Biopolymer

A biopolymer ( ancient Greek βίος bíos ' life ' with ancient Greek πολύ polý 'much' and μέρος méros 'part') is a polymer that is synthesized in the cell of a living being. In the form of B. of polysaccharides , proteins , nucleic acids, etc., biopolymers serve as energy stores ( glycogen , starch ), have structural functions for the cell ( lipid membranes ) or the entire organism ( cellulose in fibers ), have an effect on the metabolism (absorption, transport, enzyme , Excretion ), recognize conditions ( sensory system ), cause changes ( muscles , color change ), actively ward off damaging influences ( toxins , immunology ), store or convey information ( genetic , hormonal , CNS ).

The term biopolymer is often used to differentiate between materials . Here is also of technical biopolymers or Biopolymerwerkstoffen spoken to by not usable as a material biopolymers delineate. A uniform definition for technical biopolymers has not yet been established. So are including z. B. summarized materials that consist of biogenic raw materials ( renewable raw materials ) and / or are biodegradable ( bio genes and bio logically degradable polymers). This includes bio-based biopolymers that are biodegradable or non-biodegradable as well as petroleum-based polymers that are biodegradable. This is used to distinguish it from conventional, petroleum-based materials or plastics that are not biodegradable, e.g. B. polyethylene (PE), polypropylene (PP) and polyvinyl chloride (PVC).

In other definitions petroleum products will not to biopolymers ( bio counted-related polymers). On the other hand, both native polymers (e.g. cellulose and cellulose derivatives) and bio-based plastics that have been produced by extensive chemical modification of the biogenic raw materials (e.g. polylactides (PLA) from lactic acid produced with the help of white biotechnology ) can be included .

A related term is "bioplastic", which is also not used uniformly and which partially or heavily overlaps with the term biopolymer. Here, too, the prefix bio- , depending on the respective definition, is understood as bio- gen or bio- degradable and can designate both bio-based plastics and biodegradable plastics .

Natural biopolymers

The following table lists important naturally occurring (biogenic) biopolymers with the respective monomer , the type of chemical bond and examples of their occurrence:

| polymer | Monomer (s) | Bond type | Occurrence |

|---|---|---|---|

| Proteins and peptides | amino acids | Amide or peptide bond | in all living things as enzymes , structural substances, substance transport systems , chemoreceptors, etc. |

| Nucleic acids | Nucleotides | Phosphodiester linkage | DNA in all living things and many viruses as the information carrier of the genetic material, RNA z. B. as a mobile information carrier ( mRNA ) |

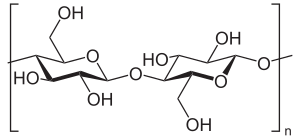

| α- polysaccharides | Mono- or disaccharides | α-glycosidic bond | as an energy store ( starch in plants, glycogen in animals) |

| β- polysaccharides | Mono- or disaccharides | β-glycosidic bond | as a structural substance ( cellulose in plant walls , chitin in mushrooms , arthropods and cephalopods , chitosan in mushrooms) |

| Lipids | Carboxylic acids and alcohols | Ester bond | in all living things as energy stores and building blocks of cell membranes, in some hormones and pigments |

| Polyhydroxyalkanoates (PHA) | Hydroxyalkanoate | Ester bond | as a bacterial reserve , such as B. Polyhydroxybutyrate (PHB) |

| Cutin | C 16 and C 18 hydroxy fatty acids | Ester bond | for sealing plant cells against water |

| Suberine | Glycerin and polyphenols | Ether and CC bonds | for sealing plant cells for water transport |

| lignin | Phenylpropane derivatives ( coumaryl , coniferyl or sinapyl alcohol ) | Ether and CC bonds | as a structural substance in woody plants |

Technical biopolymers

Technical biopolymers (biomaterials) can, according to the definition by Endres and Siebert-Rath , be divided into the three categories explained in the following paragraphs. This definition coincides with the definition of bioplastics used by European Bioplastics, which, however, is not generally applicable.

If, on the other hand, biopolymers are defined as biodegradable polymers , not all of the examples listed below under native polymers and bio-based polymers are to be included.

Plastics are usually not homogeneous products, but require various auxiliary materials and additives, which are often petroleum-based. Replacement with bio-based components is only partially possible.

Native polymers

- (see also article cellulose , starch polymer and starch as a renewable raw material )

Polymers occurring in nature or in biomass , such as. B. cellulose and starch, can be used with little or no changes or with preservation of the basic structure for the production of biopolymers:

- Cellulose and certain cellulose derivatives

- Reclaimed fibers such as viscose and cellophane

- celluloid

- Strength

Bio-based polymers

Organic compounds such as B. starch or sucrose, can be extensively modified to produce bio-based polymers:

- Polylactide (PLA): polymer of lactic acid, the monomer can e.g. B. fermentative with bacteria (white biotechnology) from organic compounds such. B. glucose

- Polyhydroxybutyrate (PHB): polymer that occurs naturally as a storage substance in bacteria, can be produced from other organic compounds by fermenting bacteria

- Thermoplastics on lignin

- Epoxy acrylates based on oils (currently mainly flax and palm oil )

Degradable, petroleum-based polymers

Certain petroleum-based plastics are biodegradable and are therefore sometimes referred to as biopolymers (or bioplastics):

- certain polyesters

- Polyvinyl alcohol

- Polybutylene adipate terephthalate (PBAT)

- Polybutylene succinate (PBS)

- Polycaprolactone (PCL)

- Polyglycolide (PGA)

Some petroleum-based polymers can be manufactured technically and increasingly commercially on the basis of renewable raw materials, especially polybutylene succinate (PBS) and polybutylene adipate terephthalate (PBAT). In these cases succinic acid and / or 1,4-butanediol are produced biotechnologically.

Biodegradation

The biodegradability is particularly relevant for the later disposal of the material. From an ecological and sustainability perspective , biodegradable plastics are of increasing interest and of increasing economic importance.

It should be borne in mind that polymers made from natural or bio-based raw materials are often biodegradable, but products can also be produced that are resistant. Likewise, polymers from fossil raw materials are often of high resistance, but degradable products can also be produced (see section Degradable, petroleum-based polymers ).

Depending on the application, unmodified raw biopolymers are mixed (blended) with other raw biopolymers in order to achieve the desired properties. Manufacturers of such blends are z. B. Novamont , Biotec, FKuR and Limagrain.

See also

Web links

- Biopolymer Database , database with properties of biopolymers for technical applications, created by FH Hannover and M-Base Engineering + Software GmbH

- Fraunhofer Institute for Applied Polymer Research , research and development in the field of biopolymers, among others

- Federal Environment Agency, investigation of the environmental effects of packaging made from biodegradable plastics (PDF; 3.1 MB) 2012

literature

- P. Eyerer, P. Elsner, T. Hirth (Eds.): The plastics and their properties. 6th edition. Springer Verlag, Heidelberg 2005, ISBN 978-3-540-21410-6 , pp. 1443-1482.

- Hans-Josef Endres, Andrea Siebert-Raths: Technical biopolymers. Hanser-Verlag, Munich 2009, ISBN 978-3-446-41683-3 .

Individual evidence

- ↑ a b H.-J. Endres, A. Siebert-Rath: Technical biopolymers . Hanser-Verlag, Munich 2009, ISBN 978-3-446-41683-3 .

- ↑ Biopolymers. Retrieved January 18, 2017 .

- ↑ a b c bioplastics . european-bioplastics.org, European Bioplastics Association , accessed on March 27, 2010.