Bench construction

The Strossenbau is a decomposition method in which the minerals of a reservoir in horizontal slices from top to bottom won be. The name of this process is based on the fact that the sole , also called the bench, is always processed. The bench construction is the oldest mining method for gang ore mining . It was the typical mining method before the 18th century and its execution is the reverse of the roof structure . It is suitable for ore veins with solid host rock . But this method is also suitable for plate-shaped deposits. The bench mining was also often used as a mining method for steep ore veins in order to move from open pit mining to underground mining .

Basics

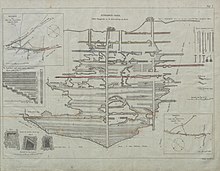

The mining of bench construction is like a staircase and takes place between a lower and an upper part of the deposit. The respective levels are referred to as bench. Each bench has a height of about one laugh . The miner calls the vertical boundary of the bench the forehead or chest. The miner calls the sloping surfaces a push . The horizontal surfaces are known as berms , which are two to three laughs wide. The miner calls the boundary of the bench in the horizontal plane the bottom. When building a bench, mining is done from top to bottom. The respective lower bench runs several meters ahead of the next above bench. When building a bench, the miner has the mineral under him. If the deposit extends beyond days, bench construction can already begin above ground and gradually move to underground construction. It is therefore advantageous when building a bench that you can start dismantling immediately as soon as a suitable means is found. When used in underground construction, there are single-wing and double-wing bench construction. With this method, each push takes the push of the previous and next higher push into account . As the mining progresses, a staircase is created that is constantly being given new additional steps in the lower part of the deposit. Depending on the deposit, these stopes are several meters high. In early mining, the stops were formed at right angles by setting fire , today the edges of the bench are provided with obtuse angles. In reservoirs with a water inflow, the bottom is slightly inclined so that the water can drain off better.

Application in underground mining

The procedure

In order to develop a mining field in bench construction, one or more cut-offs are first created. As a rule, cutting off is sufficient. From this cutting off, the dismantling can be carried out with one or two wings. The two-wing construction is used when the cutting is in the middle of the mineral body. Starting from the cut off, the individual stopes are set. The first cut begins with the cut of an approximately cube-shaped body. Once this body has been won in, the stopes are removed alternately. First the stopes are dismantled by brushing , then by falling. The direction of mining is decreasing in bench construction, the direction of prevention is striking . The extraction of each individual stope is directed downwards.

So that the cavities created during dismantling do not become too large, each new joint must be provided with a permanent extension . The mountains produced during mining are suitable for this. Wooden boxes are made to move the mountains . With this method, the conveying direction is upwards, as is the drainage. A system of weather doors is required for ventilation . With this mining method, the loss of ore on the pending bench is low, which is why this method is also suitable for mining smaller ore deposits. Since the sole can be swept clean and thus losses are largely avoided, this process can also be used for the mining of precious ores.

Offset

If the Strossenbau in deposits with less solid stand Mountains used, must the working space with offset to back up. For the recovery of the mountains, specially manufactured boxes are required, in which the resulting mountains are placed. These constructions, known as bench boxes , are created by covering rows of pit wood with planks and filling them with offset mountains. The stop boxes are also used at the same time to remove as little overburden as possible and to keep the ore yield as high as possible. The mountains are sorted out underground and put in the recovery boxes . When a recovery box is full, it is closed with wood. If there is not enough landfall, the wooden boxes are built in such a way that smaller amounts of tailings can be used. Sometimes the areas are only secured with wood. In order to have enough space for the conveyance between the individual bench boxes, the boxes are cut out. In order to ensure the ventilation of the respective mine workings, the individual sections are provided with weather doors or weather barriers .

Disadvantages of the procedure

A major disadvantage of bench construction is the high consumption of pit wood , which is required for the construction of the recovery boxes. This results in high labor and material costs. Further disadvantages are the reversal of the conveying direction and the complicated dewatering . The pit water cannot simply flow out of the pit , but is fed into channels up to the shaft and pumped out of the pit with hand pumps or buckets . A disadvantage of the promotion is that gravity cannot be used to transport the debris . The pile can initially slide down to the lowest point. From there, however, it has to be promoted up to the bottom while being thrown. This mining method is less suitable for use in coal mines, as the coal would literally crumble due to the weight of the miners standing on it.

Sidestroke construction

The side wall construction is a variant of the bench construction for mighty corridors for which the transverse construction is not suitable. From a height of two laughs , the corridor is divided into several strips, which are then dismantled individually. Start with the bottom strip. Sidestroke construction was used in the Sauberg tin mine near Ehrenfriedersdorf . There was an ore deposit there with very mighty tunnels that had been mined by setting fire. Since the dismantling of the hall bands was also worthwhile, the side shells were obtained by building side rams.

Bench construction

This mining process is a downward form of shock construction. It is used in seam-like deposits where the collapse is so great that the shock construction can no longer be used. The method is also well suited for less stable adjacent rock. In addition, this process can be used to win in suspended levitation and festivities. When using bench construction, new extraction points are created without the need to create a new, deeper floor . The process can be adapted to the conditions of the respective deposit. The working direction is backward in this process, the Verhiebrichtung stroking. The high output is advantageous with this method, but the disadvantage is that the use of this mining method results in high costs.

Application in opencast mining

Today bench mining is usually used in open-cast mining . It is used in open-cast mining, especially in lignite mining. In the 19th century, bench construction was used in the Bensberg ore district to mine lignite in open-cast mining. In open pit mining, bench construction is also very often used in quarries . To use bench construction in open-cast mining, the deposit is first prepared by removing the top layer. This is usually done with scrapers and dragline excavators; other work machines are bulldozers and shovel loaders. The overburden created in this way is deposited on heaps . The alignment is then carried out on the mountain slope by cutting into dismantling discs and then on the level by building a deep bench. In quarries, the individual stopes are drilled at an inclined angle, this is done by rotary drilling with large drilling machines. The boreholes are then filled with explosives and the rock is blasted. The extracted rock is loaded away with wheel loaders and excavators. Extraction machines such as bucket wheel excavators or continuous surface miners are used in lignite mining today . The conveyance takes place over long conveyor belts .

Individual evidence

- ^ Tilo Cramm, Joachim Huske: Miners' language in the Ruhr area. 5th revised and redesigned edition, Regio-Verlag, Werne 2002, ISBN 3-929158-14-0 .

- ↑ a b c Fritz Heise, Fritz Herbst: Textbook of mining science with special consideration of hard coal mining. First volume, published by Julius Springer, Berlin 1908

- ↑ a b c d e f Wilfried Ließmann: Historical mining in the Harz. 3rd edition, Springer Verlag, Berlin and Heidelberg 2010, ISBN 978-3-540-31327-4 .

- ↑ a b c d e f g h Ernst-Ulrich Reuther: Textbook of mining science. First volume, 12th edition, VGE Verlag GmbH, Essen 2010, ISBN 978-3-86797-076-1 .

- ↑ Hans Höfer: Paperback for miners. Second improved and increased edition, KK Bergakademische Buchhandlung Ludwig Nüssler, Loeben 1904

- ↑ E. Frey (Ed.): Luegers Lexicon of the entire technology and its auxiliary sciences. First volume A to drilling, third completely revised edition, Deutsche Verlags-Anstalt Stuttgart, Berlin and Leipzig 1926

- ↑ a b c d e f g h i j k l m Albert Serlo: Guide to mining science. First volume, fourth revised and up to the most recent edition supplemented, published by Julius Springer, Berlin 1884

- ↑ a b c Herbert Stahl (editor), Gerhard Geurts , Hans-Dieter Hilden, Herbert Ommer : Das Erbe des Erzes , Volume 3, The pits in the Paffrather Kalkmulde . Bergisch Gladbach 2006, ISBN 3-932326-49-0 , p. 103f.

- ↑ Wolfgang Reichel, Manfred Schauer: The Döhlener basin near Dresden, geology and mining. Saxon State Office for Environment and Geology (LfUG), Saxoprint GmbH Dresden, Dresden 1983, ISBN 3-9811421-0-1 .

- ^ A b c Heinrich Veith: German mountain dictionary with evidence. Published by Wilhelm Gottlieb Korn, Breslau 1871

- ↑ a b c d Gustav Köhler: Textbook of mining science . 2nd edition, Wilhelm Engelmann, Leipzig 1887

- ↑ a b c d e f g h i Georg Spackeler, Waldemar May: Bergbaukunde . 8th training letter for dismantling II. Ed .: Main Department of Distance Learning at Bergakademie Freiberg. 2nd Edition. Deutscher Verlag der Wissenschaften, Berlin 1957, p. 8 / 13-8 / 20 .

- ↑ a b c Rolf Dieter Stoll, Christian Niemann-Delius, Carsten Drebenstedt , Klaus Müllensiefen (eds.): The lignite mine, meaning, planning, operation, technology, environment. 1st edition, Springer-Verlag Berlin Heidelberg, Berlin 2009, ISBN 978-3-540-78400-5 .

- ^ A b Albert Serlo: Supplementary volume to the guide to mining science from Lottner-Serlo. Published by Julius Springer, Berlin 1872

- ^ Emil Stöhr, Emil Treptow : Basics of mining science including processing. Spielhagen & Schurich publishing bookstore, Vienna 1892

- ^ A b Wilhelm Leo: Textbook of mining science. Printed and published by G Basse, Quedlinburg 1861

- ↑ a b c d Henrike Sievers: The influence of deposit properties on the sustainable use of raw materials using the example of copper. Dissertation 2005, Rheinisch-Westfälische Technische Hochschule Aachen

- ^ A b Förderverein Rammelsberger Bergbaumuseum Goslar eV (Hrsg.): Ore mining in the Rammelsberg. Self-published by the Förderverein, Druck Papierflieger Clausthal-Zellerfeld, Goslar 2009

- ↑ a b c Ernst-Ulrich Reuther: Introduction to mining. 1st edition, Verlag Glückauf GmbH, Essen, 1982, ISBN 3-7739-0390-1 .

- ↑ a b Federal Association of the German Lime Industry eV (Hrsg.): Kalk Kompendium.

Web links

- Geo and environmental portal Freiberg: Schematic block diagram with bench construction (last accessed on February 21, 2013)

- Saxon regional association of miners, smelters and miners' associations on the topic of bench construction (last accessed on February 21, 2013)