Monorail

A monorail is the passenger or freight serving web , which is at or below a single narrow path ( " track drives", "mobile beam"). This can take on different shapes and be made of different materials. It is usually elevated, but can also run at ground level or in tunnels . The drive of monorails is mostly done with the help of electric motors , although experiments have also been made with steam propulsion and combustion engines . A few, like the suspension railway in Dresden, are driven by a rope from a stationary machine.

All monorails that have become important run in a stable equilibrium on or under their form-fitting rail. This is achieved, for example, by having a row of twin tires running on the top of the mobile beam and a high and a low row of guide tires on each side.

However, if a rail vehicle drives on only one and only linear , i.e. very narrow, rail, it needs a powerful gyro system for stabilization, such as the monorail according to Brennan or a supporting arm to a second rail running parallel to it, as is the case for some muscle- powered draisines .

Early developments

The first prototypes of the monorail come from the year 1820 by the Russian Ivan Elmanov.

In 1821 the British Henry Robinson Palmer had a patent for a monorail issued. According to this patent , a railway for transporting bricks was built in Cheshunt , England and put into operation on June 25, 1825. The vehicles hung below a rail and were pulled by a horse . In 1827, the railway pioneer Friedrich Harkort built a demonstration line in the German industrial city of Elberfeld (now part of Wuppertal ).

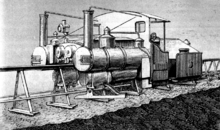

In 1875 a monorail was built in Algeria by the French engineer Charles Lartigue over a distance of 90 kilometers from Oran to Damesne . The wagons of this railway had a chassis to which carrying containers for transporting esparto grass were attached on both sides . The wagons were pulled by mules . The operation of this railway was stopped again in 1881. Further routes of this Lartigue monorail were built with special steam locomotives at an exhibition in London in 1886 and in 1888 between Listowel and Ballybunion ( Listowel and Ballybunion Railway ) in southeastern Ireland . This lift was in operation for 36 years until 1924 and has been rebuilt as a new operation since 2001 using the old templates.

Around 1870, entrepreneur engineer Eugen Langen , partner of Nicolaus Otto , built a monorail with hanging wagons for the transport of goods in his Cologne sugar factory. In 1893, Langen had a demonstration line built in Deutz with a length of 120 m by the Dortmund Union company. According to the memorandum, “a test section for the 'installation of an electrical elevated railway (suspension railway), Eugen Langen system'”. There was a two-rail and later a single-rail variant. Between 1897 and 1903 the Wuppertal suspension railway between Barmen , Elberfeld and Vohwinkel (now part of Wuppertal ) was built according to this system. On October 24, 1900 , Kaiser Wilhelm II floated with his entourage from Döppersberg to Vohwinkel. This elevated railway is still in operation today.

Stabilization against tipping over

In 1907, the Irish-Australian engineer Louis Brennan (1852–1932) developed a monorail that ran on steel wheels with double flanges on a single Vignole rail and was actively stabilized by gyroscopic systems ( monorail to Brennan ). There was a reduced-scale model and a full-size demonstration system in Whitecity / London in 1910 . There was also an attempt to introduce this railway in Germany, for which the well-known Berlin publisher August Scherl and the district administrator of the Obertaunus district , Ernst Ritter von Marx , campaigned. However, the monorail project on the edge of the Taunus was canceled before a decision was made. Bernhard Kellermann immortalized such a train in his science fiction novel " The Tunnel " (1913).

In order to absorb centrifugal forces well when cornering, the rail on monorails is placed at a slight angle to the inside of the curve. In the case of a rail with a voluminous cross-section, a rail seated like a rider in the saddle can transfer tilting moments or the centrifugal force on the vehicle to the rail. This is ideally done by means of a form fit , above all by means of wheels supporting the side of the rail profile, for example the Alweg rail. Frictional locking of rolling wheels against lateral forces as in road vehicles would in principle also be possible on cylindrical tube rails, but have high tire wear and make it necessary to steer all wheels against the slip to the side.

Apart from magnetic forces, the stabilization can also take place by gravity, namely when the train is not sitting on the rail but hangs down from it . A condition is sufficient damping against pendulum and rolling along the train as with the Wuppertal suspension railway .

advantages

Since the driveways are assembled from prefabricated parts, building projects can be realized quickly and easily; the mobile beams fit relatively well into urban scenes and the railways can even be inserted into buildings. The shadow cast is less due to the narrow, wide-spanning girders than when conventional railways or multi-lane non-conventional track vehicle systems are raised.

The supply of electrical power for the traction drive can be integrated into the support and travel rails, which saves additional power rails or overhead lines .

In the case of two-lane railways, it is necessary to raise the track on the outside of the curve to compensate for the centrifugal force . The superelevation can only be optimally dimensioned for exactly one speed. In the single-track suspension system, as implemented in Wuppertal, the track is suspended freely swinging. The transverse inclination of the carriages corresponds at every moment to the influence of the vertical ( gravity ) and lateral forces. In addition to the improved comfort for the passengers, this enables cornering at undiminished speed without the risk of derailment .

The drives , especially in the Safege system, but also in the saddle railways, are very well protected from the weather compared to conventional railways. The effort required to clear snow is very low for saddle railways, while Safege does not need to clear snow at all (hence the application examples in colder areas of Japan). Acceleration and braking capability of the usually electrically powered, and pneumatic-tired vehicles are particularly at quite low noise quite well (similar to pneumatic tires light-subways etc.); the good climbing ability due to the high adhesion of the rubber tires and the small curve radii due to the uncomplicated, strong excess heights of arches allow alignment in very difficult surroundings.

disadvantage

The track and vehicle of monorails usually come from one manufacturer and are not standardized. This means that it is not possible to build up real competition in networks (see Federal Network Agency ) in which vehicles and network infrastructure from different manufacturers and operators coexist. In addition to the lack of standardization between the systems, there is no possibility of transition from and to conventional rail (as with tram-train ) or to the road (as with lane bus ). The area of application of monorails is therefore mainly in the area of point-to-point connections, especially when larger areas are to be crossed on elevated surfaces (trade fair, parks, airports).

Economical freight transport (beyond courier goods or air transport containers) is impossible with the systems actually implemented, as these require exclusive operation with railcars due to the numerous, mostly pneumatic or solid rubber tires , especially if there are large inclines and / or canting.

Turnouts are relatively complex and expensive. There are different, differently practicable types of flexible and interchangeable points; the former bend the chassis beam, the latter swap a rigid straight track for a rigid curved track by moving or rotating a platform. Accessible switches are not possible under any circumstances.

The maximum speeds are relatively limited for the rubber-tire types. The shadow cast, although not as large as with conventional elevated railways , should not be neglected. The flexible routing and the futuristic design have a very strong visual effect and, depending on the point of view, lead to a considerable impairment or enrichment of the cityscape and landscape.

Importance and market segment

The close (proprietary) connection between track and vehicle, usually from a manufacturer, allows special improvements compared to standardized wheel-rail networks in individual cases, but reduces the ability to innovate in implemented systems and can result in supplier monopolies.

Entry into high - speed long-distance traffic was planned with the Alwegbahn from 1957 as well as with the Transrapid , and standardized use in urban areas was and is planned for suspension railway technology, and later for the Aerobus .

The corresponding format war- like disputes in the network area have so far all ended with great media coverage and public participation in favor of classic wheel-rail systems. Even the longest implemented monorail systems are nothing more than niches and isolated solutions for special cases . Also important and outstanding are (sometimes only short-term) applications for world exhibitions and trade fairs or in amusement parks .

In addition to the countless more or less complicated railways with which goods of all kinds are transported in craft and industrial companies of all sizes as well as in steep-slope viticulture, there are numerous well-established public monorails in the world (park railways and the like are not mentioned); many more are planned. The longest planned system in Tama , Japan, will one day achieve a network length of around 100 kilometers.

Types

Standing railways (saddle railways)

- System monorail according to Brennan : single Vignole rail as a track, vehicle with steel wheels with flanges on both sides , stabilization by a gyro system .

- Alweg system: Chassis beam made of concrete or steel profile, with a rectangular cross-section (often slightly drawn in at the side in the shape of an hourglass); one row of carrying wheels, a total of four rows of guide wheels (all with pneumatic tires); Power supply via busbar coated on the side (direct current)

- Alwegbahn design : chassis beams 51–90 cm wide and 88–220 cm high; Bogies; Carrying wheels below or in the cabin and with twin tires; Driving voltage 600 V

- Type Monorail Malaysia : beam width 80 cm, driving voltage 750 or 1500 V.

- Hitachi type : chassis beam width 85 cm, two instead of just one pair of carrying rims per bogie, newer series with high vehicle floor so that the carrying wheels do not jagulate the passenger compartment; Driving voltage 1500 V

- Type Disney / Bombardier : beam width 66 cm; no bogies, instead carrying wheels permanently mounted in front of and behind the cabs (no free passage between the vehicles) and only individually fitted with tires; Driving voltage: 600 V or 750 V.

- Bombardier design : like Disney / Bombardier, but fully automatic

- Box girder systems: Chassis beams made of rectangular steel profile (rarely concrete) with at least one protruding flange; Guide wheels grip the flange from below and the beam sides from the outside

- Type Bombardier UM: chassis beams made of steel or concrete

- Intamin design : mobile beams 60 cm wide and 100 cm high

- Type Severn Lamb : chassis beams made of steel or prestressed concrete

- Von Roll design (meanwhile transferred to Bombardier via Adtranz ): Chassis beam width 70 cm, with flange protruding on both sides by 12 cm, beam height 83.2 cm; Each pair of support wheels has two guide wheels that grip from below and two from the left and right; Driving current 500 V AC (two busbars painted from below)

- T-girder systems: Chassis beam with reversed T-profile, that means with a wide flange below (possibly with a narrow flange above); the vehicle weight rests on the wide lower flange, not on the narrow side

- Eurotren Monoviga type : mobile beam 190 cm wide and 130 cm high, articulated vehicles with two pairs of carrying wheels and two pairs of guide wheels per section; for high speed option to use steel instead of pneumatic tires and linear motor instead of wheel drive

- Type Urbanaut : Concrete beams of 100 cm width with a special profiled steel guide rail; guide tires arranged diagonally instead of horizontally; scalable from slow vehicles on solid rubber tires to maglev trains

- High-speed monorail: individually suspended steel wheels, linear motor drive, high speeds

Suspended constructions ( overhead conveyors )

- System Palmer

- System Eugen Langen

- Safege system : four-wheeled bogies run inside a box girder slotted at the bottom; the car bodies are suspended from the frames through the slot ; Driving current from busbars inside the girder. This is the same principle as for curtain rails with inner rollers.

- Aerorail type : Bogies run in the carrier on conventional, meter-gauge railway tracks; Driving voltage 750 V direct current

- Mitsubishi type : carrier cross-section 186 cm × 189 cm, bogies with pneumatic tires; Driving voltage 1500 V direct current

- Siemens SIPEM design : very narrow beam, hard rubber tires; Line voltage 380 V three-phase current (examples: H-Bahn in Dortmund, Skytrain at Düsseldorf Airport)

- Double-T-beam systems: the mobile beam is a conventional vertical double-T-beam made of steel or concrete

- Most of the workshop and industrial suspension systems (e.g. monorail suspension systems in mining)

- Type Titan Global Systems : hard rubber support rollers on the lower flange, guide rollers grip the web from the outside and the lower flange from below; Linear motor drive that also provides lifting power and thus greatly relieves the load on the conveyor rollers

- Double flange systems: Steel wheels with a double flange run on a single steel rail

- Langen type ( Wuppertal suspension railway , Dresden suspension railway , Ueno-Zoo Monorail ): 600 V direct current traction current

- Aerobus system : aluminum rails that are suspended from cable structures like a suspension bridge (pylon spacing up to 600 m) are encompassed by the bogies from the outside; two rows of carrying wheels

Hybrid designs

Vehicles are hung on one side of the mobile beam in such a way that one beam can be driven over on both sides

- System Futrex : Chassis beam with a triangular cross-section (base width approx. 215 cm, height approx. 168 cm) carries a specially profiled Vignole rail on both sides above and below; On the lower rails run diagonally from above outside steel wheels with inwardly curved running surfaces; on the upper rails from the inside, groups of four of rollers run

- System OTG High Road : massive, inverted T-shaped chassis beams (about 198 cm wide and 183 cm high) with by the edge cranked to the bottom flange to the web; Flanged steel wheels run on the base (supporting), on the beam side (supporting the vehicle) and on the inside of the top flange (leading); the vehicle is attached to the side of the chassis by outriggers that lead out from under the upper flange; the top of the upper flange remains free for company vehicles or the like.

- The Boynton Bicycle Railroad in Brooklyn, Long Island, New York ran on a single load bearing rail on the ground and was secured in the vertical position to a 15 foot (4.57 m) above rail with casters.

Monorail suspension railways

Systems that in principle do not touch the rail during travel, such as the magnetic levitation train ( Transrapid , M-Bahn Berlin ) and the air-cushion suspension train ( Aérotrain ), are called suspension trains .

Systems in planning or under construction

- São Paulo ( Brazil ): Metrô São Paulo (Alwegbahn) - two lines under construction, Line 2 (23 km, 20 stations) and Line 17 (8 km, 8 stations) for 2013 and 2014 as a driverless supplementary and feeder system to the Metrô São Paulo

See also

- List of monorails

- Monorail on the edge of the Taunus

- Lartigue monorail

- Transrapid

- Monorackbahn

- Monorail

- Ewing system

Examples with similarities:

- Tube rail track , made of galvanized steel tubing (also 48.3 mm diameter, nominally 1.5 ") or extruded aluminum profile (only 60.3 mm," 2 inches "), transports animal parts and meat in the slaughterhouse with wrapped, greased sliding hooks and loaded into the truck .

- Ceiling conveyor systems, for example, in the production of car parts, such as car bodies

- Detachable gondola lifts allow the gondolas in the station area to roll slowly on a rail.

- Ghost train cars drive (at the front) along only one rail, which supplies the operating voltage via sliding contacts on both sides - insulated - and also steers the motorized car around tight bends, but the drive air wheels roll on the wooden floor next to it

Web links

- Suspension railway monorail in Wuppertal, Germany

- The Monorail Society

- Maglev Monorail IMB

- One-Track Wonders: Early Monorails , website with pictures of planned and actual monorails

- US patent 7,823,512 B2 dated November 2, 2010 , Google patent page with the description including technical drawings of the bogie of the monorail from Bombardier

- Transit Monorails of the World

Individual evidence

- ^ Monorail History - Facts and Types of Monorails. Retrieved March 30, 2019 .

- ^ Neil Robinson: World Rail Atlas. Volome 7: North, East and Central Africa . 2009, p. 4.

- ^ FB Behr, Georges Petit: The Lartigue elevated single rail railway . Lartigue Railway Company, 1886

- ↑ Furgocar 50 and 60 mm rails ( Memento of the original from September 16, 2013 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , Catalog Pommier

- ↑ Rohrbahnen ( Memento of the original from March 19, 2015 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , Helmers

- ↑ Euro hook for pipe rails , bumps

- ↑ Vehicle end piece 48 + 60 mm , hump

- ↑ Poster Safety Rohrbahn ( Memento of the original June 10, 2015 Internet Archive ) Info: The archive link is automatically inserted and not yet tested. Please check the original and archive link according to the instructions and then remove this notice. , BGN meat industry

- ↑ Pipe rails up to 1500 kg / m load capacity , dguv.de (PDF file)