Energy management

For energy management include the planning and operation of power engineering production and consumption units. The goals are resource conservation as well as climate protection and cost reductions, while safeguarding the users' energy needs . The energy controlling sub-area supports cost and material efficient energy and material flow management .

Basic considerations can be

- ensuring security of supply , e.g. B. an uninterruptible power supply

- ensuring the voltage and current quality in the area of power supply

- ensuring economical electricity and heating prices

- the consideration of environmental aspects , e.g. B. through independence from fossil primary energy sources or emissions trading

The main areas of application are:

- commercial and industrial energy management in production and logistics

- the energy management for residential construction in residential building use

- building energy management, especially for complex functional buildings such as hospitals, police stations and department stores

- the municipal energy management

methodology

When planning, a distinction is made between the overall concept (strategy concept) and detailed concepts, such as thermal protection , combined heat and power , thermal insulation , covering electricity requirements, etc. In the strategy concept, it is necessary to define the general goals of the energy management concept. These include, for example, independence in energy supply ( heat or electrical energy ), increase in voltage quality, cost optimization .

The subsequent inventory and evaluation basically consists of collecting and analyzing the energy consumption of the considered property in the form of load profiles (heat and electricity), energy indicators (eg specific energy consumption per square meter and year), tendency, future developments (extension of production, increase of legal and restrictive framework conditions), as well as the corresponding evaluation and classification of the results.

Subsequently, an all-encompassing concept is worked out, which covers the strategic concept and the current and future energy requirements. It is important to work out the possible detailed concepts in detail in order to be able to carry out a final variant calculation. Possible variants could include the number of CHP modules used, the mode of operation of a CHP (heat-oriented - covering the entire heat demand with / without an increase in a peak load boiler, current-controlled - covering the cost-intensive load peaks during heavy load times), the degree of thermal insulation to be installed in a building, the use of various Be primary energy sources etc.

Finally, the developed energy management concept is to be implemented and evaluated, taking into account overall and detailed concepts. The use of extensive control technology proves to be helpful in order to both control the individual generating units used and to be able to control them independently. The process of energy management is iteratively repetitive and has to be constantly monitored. This results in successive optimization potential.

Since August 2009, the EN 16001 standard has served companies as a guideline for setting up an operational energy management system for the purpose of increasing energy efficiency on a sustainable basis. This was replaced in December 2011 by EN ISO 50001 , which is published in Germany as the DIN standard DIN EN ISO 50001. The EN ISO 50001 set of rules is structured along the lines of EN ISO 9001 (quality management systems) and the EN ISO 14001 standard (environmental management systems). Based on quality management, a PDCA cycle is also required for energy management systems to increase energy efficiency. Eccleston describes the procedure for implementing an energy management system.

Definition of terms

A number of terms such as " energy controlling " and "energy monitoring " are around the topic of energy management. A precise delimitation is difficult in practice because on the one hand there are different definitions of the terms and on the other hand some of the terms are defined quite abstractly.

Definitions for energy management range from simple systems for recording consumption data (hardware) to complex management processes (entire departments in a company and associated processes, standards, technologies, etc.). The VDI guideline 4602 tries to define a definition that also includes the economic dimension: "Energy management is the forward-looking, organized and systematic coordination of procurement, conversion, distribution and use of energy to meet the requirements, taking into account ecological and economic objectives" .

Related to the term “energy management” are the terms “energy monitoring” and “energy controlling”. In some cases, these are defined as a subset and / or data source for energy management. In the case of "energy monitoring", the focus is usually on the collection of data, while in "energy controlling" the focus is usually more on evaluation.

Organizational anchoring

Concrete organizational anchoring is necessary so that energy management can be implemented in the company. The responsibilities and the interaction of the decision-makers should be clearly regulated. The delegation of tasks and competencies should range from top management to the executive bodies. Comprehensive coordination can also ensure that the tasks are carried out.

In larger or energy-intensive companies, it would be possible to set up a separate organizational unit “energy management” to support upper management and to keep track of things. It depends on the basic form of the organizational structure where exactly this unit is connected. In the functional organization , the unit is located directly between the first (management) and the second hierarchical level (corporate functions such as production , procurement , marketing ). In a division organization , there should be a central and several division-specific energy management units, on the one hand to meet the different requirements of the individual divisions and, on the other , to meet the needs of coordination between the divisions and the head office. In the matrix organization , energy management can be integrated as a matrix function and thus reach most of the functions directly.

If you look at small and medium-sized companies , then energy management is often only a partial task of a manager. There is not enough capacity here to fill a full position with appropriate tasks. Another option is to outsource energy-related tasks and issues to an external service provider . Thanks to his specialization, he could contribute new knowledge and optimize processes.

Energy management in operational functions

facility management

The facility management is an important part of energy management, because the energy costs (25 percent on average) account for a significant proportion of the entire management costs. Facility management is mainly about facilities that do not fall into the core business of an organization, but support it (e.g. air conditioning, fire protection, hot water). DIN 32736 describes it as the "totality of all services for the operation and management of buildings, including structural and technical systems".

The central task of energy management here is to reduce the costs incurred for the provision of energy in buildings and systems without significantly restricting work processes. Above all, the availability and service life of the systems as well as the user friendliness should remain the same. In this context, the German Association for Facility Management (GEFMA eV) has already published guidelines (e.g. GEFMA 124-1 and 124-2), which contain methods and possibilities that deal with embedding energy management in the environment of a successful Deal with facility management. In this area of responsibility, the facility manager must deal with economic, ecological, risk-related and quality-oriented targets. By specifying the quality of use, he tries to minimize the total costs of the energy-related processes (provision, distribution and use).

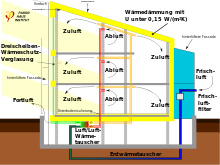

The most important key figure in this context is kilowatt hours per square meter per year (kWh / m²a). Properties can be classified according to their energy consumption using this key figure. The legal basis is provided by the Thermal Insulation Ordinance and the Energy Saving Ordinance. In order for a building to be called a low-energy house, it should be able to demonstrate a maximum consumption of 70 kWh / m²a. The passive house , which does not exceed a heating requirement of 15 kWh / m²a , is also widespread . The “passive” use of energy means that there is no need for a conventional heating system . The passive house can utilize the heat from the sun and people due to the very good thermal insulation of the building envelope. In addition, a ventilation system with a highly efficient heat exchanger ensures that the air is always fresh. However, there are also houses with a positive energy balance . These are known as energy-plus houses . The energy required in the house is generated by the house itself (for example through thermal solar systems or photovoltaic systems ) and excess energy can also be fed into the power grid.

The EnEV stipulates that the energetic state of buildings must be documented in an energy certificate. This is binding for residential buildings of all construction years since January 1st, 2009 and for all non-residential buildings since July 1st, 2009.

The operator regulations also regulate competencies, tasks and responsibilities. Since the systems also contain risk factors (e.g. oil tanks, gas pipes), it must be ensured that all tasks are clearly described and assigned. A clear regulation can help avoid liability risks.

logistics

The logistics deals with the organization , management, deployment and optimization of information and material flows along the value chain and the supply chain. Especially in the core logistical task of transporting goods, efficient energy management can save costs and protect the environment. The relevant factors are the selection of the means of transport, the duration and length of the transports as well as the cooperation with logistics service providers.

Logistics causes more than 14% percent of CO 2 emissions worldwide. For this reason, the term “ green logistics ” is becoming increasingly important.

Possible options for action in terms of green logistics are:

- Shift to environmentally friendly modes of transport such as rail and waterway

- Route and cargo space optimization

- Formation of networks of companies connected by logistics service providers

- Optimization of physical logistics processes through sophisticated IT support

Companies have the opportunity to have their logistical objectives and strategies evaluated ecologically. There is software for this which calculates the emissions using key figures such as means of transport, type of fuel, route or drive. The Institute for Energy and Environmental Research Heidelberg , together with the company Rail Management Consultants GmbH, for example, a program for carbon calculation for logistics. They were supported by five major European railway companies. The tool is called EcoTransIT and can be accessed free of charge. In addition to the direct emissions, the indirect emissions (generation, transport and distribution of energy) are also determined here. The program is suitable for companies of all sizes and can serve as a basis for the environmental balance.

In addition to the transport of goods, the transport of people should also be taken into account in the logistical strategy of companies. Particularly when traveling on business, attention should be paid to the choice and proportionality of the means of transport. In some cases, it has to be considered whether a physical presence is absolutely necessary or whether a telephone or video conference is just as useful. Home office is another option with which the company can indirectly protect the environment.

Energy procurement

In the broadest sense of business administration, procurement is understood to mean purchasing as well as procurement logistics and the determination of requirements. Efficient energy purchasing is one way of reducing energy costs. Since the liberalization of the German electricity markets in 1998, there have been significant price differences, in some cases with the same purchase volume. The establishment of the EEX energy exchange in 2002 intensified this trend. A comparison is worthwhile here. A change of energy source is also a way of reducing energy costs.

There are three basic types of procurement for organizations:

- Standardized collective agreement by an energy supply company (EVU): These contracts are suitable for small and medium-sized companies that only need a small amount of energy.

- Individually negotiated contracts with a utility company: With this type of energy procurement, the company negotiates the respective prices and quantities with the utility company itself. Above all, maximum performance, performance price, energy price, fixed price agreements and the duration of the contract are important cornerstones of the contracts with energy supply companies.

- Direct purchase at EEX (portfolio management): This form of procurement is particularly suitable for large companies that can employ experts for this purpose. The intermediate trade via the EVUs is bypassed. The experts have to find the right time to buy the respective energy source and be able to correctly assess the price trend.

A possible composition of the service packages in question can be described using the exemplary illustration of a load profile :

- The gray block represents a base load belt delivery by an energy supply company. Long-term contracts are concluded to secure the base load. The base load should be set in such a way that, as a rule, it does not fall below it during one day. The delivery must be paid for in any case, whether called up or not. Since the lowest electricity demand usually occurs at night, the level of the base load depends on the systems operated at night.

- A certain baseload is also procured via the EEX spot market. A structured electricity purchase can help to negotiate a long-term contract at the right time, which guarantees low prices.

- In addition to the permanent basic delivery, hourly and block contracts can be concluded, which can be accessed flexibly. The flexibility results in higher costs for the company.

- Balancing energy for the peak load can be procured through individual hourly contracts, which are available on the spot market at very short notice and are accordingly expensive.

production

In the production the actual carried value which is relevant for the customer. This central process can vary greatly depending on the industry . Industrial companies operate systems that require a lot of energy. Service companies, on the other hand, get by as far as possible without materials, so that here facility management or green IT is the energy-related focus.

In this context, the energy-related focus should first be identified, then evaluated and finally optimized.

Production Planning and Control

Production is usually the area with the greatest energy consumption within a company. This is why production planning and control (PPS) also play an important role. The PPS deals with the operational, temporal, quantitative and spatial planning, control, control and administration of all processes that are necessary in the production of goods. The “production planner” should therefore plan the production processes in such a way that they run as energy-efficiently as possible. Heavy electricity consumers or automated production processes can, for example, be shifted into the night. In addition, peaks should be avoided (peak shaving) so that there is a uniform load profile and contractual conditions are met.

The upcoming changes in the generation structure of energy require an increasing demand for storage capacities. The PPS also has to deal with the problem of the limited storage life of energy . In principle, it is possible to store the energy electrically, mechanically, chemically or thermally. Electrochemical storage systems based on lithium are also viewed as a pioneering technology for use in electrically powered vehicles or as an option for regulating power grids. As an alternative to conventional fuels, material storage media such as hydrogen are becoming increasingly interesting. The "Energy Storage Funding Initiative" of the Federal Ministry of Economics and Technology shows that the subject of energy storage is increasingly coming into the focus of companies and politics . In July 2012 there was the go-ahead for 60 innovative research projects in the field of energy storage. The aim of the initiative is to promote technological breakthroughs and thus support the rapid market introduction of new energy storage devices.

maintenance

The maintenance of technical systems, components, devices and equipment is intended to ensure that the functional state is maintained or restored in the event of failure. Good maintenance is essential to support energy management. In this way, energy losses and the associated increases in costs can be avoided.

Examples of how it is possible to save energy and costs with maintenance:

- De-ice cold rooms

- Check air pressure of cars and trucks

- Isolation of hot systems

- Improve leaks in building envelopes

The management level determines the strategy. This can range from very extensive maintenance (regular, preventive maintenance and control measures to prevent failures) to minimal maintenance, which is only dealt with when a defect is present.

Information technology

Green IT is at the heart of the environmentally and resource-friendly design of information technology . This refers to efforts to make the use of information and communication technology (ICT) over its entire life cycle environmentally and resource-friendly. This includes optimizing the consumption of resources during the manufacture, operation and disposal of the devices. With IT, for example, work processes can be omitted or energetically improved.

Approach options:

- Production of the devices: You should make sure that the devices are manufactured in a resource-saving manner and that they consume less electricity than comparable devices.

- Purchase and operation of the devices: Energy Star , the European Community's program for energy- saving office devices, comes to the conclusion that the operation of the devices can lead to energy differences of over 1000%. The Energy Star label can help identify energy-efficient devices. Important cornerstones are, for example, more efficient power supplies, modern standby mode and energy-saving mode.

- IT support: There are many programs that can help an organization save energy. This ranges from large ERP systems to IT support for systems. There are also commercial energy management systems. The market index for energy management software, which the NRW Energy Agency publishes as an online calculator on its website, provides an overview of the systems available on the market .

Profitability calculation

A core function of energy management includes measures and projects to increase energy efficiency . This topic focuses on making decisions that make sense in the energy industry and implementing the corresponding measures. A controlling-oriented approach makes sense here in order to get an initial overview of potential energy-related measures and their profitability and to include all relevant departments and hierarchical levels.

In the following, relevant methods and approaches are pointed out:

- Energy-related cost accounting

The most important source of information for management and therefore also the basis for most decisions is cost accounting . It serves to provide internal information for the operative planning of costs and revenues as well as their control. Energy balances represent the basis for energy-related cost accounting . Depending on the energy consumption, companies can align their cost accounting systems more closely to energy-related aspects.

- Life cycle costing

Life Cycle Costing considers the development of a product over the entire product life cycle and serves to evaluate investment alternatives. With all of the options available, all costs should be taken into account in all phases of the product life cycle. When making investment decisions, attention should therefore not only be paid to the acquisition costs, but above all to the energy costs incurred.

- Total cost of ownership

Similar to the TCO, in which a distinction is made between direct and indirect costs.

- Optimal replacement time

The optimal time to replace a system occurs when the future costs of a new device would be lower. It is irrelevant whether the system has already been written off in full or not. Sunk costs must not influence the decision-making process. Instead, a lot of attention should be paid to innovations in the energy industry or increases in energy prices. The cost comparison calculation or the investment calculation are possible methods of calculation .

- Energetic amortization

The energetic amortization, also known under the term energy payback time, describes the time that an energy-converting system must be operated until the energy that was necessary for the production of the system ( accumulated energy consumption ) has been recovered.

Energy strategies

A long-term energy strategy should be embedded in every overall strategy of a company . This can include, for example, the objective of relying more on renewable energies. Criteria for making decisions about energy investments, such as expected returns, are also defined. By formulating an energy strategy, companies have the opportunity to secure a competitive advantage over their competitors and to minimize risks.

Possible energy strategies

According to Kals, there are the following possible energy strategies:

- Passive strategy: There is no systematic planning here. The subject of energy and environmental management is not perceived as an independent field of activity. Only the most necessary topics are dealt with.

- Strategy of short-term profit optimization: The management relies exclusively on measures that promise high profitability in the shortest possible amortization period . Measures with low profitability are ignored.

- Strategy of long-term profit optimization: With this strategy, it is important to have a high level of knowledge of energy price and technology developments. The relevant measures (for example heat exchangers or power plant construction) can run for several decades. These measures can also improve the image and motivation of employees.

- Realization of all economic energy measures: The aim of this strategy is to implement all measures which have a positive profitability .

- Maximum strategy: The company is ready to even change the company's purpose for climate protection.

In reality, mixed forms of the individual strategies are usually found.

Energy strategies of companies

Many companies try to promote their image through a proactive and public energy strategy and at the same time to protect the climate. According to the “Group Strategy 2018”, Volkswagen's (VW) environmental policy is based on environmentally friendly products and resource-saving production. Building on this, almost all of the Group's locations are certified according to the international ISO 14001 standard for environmental management systems.

Competitor BMW wants to use resources sparingly and efficiently as well as strengthen the company's reputation through responsible behavior towards employees and society. The Institute for Ecological Economic Research confirms the successful implementation of this project by awarding BMW 1st place among large companies in the 2011 ranking of sustainability reports .

The first place among the SMEs is Neumarkter Lammsbräu . The brewery has anchored sustainable principles in its corporate policy. These range from strictly ecological brewing guidelines to open dialogue with suppliers, employees and customers.

It should be noted on the negative side of the ranking that every fourth of the 150 largest German companies did not want to publish any information on sustainability issues. In addition, when considering the energy strategies of companies, the topic of greenwashing should be viewed critically.

However, a study of the growth potential for the energy services market shows a growing trend in the energy management services sector. According to the study, this is roughly in the range of the market volume of energy consultancies. Accordingly, 25% of the company's energy management expenditure is spent on energy management services, 75% are internal expenditure.

Energy strategies of politics

Countries are also pursuing targeted energy strategies. In May 2011 the Swiss Federal Council decided to forego nuclear energy in the medium term. The nuclear power plants are shut down at the end of their service life and not replaced. To compensate for this, the focus will be on energy efficiency, renewable energies, fossil electricity production and the expansion of hydropower.

The European Union gives its member states clear guidelines. With the "20-20-20 targets", the member states are obliged to reduce greenhouse gas emissions by 20% compared to 1990 levels by 2020, to increase energy efficiency by 20% and to achieve a share of 20% renewable energy in total energy consumption.

The German Federal Ministry of Economics and Technology names three cornerstones of its energy policy: economic efficiency, security of supply and environmental compatibility. In addition, the Merkel II cabinet decided on June 6, 2011 to end eight nuclear power plants and to phase out nuclear power by 2022.

Ethical-normative basis of energy strategies

The basis for an energy strategy is the corporate culture and the associated ethical norms that apply in the company. Ethics , in the sense of business ethics , deals with the question of how entrepreneurial pursuit of profit and moral ideals relate to one another and which moral values result from it . Ethical norms can be expressed in company guidelines, energy and environmental policies or other documents.

The most important basic ethical ideas relevant to energy management are:

- Utilitarianism : This form of ethics works according to the maxim that those actions are good or right, the consequences of which are optimal for the well-being of all those affected by the action (principle of maximum happiness). With regard to energy management, however, the existence of external costs must be taken into account, because these are not borne by the beneficiaries of the economic activity, but by third parties (e.g. future generations). This flaw in the market mechanism can be remedied by internalizing external costs.

- Communicative Ethics : states This ethical basic idea is that each of the decision is concerned, must be involved in decision making. This takes place in a fair dialogue , whereby the result is open.

- Deontological ethics : Deontological ethics assigns certain duties to people or organizations. A general example would be the golden rule : “Treat others as you want them to treat you.” Accordingly, people should fulfill their duty and make a corresponding contribution to the energy industry.

See also

- PROFIenergy , energy management in production plants

- Lean Energy Management , energy management based on lean management principles

- EEBUS , manufacturer-independent language and communication standards for energy management in the Internet of Things

Web links

- Energy management in companies, current literature list - compiled by the ZBW, Leibniz Information Center for Economics

- Guide to operational energy management, FfE

- Energy management according to DIN EN 16001, Energy20 / SiPE

- Website of the city of Frankfurt am Main on the subject of energy management

- Innovation platform for production - project for energy and auxiliary material-optimized production (EnHiPro) funded by the Federal Ministry of Education and Research (BMBF)

- EcoTransIT - carbon dioxide calculation for logistics

- Online lexicon on energy management and energy efficiency

Individual evidence

- ↑ C. Eccleston, F. March, T. Cohen: Inside Energy: The Handbook for Implementing an ISO 50001 Energy Management Systems. CRC Press, 2011.

- ↑ Definition of terms energy management website www.e3m.de of emation GmbH, accessed on June 15, 2011.

- ↑ VDI guideline VDI 4602. Beuth Verlag, Berlin 2007, p. 3.

- ↑ Johannes Kals: Operational Energy Management - An Introduction. Kohlhammer, Stuttgart 2010, ISBN 978-3-17-021133-9 , pp. 207-212.

- ↑ GEFMA guideline 100-1: Basics.

- ↑ GEFMA 124-1 energy management: Basics and performance profile. ( Memento of the original from April 14, 2016 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. on gefma.de , accessed on April 14, 2016.

- ↑ Energy management - the central task of facility management. ( Memento of the original from September 24, 2015 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. at: energy20.net , accessed November 10, 2012.

- ↑ Johannes Kals: Operational Energy Management - An Introduction. Kohlhammer, Stuttgart 2010, ISBN 978-3-17-021133-9 , p. 77.

- ↑ http://www.passivhaus.de/ accessed on December 3, 2012.

- ↑ http://www.plusenergiehaus.de/index.php?p=home&pid=8&L=0&host=1#a1 accessed on December 3, 2012.

- ↑ http://www.bmvbs.de/SharedDocs/DE/FAQs/Energieausweis/energieausweis-faq.html?linkToOverview=js ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice. accessed on March 15, 2013.

- ↑ Johannes Kals: Operational Energy Management - An Introduction. Kohlhammer, Stuttgart 2010, ISBN 978-3-17-021133-9 , pp. 75-77.

- ↑ Archive link ( Memento of the original from January 1, 2014 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. Retrieved November 10, 2012.

- ↑ http://www.ecotransit.org/about.en.html accessed on December 4, 2012.

- ↑ http://www.ecotransit.org/targetGroup.en.html, accessed on December 4, 2012.

- ↑ Johannes Kals: Operational Energy Management - An Introduction. Kohlhammer, Stuttgart 2010, ISBN 978-3-17-021133-9 , pp. 103-105.

- ↑ http://www.energieagentur.nrw.de/unternehmen/energiebeschendung-3699.asp accessed on November 10, 2012.

- ↑ Johannes Kals: Operational Energy Management - An Introduction. Kohlhammer, Stuttgart 2010, ISBN 978-3-17-021133-9 , pp. 117-120.

- ↑ Johannes Kals: Operational Energy Management - An Introduction. Kohlhammer, Stuttgart 2010, ISBN 978-3-17-021133-9 , pp. 119-122.

- ↑ Johannes Kals: New requirements for PPS as a result of the energy transition, published in the journal Productivity Management, Issue 17, 2012, pp. 20–22.

- ↑ http://www.bmwi.de/DE/Themen/Energie/Energieforschung/foerderschwerpunkte,did=455452.html accessed on December 6, 2012.

- ↑ http://www.bmwi.de/DE/Presse/pressemitteilungen,did=497794.html accessed on December 6, 2012.

- ↑ http://www.ps-consulting.de/industrie/IH-Energiemanagement.html accessed on November 12, 2012.

- ↑ Archive link ( Memento of the original from January 25, 2013 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. Retrieved December 6, 2012.

- ↑ Johannes Kals: Operational Energy Management - An Introduction. Kohlhammer, Stuttgart 2010, ISBN 978-3-17-021133-9 , pp. 147-148.

- ↑ https://www.fr.de/kultur/strom-sparen-computer-11428700.html accessed on November 12, 2012.

- ↑ Market review for energy management software Energieagentur NRW, accessed on June 15, 2011.

- ↑ Johannes Kals: Operational Energy Management - An Introduction. Kohlhammer, Stuttgart 2010, ISBN 978-3-17-021133-9 , pp. 155-158.

- ↑ Archive link ( Memento of the original from May 14, 2013 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , accessed January 31, 2013

- ↑ Johannes Kals: Operational Energy Management - An Introduction. Kohlhammer, Stuttgart 2010, ISBN 978-3-17-021133-9 , p. 167.

- ↑ http://www.energiesparhaus.at/energie/pv_energamort.htm , accessed on February 1, 2013.

- ↑ a b J. Kals, K. Würtenberger: IT-supported energy management in: HMD - Praxis der Wirtschaftsinformatik HMD, issue 285/2012, p. 73.

- ↑ Johannes Kals: Operational Energy Management - An Introduction. Kohlhammer, Stuttgart 2010, ISBN 978-3-17-021133-9 , p. 181 .; on the limits of the monetization of external costs cf. Klaus Rennings / Henrike Koschel, External Costs of Energy Supply and Their Significance in the Concept of Sustainable Environmentally Friendly Development, p. 11 f., ZEW Documentation No. 95-06, Center for European Economic Research GmbH, Mannheim.

- ↑ Johannes Kals: Operational Energy Management - An Introduction. Kohlhammer, Stuttgart 2010, ISBN 978-3-17-021133-9 , pp. 182-184.

- ↑ http://www.umweltdialog.de/umweltdialog/reports/2011-06-08_VW-Nachhaltigkeitsbericht_2010_Auf_dem_Weg_zum_Branchenprimus.php accessed on December 14, 2012.

- ↑ Archive link ( Memento of the original dated November 14, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. Retrieved December 14, 2012.

- ↑ http://www.bmwgroup.com/bmwgroup_prod/d/0_0_www_bmwgroup_com/investor_relations/akte_zum_unternehmen/nachhaltigkeit.html accessed on December 17, 2012.

- ↑ http://www.ranking-nachhaltigkeitsberichte.de/data/ranking/user_upload/pdf/Ranking_2011_Erresult_GUN_Top_50.pdf

- ↑ Sustainability Report 2011 of the Neumarkter Lammsbräu Brewery, p. 15, available at: Archive link ( Memento of the original from March 24, 2015 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Archived copy ( memento of the original from October 22, 2014 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Archived copy ( Memento of the original dated December 31, 2013 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. Retrieved December 14, 2012.

- ↑ http://www.bmwi.de/DE/Themen/Energie/Energiepolitik/europaeische-energiepolitik.html accessed on December 14, 2012.

- ↑ http://www.bmwi.de/DE/Themen/Energie/energiepolitik,did=295096.html accessed on December 14, 2012.

- ↑ Cabinet decides to phase out nuclear power by 2022. In: sueddeutsche.de . June 6, 2011, accessed October 13, 2018 .

- ↑ Johannes Kals: Operational Energy Management - An Introduction. Kohlhammer, Stuttgart 2010, ISBN 978-3-17-021133-9 , p. 200.

- ^ A b Johannes Kals: Business Ethics and Corporate Energy Management, in: Karczewski, Leszek; Kretek, Henryk (eds): Odpowiedzialny biznes i Konsumerysm wyzwaniem XXI Wieku (Responsible Business and Responsible Consumerism as a Challenge of the XXI Century), Poland, Raciborz 2012, p. 6.