Apfelbaumer train

| Apfelbaumer train | |||

|---|---|---|---|

| General information about the mine | |||

| Rare minerals | Dolomite , rhodochrosite | ||

| Information about the mining company | |||

| Employees | 387 (1905) | ||

| Start of operation | before 1720 | ||

| End of operation | 1908/1927 | ||

| Funded raw materials | |||

| Degradation of | Iron ore | ||

| Greatest depth | 700 m | ||

| Geographical location | |||

| Coordinates | 50 ° 48 '55 " N , 7 ° 57' 14" E | ||

|

|||

| Location | Brachbach | ||

| local community | Brachbach | ||

| District ( NUTS3 ) | Altenkirchen | ||

| country | State of Rhineland-Palatinate | ||

| Country | Germany | ||

| District | Daaden-Kirchen mountain area | ||

Apple Baumer train was the largest iron ore mine in the municipality Brachbach in district Altenkirchen in Rhineland-Palatinate .

History of the apple tree pit

First mention and early years

The pit was first mentioned in a report from the Freusburg office to the Altenkirchen privy councilor Henrich von Griesheim in 1720:

"! 720 martii 6. the merchant Joh. Valentin Reuschen zu Siegen filius, who wanted to go to churches in his father's affairs, was shot badly from an ambush near Brachbach near the Ertzgrube Apfelbaum."

In 1741, the official actuary Lamprecht reported about an iron ore mine called "Apple Tree". For the first time, statistical information from the year 1803 gives precise information about the approved iron ore mining. After that, the first mining permit comes from the year 1794. The mining took place along the gangway in Pingen and day shafts from a depth of a few meters and lasted only for a few years. In 1835, one of reported Mudersbach originating Johannes Hellinghausen the mine fields "Apple Tree", "apple tree branch duct", "cherry tree" and "fox" in the dept. For the mining, metallurgical and Saline essence of the Finance Ministry in Berlin to the presumption of. On October 17, 1836 , these consolidated into the "Apple Tree Pit". By February 20, 1850, the fields "Young Apple Tree", "Pear Tree", "Nussbaum" and by February 26, 1861 the fields "Neue Fortuna", "Plum Tree", "Eichbaum" and "Tannenbaum" were added. In 1861 (another source: 1841), the trades of the mines "Apple Tree", "corner" and "Kuhle Walder train" for creating a resolutely in Siegtal accreting Community basic tunnel for water solution and promotion . The mined ores were transported from the mine dump with horse carts to the Niederschelden train station.

Sale to the Stein company

Around 1870 the "Grube Consolid. Apfelbaum" was bought by the Stein industrialists from Kirchen for 120,000 thalers. In the following time the first roasting ovens were built on the heap of the Grundstollen . From 1871 onwards, the installation of the Brachbach loading station on the Sieg line eliminated the cumbersome transport to Niederschelden. The ores were transported via a narrow-gauge railway through the "Buhlenkamp" and via the so-called "Hohen Brücke" directly to the railway.

Around 1880 the Apple Tree Union decided to sink a shaft. The starting point for this was on the northwest slope of the Windhahn <s, around 80 meters above the valley of the Sieg . With the design of the surface installations was Siegen engineer and later member of parliament Henry Macco commissioned. A new shaft building with a machine and boiler house was built within two years . Equipped with the most modern machine technology at that time ( water holding and hoisting machine , two steam boilers and a feed water reservoir), the "Apfelbaum" pit became one of the most efficient mining operations in the vicinity.

In 1882 the shaft was sunk to the bottom of the Erbstollen, which was 74 m deep , and was operational. In 1884 the second underground level was prepared in 154 m depth and the alignment started. 1890, just ten years after Teufbeginn who had Schacht already m a depth of 234 and the apple Baumer courses on the 4th floor were in loss. In 1896 was finally m at a depth of 314, the sixth sole Prepared.

To increase due to the insufficient profitability of mining operations apple tree and the idea that capacity through consolidation with the surrounding mining operations area and Kuhle Walder train that made union president Otto Stein in 1896 by the Niederscheldener Steiger James Achenbach reports create all three mines. Another expert opinion was commissioned from Ferdinand Lück, who came to the conclusion on March 30, 1896:

"... that in my opinion none of the 3 named pits Apfelbaum, Ecke and Kuhlenwalder Zug operated individually on one of the invested capital - purchase of the pit, production of the shaft, machine, boiler, pump, dump and roasting furnace systems - The operation becomes too expensive for each individual pit, as each of them sinks the machine shaft, breaks the filling point, hacks cross-passages and the necessary machine, pump, steam boiler and dump or processing and Must build and maintain roasting furnace systems. There is also now double administration, supervision, etc., so that one can assume that half of the total general expenses could be saved with only one civil engineering system for the three pits mentioned. "

History of the pit corner

Early years

The beginning of mining activities was initially limited to day shafts of shallow depth and pinging. Evidence of this is given in the minutes of an award from the year 1772. The private persons involved in mining at this point from their own resources as a sideline for agriculture only have to have earned insufficient income from the Eisenstein found there. In any case, there is no other explanation for the fact that dismantling came to a standstill a short time later. From 1827 it was Mudersbacher Muther who saw a chance for themselves in the battered ore veins and so it was the trade Johann Zöller who reported the first mine field with the name "Oberste Ecke" on November 29, 1827. On February 17, 1829 the mine ownership was granted. During the alignment work, minable cobalt corridor sections were found. And because the mining permit only allowed the mining of iron ore, the Ministry of Finance in Berlin asked to expand it for mining to include cobalt. Dismantling was permitted on February 20, 1846. In the following years, until July 30, 1861, the pit fields listed below merged to form the corner pit:

- Upper corner (born February 17, 1829)

- Upper corner of the side corridor (born June 27, 1857)

- Middle corner (born August 9, 1847)

- Bottom corner main aisle (born August 25, 1841)

- Bottom corner of the side corridor (born August 7, 1843)

- New Corner (born December 29, 1852)

- Beautiful corner (born June 27, 1857)

- Hansmichel (born September 10, 1859)

- Colonel Hansmichel (born January 18, 1849)

- Young Hansmichel (born June 26, 1857)

- Sauerborn (born July 3, 1837)

- Sauerquelle (born April 17, 1849)

- Bock (born September 10, 1859)

- New Association (born September 4, 1860)

- Michel (born September 22, 1860)

- Encore II (born September 22, 1860)

History of the Apfelbaumer Zug composite mine

After long and tough negotiations and disputes between the owners of the pits, Apfelbaum, Ecke and Kuhlenwalder Zug finally consolidated into the Apfelbaumer Zug mine on February 13, 1897. The legal entity of the mine was the 1000-part union of the same name, Apfelbaumer Zug. At the founding meeting, the 1000 Kuxen were in the hands of Otto Stein (200), Alfred Stein (200), Dr. Felix Rauschenbusch (200), Friedrich Zöllner (200), Karl Zöllner (100) and Gustav Contelle (100). The mining board was formed by Steiger Jakob Achenbach and the trades Rauschenbusch and Otto Stein. In the following period, as described below, considerable financial resources were raised to promote operational efficiency.

From 1897, the sixth was civil sole for main haulage level expanded. Not far from the Apfelbaumer Schacht, an approx. 800 m long cross passage in the direction of the Kuhlenwalder Zug was excavated and completed in 1903. Due to the large distance between the Kuhlenwald and Apfelbaum shafts, the decision was made to use a 6-hp petrol locomotive , probably the first in the Siegerland iron ore mining industry. Operations manager Klein described the operation of the gasoline locomotive as follows:

"The locomotive is supposed to move the empty and loaded wagons through the double-track, 780 m long cross passage after the Kulnwaldgang and beyond the same means (ds Kulnwald, Langgrube, Lück, Anton, Junge Anton and Wasserquelle) falling mountains and iron stones In trains of 12-15 wagons bring the apple tree train to shaft 1. An empty wagon weighs 260 kg, contents 650 kg, locomotive 2700 kg. A whole train would therefore weigh 16,350 kg. The pit rails are 65 mm high, weigh each running m 7 kg and with a good iron sleeper pad are sufficient for the weight specified above. Track width 550 mm, the conveyor lengths are 780-1400. When the machine is taken out of operation, it should be housed in a lockable room. We intend to store the petrol magazine The same should be bricked up on both long sides, arched and locked by a door be obtained. A pump is placed on the barrel, which pumps the gasoline through a gas hose into the gasoline container on the locomotive, which means that there is almost no danger of anyone approaching the light. "

On October 24, 1898, Jakob Achenbach presented a project for a "processing facility" that had been worked out by the Wippermann company in Cologne-Kalk, which was then implemented:

"The processing should serve to separate the iron ore from clay slate, greywacke, quartz etc. and be used alternately to raw and roasted spath. The conversion will take place every month. The institution consists of an operating machine, a rod drum, 3 separation drums, a reading table, a bucket elevator and a rolling or crushing mechanism. The iron stone conveyance from the pit is not crushed, but runs directly over a rod drum, where the coarse from the fine conveyance is separated. The coarse iron stone is transferred directly to the roasting ovens, the medium type makes the way over the reading table to be sorted. The pits are conveyed up through the bucket elevator, then passes through two separation drums, after which they fall into the junk boxes of different grain sizes and are cleaned. The sludge goes into a sump, which is separated by a number of walls, in order to clarify the water or rust spar from the so-called surrender dump are used, this material is fed to the crushing mechanism and crushed, lifted up by the bucket elevator, goes over the separation drums into the type case and is treated like rust spar. "

In 1899 the processing plant was completed and started operations. A cable car was built to transport the processed ore directly to the "Neue Brachbacher Hütte". However, despite all efforts and investments, the mine operation did not work economically in the following months either. Financial difficulties prompted the Apfelbaumer Zug union in August 1899 to offer the mine to Phönix Eisenwerke and Rheinische Stahlwerke for purchase. But the smelter entrepreneurs refrained from doing so. In the spring of 1900, the Stein and Rauschenbusch trades finally managed to sell their Kuxen to Rheinische Bank AG . In the following three years there was a permanent change in the chairmanship of the union. The reasons for this are not given in the reports received from the union meetings. On May 4, 1903, the Apfelbaumer Zug trade union bought the neighboring Lück, Anton, Junge Anton and Langgrube mines for 27,000 marks. On May 24, 1904, plum trees 1–4, Susanna, willow trunk and water source were added. Between 1906 and 1908, the main apple tree shaft was sunk to its final depth of 393.67 m and the 7th and 8th underground excavation levels were laid. But there were hardly any ore deposits worth mentioning to be found at this depth.

The mining accident in 1908

On the night of Aug. 8, 1908 August 9, 1908, the shaft tube between the sough and first broke away from a, civil engineering sole by sweeping transition column , large rock masses. Both the wooden shaft lining and the pump lines installed in the shaft were torn down with it and the shaft was almost completely destroyed. Four staff members, the repair work on the sixth civil sole were employed, managed an independent recovery over the adjacent long pit (other sources say is that the miners over the adjacent pit corner saved). A surviving miner described that fateful day as follows:

"Early in the morning we had filled lorries on lorries with iron rock in the“ apple tree ”pit and we were happy that the hand of the clock slowly moved to three, because then the shift change. We got ready for the exit and went through the tunnel to the delivery shaft Suddenly there was a thunderous crash above us, a rumble of rock and the rush of water. We involuntarily backed away so as not to be hit by the falling rock. Our lights went out and we stood in the dark. A paralyzing horror seized us. The shaft How should we ever see the daylight again? The master from the pump room came up hastily and shouted in desperation: "We are drowning, the pump no longer works, we are lost!" Then some of my buddies lost their nerves and howled like Little children. One kneeled down and in his anguish prayed out loud the “Our Father.” Others followed him. Only an old miner showed in all his despair ment showing no signs of fear. As the miner's light flickered again, he calmly drew his strand of tobacco out of his pocket, cut a piece off and put it in his mouth. Then he exclaimed into the general confusion: “We are not lost, men! You have also prayed enough. Now get up and follow me, I know another way out. ”As if the sun wipes away the gloom and lets it shine in a new light all night, these words transformed faces. With fresh courage we walked after the old buddy who had spoken so firmly and confidently. We padded for a long time through abandoned tunnels. The water dripped down on us from the ceiling. Our shadows flitted ghostly over the tunnel walls. Nobody spoke a word. After a long time it got light in front of us. With a happy heart we stepped out of the tunnel entrance of the “Corner” pit into the bright light of day, escaping the death of a miner. Everyone shook hands with the Fiihrer in silence. Then we hurried to the "apple tree" pit, where they had been worried about us. "

Due to the financial difficulties before the accident, the union decided to shut down the mine. 290 employees lost their jobs. The mechanical equipment of the daytime facilities was dismantled and sold.

Recommissioning by HOESCH and final shutdown

During the First World War there was an increased need for iron ore for armaments production. The Apfelbaumer Zug union leased the dump to the Niederrheinische Hütte in Duisburg for reprocessing . The HOESCH Group owned most of the Kuxe until 1917 and planned to mine again ore in the following period.

On September 30, 1920, the commissioning of the mine was requested from the Oberbergamt in Bonn and asked for permission to ride a rope in the Apfelbaum shaft. From October 1920, a new auxiliary conveyor facility was built at the Apfelbaum shaft and 20 miners were busy digging up the shaft. The shaft joints were generously torn down and the wooden shaft fittings that were still preserved were replaced by iron strokes . The breaking point below the bottom of the Erbstollen was generously and extensively secured with concrete.

The corner of the weather shaft was also completely cleaned up and received both a new shaft extension and a wooden auxiliary conveyor frame.

By 1923 the workforce had increased to 80. The daytime facilities at the Apfelbaum shaft were supplemented by a new hoisting machine house, compressor house and a transformer station.

However, the overall economic situation deteriorated to a considerable disadvantage for the mine.

On January 1, 1927, the Apfelbaumer Zug mine was closed for good.

All mechanical equipment was dismantled and sold. The corner and apple tree shafts were closed with iron-proven concrete seals on the hanging bench. A local construction company acquired the extensive spoil dump and used the stone in road construction for several years. Only the shaft building made of quarry stone and the new hoisting machine house built by HOESCH on the apple tree remained after the closure and were given a new use.

Promotion and workforce

| year | Promotion of Spateisenstein | Mining copper ore | Total workforce | Workforce underground | Workforce for days |

|---|---|---|---|---|---|

| 1897 | 31 381 tons | 393 tons | 270 | 170 | 100 |

| 1898 | 30 877 tons | 655 tons | 313 | 195 | 118 |

| 1899 | 32,302 tons | 555 tons | 305 | 199 | 106 |

| 1900 | - - - | - - - | 327 | 205 | 122 |

| 1901 | 28,972 tons | 420 tons | 333 | 220 | 113 |

| 1902 | 28,791 tons | 479 tons | 279 | 181 | 98 |

| 1903 | 38 291 tons | 3,699 tons | 321 | 205 | 116 |

| 1904 | 44 569 tons | 1,364 tons | - - - | - - - | - - - |

| 1905 | 44 893 tons | 964 tons | 387 | - - - | - - - |

| 1906 | 53 403 tons | 850 tons | 370 | - - - | - - - |

| 1907 | 45 472 tons | 1,040 tons | 356 | - - - | - - - |

| 1908 | 22,727 tons | 561 tons | 290 | - - - | - - - |

| 1909 | 615 tons | - - - | 5 | - - - | - - - |

| 1916 | - - - | - - - | 1 | - - - | - - - |

| 1917 | - - - | - - - | 4th | - - - | - - - |

| 1918 | - - - | - - - | 2 | - - - | - - - |

| 1919 | - - - | - - - | 22nd | - - - | - - - |

| 1920 | 2,042 tons | - - - | 20th | - - - | - - - |

| 1923 | - - - | - - - | 80 | - - - | - - - |

| 1924 | - - - | - - - | 45 | - - - | - - - |

Tunnels and shafts

| Surname | Year of origin | length |

|---|---|---|

| Oberer Apfelbaumer Stollen | - - - | |

| New Apfelbaumer Stollen | - - - | |

| Deep Ecker and Apfelbaumer tunnels | - - - | |

| Middle Ecker tunnel | - - - | |

| Upper Ecker tunnel | - - - | |

| New Ecker tunnel | - - - | |

| Water source tunnels | - - - | |

| Long pit deep tunnel | - - - | |

| Upper Kuhlenwald tunnel | - - - |

| Surname | Year of origin | Depth | Dimensions |

|---|---|---|---|

| Apple tree shaft | 1880 | 393.67 meters | 4.50 x 5.00 m |

| Manhole corner | 1879 | 166.35 meters | 4.40 x 1.42 m |

| Kuhlenwald blind shaft | 1903 | 313.00 meters | - - - |

| Blind shaft long pit | 1871 | 182.00 meters | 3.77 x 1.57 m |

| Blind shaft water source | 1871 | 64.00 meters | - - - |

After the shutdown

The residential building

The first two apartments in the old building complex were built in 1942, mostly for mining families. Corresponding renovation work was carried out by two more apartments by 1965. That year, the municipality of Mudersbach acquired both the buildings and the mine itself from Erzbergbau Siegerland AG. In 1972 the roof structure of the shaft hall caught fire. The fire affected the statics of the building so enormously that the apartments in this part of the building were unusable. On August 17, 1974, the collapse of the Hohegrete pit in Wickhausen near Hamm (Sieg) led to a comprehensive review of all day shafts in the Altenkirchen district that were closed before 1940, including those of the Apfelbaumer Zug pit. However, checking the seal on the Apfelbaum shaft turned out to be extremely difficult, because the concrete slab was in a hallway of the residential building and partition walls had been erected on it as early as 1942 during the renovation work for housing purposes. Only the testimony of a miner who was still living at the time and who had witnessed the decommissioning work provided a rough overview of the dimensions of the shaft cover. After that, after the shutdown in 1927, he cut iron girders himself, pushed them onto the shaft, paneled the space in between with metal sheets and finally applied mixed lean concrete by hand.

After officials of the responsible mining authority only carried out a visual inspection of the manhole cover at an on-site meeting with representatives of the municipalities of Brachbach and Mudersbach and refused any more in-depth inspection, the Brachbach mayor himself punched a hole in the cover. He discovered that the slab on the apple tree shaft was only 16 cm thick and that there was a mortal danger for the 27 people living in the building. All four families were evacuated immediately.

Plans to retrospectively secure the shaft and set up a mining museum in the buildings were discarded for reasons of cost. In 1975 the building complex was on fire again. As it turned out only recently, the major fire was caused by three young people playing around with a lighter.

In 1977 the shaft building was demolished.

Research

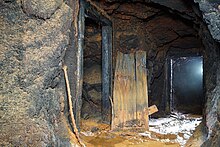

In 2008, a group of former mining researchers set out to explore the remaining near-day pit structures of the closed Apfelbaumer Zug mine for the first time. The purpose of the research project, which continues to this day, is a comprehensive documentation of the preserved mining historical evidence of the village of Brachbach. The following photos show only a small part of the mine workings still preserved.

See also

Individual evidence

- ↑ a b c d Alfons Jasnoch: From Brachbach's story . Ed .: Local community Brachbach. 1st edition. tape 1 . Self-published, Brachbach 1996, p. 78-149 .

- ↑ a b Otto Becher: Chronicle and local history of the community of Mudersbach . 1st edition. Self-published, Mudersbach 1949, p. 255-259 .

- ↑ a b c d e f g h i j k l m n o Prof. Dr. Rainer Slotta: The Apfelbaumer Zug shaft building - a lost technical monument of the Siegerland iron ore mining . In: Der Anschnitt 2-3 / 1980 . 1st edition. tape 32 . German Mining Museum, Bochum 1980, p. 117-146 .

- ↑ Landkreis Altenkirchen (ed.): Land to Sieg and Wied - local history of the district Altenkirchen . 1st edition. Altenkirchen 1986, p. 43 .

Web links

- Gerd Bäumer: Ore mining in the Siegerland area ( Memento from November 7, 2001 in the Internet Archive )