematic LCDs ( STN-LCDs) at Brown, Boveri & Cie, Baden (now Asea Brown Boveri , ABB). The characteristic curve of STN cells is better suited for controlling passive matrix displays than that of TN cells.

Attempts were made early on to connect individual switching transistors to each pixel in order to circumvent the characteristic curve restrictions of a passive matrix display. This required thin film transistors (English thin-film transistor , TFT) of suitable dimension and connection technology are applied in a matrix arrangement on the glass substrate of the liquid crystal display. A display using this technique is called an active matrix display because the operation of the individual pixels is actively controlled by the associated transistors. The ideas for this were formulated in 1968–1973 at the Radio Corporation of America (RCA) and at Westinghouse Research Laboratories , USA. It still took some time until the technological prerequisites for mass production were worked out. In particular, experiments were carried out with various semiconductor materials until a type of amorphous silicon (see thin-film transistor ) suitable for field-effect transistors in thin-film technology prevailed. This material-technical breakthrough came in Europe. Japanese companies played a leading role in the realization of commercial products. Without the aforementioned advances in electronic control, large-area television liquid crystal screens would not have been possible. However, because of the numerous additional process steps for TFTs, active matrix displays are more expensive to manufacture and can therefore also have pixel errors, so that passive matrix displays are still used for simpler displays with less information content.

Contacting

From the beginning, the task was to connect the transparent conductor tracks on both LCD glass substrates with the control electronics. For this purpose, new connection techniques have been developed. For displays with a contact grid that is not too narrow, so-called zebras (see conductive rubber ) are used, which consist alternately of insulating and conductive elastomer "channels". In the adjoining picture with a comparative scale in centimeters, the dark grid of the zebra rubber of 180 micrometers is therefore only visible when you click on the image with an enlarged view: the pink isolating elastomer tape contains the black guide elements, separated by isolating elements. Due to the structure (the elements are much smaller than the surfaces to be contacted), positional tolerances of the rubber are irrelevant. The rubber can cushion dimensional tolerances. Typical applications are displays with seven-segment displays .

Solutions with chip-on-glass were tried out early on . Soldering points were applied to the contacts of the control circuits, then the chip was positioned on the corresponding contacts of the display and then soldered on at an elevated temperature. An important advance was the use of flexible, thin printed circuit boards with corresponding connecting tracks for display, which allow a narrow contact grid. These circuit boards often carry the ICs as bare chips ( flip-chip assembly ), which convert the digital serial data streams.

Passive matrix displays

In the case of passive matrix displays , the picture elements (a segment or a symbol) are controlled in time-division multiplex mode. This means that each picture element is directly and permanently connected to a control circuit whose output has a low resistance. Therefore, the charge applied at the time of addressing dissipates relatively quickly and has to be renewed again in the following frame . This change in the electrical control leads to pronounced modulations of the optical response of the display (so-called frame response ).

When addressing and driving via a matrix with active components in active matrix displays, a charge is applied to the picture element at the time of addressing, to which an additional capacitor is usually connected in parallel (storage capacitor). After the charge has been applied, the level of which corresponds to the data information, the active component (usually a thin-film transistor , TFT ) is switched back to the high-resistance state, which means that the charge and thus the control are essentially retained during one image period. In active matrix displays, this type of control causes a higher effective voltage across the picture element, thus a higher level of control of the liquid crystal and thus an improved contrast and a reduced dependence of the contrast on the viewing direction.

Advantages and disadvantages

The LC screens have several advantages over the older cathode ray tube (CRT) screens .

- Lower power consumption: regardless of the image content, LC screens are constantly illuminated over the entire display area. Despite this fundamental weakness is the light output (English luminous efficacy ) in LCD with typically 2 to 4 lm / W still about twice as high as for plasma screens with filter (normal delivery).

- Low radiation: LCDs do not emit X-rays (also applies to CRTs from TCO 99 ) and generate a lower magnetic field . Electromagnetic fields are, however, emitted and, just like with CRTs, contain the image information ( compromising radiation , problem security against eavesdropping , plus Van Eck phreaking ).

In addition, they have a flicker-free, distortion-free image that is sharp at ideal resolution, is lighter and has a low installation depth. In contrast to display devices with cathode ray tubes, liquid crystal screens are in practice not affected by magnetic fields such as the earth's magnetic field or the magnetic fields of overhead lines , NMR devices, transformers or loudspeakers.

During the development of the devices, at least up to the development of LCD controlled by TFTs, there were disadvantages due to the low contrast and the long switching times. In the meantime, the color rendering of LCDs (the representable color space, English color gamut ) can even meet extreme requirements by adjusting the background lighting ( extended gamut , multi-primary display ). Another problem was the limited range of viewing directions with constant contrast and constant color impression. Newer techniques such as in-plane switching (IPS), multi-domain vertical alignment (MVA) and patterned vertical alignment (PVA), as well as the use of birefringent compensation films ( retarder sheets ), helped. These disadvantages still exist, but are nowhere near as serious as they used to be. Since each pixel represents a small unit of its own, there are occasional production-related errors: Pixels that only glow in one color or that render the specified color incorrectly. Depending on the number of defective pixels, the displays are classified into different error classes, which can have an impact on the price.

The physical resolution of the image is determined during production ; control with a signal of a different resolution can lead to a loss of quality. A TFT-based LC screen provides a much sharper image compared to a CRT screen - but only in its design-related physical resolution. Lower resolution signals need to be interpolated and appear blurry. Alternatively, the image can also be displayed in full sharpness with black borders centered (with a digital connection, this can usually be set in the graphics card driver).

The background lighting by cold cathode tubes is filtered in order to preserve the basic colors of the pixels (mostly red, green and blue), but a compromise has to be found between brightness and color rendering quality. The colors of LCD are by no means less saturated than those of CRT or plasma display technology. Only about 4% of the generated light penetrates the panel (with white image content).

One reason why tube monitors (CRT) often performed better than flat screens in tests is by no means the better black level in the dark room and the contrast to the bright areas of the image when there is no ambient light on the screen, but the better reproduction of moving image content (see below ). In the meantime, however, LCD technology has advanced so far that sometimes better results (depending on the type of panel) can be achieved than with CRT monitors.

The backlight fluorescent tubes have a finite lifespan (around 100,000 hours). The quality of the display of white surfaces, which is influenced by the background lighting, changes significantly to yellowish after only a few thousand hours of operation, as the luminosity of the fluorescent tubes decreases over time. However, the brightness of CRT monitors also decreases in the course of operation. The background lighting by means of LEDs is more resistant to aging, but also shows slow signs of aging depending on the type of light-emitting diodes used and the mode of operation. In addition, lighting by means of LEDs enables a more compact design, more homogeneous illumination and increased contrast through selective control depending on the image content.

Switching times and techniques

The response time of modern LCDs is currently between 1 ms and 5 ms. The response time is the period of time that elapses when the luminance (brightness) of an image area changes from 10% to 90%; here 0% and 100% are the luminance of the steady (steady) states. The image build-up time according to ISO 13406-2 is the sum of the switching times from light to dark (or vice versa) and back again. Due to the asymptotic switching process, switching times of <3 ms are required according to ISO 13406-2 in order to avoid visible streaking.

Formulas

The switch-on time (increasing voltage) and the switch-off time (decreasing voltage) result from the formulas of Jakeman and Raynes:

- With

Here is the rotational viscosity of the liquid crystal, which describes the "inertia" of the liquid crystal to a change in orientation; the distance between the glass plates (= thickness of the liquid crystal layer); and the elastic constant , which indicates the “force” (torque) of returning the crystals to their original orientation.

For example, a large accelerates the return of the crystal to its initial state, but also counteracts the alignment of the crystal when a voltage is applied (due to the correspondingly increased threshold voltage ). Switching speeds can also be increased by reducing the layer thickness . If, for example, the layer thickness is reduced by 30% ( ), the switching times are reduced to around half (because ).

Motion blur

In hold-type displays such as LCD and OLED screens , the state of a pixel remains for the duration of a picture period until the applied voltage is changed in the course of the picture build-up of a new picture (preservation display ). Since the eye integrates the “brightness” over an image period when following moving image content ( smooth pursuit eye tracking ), while the image content remains fixed, the image on the viewer's retina is blurred. This is especially noticeable when fast moving scenes and is therefore as motion blur (also English. Motion blur ), respectively. It should be noted that even with vanishingly short switching times, i.e. with almost infinitely fast switching, the motion blur would not be eliminated because of the preservation display, which is why the blurring effect also occurs with fast OLED screens.

In addition to this principle-related blurring, the delayed acceptance of the target value creates undesirable effects ("streaks", "tail", "smear") with individual pixel elements, which are similarly disruptive. With LCDs, this type of motion blur has now been reduced considerably. The reaction time of "gray to gray" (English. Gray to gray ) is on average 6 ms, but the switching times in extreme situations (white-to-black, black-white after-, black to gray) materially differ .

Approaches to optimization

- viscosity

- One tries to counteract the motion blurring by further reducing the switching times of the displays, above all by reducing the viscosity of the liquid crystal materials used.

- Simple overdrive technologies

- With overdrive technology , a voltage is briefly applied to the LCD cell that is higher than that required for the actual brightness value. This makes the crystals align faster. The next picture must be temporarily saved for this. This information is used together with correction values specially adapted to the respective display in order to be able to calculate the exact time during which the overvoltage may be present without the respective pixel being overdriven. However, this does not work when the crystal is reset: since there is no less than no voltage (the control is carried out with alternating voltage), the crystal has to relax passively. Due to the buffering, the image is displayed about two to five bars late. This offset can become noticeable when viewing films due to image-sound asynchrony (the sound precedes the image). Image buffering also has a negative impact on computer games that require fast reactions from the player.

- Predistortion (inverse filtering)

- The integration of the eye from the next image is calculated from the data of the current and next image. The precise switching properties of the respective panel type are also required for this.

- Black Stripe Insertion

- In order to counteract the motion blur due to the preservation display, the pixels or the entire display can also be switched dark for a short time. However, the dark phase must not exceed 55% of the image time at 50 Hz control frequency (at 60 Hz it is 70% and at 75 Hz it is 85%): otherwise the image will flicker.

- Blinking backlight

- Also called "strobing": When using LEDs for backlighting LCDs (so-called LED televisions or screens), this method can be implemented more easily than Black Stripe Insertion, since the pixels do not have to be controlled faster, but for pixel areas or screens. the entire display and the backlight can be switched off for a fraction of a full screen duration.

- Scanning backlight

- Also called "field sequential": The LC display is not illuminated with white light, but successively with red, green and blue primary lights (often by LED ). Since no brightness-reducing color filters are required in LCDs with time-sequential control with the primary colors and there are high luminance levels, the loss of brightness can be more easily compensated for by the sequence sequence. However, with this technique one meets an old acquaintance of the projection technique: the rainbow effect .

- 100/120 Hz technology and 200/240 Hz technology

- Synthetic intermediate images are calculated here and then output together with the original images. This increases the real frame rate by an integral multiple. 24 fps (cinema standard) become 48, 72, 96 or even 120 fps. This can significantly reduce streaks from hold displays. In addition to the reduction of motion blurring, movements and tracking shots are reproduced much more smoothly. However, due to the motion interpolation, particularly with slightly noisy image sources, a more or less clear separation between the foreground and background in the image can be observed ( soap opera effect ). The 100/120 Hz technology is now (2008) used in many high-quality displays. 240 Hz devices are announced. Another advantage of this technique is that overdrive can be applied more finely. It should be noted, however, that the greatest improvement can be seen between the “100/120 Hz displays” and those with lower frame rates, since the human brain can only consciously process larger differences between the frequencies without practice.

Possible uses

In digital watches and calculators LCDs are used since the early 1970s. These monochrome displays without background lighting are characterized by the lowest possible energy consumption and a very long service life and can be used wherever a long, maintenance-free operation is required.

Later, LCDs were used as active matrix displays with backlighting via other portable or battery-powered devices such as cell phones , notebooks and the like.

Typical resolutions for computer flat screens range from 1024 × 768 pixels (38 cm / 15 ″) to 2560 × 1600 pixels (76 cm / 30 ″) to 3840 × 2160 pixels, for notebooks they range from 800 × 480 pixels to 3200 × 1800 pixels. PDAs and portable DVD players have resolutions between 320 × 240 and 800 × 480 pixels, displays of still and video cameras between 160 × 176 pixels (84 thousand pixels) and 640 × 480 pixels (900 thousand pixels). In the case of smartphones in particular , Apple has created a new marketing term for high image resolution with the “ Retina display ”.

In the meantime, LC and plasma displays have largely replaced the cathode ray tube. This applies to computer monitors (since 2006) and televisions with larger screen sizes (since 2008). Other areas of application such as oscilloscopes have also been used by computer-controlled LCD for a long time. In 2003, more LCDs were sold in Germany than conventional tube monitors for PCs and in 2006 more flat-screen televisions - i.e. LCD and plasma screens - than tube sets.

Attempts to implement screen projectors with LCD matrix displays began in the 1970s. The Imagina 90 was the world's first large-format video projector with a liquid crystal image generator to be produced in series, which was also suitable for continuous operation.

production

LCD technology has experienced an enormous upswing in recent years, particularly due to the development of flat screens. Large production facilities for flat screens were initially set up in Japan. However, industry soon began to emigrate to the new Asian industrial nations, which attracted cheap labor and abundant government subsidies. Currently, the main focus of the flat panel display industry is in Taiwan and especially South Korea . In South Korea, the world's largest flat screen manufacturers based there - Samsung , LG Display and Chi Mei Optoelectronics (CMO) - currently (2008) operate the largest LC screen production facilities. Even more cost-effective production sites have reached China . Production facilities for the manufacture of high-quality flat screens are currently (2008) under construction.

environmental Protection

From the point of view of climate protection , the production of liquid crystal screens is seen as problematic, since large quantities of substances that are harmful to the climate would be used in traditional production . In the important "array process", in which the TFT control matrix is applied over a large area to thin glass panes, potent greenhouse gases such as sulfur hexafluoride (SF 6 ) - GWP 22800 CO 2 e - and nitrogen trifluoride (NF 3 ) - GWP 17200 CO 2 e - are emitted on a large scale Scope used and released into the atmosphere, as a 2008 study shows.

See also

- Cholesteric liquid crystal display (ChLCD)

- Ferroelectric Liquid Crystal Display (FLCD)

- Fringed wing damage monitors

literature

- ME Becker: Moving images on LCD monitors . In: Electronic Displays . 2005 ( online version ( memento from February 20, 2012 in the Internet Archive ) [PDF; 443 kB ; accessed on January 13, 2009]).

- ME Becker: Motion Blur Measurement and Evaluation: From Theory to the Laboratory . In: SID'07 International Symposium Digest of Papers . tape 38 , no. 2 , 2007, p. 1122 ( online version ( memento of January 8, 2012 in the Internet Archive ) [PDF; 292 kB ; accessed on January 13, 2009]).

- Armin Gärtner: LCD monitors - Part 1: Basics and technology . In: mt medical technology . No. 2 , 2008, p. 54–66 ( online version ( memento from June 29, 2016 in the Internet Archive ) [PDF; 1.6 MB ; accessed on May 29, 2013]).

- Armin Gärtner: LCD monitors in medical technology . In: Medical technology and information technology . tape 5 . TÜV Media Verlag, 2009, ISBN 978-3-8249-1150-9 .

- Haiying Wang, Thomas X. Wu, Xinyu Zhu, Shin-Tson Wu: Correlations between liquid crystal director reorientation and optical response time of a homeotropic cell . In: Journal of Applied Physics . tape 95 , no. 10 , 2004, p. 5502–5508 , doi : 10.1063 / 1.1707210 ( full text [PDF; 144 kB ]).

- Peter J. Wild: Movable order . In: Franz Betschon et al. (Ed.): Engineers build Switzerland - first-hand history of technology , Verlag Neue Zürcher Zeitung, Zurich 2013, ISBN 978-3-03823-791-4 .

Web links

- Liquid crystals - the right mixture for every LCD technology. Merck , November 15, 2017.

- The flat screen

- Crystec Technology Trading GmbH, The manufacture of liquid crystal screens

- 4kmobile.de: Functional principle of an LCD / TFT display

swell

- ↑ a b Hiroshisa Kawamoto: The History of Liquid-Crystal Displays Archived from the original on February 9, 2012. (pdf; 924 kB) In: Proceedings of the IEEE . 90, No. 4, August 7, 2002, pp. 460-500. doi : 10.1109 / JPROC.2002.1002521 . Retrieved February 27, 2019.

- ↑ Otto Lehmann: Liquid crystals: as well as plasticity of crystals in general, molecular rearrangements and changes in the state of aggregation . Wilhelm Engelmann, Leipzig 1904 ( limited preview in the Google book search).

- ↑ a b David Dunmur, Tim Sluckin: Soap, Science, & Flat-Screen TVs . Oxford University Press, Oxford, New York 2011 ( limited preview in Google Book search).

- ^ Yngve Björnståhl: Studies on anisotropic liquids . (pdf; 30.7 MB) In: Annals of Physics . 361, No. 11, February 10, 1918, pp. 161-207. Retrieved February 28, 2019.

- ↑ patent GB441274 : Improvements in or relating to light valves. Registered July 13, 1934 , published January 13, 1936 , inventors: Barnett Levin, Nyman Levin.

- ^ Benjamin Gross: The TVs of Tomorrow - How RCA's Flat Screen Dreams Let To The First LCDs . The University of Chicago Press, Chicago and London 2018 ( limited preview in Google Book search).

- ↑ Patent CH532261 : light control cell . Registered on December 4, 1970 , published December 31, 1972 , inventors: Wolfgang Helfrich, Martin Schadt.

- ↑ Patent US3731986 : Display devices utilizing liquid crystal light modification. Registered on April 22, 1971 , published May 1973 , inventor: James L. Fergason.

- ↑ PJ Wild, PU Schulthess: Liquid Crystal Bar Graph Displays . In: Conference on Displays, IEE Conference Publication No. 80, September 1971, pp. 161-164.

- ↑ Patent US3834794 : Liquid Crystal Field Sensing Measurement and Display Device. Published on September 10, 1974 , inventor Soref R ..

- ↑ Patent EP0131216 : Liquid crystal display . Published October 28, 1987 , Inventors: H. Amstutz, D. Heimgartner, M. Kaufmann, TJ Scheffer.

- ↑ Patent DE4000451 : Electro-optical liquid crystal switching element . Published on July 11, 1991 , inventors: G. Baur, W. Fehrenbach, B. Staudacher, F. Windscheid, R. Kiefer.

- ↑ Patent US5598285 : Liquid crystal display device. Published January 28, 1997 , Inventors: K. Kondo, H. Terao, H. Abe, M. Ohta, K. Suzuki, T. Sasaki, G. Kawachi, J. Ohwada.

- ↑ a b Andreas Wilkens: For the first time, more LC displays sold than tube devices . On: heise.de , March 16, 2004

- ↑ Woodhead Publishing 2013, Organic Light-Emitting Diodes, page 447 (English, at Google Books), accessed June 8, 2013.

- ↑ Michael E. Becker: Kristallmanufaktur - Steps on the way to the direction-independent LC screen. c't-Magazin, No. 22, 2005, pp. 222-226

- ↑ A. Boller, H. Scherrer, M. Schadt, P. Wild: Low electrooptic threshold in new liquid crystals . In: Proceedings of the IEEE . tape 60 , no. 8 , July 1972, p. 1002-1003 , doi : 10.1109 / PROC.1972.8831 .

- ↑ First-Hand: Liquid Crystal Display Evolution - Swiss Contributions

- ↑ a b P. J. Wild: Matrix-addressed liquid crystal projection display. In: Digest of Technical Papers, International Symposium, Society for Information Display. 1972, pp. 62-63.

- ↑ PM Alt, P. Pleshko: Scanning limitations of liquid-crystal displays . In: IEEE Transactions on Electron Devices . tape 21 , no. 2 , 1974, p. 146-155 , doi : 10.1109 / T-ED.1974.17884 .

- ↑ J. Nehring, AR Kmetz: Ultimate limits for matrix addressing of RMS responding liquid-crystal displays . In: IEEE Transactions on Electron Devices . tape 26 , no. 5 , April 1979, pp. 795-802 , doi : 10.1109 / T-ED.1979.19495 .

- ^ TJ Scheffer, J. Nehring: A new, highly multiplexable liquid crystal display . In: Applied Physics Letters . tape 45 , no. 10 , 1984, pp. 1021-1023 , doi : 10.1063 / 1.95048 .

- ↑ Bernard J. Lechner, T. Peter Brody and Fang-Chen Luo, Forefathers of Flat-Panel Display Technology, to Receive 2011 IEEE Jun-ichi Nishizawa Medal. August 10, 2011, archived from the original on September 12, 2013 ; Retrieved October 29, 2013 .

- ↑ T. Peter Brody , J. A Asars, G. D Dixon: A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel . In: IEEE Transactions on Electron Devices . tape 20 , no. October 11 , 1973, p. 995-1001 , doi : 10.1109 / T-ED.1973.17780 .

- ^ PG le Comber, WE Spear, A. Ghaith: Amorphous-silicon field-effect device and possible application . In: Electronics Letters . tape 15 , no. 6 , February 15, 1979, p. 179-181 , doi : 10.1049 / el: 19790126 .

- ↑ S. Mito, T. Wada; Application of liquid crystal to calculator on substrate electronic calculator. In: Proc. 5th Int. Liquid Crystal Conf. 1974, pp. 247-248.

- ↑ Oleg Artamonov: New C-PVA Solutions: Samsung SyncMaster F2080 and F2380. Archived from the original on January 5, 2010 ; Retrieved February 20, 2011 .

- ↑ E. Jakeman, EP Raynes: Electro-optic response times in liquid crystals . In: Physics Letters A . tape 39 , 1972, p. 69-70 , doi : 10.1016 / 0375-9601 (72) 90332-5 .

- ↑ Andreas Donath: Flat screen TVs overtake tube TV sales . On: Golem.de , January 23, 2007

- ↑ Ulrike Kuhlmann: China wants more LCD fabs . On: heise.de , May 24, 2008

- ^ RF Weiss, J. Mühle, PK Salameh, CM Harth: Nitrogen trifluoride in the global atmosphere . In: Geophys. Res. Lett. tape 35 , no. 20 , 2008, ISSN 0094-8276 , p. L20821 , doi : 10.1029 / 2008GL035913 .