Firing

A furnace is a technical device for generating heat by burning suitable fuels . In official or legal German and by chimney sweeps , firings are called fireplaces (see below, in the section on Switzerland ). What is defined as a fireplace must be approved by an authority in Germany and many other countries ; there is also a regular fireplace show.

The largest number of fireplaces is used to heat buildings . In the past, ovens and stoves were used for this purpose , which have now been largely replaced by boilers and hot water heating systems.

Large combustion systems or small combustion systems

The legal regulations differ in the following countries:

Germany

The first Regulation implementing the Federal Pollution Control Act (the Regulation on small and medium-sized combustion plants , colloquially small furnaces Regulation , shortly 1. BImSchV ) defines small combustion plants . This regulation applies to:

- Firing systems for wood and coal below 1 megawatt (MW) thermal output,

- Systems for straw, grain and similar vegetable fuels with a thermal input of less than 0.1 MW,

- Oil and gas firing systems with a thermal input of less than 20 MW.

For large combustion systems (abbreviated: GFA) the ordinance on large combustion, gas turbine and combustion engine systems (13th BImSchV) applies .

In 2010 the 1st BImSchV was amended. More stringent requirements and retrofitting obligations for existing old systems came into force. There are transitional regulations until 2025. Since 2008, certain tasks no longer have to be taken over by a district chimney sweep , but can also be transferred to another chimney sweep .

Austria

The Austrian Firing Systems Ordinance applies nationwide to firing systems in commercial facilities and differentiates systems according to size. The approval of small combustion systems for space heating and hot water preparation is regulated by the federal states; all nine federal states have agreed on uniform provisions with the "Agreement pursuant to Art. 15a B-VG on the placing on the market of small combustion systems" U. not yet implemented, this contains the following definition: "Small combustion systems are technical facilities up to a fuel heat output of 400 kW, which are intended for the purpose of obtaining useful heat for space heating or hot water."

Switzerland

The Swiss Clean Air Ordinance (LRV) contains different regulations for fireplaces and fireplaces. This concerns the precautionary limitation of emissions in systems that pollute the air, waste incineration outdoors, the requirements for combustibles and fuels, the maximum permissible pollution of the air (immission limit values), as well as the procedure in the event that the immissions are excessive.

Classification according to the type of fuel

Gas firing

Since the expansion of the gas network in the 1960s and 1970s, natural gas has been available at most locations. Natural gas firing has the following advantages over firing with other fuels:

- There is no fuel storage.

- In the combustion no ash falls and with correct burner setting hardly soot on. Cleaning of the burner and the combustion chamber is still necessary annually.

The natural gas firing systems are less prone to failure. In contrast to firing systems for solid fuels, the intervention of a heater or boiler attendant is not required. To save personnel, many small and medium-sized coal-fired boiler systems have been converted to gas firing. The systems were designed for operation without constant supervision.

In Germany, natural gas firing with a heat output of up to 20 MW is subject to the regulation for small and medium-sized firing systems (1st BImSchV). The permissible emission of nitrogen oxides (NO x ) is limited to 80–150 mg per m³ exhaust gas, depending on the output or the operating temperature of the boiler. Firing systems over 20 MW are subject to approval.

Other gaseous fuels

In addition to natural gas, other gases are also burned, namely:

- Liquid gas ; When operating low-power burners, the vapor phase can be drawn off directly from the liquid gas storage container and fed to the burner. Powerful burners are seldom operated with liquefied gas, as the requirements for the storage and transport of the gas are increasing. The storage of liquefied gas in systems with more than 3 t is only permitted in underground containers. A larger amount of gas can only be withdrawn via the liquid phase; this passes through an evaporator.

- Partially purified coke oven gas; In the case of this gas, the precipitation of tar oils , a high sulfur content, residual benzene and increased formation of nitrogen oxides must be taken into account. The seals used must be resistant to benzene. Measures to reduce emissions may have to be taken.

- Town gas is purified coke oven gas , which mainly consists of hydrogen, methane and carbon monoxide. If the gas is supplied with consistent quality, the combustion is unproblematic.

- Mine gas is extracted from open and closed mines . The calorific value can fluctuate very strongly, in particular due to a varying proportion of air. Therefore, an O 2 control must be provided for boilers fired in this way. If it is possible to supply a gas with an oxygen content below the upper explosion limit , suitable explosion protection measures ( flame arrester , concentration measurements) must be provided.

- Sewage gas can also be used to fire steam boilers. It must be taken into account that the calorific value can fluctuate. If an ingress of oxygen cannot be ruled out, explosion protection measures must be provided. It must also be taken into account that the gas contains hydrogen sulfide , which can lead to corrosion in the gas line.

- Landfill gas (see notes on sewage gas),

- Biogas (see comments on sewage gas).

Gas control line

A gas control line - also known as a gas ramp - contains control and safety devices (see graphic) to achieve safe and defined combustion in the connected steam or hot water boiler. It usually consists of a double gas valve, gas pressure switch max (optional), gas filter, gas ball valve , pressure regulator (low-pressure medium- pressure regulator ) or pressure reducer , thermal shut-off device (TAE) and gas meter . The pressure reducer is installed in order to ensure a constant gas pressure upstream of the burner, regardless of changing primary pressures. If the gas pressure changes, the gas and air ratio on the burner would change. Then either an unstable flame or a very sooty combustion with CO formation can occur. If the secured gas inlet pressure can be greater than the permissible operating pressure of the components of the gas train, then a safety shut-off valve (SAV) and safety relief valve (SBV) must also be installed upstream of the regulator.

The minimum and maximum permissible gas pressure must be monitored by a pressure monitor if the gas pressure regulator shows a defect. During standstill or during pre-ventilation, no gas must enter the combustion chamber, as otherwise a deflagration can occur. Therefore, the solenoid valves in the gas train must close securely. For safety reasons, there are two gas solenoid valves, and before each burner start, after the chain of monitors has been triggered, a check is carried out in the burner sequence program to determine whether the valves are tight (gas tightness check).

Gas burner

Monoblock burners are used for heat outputs of up to around 10 MW . With these, the combustion air fan is integrated in the burner. The fan is set up separately for larger burners. While the main flame is ignited with the main flame in the low-fire position for burners with a lower output, separate pilot burners are used for higher outputs .

Gas burners with low output (<1 MW) are equipped with a simple step output control (mostly 2 steps), which are switched on or off depending on the steam pressure in the boiler. Continuously controlled burners ( modulating burners ) are mainly used. The control flaps for gas and air are mechanically coupled via rods ( mechanical connection ). The exact setting of the gas or air volume is made using a cam that is set by the fitter at various load levels. The setting is made so that there is always an excess of air of around 5%. Gas burners with an electronic network are now increasingly used. Instead of the mechanical coupling of the control flaps, separate electrically operated control valves are used for the gas and air routes . To set the control valves, the opening angles for the optimal combustion parameters are determined for different outputs and entered into the computer for the burner control.

In order to keep the air ratio as low as possible and to reduce exhaust gas losses, the control of the fuel-air ratio is superimposed on an O 2 control in order to compensate for the disturbance variables of the gas calorific value, temperatures and gas pressure. The residual oxygen in the exhaust gas is reduced to around 2%. As the amount of exhaust gas is reduced, the efficiency of the combustion increases and the combustion air fan requires less energy.

A special form of the gas burner is the pore burner , which burns gas or vaporized flammable liquids using catalysts , whereby the combustion is possible at lower temperatures. One advantage is that fewer nitrogen oxides result from the reaction of atmospheric nitrogen with atmospheric oxygen and the avoided enthalpies of formation still result in a higher heat yield.

Liquid fuel firing

The liquid fuels essentially include heating oils obtained from crude oil distillation , the qualities of which are standardized in DIN 51603. This group also includes ethanol , methanol and bio-oils obtained from plants (e.g. biodiesel ), stearic oil , animal fat or used deep-frying fat. The sharp rise in energy prices has made the energetic use of these substitutes profitable; process engineering has made great strides.

In the 1960s, heating oil prevailed as a fuel for small and medium-sized furnaces. Its direct competitor was natural gas; its specific energy price was a little higher for a long time.

When using heating oil in firing systems, there is additional effort for the heating oil storage compared to gas firing. As long as there is no severe frost, the storage and delivery of heating oil EL (extra light) is unproblematic. At temperatures below −15 ° C, paraffin can flocculate out of the heating oil and hinder the transport and atomization.

Much cheaper than the extra-light quality is heavy heating oil , or heating oil S for short. At ambient temperature, heating oil S is very viscous and cannot be pumped. It must therefore be heated in the tank and the pipes must be equipped with trace heating. The substitute fuels animal fat and deep-frying fat have a similar viscosity behavior and the cost of heating is the same.

Firing systems for heating oil EL with a thermal output of up to 20 MW are subject to the regulation for small and medium-sized firing systems (1st BImSchV ). The permissible emission of nitrogen oxides is limited to 180–250 mg / m³ exhaust gas, depending on the output or the operating temperature of the boiler. The resulting soot is determined by the soot number , which must not exceed 1. The decisive factor is the Ringelmann scale , with which the blackening of a filter paper is compared through which a defined amount of exhaust gas is drawn. Firing systems for EL heating oil with a thermal output of more than 20 MW as well as furnaces for heavy types of heating oil are subject to approval.

The fuel oil EL has the following advantages:

- In general, no special devices for limiting emissions need to be installed,

- A simply constructed atomizing burner can be used,

- The operator can choose the cheapest provider

- With the correct burner setting, only slight soot and ash build-up will occur.

When using heavier types of heating oil (heating oil M and heating oil S), the advantages of heating oil EL do not apply. Due to the chemically bound nitrogen in the fuel, the nitrogen oxide formation is relatively high, so that additives usually have to be used to keep emissions within the permissible range, for example by injecting urea ( known as AdBlue in vehicles ). Larger amounts of dust form, so that the boiler has to be cleaned frequently on the flue gas side. In addition, the use of heavy heating oils is subject to approval. The heavy types of heating oil must be heated; escaping oil forms a sticky mass that is difficult to remove. The operation of these furnaces is more labor intensive. The decisive advantage over the 'extra light' type of heating oil is the significantly lower price.

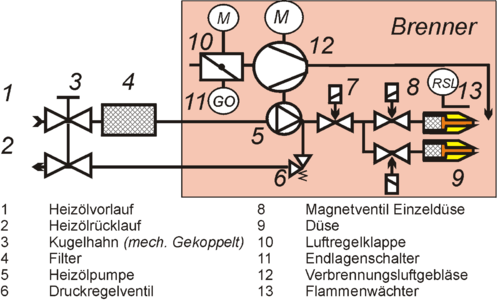

Oil burner

Monoblock burners are used for heat outputs of up to around 10 MW . With these, the combustion air fan is integrated in the burner. The fan is set up separately for larger burners. In the case of low-power burners, the heating oil is ignited at low fire. In systems that use oils that are more difficult to ignite (e.g. heavy fuel oil), a separate gas-fired pilot burner is used.

The liquid fuel must be atomized as finely as possible in the combustion chamber in order to achieve a large surface for the combustion reaction. For reasons of emissions, a long dwell time and the lowest possible combustion temperature should be aimed for in order to achieve good burnout with low nitrogen oxide formation.

The following forms of atomization are used technically:

- Pressure atomization,

- Rotary atomization,

- Atomization using an atomizing medium.

Pressure atomizer

When using pressure atomization, the oil is directed through a nozzle. The initial pressures are 6–30 bar; the entire pressure energy is converted into kinetic energy. When the oil jet emerges from the nozzle, fine oil droplets form, which form a large reaction cross-section. If very small nozzles are used, for example burners for individual houses, EL heating oil should also be warmed up in order to reduce the viscosity . A viscosity of 1 to 3 mm 2 / s is required for pressure atomizers .

Often you will find an electrically heated nozzle holder. The reason for this is that this is intended to reduce the viscosity of the heating oil in order to enable finer atomization, which benefits efficiency. Such facilities are at risk from solid components of the last combustion cycle from the fuel oil stored in the open atmosphere (microorganisms in the tank), which when the nozzle assembly is initially cold are burned by its heating before the oil flow is released. Filtering to defined particle sizes (e.g. mesh size of 200 µm = 0.2 mm) can help.

The burner can be regulated in different ways. Several nozzles are built into the burner head of the stage burner. Depending on the performance requirements, nozzles are switched on or off via the control of solenoid valves. Burners with up to three nozzles are offered.

A stepless regulation is called a modulated regulation . The method is also known as a return atomization burner . This is technically implemented by a control valve in the heating oil return, which is controlled in conjunction with the position of the combustion air flap. This can be implemented as a mechanical connection (lever or cable connection) or in the form of an electrical connection with control valves.

Selection of the heating oil nozzle size

The fuel oil EL throughput of a fuel oil nozzle is specified in USgal / h (US gallons per hour). One USgal / h corresponds to 3.785 l / h; with the density of heating oil EL of 0.84 kg / l, a USgal / h becomes a mass flow of 3.18 kg / h. The value applies to an oil pressure of 100 pounds-force per square inch (PSI), German: force pounds per square inch . This corresponds to around 6.89 bar, the value is usually rounded up to 7 bar. In the event of a deviating oil atomization pressure, the pressure-corrected volume flow can be calculated using Bernoulli's energy equation.

The heat output of a heating oil EL burner in kW with the specification of the oil throughput on the nozzle with the unit can be calculated using the formula:

With

- in according to the nozzle marking

- in

- in according to the set pump pressure.

The boiler efficiency can be used as a first approximation . The calorific value (previously lower calorific value) of heating oil EL is:

and based on the volume:

With this information, the oil throughput in can be determined for a given heat output , and thus the nozzle can be selected.

In addition to the specification of the throughput at 7 bar pump pressure, a heating oil nozzle is also marked with the nozzle characteristics (full cone, half cone or hollow cone) and the spray angle in degrees (°).

Rotary atomizer (rotary atomizer)

When using atomizing burners, the viscosity of the liquid fuel does not have to be in the range of 1 to 3 mm 2 / s, as is the case with pressure atomizers . Special fuels usually do not have a defined quality, so that the fuel throughput depends on the batch. When these substances are burned, the limits of pressure atomization are reached.

The rotary atomizer is an atomization method to burn these more problematic materials. In these atomizers, the liquid fuel is fed at low pressure via a distributor onto the inner surface of a horizontally arranged and rapidly rotating cup. The cup widens up to the combustion chamber, so that the oil flows to the cup outlet, driven by centrifugal force. The oil film that tears off at the end of the cup leads to the formation of fine oil droplets, which are atomized with the swirl into the combustion chamber. Part of the atomizing air is directed into the cup, the other part flows in an annular gap around the cup. The flame pattern is influenced by the addition and distribution of the atomizing air.

The advantage of the rotary atomizer is that it is independent of the viscosity properties of the fuel. The rotation of the beaker must be monitored, otherwise the low-pollutant combustion cannot be guaranteed (formation of CO and soot). A pressure monitor is used to determine the differential pressure on the rotating cup. If the value falls below the limit, the furnace is switched off.

Nebulizer with nebulizer media (injection nebulizer)

If liquid fuels are burned with an atomizing medium, one also speaks of an injection atomizer . The liquid fuel is fed to a nozzle with a relatively high pre-pressure. The atomizing medium, usually compressed air or steam, is introduced into the nozzle.

Steam is used as an atomizing medium, especially with larger burners. The advantage is the high temperature of the steam, which reduces the viscosity of the fuel. Around 5–10% of the fuel must be used as steam. Steam atomizers have a beneficial effect on reducing nitrogen oxide formation as the water vapor cools the flame. The water vapor partially dissociates and the oxygen radical reacts with the carbon of the fuel, so that carbon monoxide is first formed in the flame core. This means that fewer carbon particles can form, which are responsible for the strong radiation from oil flames. The flame gives off less energy through radiation; thus the exhaust remains hotter compared to other atomization methods.

Solid furnaces

Solid fuel firing can be distinguished on the one hand according to the fuel used and the firing method. The suitable firing method depends on the preparation of the fuel.

Grate firing

The grate furnace is used for lumpy fuels (gas-rich hard coal, wood chips). The area of application for grate firing ranges from room stoves to automatic grate firing systems such as traveling grates, vibrating grates or step grids. In these systems, primary air is fed through the grate and secondary air for post-combustion. The air volume can usually be adjusted depending on the zone.

A further development was necessary due to the special requirements for waste incineration , since this fuel has a low calorific value, the composition is heterogeneous and the fuel itself is often moist. Roller grates or scraper grates are used here. The grate of the grate is rigid, but individual grate bars or rows of bars can be moved.

Retort firing

Retort firing is a type of firing that is often found in coal combustion; however, it can also be used for numerous fuels such as pellets or grain. The fuel is brought into the retort from below at a clocked rate using a screw. Combustion and output are regulated by a fan that blows in at the exit of the fuel from the retort. The fuel then piles up on the retort. With optimal firing, the completely burned ash falls from the edge of the retort into an ash pan at the end of the process.

Fluidized bed combustion

In fluidized bed firing , the crushed fuel is fluidized and combustion takes place in a fluidized bed.

Dust firing

With dust firing , a homogeneous fuel ( hard coal , lignite , wood dust ) is ground in a coal mill and blown into the combustion chamber via a dust burner . The wood dust is mostly a waste product from wood processing.

A variant of dust firing is the melting chamber firing . Due to the special shape of the combustion chamber, very high slag temperatures are achieved, so that the slag remains liquid and the discharge flows into the purifier through the natural gradient.

Optimization of the furnace

Due to rising fuel prices, techniques have been developed to optimize furnaces and to increase efficiency and to use low-quality, cheap fuels (with high water or pollutant contents).

Optimization of fuels

Examples of fuel optimization would be:

- Reduction of the sulfur content of heating oil

- Delivery of kiln-dried logs

- Production of wood pellets with precisely defined properties (water content)

Optimization of the burner

The optimization of the burner aims to improve the combustion by reducing pollutants (carbon monoxide, nitrogen oxides). This is done by reducing the excess air to just above the stoichiometric ratio λ = 1. Since the 1980s, lambda probes have been used to fine-tune the air volume. By specifying a fixed, defined excess of air, fluctuations that are caused by temperature-related differences in density of the combustion air and possibly the fuel gas and mechanical play in the control of the fuel control valves can be compensated for. The first lambda probes were quite prone to failure; Satisfactory service lives of the probes are now achieved. In the 2010s, modified zirconium dioxide probes for use in gas firing systems came onto the market, which are sensitive to unburned components such as carbon monoxide and hydrogen and which have a steep characteristic curve when the CO content increases. The combustion is operated by the combustion manager used in such a way that the combustion air is regularly reduced until the characteristic increase in CO occurs. While the excess air is reduced to approximately λ = 1.025 when using oxygen probes, when using the CO probe, depending on the geometry of the furnace and the flame formation, λ = 1.005 to 1.008 can be achieved.

Improvement of the heat transfer

The aim of improving the heat transfer in a boiler is to lower the exhaust gas temperature and largely cool the exhaust gas. Due to partial condensation of the water vapor in the exhaust gas flow, the chemically bound energy converted into heat can be better used with the condensing technology . Even with industrial steam boilers, feed water preheaters (Eco) and, if necessary, preheaters for the make-up water or combustion air (Luvo) are used as standard.

Safety devices

Furnaces on steam boilers

Defined parameters must be adhered to when supplying fuel for firing a steam boiler . If the fuel supply takes place automatically, it must be safely interrupted if a safety criterion of the boiler system (e.g. lack of water) responds.

The safe ignition of the fuel and the monitoring of a furnace during operation are safety-relevant criteria to prevent deflagration with serious damage.

For this reason, control devices must be integrated into the devices for transporting fuel to the furnace, and equipment must be installed (see control and regulation ) that safely interrupt the flow of fuel.

In the case of a hot water heater that is directly fired with solid fuel , a thermal discharge safety device ensures that cold drinking water is supplied if the flow line overheats and the excessively hot water is discharged (usually into the sewer system).

Furnaces for gaseous or liquid fuels

Deflagrations can occur due to deficiencies in the furnace. A gas accumulation in the combustion chamber that is ignited is particularly dangerous. A stoichiometric gas-air mixture creates an explosion pressure of around 8 bar, which destroys the combustion chamber and the exhaust gas routes.

Flame guard

The flame monitor - also known as a flame sensor - has the function of monitoring the formation of the flame. For oil and gas firing, UV photodiodes can be used, the signal of which is amplified. Due to the high temperature in the flame, the gas is partially ionized and therefore has a measurable electrical conductivity. In the case of gas firing, this is used by inserting an insulated tungsten rod into the flame and measuring the current against the burner mass.

Burner control

The control of gas and oil burners takes place via a burner control , which includes the following functions:

- Closing the safety quick-closing valves for the fuel when a safety-relevant limiter is triggered (e.g. lack of water, overpressure) or when the emergency stop button is pressed,

- Compliance with and monitoring of the pre-ventilation in order to purge unburned gases from the boiler,

- The flame monitor is connected to the burner control. If the flame fails, the safety quick-closing valves for the fuel must be closed within a specified safety time.

- The pressure monitors for gas pressure min and combustion air min are connected to the burner control. If the pressure is insufficient, the safety quick-closing valves must be closed.

The burner control monitors safety-relevant functions. A release of fuel if the flame fails has the consequence that the entire flue gas space of a boiler is filled with an explosive gas-air mixture. Reignition at this point will result in deflagration and possibly destruction of the boiler. The automatic burner control must therefore be component-tested or subjected to an individual test. Automatic firing systems for gas are tested in accordance with the EC directive on gas appliances 90/396 / EEC and bear the assigned CE mark .

Up to the beginning of the 2000s, automatic firing systems were preferably designed as electromechanical components that had a roller control via which the fuel valves, combustion air fan and, if applicable, the oil feed pump are controlled. Relay controls were used for more complex systems, some of which had to be redundant in order to meet the safety requirements. For larger systems that are equipped with an electronic compound control and, if necessary, with an oxygen optimization for energy optimization, electronic fail-safe controls with microprocessors are now used, which allow a large number of parameterizations. The term combustion manager has established itself for these devices .

For shell boilers that are equipped in accordance with the European harmonized EN standard, the requirements for combustion systems for liquid and gaseous fuel for the boiler ( EN 12953-7) must be observed.

history

Orders from Count Palatine Karl IV. From 1772 also served to prevent a fire in connection with domestic fireplaces. According to the simultaneous building regulations, no more wooden chimneys were allowed to be erected, no more wooden hoses were allowed to be installed, which had to lead the smoke from the fireplace to the fireplace, just as it was forbidden to lead stovepipes out of the window.

Web links

literature

- Fritz Mayr (Hrsg.): Handbook of boiler operating technology: power and heat generation in practice and theory. 10th edition. Resch, Graefelfing 2003, ISBN 3-930039-13-3 .

Individual evidence

- ↑ a b c Text of the ordinance on small and medium-sized combustion systems

- ↑ Anja Behnke: Amendment of the ordinance on small and medium-sized combustion systems. Federal Environment Agency (publisher), October 2010, ( PDF file ) last accessed in October 2012, p. 3.

- ↑ Free and sovereign tasks , website of the Federal Association of Chimney Sweepers

- ↑ Legal information system of the Federal Chancellery on April 1, 2014: Combustion Systems Ordinance

- ↑ For more information on the implementation of the “Agreement in accordance with Art. 15a B-VG on the placing on the market of small combustion systems”, see also emission limit values, comparison of the approval limit values in Austria, Germany and Switzerland and “Agreement on protective measures relating to small combustion systems” of the Province of Upper Austria

- ↑ Clean Air Ordinance of December 16, 1985, as of April 1, 2020. Swiss Federal Council, April 1, 2020, accessed on April 20, 2020 .

- ↑ Emission limit values, comparison of the approval limit values in Austria, Germany and Switzerland

- ↑ lamtec.de: CO control the better alternative to O control in gas firing

- ^ Franz-Josef Sehr : The fire extinguishing system in Obertiefenbach from earlier times . In: Yearbook for the Limburg-Weilburg district 1994 . The district committee of the Limburg-Weilburg district, Limburg-Weilburg 1993, p. 151-153 .