Environmental protection in maritime shipping

The environmental protection in shipping internationally often called Green Shipping called, has grown in importance for several decades.

The engines of ocean-going vessels emit exhaust gases into the atmosphere and liquid and solid waste from ships into the sea . There are ecosystems in the sea (see also marine protection ).

Various legal agreements and voluntary initiatives contain rules on this pollution. There are numerous shipbuilding concepts that aim to make ship operation more environmentally friendly. When ships go faster, their fuel consumption increases exponentially. In view of the high oil prices, slow steaming is worthwhile for many ocean-going vessels .

Overview of the environmental pollution caused by shipping

Marine propulsion

The Maritime is by far the largest carriers of the world economy . Without them, globalization would not have been possible since World War II. In 2000, shipping provided a transport performance of around 42,500 billion ton-kilometers. At 5–10 g / t km, their specific energy consumption (= SEC = energy consumption per ton and transport kilometer) is far lower than that of other means of transport such as cargo aircraft (400–600 g / t km), railways and trucks. In contrast, the transport speed is relatively low. The extremely high fuel prices in the past 10–15 years (1999 = $ 60 / t heavy fuel oil; 2013 = $ 600 / t heavy fuel oil) have resulted in e.g. B. container ships drive more slowly and thus consume significantly less fuel. In addition, measures are taken to reduce propulsion power through propulsion-improving measures (guide surfaces in front of and behind the propeller) and friction reduction ( air lubrication ).

Marine diesel oil has a relatively high sulfur content; the exhaust gases from marine diesel engines therefore contain a lot of sulfur dioxide . The sulfur content of heavy oil averages 2.5 percent. A low specific energy consumption also means a low CO 2 pollution; In the case of drives with internal combustion engines, the CO 2 emissions are roughly proportional to the fuel consumption by a factor of 3. The NO x emissions and the sulfur dioxide emissions depend on the combustion process and the sulfur content in the fuel; they can be directly influenced by the type of fuel.

In shipping, as with other modes of transport (cars, trucks, planes, railways), environmental pollution occurs through exhaust gases, waste, oil, sewage and chlorofluorocarbons, nitrogen oxides, CO 2 and sulfur dioxide in the exhaust gas. The maximum NO x emissions have been regulated by an IMO regulation since 2000 . The manufacturers of marine engines such as MAN B & W , Wärtsilä / Sulzer AG , Mitsubishi , MaK , MTU , Deutz and others have researched various processes and further developed their engines accordingly. Modern engines meet these regulations by controlling the internal combustion of the engine. Higher requirements are achieved through direct or indirect addition of water and the highest requirements through measures external to the engine, e.g. B. with a downstream catalyst or exhaust gas recirculation .

In "Kohler, HW. Assessment of NOx emissions by the global shipping ship and port, No. 11/2002," the result of a survey carried out by MAN B & W study is the worldwide NO x Environmental Burden by shipping shown. The basis of this study were the emission characteristics of the main and auxiliary machines of ships, realistic boundary conditions for the operation such as duration of use, load, type of fuel and real specific fuel consumption of the engines. More than 90,000 ships larger than 100 GT are registered worldwide, with 117,000 propulsion engines with a total nominal output of 286 million kilowatts, i.e. H. an average of 3,200 kilowatts of drive power per ship. A nominal output of 30 million kilowatts was specified for the auxiliary engines.

The result of this study was that international shipping consumed around 282 million tons of fuel in 2001 and, with 23.5 million tons of NO x, caused about 15 percent of man-made global NO x emissions. The annual global NO x emission was around 195 million t, around 156 million t of which were caused by humans through industry, traffic and house fires . Shipping and air traffic contributed a total of 26.4 million tons.

The sulfur dioxide emissions of the ship's engines depend on the fuel used. In shipping today, it is predominantly highly viscous heavy oil that is burned, which is heated to 100–140 ° C in order to achieve the required injection viscosity. A cheap fuel, the price fluctuated between 1999 and 2009 between 60 and 600 US dollars / ton (equivalent to 0.06-0.60 US dollars per liter). The alternative would be marine diesel oil (MDO) , which is almost twice as expensive, or low-sulfur heavy oil with 0.6–0.9 percent sulfur, which is offered at many bunker stations for a surcharge. All of these fuels have so far been tax-free due to cross-border traffic and the lack of unity among the global community. According to the International Maritime Organization (IMO), heavy fuel oil may contain up to 4.5 percent sulfur, the average sulfur content is around two to three percent.

With the help of the fuel used by shipping (mainly heavy fuel oil), the CO 2 and SO 2 emissions can also be roughly determined. In 2001, around 800–900 million tons of CO 2 and 10–14 million tons of sulfur dioxide were released into the atmosphere by ships with a sulfur content of two to three percent in the fuel. Lloyd's Register of Shipping reported 10 million tons of SO 2 per year and 9.3 million tons of NO x per year .

As part of an AiF research project at the Technical University of Hamburg-Harburg , various methods for NO x reduction on ships were compared. An aid was drawn up with which shipyards and shipping companies receive clear decision-making criteria for equipping or retrofitting their ships to reduce pollution.

Sulfur reduction

At the end of 2009, a desulphurisation system was installed on the Timbus , a ship owned by the Rörd Braren shipping company from Kollmar, to test the system in sea operation. Here, as part of a research project by the TU Hamburg-Harburg and the 'Couple Systems GmbH', investigations are being carried out on flue gas desulphurisation in real ship operation. This is a "dry process" that has proven itself in land power plants. Two other processes in ship technology are called "wet processes"; they work with fresh water or sea water.

At the beginning of 2010, the manufacturer Alfa Laval Aalborg BV installed a desulphurization system based on the wet system on board the “Tor Ficaria” of the Danish shipping company “ DFDS Tor Line ”. This hybrid system can be operated with fresh water or with sea water. The wet scrubber cleans the exhaust gases passing through the main engine of type MAN B&W 9L60MC-C (total output around 21 megawatts).

Oil sludge

Even if the spectacular accidents such as Exxon Valdez , Erika or Prestige shake up the public at regular intervals, the illegal disposal of oil residues is also a major burden on the environment. The oil residues on the ships mainly arise when cleaning the heavy fuel oil. Around one percent (around 2.8 million tons worldwide) of the heavy fuel oil remains as oil sludge after separation and filtering . Oil sludge is also produced when cleaning lubricating oil and removing oil from bilge water. With Bilge the deepest areas are referred to in the machine and holds that collect on the two sides of the ship condensate and leakage of water. There is a mixture of sea water, fresh water, heavy oil, lubricating oil, cold cleaning emulsions and dirt in the engine room bilges. This mixture, known as bilge water, used to be pumped outboard with a bilge pump .

A bilge water de-oiler is now prescribed for cleaning , which removes the oil from the bilge water. A residual oil content of 15 ppm is permitted, i.e. H. 15 grams of oil per 1,000 liters of bilge water. This limit value is specified by the MARPOL system I and is monitored by a measuring device. If the limit is exceeded, an alarm is triggered and the outboard valve is closed. The amount of bilge water that arises depends on the type and size, but also on the condition and age of the ships. The IMO calculates an average of around 2–3 m³ per ship per day, which is extrapolated to 1,000–1,500 t of oil sludge per ship and year.

Since not all systems work properly and higher limit values apply to oil tankers, the real value is significantly higher. The oil sludge is collected in sludge tanks and delivered to the port if the appropriate infrastructure is in place. An experienced captain described that this is not always the case. But the disposal costs are also a reason to illegally dispose of oil sludge in the sea, although oil diaries with entry of the bunkered fuels and disposed of oil sludge are required.

Ballast water

With their ballast water, which is necessary for ship stability, ships carry organisms such as small fish, plankton or even germs around the world. In this way, numerous alien species have now settled in places around the world where they were not originally at home. The follow-up costs for damage caused by introduced organisms can hardly be quantified, but the immigration of invasive organisms creates problems in their new areas of distribution, because they often assert themselves initially unhindered by local competitors, predators and parasites and, in the worst case, uncontrolled can multiply.

In 2004 the IMO passed the international ballast water convention , which is expected to come into force in the next few years. Two standards are defined, in the so-called Ballast Water Exchange Standard , ballast water absorbed on the high seas at a distance of at least 200 nautical miles from the nearest coast and at a water depth of at least 200 meters must be exchanged in such a way that a volumetric exchange rate of at least 95 percent is achieved .

The Ballast Water Performance Standard regulates the number of aquatic organisms and bacteria in the ballast water to be exchanged, so that ballast water management, i.e. H. the treatment of ballast water is unavoidable. In practice, ballast water can be exchanged using three different methods. The ballast water treatment systems can be divided into mechanical, physical and chemical processes according to their operating principle. In general, these methods are used in combination. For example, mechanical filters are combined with UV lamps (physical) and / or lethal chemicals. In all systems, electrical or thermal energy must be used for ballast water treatment. In addition to this additional energy generation in the form of electricity, the use of chemicals in some processes leads to an increase in the operating costs of a ship.

Sewage

The literature gives about 600,000 to 800,000 crew members for the roughly 90,000 ships involved in cargo shipping. There are 40 to 60 million man-days on the approximately 400 passenger ships, which, taking into account the crew, can be converted into 200,000 to 250,000 permanent persons. This results in a total of around 1 million people in commercial shipping whose garbage and sewage have to be disposed of. Not included are the fishing fleets, the island trip close to the coast and the pleasure boat trip with their countless sailing and motor boats.

For wastewater treatment, the shipbuilding supply industry has developed compact biological wastewater systems which are now state of the art and have been installed on almost all seagoing vessels. For particularly protected marine areas such as B. the polar regions systems with the highly effective membrane technology are required. The first generation has proven itself in on-board use. For example, there is a compact system on the research vessel Polarstern .

Garbage disposal at sea

Until well into the 1980s, industrial waste such as dilute acid was dumped in the North Sea or chemical waste was incinerated at sea. The disposal of industrial waste has now been banned. The industrial incineration of land waste at sea is also a thing of the past. Small waste incineration plants for disposing of the waste generated on board can still be found on most of the seagoing vessels. In this area, too, the guidelines to be complied with have become stricter, but a general ban is not in sight for the time being, despite individual efforts.

Antifouling paints

TBT is the abbreviation for tributyltin compounds . The dangers of TBT-containing antifouling paints on the underwater hull have been proven; the IMO ( International Maritime Organization ) decided in October 2001 to ban them. Since January 1, 2003, they are no longer allowed to be used. TBT-free paints containing copper and other biocides have been developed. In addition, biocide-free coatings are developed and used; they have a lifespan of 24 to 36 months. New coatings containing TBT have been prohibited since January 1, 2003, and since 2008 they are no longer allowed to be contained in the blasting material of shipyards .

CFC / Halon ban

The Montreal Protocol of 1987 regulates the renunciation of ozone-depleting substances. On May 6, 1991 the ordinance banning certain halogenated hydrocarbons that deplete the ozone layer ( CFC-Halon Prohibition Ordinance ) came into force in the Federal Republic of Germany, which prohibits the use and storage of halons since the expiry of the use-by period on December 31, 1993 prohibited (the ordinance was replaced on December 1, 2006 by the chemical ozone layer ordinance ). The previously used halon fire extinguishing systems have since been banned.

The use of the refrigerants R12 and R22 is also to be ended according to this regulation, and a conversion to the more environmentally friendly R134a and other products has been carried out. Ammonia , which was previously used but has since been banned due to its toxicity, but is more environmentally friendly , has been re-approved and used on some ships.

Ship demolition

The majority of the ship tonnage scrapped worldwide is scrapped in Asia on flat beaches - not in demolition yards. The type of scrapping practiced there using the simplest means, numerous pollutants enter the environment. The IMO is making efforts to create uniform conditions for dismantling ships worldwide. The EU is also dealing with the issue. The goal is a more environmentally friendly dismantling of the decommissioned ships in the previous substandard dismantling centers. At the same time, this complex of topics is closely linked to the creation of safe working conditions in the shipbuilding yards.

Two factors have contributed to the high number of ship demolitions since 2009: on the one hand, new large ships are displacing smaller old ships; On the other hand, in many segments of the merchant shipping there has been a shipping crisis that has persisted since mid-2008 , which means that (unlike in boom years) the relatively small older ships can hardly find employment. With scrap prices of around US $ 500 per ton (as of 2012), ship owners also get (sometimes urgently needed) liquidity; some of them can no longer afford to temporarily shut down ships in the hope of better times .

International legal agreements

The International Maritime Organization (IMO), a sub-organization of the UN, has ensured that internationally binding rules for maritime environmental protection have been drawn up. These rules, such as B. the International Convention for the Prevention of Pollution from Ships by Ships from 1973, 1978 (Marpol 73/78; Marpol = Marine Pollution) must be observed by the shipping nations. This rule was supplemented and updated with the rules for reducing pollutant emissions. The Helsinki Agreement (1974) protects the marine environment of the Baltic Sea and its accesses, and the OSPAR Agreement (1992 ) protects the marine environment of the North Atlantic and the North Sea. The Montreal Agreement (1987) for the protection of the atmosphere regulates the production and use of ozone-depleting substances ( halon , CFC ). Another important element was the adopted by the IMO on 13 February 2004 Convention for the Control and Management of Ballast Water and Sediments from ships created (International Convention for the Control and Management of Ships Ballast Water and Sediments).

For these rules to come into force, they must at least be ratified by the states that hold the majority of the international tonnage. These international regulations were created as a global legal framework. The monitoring is carried out by national authorities such as B. the classifications, the trade associations and the port state controls.

The 'Maritime Environment Protection Committee' (MEPC) of the IMO decided in mid-2013 to change the MARPOL convention so that the stricter nitrogen oxide limit values (NOx) for shipping according to Tier III should not come into force until 2021 instead of 2016. This was justified with the allegedly insufficient level of development of the corresponding technologies. In fact, the MEPC had a report from an IMO working group in which a sufficient number of application-ready technical solutions for NOx reduction (such as scrubbers, SCR systems or LNG drives) are documented.

Initiatives on a voluntary basis

Blue Angel for seagoing vessels

The Cellus received on 21 November 2002 as the first commercial ship in the world the Blue Angel , an eco-label, which is now known by many environmentally friendly products. The Blue Angel for environmentally friendly shipping is awarded by the Federal Environment Agency and places high demands on the shipowner, the crew and the ship with its technical equipment. Requirements are good personnel management , optimal safety management , well functioning waste management , treatment of waste and bilge water , CFC-free refrigerants, TBT-free underwater paint and lower sulfur and nitrogen oxide emissions in the exhaust gases. All of these requirements are checked, approved, evaluated and documented by experts.

The Cellus is a ship owned by the shipowner Rörd Braren from Kollmar . Two sister ships of the Cellus ( Timbus and Forester ) were equipped with an SCR catalytic converter in the course of their construction.

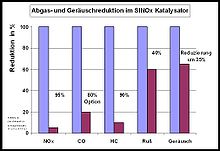

On the three identical vessels exhaust aftertreatment takes place in a catalyst: in ceramic elements from titanium oxide is urea injected. The system known as SCR (Selective Catalytic Reduction) reduces the nitrogen oxides in the exhaust gas, the unburned hydrocarbons (HC), soot particles and noise emissions. This system was supplied by Siemens AG, which developed this technology under the name SINOx for power plants. Around 80 systems have been used in shipping to date.

The Blue Angel for environmentally friendly shipping can be seen as a paradigm shift (award, not penalty).

Shipping companies around the world have been struggling with a shipping crisis since August 2008 ; since then, environmental protection has been practiced by means of slow steaming . Many ships only have a lifespan of 20 to 25 years, depending on the market situation; Against this background, it is so far (as of 2012) unlikely that an owner will retrofit an SCR catalytic converter in a used ship.

HELCOM

The HELCOM is an intergovernmental Commission of Baltic Sea States, pronounce what recommendations to protect the Baltic Sea. The bonus systems implemented in this context in Sweden, for example with graduated port fees, are encouraging ship operators to rethink their approach. The difference in fees of up to EUR 6,000 for calling at a Swedish port between conventional and environmentally friendly ships is a key incentive for environmental protection.

Green Ship of the Future

The Green Ship of the Future initiative, founded in 2008, is an association of currently fifteen Danish participants from the maritime industry, including companies such as AP Møller-Mærsk , Odense Steel Shipyard , MAN Diesel and Aalborg Industries and several Danish universities, such as the Technical University of Denmark . The project is concerned with the development of technologies with which substantial emission reductions can be achieved in maritime shipping. The desired goals are a reduction in carbon dioxide emissions by 30 percent and a reduction in nitrogen oxide and sulfur emissions by 90 percent each.

Trend towards larger ships

Large ( VLCC ) and very large ( ULCC ) oil tankers (“supertankers”) have been built since 1966. ULCC tankers are 320,000 to 550,000 dwt; Lloyd's Register of Shipping names (July 2011) 300,000 dwt as the limit. For example, four ULCC large tankers were built in France in the mid-1970s ( Batillus class : Lüa 414.22 m, width 63 m and 273,550 GRT). The longest tanker to date was created by lengthening a tanker built in Japan in 1975/76 by 81 m to a length of 458.45 m (for more see tanker # increase in size ).

The size of newly built container ships has increased enormously since the introduction of this type of ship (see container ship # generations ). A 13,000 TEU ship emits around 8 grams of CO 2 per tonne-kilometer .

See also

literature

- Hochhaus, K.-H .; Mehrkens, C .: Ballast water treatment on seagoing ships - an overview , Schiff & Hafen 2006

- Hochhaus, K.-H .; Isensee, J .: Blue Angel for Cellus - Environmental Aspects in Worldwide Shipping . People & Technology (VDI / VDE) No. 2/2003.

- Michael Vahs: “Green Ship” as a future task in: Schiff & Hafen , Vol. 62, No. 1, January 2010, pp. 34–37

- Alexander Proelß / Killian O'Brien: International and European law requirements for exhaust gas emissions from seagoing ships (PDF file; 284 kB), in: Journal of Public Law in Northern Germany (NordÖR) 2011, 97.

Broadcast reports

- Hermann Vinke : Climate killer shipping - How "Green Shipping" is supposed to change seafaring , Deutschlandfunk - " Background " from August 25, 2018

Web links

- Link page to various maritime environmental protection issues (English)

- International Consortium for Green / Clean Shipping: The International Association for Catalytic Control of Ship Emissions to Air

- Blue Angel for the CELLUS

- Approaches to the Realization of Green Shipping (2010, 17 p., Institute for Shipping Economics and Logistics ; Excerpt from: Maritime Economy - Theory, Empiricism and Politics: Festschrift for the 65th birthday of Manfred Zachcial , 2010, ISBN 978-3-631-60960 -6 ; PDF; 250 kB)

- Air lubrication for ships: Air lubrication for ships

Individual evidence

- ↑ Christoph Thielen and Horst Rulfs : Reducing nitrogen oxide emissions on ships, ships and ports , No. 4/2008. Detailed: Final report AiF 14640N, comparative studies of various methods for NOx reduction on ships. ( Memento from February 2, 2014 in the Internet Archive )

- ^ FAZ January 19, 2010: The cleanliness at sea demands a high price

- ↑ Danish Ministry of the Environment : Exhaust Gas Scrubber Installed Onboard MV Ficaria Seaways (pdf, 31 p .; 848 kB)

- ↑ More than one year in operation ( page no longer available , search in web archives ) (experience report; presentation)

- ↑ Schwarzer, J .: The disposal problem on ships in ports from the perspective of the shipowner; Yearbook of the Shipbuilding Society , 1998

- ↑ Henckeroth, J .: Illegal disposal of oil residues; Engineer Journal, Jan./Febr. 2003

- ↑ Procedure for ballast water treatment

- ↑ Hochhaus, K.-H .; Mehrkens, C .: Ballast water treatment on seagoing ships - an overview, Schiff & Hafen 2006

- ↑ No more ship coatings with TBT , Greenpeace, January 2, 2003.

- ↑ Beluga measures maximum values of TBT in the silt around shipyards on a tour through the ports of the North Sea and Baltic Sea ( Memento from July 16, 2013 in the Internet Archive ), Greenpeace.

- ↑ Höft, H .: The use of CFC-containing refrigerants; Yearbook of the Shipbuilding Society 2000

- ↑ HANSA: Thanks to the shipping crisis, the scrapping industry is flourishing ( Memento from July 5, 2013 in the Internet Archive ) (published in HANSA 6/2012).

- ↑ Resolution MEPC.235 (65), adopted on May 17, 2013: Amendments to the annex to the 1978 Protocol to the 1973 International Convention for the Prevention of Pollution from Ships (amendments to Forms A and B of the supplements to the IOPP certificate according to annex I of MARPOL) BGBl. 2014 II pp. 709, 710

- ↑ Nikos Späth: Mistakes of the IMO ( Memento from July 8, 2013 in the web archive archive.today ), Editorial HANSA 07-2013, Hansa - International Maritime Journal .

- ↑ Peer Schmidt-Walther: Green seafaring under "Blue Angel". Awarded the environmental Oscar. In: Ders .: Freighter trips. As a passenger on board. Koehlers Verlagsgesellschaft, 2nd revised edition, Hamburg 2010, pp. 36–41, ISBN 978-3-7822-1016-4 .

- ↑ a b Strassmann, B .: Clean at sea; Ingenieur Journal, Jan./Feb. March 10, 2003

- ↑ Blue Angel

- ↑ Hums, E .; Römich, H .; Fraunhoffer, H .: Operating Experience on Urea-SCR Technology for Marine Diesel Engines; STG lecture Wilhelmshaven, 2000

- ↑ website of Green Ship of the Future (English)

- ^ Vessel size groups . On: people.hofstra.edu

- ↑ Infosheet No. 30 - Modern ship size definitions ( Memento of February 4, 2012 on WebCite ), Lloyd's Register (PDF; 222 kB).

- ↑ Large ships - efficiency in every detail ( Memento from September 24, 2015 in the Internet Archive ), Association of German Shipowners .