Molten salt reactor

Molten salt reactors ( English molten salt reactor , MSR ) or molten salt reactors are reactors in which the nuclear fuel in the form of molten salt, is present (for example, uranium chloride ). With this type of reactor, the nuclear fuel is evenly distributed in liquid form in the primary circuit of the reactor, a core meltdown in the classic sense is therefore excluded - the core is always in the intentionally molten state. Liquid salt reactors can be designed with a moderator and thermal neutrons or without a moderator with fast neutrons; in both cases, operation as a breeder reactor is also possible. Molten salt reactors allow a design with a strongly negative temperature coefficient , which in principle makes a performance excursion, such as the one in the case of the Chernobyl nuclear disaster, impossible.

Liquid salt reactors work at atmospheric pressure and not, like pressurized water reactors or boiling water reactors , at pressures of 50-150 bar , which is why a steam explosion in the area of the reactor core is not possible.

Removing neutron-absorbing fission products from the reactor during operation leads to a better neutron yield. This means that a molten salt reactor can theoretically also be operated as a breeder reactor and once started with a small amount of fissile material such as 235 uranium or 239 plutonium , it can only be fed with non-fissile nuclides ( e.g. 232 thorium ) as breeding material. In English, this concept is also called liquid fluoride thorium reactor (LFTR) , pronounced lifter .

Since molten salt reactors work with permanent reprocessing, it is in principle possible to extract weapons-grade fissile materials from the process. This aspect is controversially discussed.

Despite some of the advantages of molten salt reactors, only two smaller research reactors have been built to date. For commercial energy generation on a large scale, they are being examined - along with five other concepts - as part of the Generation IV International Forum for future nuclear power plants .

Some of the proponents consider the LFTR to be an important and meaningful contribution to global energy supply. For example, China sees the concept of the molten salt reactor as an important component for medium and long-term energy supply.

history

Aircraft Reactor Experiment

The development of molten salt reactors began with the military Aircraft Reactor Experiment. Since molten salt reactors work under slight overpressure, they were considered particularly suitable for aircraft. As part of the NEPA ( Nuclear Energy for the Propulsion of Aircraft ) program launched by the US Air Force in 1946 , a reactor was built and a test run was completed in 1954. The reactor was in critical condition for 221 hours , of which 74 hours were in the megawatt range. Filled with mixtures of the fluorides of sodium , zirconium and uranium (53: 41: 6 mol %), it reached maximum temperatures of 860 ° C and a thermal output of approximately 2.5 MW. Beryllium oxide served as moderator and neutron reflector , with an additional cooling circuit with liquid sodium for the reflector. With the availability of ICBMs , the idea of a long-range nuclear powered bomber was ultimately discarded.

Molten Salt Reactor Experiment MSRE

Comparable to the development and construction of the first pressurized water reactors for civilian energy generation based on the successes with nuclear-powered submarines , research was carried out in the 1960s with the Molten Salt Reactor Experiment into making it usable for electricity generation. The construction of a reactor was completed in 1964, the test operation ran from 1965 to 1969. During this period, the experiment was critical for a total of about two years.

The reactor with a maximum thermal output of 8 MW confirmed in principle the feasibility of the concept. There was no generator to produce electricity; the heat was released into the environment via fans. In addition, no attempt was made (as planned in the LFTR) to incubate fissile material and to remove fission products other than noble gases . But it was shown that the reactor core can be operated at temperatures of up to 650 ° C for a longer period of time. In addition, the corrosion of the components made of the Hastelloy-N alloy through which the molten salt flows was found to be low. In a final report by the Atomic Energy Commission of America , corrosion from the molten salts was classified as negligible.

The experiment confirmed a number of other expectations: the stability of the liquid in relation to radiation, the presence of many fission products in the form of non-volatile ionic compounds and the easy separation of interfering noble gases (especially 135 xenon , see continuous processing ). Disadvantageous proved, among other things, despite the use of isotopically pure 7 Lithium high tritium production and the strong contamination of all circulatory walls with deposited fission products.

Both 235 uranium and 233 uranium ( hatched from thorium in other reactors) were used as fuels . Graphite served as the moderator . The reactivity coefficient of the reactor was strongly negative both when operating with uranium and thorium and essentially corresponded to the values calculated in advance.

As discovered in 1994 during the dismantling, it was an escape of large quantities 233 come uranium from the salt into the exhaust system of the reactor. There was no significant leakage of radioactive isotopes because they were bound in the salt. Because of the risk of criticality in the exhaust system, the area around the MSRE had to be evacuated. The estimated time for the decontamination of the exhaust system was exceeded by 16 times because a suitable tool first had to be developed. Since about 5% of the MSRE fissile material had got into the activated carbon filter of the exhaust system, extensive studies on the criticality safety of the exhaust system were carried out during the renovation work. It is believed that radiolysis of fluoride led to fluorine , which with UF 4 ( uranium (IV) fluoride ) formed the volatile UF 6 ( uranium hexafluoride ), which was then released into the exhaust system in an unplanned manner. Such fissile material volatilization had previously been ruled out as chemically impossible in the MSRE. This release process is said to have only taken place when the salt had solidified in the storage tanks after the reactor was shut down. Overall, the renovation was successfully completed without the employees being exposed to radiation exposure that exceeded limits

The results of the MSRE played a major role in the evaluation of the planned successor project MSBR described below .

The Molten Salt Breeder at Oak Ridge National Laboratory

When the limited uranium supplies in the world became clear at the end of the 1960s, various reactor concepts were developed that were supposed to “breed” additional nuclear fuel . In the USA there were mainly two competing concepts, that of the sodium-cooled "fast breeder" (such as the EWC II at the Oak Ridge National Laboratory , the Kalkar nuclear power plant or the BN reactors in Russia) and a molten salt reactor as a thermal one Breeder . In the Oak Ridge National Laboratory , a breeder concept for a Molten Salt Breeder (MSBR) with 1 gigawatt was developed. Was used LiF - BeF 2 -THF 4 -UF 4 as a fuel in a single fluid concept. NaF -sodium beryllium fluoride 4 was provided as a secondary coolant . According to the calculations, this approach could have spawned additional nuclear fuel. However, more recent, refined calculations show that the MSBR would have had a positive temperature coefficient of reactivity and would therefore hardly have been acceptable for safety reasons. In fact, molten salt reactors, when operated as thermal breeder units, require particular care when designing to avoid a positive temperature coefficient .

The US government under Richard Nixon invested a considerably larger development effort in the more advanced "fast breeder" than in the MSBR. When the head of the MSBR project, Alvin M. Weinberg , warned of the (later really occurring) exploding costs and above all of the dangers of the "fast breeder" concept and, in parts, of the light water reactor , he said he was resigning in 1973 suggested and after an evaluation the financing of “his” MSBR project stopped. This MSBR evaluation came to the rather sobering result: ... This evaluation has again confirmed the existence of major technological and structural problems which impair the usability as a reliable and economical breeder for the electricity supplier ... The major problems with the MSBR are by their nature rather more difficult and in many ways specific to this concept ... If reliable indications of workable solutions emerge, a reassessment could be made ... Material issues (more pronounced corrosion than in the MSRE due to a different neutron spectrum), the increased release of tritium and greater uncertainties with regard to components that have not yet been adequately tested are highlighted as problems. Other work on the MSR was also significantly reduced after this evaluation.

Working in Germany

Before 1975, there was also limited work on MSR in Germany. At the KFA Jülich (now Forschungszentrum Jülich ) there was a study on the MSR to clarify whether the MSR is suitable for a large-scale German research project. The then scientific-technical KFA managing director at times advocated the MSR. However, the director of Jülich reactor development Rudolf Schulten successfully prevented the development of a competing technology and propagated an alternative type of reactor, the pebble bed reactor , on which he was researching himself; he rejected the MSR as an “unparalleled horror” and later described it as one of his great achievements to have prevented the MSR development in Jülich.

Dual Fluid Reactor (DFR)

The dual-fluid reactor is a reactor concept developed by the non-profit Institute for Solid State Nuclear Physics (IFK) in Berlin with the aim of combining the advantages of the molten salt reactor and the metal-cooled reactors. This is intended to achieve the sustainability, safety and profitability goals of Generation IV . According to this concept, the reactor has a core in which a fuel made from liquid chlorine salts of uranium and plutonium circulates, and lead cooling. It has a hard neutron spectrum and uses combined online high temperature reprocessing. The IFK advertises it with outstanding safety properties, extremely low costs and the ability to remove highly radioactive waste such as B. to destroy plutonium or spent fuel in short periods of time. So far (as of December 2019) this type of reactor has only been available on paper.

Newer research and development

MSR development in China

Since January 2011, several molten salt reactor concepts have been researched and developed in China. So far it has been assumed that it will take around 20 years for salable prototypes to be built and exported. Kun Chen from the Chinese Academy of Sciences assumed a functional research FSR in 2015. The date for the completion of this Chinese 2 MW MSR has meanwhile been postponed to 2020 at the earliest.

Molten Salt Fast Reactor MSFR

The safety problems of larger MSRs when used as thermal thorium incubators (see temperature coefficient and MSBR ) have led to the first development work for "fast breeders" based on MSR, ie MSFR, since 2005. These MSFR have no graphite moderator, so they work with fast neutrons. The focus of work at MSR within the Generation IV development program has now largely been switched to MSFR, since doubts have grown in the MSR developer community that the elementary safety problems of the larger thermal MSR breeders originally pursued, which can be traced back to Weinberg, can be satisfactorily solved. The MSR work within the framework of the European Sustainable Nuclear Energy Technology Platform is now also concentrating on MSFR. However, there is no operational experience whatsoever for MSFR, and theoretical investigations are only just beginning. According to the developer, the MSFR should - unlike the thermal MSR breeder - always have a large negative void coefficient and a large negative temperature coefficient of reactivity and thus meet the relevant safety standards.

Pebble Bed Advanced High Temperature Reactor

The Pebble Bed Advanced High Temperature Reactor (PB-AHTR) belongs to the reactor concepts with molten salt cooling (but not to the MSR in the narrower sense ) . This is essentially a pebble bed reactor , but with liquid salt instead of helium cooling and with the fuel elements being guided through the core. The proponents of the PB-AHTR consider it easier to implement than the LFTR, as it is more closely based on classic reactor concepts and avoids some of the disadvantages of the pebble bed reactor thanks to the liquid salt cooling.

Fluoride-cooled high-temperature reactor FHR

For the reasons mentioned in the previous subsection, the FH Council has been pursuing another MSR project in Generation IV since 2008, which is similar to the PB-AHTR mentioned above. It is a new reactor concept that combines spherical graphite fuel elements, liquid salt as a coolant, safety systems of sodium-cooled high-speed reactors and the Brayton cycle . The FHR is intended to generate electricity as well as provide process heat for industry.

functionality

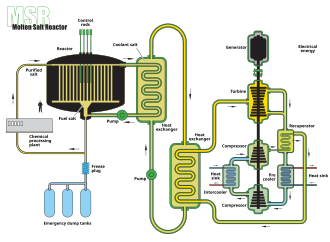

The entire contents of the reactor, consisting of fuel, cooling liquid and fission products - with the exception of any graphite moderator that may be present - constantly circulate between the reactor vessel and the first heat exchanger. The molten salt is only critical in the reactor core, since only here the graphite moderator is present and the ratio of volume and surface is large enough. On the way through the first heat exchanger (which is located inside the reactor containment because of the radioactivity of the melt), the melt is subcritical. The heat is conducted to the steam generator outside the containment via another cooling circuit (also with a liquid salt).

In addition to producing heat, a molten salt reactor can also produce fissile material as a breeder reactor . With thorium as breeding material can sufficiently with thermal neutrons in theory 233 uranium be generated for the operation of the reactor.

There are three different construction principles as a breeder reactor: Single Fluid (only one liquid salt circuit), Two Fluid (two circuits with liquid salt) and Dual Fluid (two circuits with different liquids).

Single fluid MSR

There is only one salt cycle here, which contains both breeding material and fuel. The two above-mentioned test reactors ARE and MSRE were small single fluid MSRs with no significant amounts of breeding material.

Molten salt reactors need a significantly better neutron efficiency in order to function as breeder reactors, and as a single fluid design would therefore have to be significantly larger (e.g. at least 1000 MW for the MSBR concept).

Two Fluid MSR

In the Two Fluid MSR, two different liquid salt mixtures circulate in separate tanks:

- In an inner container (the “active core”) a mixture rich in nuclear fuel (e.g. 233 uranium). Nuclear fission takes place in this salt.

- This is enclosed by a further container with a mixture rich in brood material (e.g. 232 thorium), called "coating salt". New fuel is created in this salt by capturing neutrons.

The heat transport to the steam generator then takes place similar to the Single Fluid MSR via separate heat exchangers for the two salt circuits.

Part of the two salt mixtures is continuously processed in a system connected to the reactor: cleavage products are removed from the active core. Breeding nuclear fuel (e.g. 233 U) is extracted from the coating salt and fed to the active core.

The Two Fluid MSR offers great advantages in continuous reprocessing. The vast majority of fission products occur in the active core, only to a small extent in the coating salt. This eliminates the time- consuming separation of the fuel and breeding material from the fission products , which is necessary with the Single Fluid MSR . The intermediate stage 233 Pa also arises in the coating salt, where it can absorb fewer neutrons than in the core or a single-fluid concept. The coating salt also reduces the number of neutrons that are lost to the outside world. This means that relatively small breeder reactors are also possible.

The draft of a Two Fluid MSR presented by the Oak Ridge National Laboratory envisaged a network of four relatively small reactor units, each approx. 3 m in diameter and approx. 6 m in length, which should provide approx. 250 MW per unit. The small units should be replaced as a whole after the graphite has had a service life of around eight years, since it did not seem possible to replace the graphite.

However, there are still considerable technical problems due to the different thermal expansion of the container material and the graphite, as well as their effect on welds and connection points.

Dual fluid reactor

In the dual fluid reactor (DFR), a salt mixture circulates in one container and a molten lead for cooling in another circuit.

- In an inner container (the “active core”) a mixture rich in nuclear fuel (e.g. 235 uranium or 239 plutonium). Nuclear fission and the incubation process take place in this salt.

- This is enclosed by another container with lead for cooling and for reflecting the neutrons.

A part of the salt mixture is continuously processed in a plant connected to the reactor: Fission products are removed from the active core, and the nuclear fuel that has been produced remains in the plant.

The DFR is said to offer great advantages in continuous remanufacturing. Since the heat does not have to be dissipated through the salt medium, the speed of rotation can be reduced to such an extent that continuous online processing is possible.

It is planned to use fast neutrons. This means that graphite does not need to be used for moderation. This should make construction and safety easier.

Continuous processing

Highly volatile fission products such as noble gases leave the reactor liquid by themselves or with the help of simple technical aids, such as. B. the generation of gas bubbles in the melt. Particularly noteworthy is the constant removal of 135 xenon from the reactor. The radioactive 135 xenon is formed during reactor operation from one of the most common fission products (see xenon poisoning ) and in turn absorbs extremely strong thermal neutrons. Since it continues to arise for some time after switching off, it temporarily (hours) prevents the power from being started up again. This problem, which occurs with conventional nuclear power plants after each shutdown from full load, was z. B. indirectly involved in the Chernobyl accident . Continuous removal prevents this xenon poisoning in the FSR. The separated 135 xenon then decays with a half-life of 9 h into radioactive long-lived 135 cesium , which has to be disposed of.

It is also intended to continuously divert a small part (e.g. 1-10% per day) of the reactor inventory and process it in a reprocessing plant connected to the reactor. The non-volatile decomposition products present in the molten salt, most of which are present as fluorides, can be separated off. Existing fuel and breeding material as well as any transuranic elements are returned to the reactor with the molten salt. In the case of the MSFR in particular , considerations are being made on the use for the transmutation of long-lived nuclides to reduce the repository problem. Since transmutation has to be coupled with processing, a reactor with integrated continuous processing is advantageous. With the comparatively lower neutron yields from thermal MSR breeders, efficient transmutation encounters difficulties.

Continuous reprocessing has several advantages:

- The total mass of fission products in the reactor is kept low. In the event of an accident, there would be correspondingly less radioactive fission products and consequently less decay heat in the reactor. However, the separated radioactive materials have to be stored elsewhere and may represent an additional safety risk there in the event of an accident (comparable to the fuel element storage pool in Fukushima ).

- The reactor contains less neutron poison , i. that is, the neutron yield is higher. This makes it easier to operate as a breeder reactor and as a transmutation system for transuranic elements.

- The separated, still “fresh” cleavage products could u. U. usable radionuclides can be obtained that would have decayed after long storage.

A disadvantage is the easy separability of weapons-grade fissile materials or their precursors (e.g. 233 Protactinium ), as discussed in the section on proliferation risks . The security risks of continuous remanufacturing have also not yet been adequately investigated.

costs

Due to the ongoing development and lack of experience, it is difficult to estimate the costs. In 1980, the ORNL calculated that a molten salt reactor would cost roughly the same as a conventional reactor.

On the one hand, the costs decrease compared to the LWR due to the lower pressure and savings in the less complex containment . On the other hand, there are also additional costs, among other things due to the more expensive materials for the higher temperatures, the system for gas treatment and the collection of tritium . A cost estimate is also made more difficult by the fact that the licensing regulations do not yet provide for the specific features of the molten salt reactor.

In the case of the thorium cycle, the costs for the pure fuel (thorium) are very low, and the costs for producing the fuel rods are also eliminated in the case of the molten salt reactor. But there are also the costs for the separation of the fission products.

If the dual fluid reactor works as it should, it could be operated directly with spent fuel elements from light water reactors. The fuel could even be used as a source of income, because the German government budgeted billions for the disposal of these elements.

advantages

Passive safety

As with other reactors, a negative temperature coefficient for reactivity is aimed for. An increase in temperature then reduces the output and stabilizes the reactor. According to today's understanding of safety, reactors with an effectively positive temperature coefficient, such as B. the Chernobyl reactor , no longer approvable. With a suitable design, a performance excursion can be limited with a strongly negative temperature coefficient of reactivity and the large permissible temperature increase in the MSR . A strongly negative temperature coefficient and a high breeding factor are, however, largely mutually exclusive when designed as a thermal breeder.

Three factors contribute to the temperature coefficient of reactivity in the MSR:

- A higher temperature increases the effectiveness of neutron absorbers such as thorium. This is a desired negative contribution to the temperature coefficient.

- The heating of the graphite moderator in the case of a reactor with thermal neutrons, on the other hand, usually leads to a positive contribution to the temperature coefficient, which in the MSBR concept would even have led to an overall positive temperature coefficient of reactivity.

- Due to the thermal expansion of the salt, the amount of salt in the reactor core decreases or the relative proportion of moderator increases with increasing temperature. Bubbles in the molten salt lead to a similar effect, which then determines the vapor bubble coefficient . A negative vapor bubble coefficient and thus also a negative contribution from thermal expansion is desirable. This is the case for small I&C, but for large reactors this requirement means a restriction on the permissible proportion of moderator. In the meantime, there is even doubt that a thermal MSR breeder can be built with sufficient safety in this regard, which has led to development work for fast MSR breeders . A thermal MSR that breeds less fissile material than consumes (i.e. is not a breeder) can, however, be implemented with a negative temperature coefficient of reactivity and thus with sufficient safety. The same applies to MSR with fast neutrons.

A fuse protects against the effects of a failure of the external power supply. There is an opening in the bottom of the reactor vessel. During operation, the reactor liquid is actively cooled and seals in the solid state of aggregation this opening. If the heat of reaction cannot be dissipated, for example if the circulation pumps fail, this salt melts and the reactor liquid flows off into storage tanks below the reactor. Due to their shape and the lack of moderator material, there is no longer any chain reaction in these tanks. The shape of the tanks is also optimized for the removal of (decay) heat and enables the reactor liquid to be cooled without an external energy source. The combination of fuse and storage tank leads to the reactor being shut down to a safe state without the intervention of personnel or active safety systems and independent of external energy supply or supply of coolant ( intrinsic safety ).

Even if pipes in the primary circuit break or the reactor vessel itself is damaged, the molten salt flows through drains on the floor of the reactor building into the storage tanks.

Temperature and pressure

A eutectic is used as the cooling liquid . Its melting point, which is lower than that of a pure salt, allows more heat to be extracted from the cooling liquid in the heat exchanger without risking the melt solidifying. The lower melting point is also beneficial for the smooth drainage into the storage tanks and for starting the reactor. With the latter, the salt has to be melted by an external energy source before reaching criticality.

One possible reactor liquid is FLiBe, a eutectic made from 50% lithium fluoride and 50% beryllium fluoride . The melting temperature is 459 ° C, the boiling temperature 1430 ° C. Even at a temperature of 1000 ° C, the vapor pressure is still small. The pressure in the salt circuit is determined by the circulation pump and is in the order of 0.5 MPa, significantly lower than in a water-cooled reactor. The reactor vessel and the pipes of the cooling circuit can therefore be thinner. The containment does not have to be designed to hold up large amounts of steam, which would be produced in the event of a pressure loss after a leak in a water-cooled reactor. In the event of a malfunction, a chemical explosion is excluded according to the current state of knowledge, and there are also no large amounts of gas that have to be prevented from escaping into the environment.

The higher the temperature of the cooling medium, the more efficiently a heat engine can convert the heat into work. With water / steam cycles, efficiencies of up to 42% can be achieved at the maximum permissible temperature of 550 ° C, with gas turbines above 900 ° C even higher values. That compares to the 33% that is achieved in today's water-cooled reactors. The attainable temperature of a molten salt reactor is limited first of all by the materials from which it is built. The reactor vessel must be corrosion-resistant and withstand the flow of neutrons. The two test reactors (ARE and MSRE) were operated at 650-850 ° C. This indicates a potential for efficiency increases.

In the dual fluid reactor , sodium or lead is used as the cooling liquid, which makes even higher temperatures above 1000 ° C possible and necessary. On the other hand, there would be almost no overpressure in the liquid circuits, which is advantageous in terms of safety.

Thorium as fuel

Since the neutron yield of the thorium cycle is relatively large in the thermal spectrum, new fissile material can be produced during operation. Thus, after an initial charge of about 235 uranium or 239 plutonium, the criticality of the reactor can be maintained by simply adding the non-fissile nuclide 232 thorium. 232 Th is converted to 233 Th by neutron capture ; this is converted into 233 protactinium by beta decay with a half-life of 22.3 minutes , which in turn is converted into fissile 233 U by beta decay with a half-life of 27 days .

This breeding process was already used in the THTR-300 thorium high-temperature reactor in Germany at the end of the 1980s . A mixture of 10% highly enriched 235 uranium and 90% thorium served as fuel . Thorium stretches the primary fissile material in such mixed fuels, but cannot replace it.

The mentioned problems of thermal thorium breeders with positive temperature coefficients have led to the switch to fast thorium breeders. In the fast neutron spectrum, the thorium cycle is clearly inferior to the uranium / plutonium cycle in terms of neutronic efficiency.

When using thorium, there are hardly any transuranic elements in comparison to uranium reactors . This reduces the amount of long-term radioactive nuclear waste . However, the amount and type of fission products produced largely correspond to those of uranium fission; this also applies to extremely long-lasting fission products such as 129 I (half-life 15.7 million a). Furthermore, the long-lived isotope 231 Pa (half-life 32,760 a) is produced from thorium in significant quantities via the (n, 2n) reaction , which also (although no transurane) as a highly toxic α-emitter requires a safe repository for several hundred thousand years. Other long-lived actinides of the thorium cycle are 229 Th (7,500 a) and 230 Th (75,400 a). If thorium is used, the toxicity of the long-lived nuclear waste is significantly lower, but the need for a safe long-term repository remains.

Thorium is three to five times as abundant in the earth's crust as uranium, in particular more frequently than the isotope 235 uranium, which is used in most reactors today and only accounts for 0.7 percent of natural uranium . Thorium would therefore be available for a long time (millennia) even with the expected increasing energy consumption of mankind if it is used in thermal breeders. However, this advantage is given to an almost similar extent when using more developed “fast breeders”, which can also breed additional fissile material from the non-fissile main part of the uranium, the 238 uranium.

A leading consortium in molten salt reactor development, the Canadian company Terrestrial Energy , abandoned thorium use with its IMSR (Integrated Molten Salt Reactor) concept in 2013 and has returned to uranium (<5% enrichment). The main factors were the proliferation risks of the thorium cycle and the problems of thermal thorium breeders with regard to criticality security, which prevent successful marketing. The IMSR is designed as a thermal reactor, dispenses with an integrated reprocessing of the salt and has a classic emergency cooling instead of a melt plug system that is considered to be insufficiently reliable, as well as control rods.

Efficiency

As in every breeder reactor, in a molten salt reactor, theoretically, almost the entire breeding material, here thorium, can be used for energy production, while in conventional light water reactors only a small percentage of the uranium can be used. To obtain the same amount of energy, the latter requires around 30 times more uranium than would be the case in a thorium molten salt reactor or other breeder reactor. However, the breeding factors that can be achieved in the LFTR are smaller than in the fast breeder .

Molten salt reactors can theoretically breed additional fissile material to a small extent or, like all reactor types (see e.g. MOX ), use existing fissile material (e.g. from atomic bomb production).

disadvantage

acceptance

The existing reactor industry continues to prefer conventional uranium-plutonium fuel cycle reactors and hardly invests in LFTR. In the opinion of LFTR proponents, this is due to the fact that they not only go through a process of rethinking, but also have to forego existing sources of income, for example in the production of fuel rods. According to LFTR critics, the noticeable reluctance of the nuclear industry to deal with the LFTR is due to doubts about its feasibility.

Operational and security issues

Since fission material and fission products are constantly being diverted out of the active core, the effective proportion of delayed neutrons is low, which considerably impairs controllability.

The deposition of fission products, which are sparingly soluble in the molten salt, on the surfaces of the circuit ( plate out ) reaches a considerable extent and affects e.g. B. the maintenance options.

In contrast to most other reactor concepts, there is no modern safety assessment ( probabilistic safety analysis PRA / PSA) for molten salt reactors. Overall, the accident spectrum of the LFTR differs significantly from that of other reactor types. Even the development of methods for the safety analysis of LFTR is still at a very early stage.

In graphite-moderated LFTR, there can be positive power feedback with a corresponding potential for accidents . Investigations into LFTR-specific criticality accidents caused by the crystallization of nuclear fuel ( loss of fuel solubility event ) have only just begun.

The tritium production in LFTR is due to the lithium content of 35 PBq / (GW el a) about 50 times as large as in pressurized water reactors or in fast breeders. Because of the relatively high temperatures , tritium also diffuses relatively easily through the walls of the reactor vessel. As a result, tritium retention was already seen as one of the greatest problems with the MSRE. The immature tritium treatment was also a major argument in rejecting the MSBR.

To get around this, the developers of the Dual Fluid Reactor plan to use a UCl 3 / PuCl 3 salt solution instead, which would generate significantly less tritium.

Stage of development

So far, no reactors have been built in the capacity now designed. Likewise, the necessary reprocessing has not yet been tested on a larger scale. The same applies to the use of and breeding with thorium in molten salt reactors. The overall development effort required is estimated by British nuclear experts to be so high that another 40 years should pass before an MSR is ready for series production.

Proliferation Risks

With thorium as fuel, 233 uranium is also produced in the course of the process . 233 Uranium has a similarly small critical mass as 239 plutonium, but a much smaller spontaneous fission rate than weapons plutonium, so it is considered an optimal nuclear weapon material . Obtaining pure 233 U from thorium , which would be useful for nuclear weapons, is difficult. In addition to 233 U, something 232 U is created at the same time (among other things from 230 Th which is also contained ), and these two isotopes are almost impossible to separate. In the decay chain of 232 U hard produced gamma rays . This makes handling difficult and, in the opinion of many nuclear scientists, considerably restricts their use for nuclear weapons. However, other scientific analyzes indicate a clear risk of proliferation from 233 uranium from thorium despite the presence of 232 U. It is also argued that 233 U contaminated with 232 U is unattractive for nuclear-weapon states, but by no means for states or terrorist groups that want to gain illegal access to nuclear weapons, because the explosive power of 233 U is hardly reduced by 232 U. Finally, it should be noted that it is not 232 U itself that causes the disruptive hard gamma radiation, but rather 208 Tl, a nuclide in the decay series, which only arises with a significant time delay. For the first months after the 232 U / 233 U separation, its radiation is therefore considerably lower, which makes it easier to handle in this phase. Furthermore, more recent studies confirm the assumption made earlier that there is a considerable potential for abuse, especially when using thorium: Through continuous separation of 233 Pa (half-life: 1 month), relatively pure , i.e. 232 U-poor, high-weapon 233 U can be obtained in the LFTR . Corresponding would be considerably more difficult in the U / Pu cycle. This separation of 233 Pa is - for reasons of the most efficient operation possible - even provided in many LFTR variants and was tested on a laboratory scale as part of the MSBR development. Such a 233 U could be detonated in a simple gun-design nuclear weapon and would not require a complicated implosion technique as in the case of plutonium.

In order to reduce the risk of proliferation with MSR, it was proposed as early as the 1970s to add 238 U to the liquid salt. But this is almost ineffective with 233 protactinium separation; it is only effective if uranium, i.e. 233 U / 238 U, is isolated from the molten salt, but it always has the disadvantage that the problematic transuranium elements in the repository are formed from 238 U. A correspondingly better designed MSR against proliferation risks was presented in the USA in 1980 (DMSR): In addition to the addition of 238 U, this concept, apart from the removal of noble gases, provides no or only online reprocessing of low capacity. However, the DMSR cannot be operated as a thermal breeder, but is dependent on the constant addition of 235 U fissile material in addition to the thorium and 238 U supply . The supply of fissile material would, however, remain significantly lower than in a conventional LWR and the uranium reserves could be expanded by a factor of 3 to 5 in this way.

Regardless of the thorium, the combination of reactor and reprocessing plant, which is contemplated in the LFTR, inevitably represents a high risk of proliferation.

disposal

The problem of treating and disposing of slightly to moderately irradiated machine and system parts is similar to that of conventional uranium reactors; the amount is also dependent on the structure and lifespan of the plant, etc. An additional difficulty in disposal is that fission product fluorides are not considered to be suitable for final storage, i.e. must first be processed into a form suitable for final storage.

Critical expert studies on MSR and thorium use

The literature by Mathieu and other authors also provides an overview of the disadvantages and challenges.

The UK government's National Nuclear Laboratories (NNL) have issued several thorium and LFTR assessments on behalf of the UK government since 2010. The main points of criticism are the immature character of these technologies, the largely lacking evidence for the claimed advantages and favorable properties, the unwillingness of the nuclear industry to provide the necessary cost-intensive evidence, and doubts about economic advantages. NNL considers many of the claims of the Thorium / LFTR proponents to be far exaggerated and warns against euphoria.

As early as 2008, a report prepared for the Norwegian government with the participation of international experts warned against high hopes regarding the use of thorium.

The whistleblower Rainer Moormann published a critical statement on the use of thorium in 2018 and pointed out, above all, the increased risk of proliferation due to the fact that an atomic bomb made of 233 U could easily be built, even for terrorists .

Web links

- Detailed description of the technology and current plans for the construction of power plants

- With thorium into the nuclear future on January 18, 2008

- Thorium: Not 'green', not 'viable', and not likely (PDF file; 277 kB) Collection of critical arguments on thorium and LFTR by Oliver Tickell (English)

- Thorium reactor - molten salt reactor: old lies - repackaged / "Thorium - nuclear power without risk?" A criticism of the BUND regional association

- Video recording of a panel discussion on the use of thorium in molten salt reactors, Karlsruhe, December 2018

Individual evidence

- ↑ Jérôme Serp et al. "The molten salt reactor (MSR) in generation IV: Overview andperspectives", Progress in Nuclear Energy 77, 308-319 (2014) [1]

- ↑ Badawy M. Elsheikh, "Safety assessment of molten salt reactors in comparison with light water reactors", Journal of Radiation Research and Applied Sciences 6, pp. 63-70 (2013)

- ^ Fluoride-Salt-Cooled High-Temperature Reactors, Oak Rich National Laboratory

- ↑ a b c d e Jungmin Kang, Frank N. von Hippel: U-232 and the Proliferation-Resistance of U-233 in Spent Fuel.

- ^ Richard Martin: About the Book SuperFuel. In: superfuelbook.com. August 13, 2013, archived from the original on May 1, 2015 ; accessed on January 30, 2015 (English).

- ^ William Pentland: Is Thorium the Biggest Energy Breakthrough Since Fire? Possibly. In: forbes.com. September 11, 2011, accessed January 30, 2015 .

- ↑ China blazes trail for 'clean' nuclear power from thorium - Telegraph. In: telegraph.co.uk. January 6, 2013, accessed January 30, 2015 .

- ↑ Lars Schall: Chinese pave the way for thorium use. In: larsschall.com. January 12, 2013, accessed January 30, 2015 .

- ^ Jonathan Tennenbaum, "Molten salt and traveling wave nuclear reactors". Asia Times, February 4, 2020 [2]

- ↑ ES Bettis u. a .: The Aircraft Reactor Experiment-Operation . (PDF) In: Nuclear Science and Engineering . 2, 1957.

- ↑ ES Bettis u. a .: The Aircraft Reactor Experiment-Design and Construction . In: Nuclear Science and Engineering . 2, 1957.

- ^ PN Haubenreich, JR Engel: Experience with the Molten-Salt Reactor Experiment . (PDF, reprint) In: Nuclear Applications and Technology . 8, 1970, pp. 118-136.

- ↑ a b c d U.S. ATOMIC ENERGY COMMISSION : An Evaluation of the Molten Salt Breeder Reactor. Wash-1222, Washington, DC (September 1972)

- ↑ Data sheet for Hastelloy-N on the manufacturer's website, the alloy was developed for the MSRE. [3]

- ↑ Paul N. Haubenreich, and JR Engel, "Experience with the molten salt reactor experiment", [4]

- ↑ Molten Salt Reactor Program Semi Annual Progress Report For Period Ending July 31, 1964 [5]

- ↑ An evaluation of the molten salt breeder reactor, Atomic Energy Commission [6]

- ^ Paul N. Haubenreich & JR Engel, Experience with the Molten-Salt ReactorExperiment, Nuclear Applications and Technology 8, p. 131 (1970)

- ^ BJ Gilliam et al. a .: ALARA CONTROLS AND THE RADIOLOGICAL LESSONS LEARNED DURING THE URANIUM FUEL REMOVAL PROJECT AT THE MOLTEN SALT REACTOR EXPERIMENT PROJECT. In: WM'02 Conference. 24.-28. February 2002, Tucson , AZ.

- ↑ DF Hollenbach, CM Hopper: Criticality safety study of the MSRE auxiliary charcoal bed Technical Report, from September 1, 1996 doi: 10.2172 / 408664 Oak Ridge National Lab., TN (United States)

- ^ BJ Gilliam et. al, "ALARA CONTROLS AND THE RADIOLOGICAL LESSONS LEARNED DURING THE URANIUM FUEL REMOVAL PROJECT AT THE MOLTEN SALT REACTOR EXPERIMENT PROJECT", WM'02 Conference, February 24-28, 2002, Tucson, AZ [7]

- ^ MW Rosenthal u. a .: The Development Status of Molten-Salt Breeder Reactors . In: Oak Ridge National Laboratory . ORNL-4812, August 1972.

- ↑ A. Nuttin, D. Heuer et al. a .: Potential of thorium molten salt reactors: detailed calculations and concept evolution with a view to large scale energy production. In: Progress in Nuclear Energy. Volume 46, 2005, pp. 77-99 doi: 10.1016 / j.pnucene.2004.11.001

- ^ C. Renault, M. Delpech: The Most Project: Key-Points and Challenges for the Feasibility of Molten Salt Reactors . In: Proceedings of the ICAPP'05 Seoul, Korea, 15. – 19. May 2005.

- ↑ a b c d e L. Mathieu u. a .: Possible Configurations for the TMSR and advantages of the Fast Non Moderated Version. In: Nuclear Science and Engineering . Number 161, 2009, pp. 78-89.

- ↑ CY Zou, XZ Cai, DZ Jiang, CG Yu, XX Li, YW Ma, JL Han, JG Chen: Optimization of temperature coefficient and breeding ratio for a graphite-moderated molten salt reactor. In: Nuclear Engineering and Design . Volume 281, number, 2015, pp. 114–120, doi : 10.1016 / j.nucengdes.2014.11.022 .

- ^ Nixon, Thorium Australia. (No longer available online.) In: thoriumaustralia.org. Archived from the original on July 10, 2015 ; accessed on January 30, 2015 (English).

- ^ Alvin M. Weinberg: The First Nuclear Era . Springer Science & Business Media, 1994, ISBN 978-1-56396-358-2 , pp. 206-207 ( limited preview in Google book search).

- ^ The Nuclear Green Revolution: Alvin Weinberg's integrity and vision. In: nucleargreen.blogspot.de. December 27, 2010, accessed January 30, 2015 .

- ↑ Bernd-A. Rusinek : Between heaven and earth: reactor projects at the Jülich nuclear research facility (KFA) in the 1970s. P. 16

- ^ A. Huke, G. Ruprecht, D. Weißbach et al .: The Dual Fluid Reactor - A novel concept for a fast nuclear reactor of high efficiency . Annals of Nuclear Energy , Vol. 80 (2015) pp. 225-235, doi: 10.1016 / j.anucene.2015.02.016

- ↑ Dual Fluid Reactor. In: dual-fluid-reaktor.de. July 4, 2013, accessed January 30, 2015 .

- ↑ Kai Stoppel: Will nuclear power save us from climate collapse? In: n-tv.de. December 15, 2019, accessed December 15, 2019 .

- ↑ China bets on thorium. In: theregister.co.uk. October 27, 2004, accessed January 30, 2015 .

- ↑ Kun Chen from Chinese Academy of Sciences on China Thorium Molten Salt Reactor TMSR Program on YouTube , August 10, 2012.

- ↑ Mark Halper: Completion date slips for China's thorium molten salt reactor. (No longer available online.) In: the-weinberg-foundation.org. October 30, 2012, archived from the original on April 21, 2017 ; accessed on January 30, 2015 (English).

- ^ A b Molten Salt Reactor (MSR). In: gen-4.org. Accessed January 30, 2015 .

- ↑ Strategic Research Agenda - Annex January 2012 - Molten Salt Reactor Systems (PDF file)

- ↑ A modular pebble-bed advanced high temperature reactor. (PDF) May 16, 2008, p. 96 , archived from the original on January 1, 2014 ; Retrieved February 1, 2017 (English, report from the University of Berkeley).

- ↑ FLUORIDE-SALT-COOLED HIGH-TEMPERATURE REACTORS (FHRs) FOR BASE-LOAD AND PEAK ELECTRICITY, GRID STABILIZATION, AND PROCESS HEAT ( Memento from May 22, 2013 in the Internet Archive ) (PDF file)

- ^ Charles Forsberg: Fluoride-Salt-Cooled High-Temperature Reactors for Power and Process Heat 2012 World Nuclear University Institute Christ Church, Oxford, England, July 10, 2012

- ↑ Section 5.3, WASH 1097 “The Use of Thorium in Nuclear Power Reactors”, available as PDF: Liquid-Halide Reactor Documents, accessed on April 29, 2012.

- ^ RC Robertson, OL Smith et al. a .: Two-Fluid Molten-Salt Breeder Reactor (Design Study) from January 1, 1968

- ↑ a b J. R. Engel, WR Grimes u. a .: Conceptual Design Characteristics of a Denatured Molten-Salt Reactor With Once-Through Fueling July 1980, p. 137.

- ↑ a b c L. Mathieu u. a .: The Thorium Molten Salt Reactor: Moving On from the MSBR. 2005

- ↑ Michael Odenwald: Physics: Does a safe nuclear power plant exist? In: Focus Online . May 15, 2012, accessed January 30, 2015 .

- ↑ Dominique Greneche, William J. Szymczak u. a .: Rethinking the Thorium Fuel Cycle: An Industrial Point of View. ( Memento of July 9, 2015 in the Internet Archive ) Proceedings of ICAPP 2007, Nice, 13.-18. May 2007, Paper 7367

- ↑ https://www.terrestrialenergy.com/technology/

- ^ A b c C. Forsberg: Molten-Salt-Reactor Technology Gaps . In: Proceedings of ICAPP'06 2006, Paper 6295.

- ^ A b C. Forsberg: Safety and Licensing Aspects of the Molten Salt Reactor. 2004 American Nuclear Society Annual Meeting, Pittsburgh , Pennsylvania , April 13-17. June 2004.

- ↑ Zhangpeng Guo et al. a .: Simulations of unprotected loss of heat sink and combination of events accidents for a molten salt reactor. In: Annals of Nuclear Energy. Volume 53, 2013, pp. 309-319 doi: 10.1016 / j.anucene.2012.09.009

- ↑ FJ Arias: Fuel relocation in Molten Salt Reactors in a loss of fuel solubility event. In: Nuclear Engineering and Design. 250, 2012, pp. 412-416, doi: 10.1016 / j.nucengdes.2012.06.009 .

- ↑ GT Mays u. a .: Report ORNL / TM-5759. April 1977.

- ↑ a b The Thorium Fuel Cycle ( Memento from January 26, 2013 in the Internet Archive ) (PDF file)

- ↑ a b Comparison of thorium and uranium fuel cycles. In: National Nuclear Laboratory Volume 11, 11593, Number 5, March 2012

- ↑ What is weapon grade material? - About the difficulties of building an atomic bomb! ( Memento from November 10, 2003 in the Internet Archive ) In: kernenergie-wissen.de

- ↑ a b J. R. Engel u. a .: Conceptual design characteristics of a denatured molten-salt reactor with once-through fueling. Technical Report ORNL / TM-7207, July 1, 1980, Oak Ridge National Lab., TN (USA) doi: 10.2172 / 5352526

- ↑ a b THORIUM AS AN ENERGY SOURCE - Opportunities for Norway Oslo

- ↑ SF Ashley, GT Parks et al. a .: Nuclear energy: Thorium fuel has risks. In: Nature. Volume 492, Number 7427, December 2012, ISSN 1476-4687 , pp. 31-33, doi: 10.1038 / 492031a , PMID 23222590 .

- ↑ Thorium: Proliferation warnings on nuclear 'wonder-fuel'. In: phys.org. December 5, 2012, accessed January 30, 2015 .

- ^ Mark Halper: Benefits of thorium as alternative nuclear fuel are 'overstated'. In: guardian.co.uk. September 13, 2012, accessed January 30, 2015 .

- ↑ Reinhard Wolff: Thorium is also not a solution. In: taz.de . January 6, 2009, accessed January 30, 2015 .

- ↑ John Acher: Experts cast doubt on Norway's thorium dreams. In: reuters.com. February 15, 2008, accessed January 30, 2015 .

- ↑ http://www.strahlentelex.de/Stx_18_746-747_S01-05.pdf

- ↑ https://www.wiseinternational.org/labels/thorium

![{\ mathrm {^ {{232}} _ {{\ 90}} Th \ + \ _ {{0}} ^ {{1}} n \ \ longrightarrow \ _ {{\ 90}} ^ {{233} } Th \ {\ xrightarrow [{22.3 \ min}] {\ beta ^ {-}}} \ _ {{\ 91}} ^ {{233}} Pa \ {\ xrightarrow [{26,967 \ d}] {\ beta ^ {-}}} \ _ {{\ 92}} ^ {{233}} U}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/e69ba8c959dd5ab6f587b18437ec429f67229b02)