Electricity meter

An electricity meter or electricity meter is a measuring device that records the energy supplied from an electrical supply network. The use of the extracted energy is sometimes referred to as energy consumption . In this sense it is an energy meter ; the measured values are preferably given in kilowatt hours (kWh).

With electromechanical counters, the revolutions of a visibly rotating disc are counted, with electronic counters internally generated electrical impulses. An intelligent meter is also integrated into a communication network through which it receives and sends data.

The difference between two readings from a calibrated meter is used to bill an electricity delivery.

In the early phase of electrical supply networks, there were direct current networks in which electricity meters measured the electrical charge that had flowed through them in units of ampere-hour . Today they are only of historical interest.

General

The widespread meters record the electrical current flowing through the loads as well as the applied alternating voltage , multiply their instantaneous values according to the sign (as in the case of active power measurement) and determine the active energy used by integrating them over time . This is sometimes also called active consumption.

There are versions as "alternating current meters" and "three-phase energy meters" for single-phase and three-phase alternating current . In addition to the usual household electricity meters for 10 (60) A, electricity meters for 100 A are also widespread for commercial use (including construction sites, festive events). These direct measuring electricity meters are designed for a nominal voltage of 230 V (corresponding to 400 V between the outer conductors ).

The maximum or limit current in amperes that the meter can withstand continuously without being damaged is given in brackets after the nominal current . The calibration error limits must also be adhered to up to this current value . The nominal current is primarily relevant for the calibration; the measuring points that are checked during the calibration process refer to this value.

Larger energy consumption in industry is often measured using so-called transducer meters. These counters multiply the measurement data from current transformers and voltage transformers . The secondary side of these converters generally has a nominal current of 5 A or a nominal voltage of 100 V, for which the meter is also designed. Depending on the requirements, only current transformers are used, for example, while the voltage paths are directly connected to the network. These transducer meters are also subject to calibration according to the calibration law .

In addition to the active energy, meters for larger technical systems can also display the current active power or record the reactive energy in kvarh . Some meters save load profiles, in particular the amount and time of a load peak. Other meters have pulse outputs for further processing the current power or energy measurement, the frequency of which is proportional to the power.

Billing

For small consumers (households) only the consumed active energy is calculated, i.e. the time integral of the active power.

The integral of the reactive power is also measured and calculated for large consumers (industry) because this form of power places an additional load on the supply network. It requires stronger lines as well as transformers and causes increased line losses. Therefore, reactive energy is also a billing feature for energy suppliers.

Tariff switching

The tariff changeover is used in the so-called low - load phases (usually in the afternoon and at night) to supply , for example, electrically operated heat storage heating systems at times of low demand. For the energy supplier, this time-controlled connection or disconnection of consumers balances the network load.

With electromechanical energy meters, two or more counters are used for tariff switching in order to be able to bill different tariffs based on time. A central control system uses built-in or external tariff switching devices , for example tariff time switches or ripple control receivers , to switch between these counters .

With special contract customers (industry), further electromechanical counters were used for energy measurement. Here, there is a complete switch to electronic meters with a recording of the instantaneous values of the load profile. In many cases, these meters are connected to the telephone network with a data line, for example, in order to be able to bill without delay. Counters with the transmission of data via return channel-capable ripple control technology or via mobile radio networks are also known.

Load shedding

Main article: Load shedding (power grid)

If an agreed tariff feature is exceeded, a load can be shed through a set limitation of the power value or the amount of energy. Alternatively, if the load is exceeded in this way, a different tariff is used for the duration of the period. Such tariffs can no longer be recorded with simple meters.

Types of electricity meters

Ferraris counter

Ferraris meters based on the induction principle, named after the Italian Galileo Ferraris , are widespread . They are available in versions for single or three-phase alternating current . The respective conductor current and the associated voltage between the outer conductor and the neutral conductor induce a rotating magnetic field in a Ferrari rotor (aluminum disc, also Ferrari disc), which generates a torque in it through eddy currents . This is proportional to the product of the instantaneous values of current strength and voltage and thus averaged over time to the active power. The disc runs in an eddy current brake consisting of a permanent magnet , which generates a braking torque proportional to the speed. The disc, the edge of which is visible from the outside as a cutout through a window, has a rotational speed that is proportional to the active electrical power. The number of revolutions is then proportional to the electrical energy actually drawn. On the nameplate in the picture opposite, the meter constant is given as 75 U / kWh.

In the reverse process, the current power can be estimated by counting the revolutions over a certain period of time. The energy known from the number and the meter constant is then divided by the counting time.

In their usual structure, Ferraris meters only add up the active power, even with harmonic or displacement reactive current components. There are similarly structured reactive consumption meters which add up the inductive or capacitive reactive power. Their internal circuit corresponds to the circuit for reactive power measurement .

Double and multi-tariff electricity meters

These meters can count the consumption divided into two or more tariffs, see section tariff switching . The illustration opposite shows a two-tariff meter with an integrated ripple control receiver for audio-frequency signals on the power line ( ripple control technology ).

Electronic energy meters

Electronic energy meters do not contain any mechanically moving elements. The current flow is recorded either by means of current transformers, current measuring systems with Rogowski coils , shunt resistors or Hall sensors . The further processing of the measured values takes place with an electronic circuit. The result is fed to an alphanumeric display (usually liquid crystal display , LCD ).

State-of-the-art meters for active and reactive energy in 2014 also record harmonics of voltages and currents up to the 16th harmonic. The results are usually saved in a register that can be read either directly on the display or via communication.

Electronic energy meter with remote reading

Intelligent or electronic meters can be read remotely via data interfaces by end customers, energy supply companies or building automation or smart home systems. In addition, they offer many other functions, for example the tariff can be changed with electronic meters without intervening in the meter. The data interfaces used are infrared , S0 interface , M-Bus , floating contact , KNX (previously EIB ), 20 mA current interface (connected to GSM , PSTN modems) or Power Line Carrier (PLC).

Electronic meters can have an integrated remote shutdown facility. This allows the energy supplier to remotely disconnect the customer from the power grid, e.g. B. as a last resort if he has not paid his bill. In Germany, however, only meters without this option are used, because on the one hand a potential security risk is avoided (malicious, possibly massive shutdown by attackers) and, on the other hand, it cannot be ruled out that no one will be harmed by the voltage that is again available when the device is switched on again. This is to be distinguished from the possibility provided in Germany to forward a control signal to a device of the connection user via the meter, e.g. B. to control the power supply. In this case, this device can be controlled by the network operator or other service providers. A complete shutdown of the power connection can never take place.

In Germany, following the amendment to the Energy Industry Act (EnWG) and the new Measurement Access Ordinance (MessZV), since January 1, 2010, it has been mandatory to use intelligent meters in new buildings and modernizations.

Retrofittable meter readers

For meters of conventional design with a mechanical consumption display, it is possible to equip them with a readout device. These devices record the counter reading of the mechanical consumption display with the help of an optical device. By means of character recognition (OCR) is the captured image in an electronic information transformed. As with electronic energy meters, this information can then be transmitted via various data interfaces. This means that the meter can be read automatically (AMR, Automated Meter Reading) and manual reading is no longer necessary.

Cashier, coin and prepayment counters

( English prepaid for 'prepaid')

In some countries there are also cashier counters (coin counters) which enable a defined amount of electrical energy to be called up by inserting money , tokens or, more recently, by using chip cards , chip keys or entering a PIN .

In Germany and Switzerland, such meters are used in communal laundry rooms in apartment buildings and occasionally by energy supply companies for customers with poor payment behavior. They also prevent the build-up of financial debts, as only the amount of energy already paid for is given away. Prepayment meters with chip cards are widespread in South Africa, for example, and with chip keys in the United Kingdom.

Load profile counter

For major customers (from 100,000 kWh / a), the electricity consumption is not only billed based on the energy used (in kWh) and reactive work (in kvarh), but also or only according to the energy used in each registration period. Load profile counters are installed for this, which store a measured value after each registration period. This is known as a registering performance measurement (RLM).

Several load profiles can be recorded and saved at the same time in a load profile counter. These meters are typically read remotely.

The registration period in Germany is fixed at 15 minutes. The saved measured value can be the

- average power used in kW or kvar

- Meter reading in kWh or kvarh

- Energy consumption in kWh or kvarh

the last registration period.

For smaller customers, the load profile is simulated using a standard load profile (e.g. H0 for household customers ).

Energy cost meter

The power consumption of individual devices can be measured with plug-in energy cost meters, even over a longer period of time. This is useful for devices such as refrigerators that do not have constant power consumption. Usually you can enter the price per kWh and then see the costs that a device causes. The devices can often only insufficiently handle non- sinusoidal currents and high reactive current components.

DC meter

Due to the public supply of electrical energy on an alternating current basis, direct current meters are of little importance. Direct current consumers such as electroplating plants or direct current railways , for example trams for historical reasons, are supplied from the alternating voltage network with corresponding power converters and rectifiers . For direct current systems such as photovoltaic systems, battery systems, direct current machines or pulsed direct current controls, direct current energy meters are still manufactured as electronic measuring devices. (As of May 2020)

Historical direct current meters worked on a similar principle as the Ferrari meters, but the torque proportional to the power was generated with a direct current motor, the excitation of which was generated by a coil through which the load current flows and whose armature current was obtained from the mains voltage via a series resistor.

The mercury coulometer is a component that can be referred to as a real electricity meter (in the sense of a balancer of the electric charge ) ; it is sometimes used as an operating hours counter. It consists of a column of mercury (similar to a thermometer) located in a glass capillary, which is interrupted by a tiny amount of an electrolyte. When a current flows through it, the mercury is transported to the opposite end, whereby the area of the electrolyte visibly migrates through the column. The current-time product appears linearly as the distance covered by the electrolyte on the glass tube provided with a scale . If the component is operated at constant voltage via a series resistor, the operating time can be determined. After the time has elapsed, the device can be used again with reversed polarity - the area of the electrolyte now moves back.

With the mercury electrolyte meter, also called STIA meter ( English mercury electricity meter ) or Edison meter , the (solid) precipitation was not measured, but the decomposition products - mercury and hydrogen. After the patents of Edison's electrolyte meter had expired, it was its further development. The mercury fell into a glass tube when the current passed through. This was installed above a scale showing the kilowatt hours. The disadvantage of this technique was that after a certain time the glass tube was completely filled and no further counting was possible. Therefore, the meter had to be read at relatively short intervals and then the measuring tube had to be tilted to enable the meter to run again. The Stia meters (name Stia = Schott Jena; inventor: Max Grossmann, Jena, 1922), which are mainly used by small consumers, worked with a mercury anode, with a porous partition between the anode and the cathode. Many old meters have the designation Unter-Stia on the labels . This means that these meters acted as sub-meters in a larger electrical system (e.g. apartment building). Hydrogen meters worked similarly. With them, the hydrogen generated at the cathode was collected and then the consumption was also read off on a scale.

Electrolyte meters have a high measuring accuracy (± 1%) compared to contemporary measuring methods and were relatively simple in design. For this reason, they represented an alternative to motor meters for recording small amounts of electricity consumption. With the conversion to alternating current, the era of electrolyte meters came to an end.

Norms

The European standards EN 50470 and EN 62053 apply to AC electricity meters. EN 62056 (in some parts currently draft) as well as EN 60870 for telecontrol devices must be observed for the associated data communication.

accuracy

Calibration and traffic error limits

The accuracy of the counter is specified as an accuracy class . Classes A, B and C according to MID (see below) that are common today roughly correspond to classes 2, 1 and 0.5 that were common in Germany in the past (the number corresponded to the relative error limit in percent). In the household sector, meters of class A or 2 are mostly used (often identified by the label “Cl. A”, with older meters also “Cl. 2”, “Class 2” or “(2)”).

The exact definition of the classes is specified in the EU Directive 2014/32 / EU and was adopted in the calibration regulations for Germany; the following exemplary values result for electricity meters:

| Accuracy class | A. | B. | C. |

| multi-phase load | 3.5 | 2 | 0.7 |

| single-phase load with multi-phase meter | 4th | 2.5 | 1 |

At more extreme operating temperatures and at very low loads, significantly larger errors are permissible, e.g. B. the specified error limits almost double for an operating temperature range of −25 ° C ... −10 ° C or +40 ° C ... +55 ° C.

The permitted traffic error limits of the meter (which may occur during the operating time of the meter) are twice as high as the calibration error limits specified above. Therefore, the Federation of Energy Consumers recommends only from a measured deviation of 15% between the electricity meter and any existing ones Measuring devices to have the meter checked by the network operator.

If there is a lot of electrical work to be counted, counters of the accuracy classes 1, 0.5 and 0.2 (mostly in connection with instrument transformers ) are also used. The highest requirements exist, for example, at the transfer point from the power plant to the network or between transmission networks. Toroidal cores made from special alloys enable high-precision electronic energy meters in a DC-tolerant design.

Legal calibration

Every energy meter that is used for billing energy consumption in Germany has so far had a calibration mark in accordance with the calibration law.

Electricity meters that are used in business transactions are subject to calibration in Germany . After the calibration period has expired (8 years for electronic meters, 12 years for mechanical transducer meters with induction mechanism [with rotor disc] or 16 years for mechanical meters with induction mechanism), the measuring device must be replaced or the calibration validity extended. Exceptions are possible. A common procedure for extending the calibration validity is random sampling .

The calibration is carried out at (state-approved) test centers. Many network operators and manufacturers have their own test centers. However, there are also companies that have specialized in calibration. The state authority responsible for calibration in Germany is the PTB in Braunschweig.

Technical quality

The European Measuring Instruments Directive (MID) has been regulating the placing on the market of various new measuring instruments intended for end users in Europe since October 30, 2006 - including real electricity meters. It does not regulate the calibration obligation and the requirements after placing on the market or commissioning. That is reserved to national law. However, the Member States have to justify themselves to the Commission and the other Member States if they do not regulate it. MID-compliant measuring devices no longer need to be calibrated before being used for the first time.

The MID requirements currently replace many valid national requirements for calibrated meters (for example in Germany, Austria, Switzerland and Scandinavian countries). They are mostly identical to the PTB approval in Germany, in some cases a little harder. For older approvals (e.g. PTB) there was a transition period until October 30, 2016. All meters with PTB approval that were on the market on October 30, 2006 could therefore continue to be placed on the market until October 30, 2016. Only newly introduced measuring devices have to comply with the MID. Incidentally, the corresponding test in Germany is carried out exclusively by PTB, but can be applied for in any member state and must then be recognized in every member state.

For electricity meters, the MID formally only applies to active electricity meters. This results in a problem for meters that measure both active and reactive power: A MID declaration of conformity is required for the device part of the active measurement. An initial calibration may no longer be prescribed; the part for the blind measurement must be conventionally approved or calibrated according to the respective calibration law.

Measurement errors due to electromagnetic interference

Due to an unregulated interference frequency range between 3 kHz and 150 kHz, there were large measurement deviations from the actual amount of energy with electronic meters. This problem has been known in practice since 2010 at the latest, especially when feeding in renewable energy via inverters.

In March 2017, a study by employees of the University of Twente, the Amsterdam University of Applied Science and the company Thales Nederland appeared, in which several electronic meters from the years 2007 to 2014 measured errors between −32% and +582% compared to a comparator device Basic electromechanical Ferraris meters were found. The deviations were observed with non-linear loads such as dimmed lights. Possible causes are the reaction of the conducted high-frequency interference radiation of these loads on the meter, high rates of rise of the currents and the deviations of the current from a sinusoidal time curve. When calibrating the electronic meters, however, only linear loads and sinusoidal currents are used, so that these measurement errors do not occur there. In addition, the details of the measuring process in electronic meters are implemented in software of a signal processor and are usually a company secret. For this reason, consumer advocates and network operators in the Netherlands are calling for a comprehensive inspection of all smart meters.

In Germany, the Physikalisch-Technische Bundesanstalt has been working on improving the test requirements for electricity meters since 2007. In a statement on the study by the University of Twente, it was stated that after a standardization gap between 2 and 150 kHz has been closed, "the legally prescribed traffic error limits are not exceeded for the meters used and intended for use in Germany over a billing period". Nevertheless, the problem is taken seriously and will, among other things, support the calibration authorities in their activities. The introduction of modern measuring devices and intelligent measuring systems is not endangered according to the assessment of PTB, the counter designs provided for this are devices that were developed by the manufacturers after the problem of standardization gaps had been eliminated. Before a decision on a further tightening of the requirements should be awaited for the publication of further details on the validity of the measurement methods used and the relevance of the curve shapes generated for the investigations for everyday operation by the University of Twente.

Assembly

Installation site

In many countries (USA, Scandinavia, China) household electricity meters are often installed outside the home. In Germany, the systems are usually installed in the house on a so-called meter board or, in accordance with standards, in a meter cabinet (see distributor) . For these meter cabinets there was the so-called TAB ( Technical Connection Conditions ) of the respective electricity network operator . With the TAB 2000 an attempt was made to standardize this multitude of TABs. The TAB 2000 and its successors are now used by most energy providers and adapted to their own needs (network types, control of consumers, ...) with appendices. The TAB 2000 and its successors have meanwhile found their way into the VDE standards in the form of application rules.

In the case of single and two-family houses, the installation can be carried out either in a freely accessible room within the building or in a special house connection room . In some regions you can also find house connection boxes outdoors, for example on the property line or on the building itself. For some time, a house connection room has been mandatory for new apartment buildings, in older buildings the meters are often located in the apartments or on the landings in front of the apartment doors.

In single-family houses, the fuses for the individual rooms and devices as well as the distribution of the data technology (satellite / cable connection, network technology, telephone) are often located in the meter cabinet .

For apartment buildings that laid technical connection requirements of the grid operators often find that in the meter cupboard only Zählervorsicherungen may be included. Fuses for individual circuits were therefore to be installed exclusively in separate sub-distributions (usually in the respective residential units). Exceptions exist in some cases for special installations such as the switchgear required by the energy supplier in connection with night storage heating . In the course of the standardization of the TABs, a limited number of security elements is now again permitted directly in the meter box in many cases. These are often used to connect the lighting and socket outlet circuits in the basement.

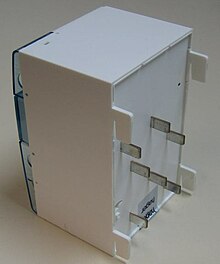

Electronic household meter (eHZ)

The Association of Network Operators (VDN) initiated the development of an electronic household meter in 2001. In addition to the electronic counter, this meter should also have new design features:

- Modules can be retrofitted, e.g. B. for services or remote data transmission

- Uniform recording technology for meters

- Reduction of the counter spaces

- Uninterrupted meter change

- Reduction of assembly times.

Today, the term eHZ is primarily understood to mean the structural features. These are described in a specification by the VDE FNN . The eHZ is standardized in the electrotechnical product standard DIN V VDE V 0603-5. The eHZ is either installed on appropriately equipped meter positions or using adapter plates that are attached to the cross rails of the meter cabinets. The eHZ is attached to the meter using four retaining claws and electrical contact is made with plug-in contacts for the three phases and zero. So it can be changed without screws.

With the eHZ, the meter is changed without interrupting the power supply. This is done using sliding busbars that bridge the connection points of the meter when the meter is changed. While the meter is being replaced, there is an uncounted supply.

history

The billing of the actually used energy followed the electrification of industrial companies and households. First, a fee per "consumer" was charged e.g. B. charged per lamp without taking into account the actual energy consumption. This system led to energy purchases through subsequent installations, which were not offset. Electrical energy cannot be stored; constant generation would be necessary for high profitability. High earnings were from industry during the day and from households in the evening. The energy producers tried to make their installations more economical with cheaper tariffs during the night.

This was only possible with consumption-based registration and billing - the need for electricity meters also with tariffs became necessary.

Edison made the first “usable” electricity meter in 1880.

Populous countries like China and India have been trying for years to introduce household electricity meters across the board. The installation of electronic counters with payment systems based on chip cards is preferred.

See also

Web links

- Smart meter in pilot use at an energy supplier in Germany

- Lueger 1904: historical electricity meter at Zeno.org . In: Otto Lueger: Lexicon of the entire technology and its auxiliary sciences . 2nd Edition. tape 3 . Stuttgart / Leipzig 1906, p. 409-413 .

Individual evidence

- ↑ Kurt Bergmann: Electrical measurement technology . Electrical and electronic processes, plants and systems. Viewegs Fachbücher der Technik, Braunschweig / Wiesbaden 1981, ISBN 978-3-663-00008-2 , doi : 10.1007 / 978-3-663-00157-7 ( limited preview in the Google book search).

- ↑ G. Gruhn, A. Hebestreit: Taschenbuch der Messtechnik . Chapter 2: Measuring electrical quantities. Ed .: Jörg Hoffmann. Fachbuchverlag Leipzig at Carl Hanser Verlag, Munich 2015, ISBN 978-3-446-44511-6 (688 pages, limited preview in the Google book search).

- ↑ a b EU Directive 2014/32 / EU on the provision of measuring devices on the market , Annex V (p. 209), accessed on March 23, 2020

- ↑ Digital single-phase energy meter SDM120D for active consumption. ELV, accessed on March 23, 2020 (use of the term "active consumption" in an online catalog).

- ↑ Energy consumption meter . ABB , 2014, archived from the original on April 13, 2014 ; accessed on April 9, 2014 (energy consumption meter for active and reactive energy, state-of-the-art).

- ↑ VDN guideline - description of services for measurement and billing of network use. (PDF) Association of Network Operators V. - VDN - at VDEW , July 2006, archived from the original on June 5, 2012 ; Retrieved January 13, 2012 .

- ↑ Patent US1557931 : Electrolytic electricity meter. Published on October 20, 1925 , applicant: Jenaer Glaswerk Schott & Genossen , inventor: Max Grossmann.

- ↑ Directive 2014/32 / EU for measuring devices (MID) - information for users of electricity meters. (PDF) Gossen Metrawatt, accessed on May 10, 2018 .

- ↑ a b Calibration testing of electricity meters in accordance with Section 7h of the Calibration Ordinance (“MID meters”). (PDF, 175 KBytes) Physikalisch-Technische Bundesanstalt (PTB) , accessed on May 10, 2018 . Available under PTB test rules. (See “Volume 6: Electricity meters and additional devices”).

- ↑ Nikolaus Huhn: Calibration and error limits of electricity meters. Association of Energy Consumers, accessed on May 10, 2018 .

- ↑ Jörg Kirchhof: Limit value gap - inverter disrupts electricity meter. Fraunhofer Institute for Wind Energy and Energy System Technology , 2010 ( access to PDF file ), urn : nbn: de: 0011-n-1290049 , accessed on November 28, 2018

- ↑ Frank Leferin, Cees Keyer, Anton Melentjev: Static Energy Meter Errors Caused by Conducted Electromagnetic Interference . In: IEEE Electromagnetic Compatibility Magazine . tape 5 , no. 4 , March 1, 2017, p. 49–55 , doi : 10.1109 / MEMC.2016.7866234 (English, storage.googleapis.com [PDF]).

- ↑ Frank Dohmen: Smart electricity meters charge consumers too much. In: Der Spiegel . March 10, 2017, accessed March 25, 2020 .

- ↑ Hanna Decker: Intelligent electricity meters produce expensive measurement errors. In: FAZ.net. March 10, 2017, accessed March 10, 2017 .

- ↑ Press release of the PTB of March 13, 2017 on measurement errors in electronic electricity meters. PTB, March 13, 2017, accessed on February 18, 2020 .

- ↑ N. Nüssel, H. Senkbeil: Meter places for electronic household meters (eHZ). (pdf; 214 kB) In: Electrical practitioners . March 1, 2005, accessed February 20, 2020 .

- ↑ Specification eHZ. Electronic household meters in plug-in technology, structural features. (pdf; 420 kB) VDE FNN, January 11, 2010, accessed on February 20, 2020 .

- ↑ A. Jungfleisch: Standards situation at the eHZ. (pdf; 82 kB) Elektropraktiker, April 5, 2007, accessed on February 20, 2020 .

- ↑ Information on electronic household meters and uninterrupted meter replacement. (pdf; 1.2 MB) RWE Rhein-Ruhr distribution network, July 16, 2008, accessed on February 20, 2020 .

- ↑ Matthias Wiesmann: Karl Heinrich Gyr (1879-1946): the development of the global company Landis & Gyr . Association for Economic History Studies, Zurich 2012, ISBN 978-3-909059-57-7 .

- ^ CHW Gerhardi: Electricity meters: their construction and management . "The Electrician" Printing and Publishing Company, London 1906.

- ↑ Etienne de Fodor: The electrical consumption meter . A. Hartleben Verlag, Vienna / Pest / Leipzig 1891.