Isomannid

| Structural formula | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||

| General | ||||||||||||||||

| Surname | Isomannid | |||||||||||||||

| other names |

|

|||||||||||||||

| Molecular formula | C 6 H 10 O 4 | |||||||||||||||

| Brief description |

white to light yellow crystal powder |

|||||||||||||||

| External identifiers / databases | ||||||||||||||||

|

||||||||||||||||

| properties | ||||||||||||||||

| Molar mass | 146.14 g mol −1 | |||||||||||||||

| Physical state |

firmly |

|||||||||||||||

| Melting point | ||||||||||||||||

| boiling point | ||||||||||||||||

| solubility |

|

|||||||||||||||

| safety instructions | ||||||||||||||||

|

||||||||||||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . | ||||||||||||||||

Isomannide is a two- cis -ständigen tetrahydrofuran rings fused bicyclic oxygen-containing heterocycle from the group of diols . Like the stereoisomeric - also known as isohexides - 1,4: 3,6- dianhydrohexitole isosorbide (from D - sorbitol ) and isoidide (from L - iditol) is isomannide from the precursor - sugar alcohol D - mannitol ( D - mannitol ) by twofold Dehydration accessible. Isomannide is discussed in particular as a diol component made from renewable raw materials for polyester , polycarbonate and polyurethane .

Occurrence and representation

The appearance and properties of isomannide were first described in 1884. When mannitol (from D - fructose by catalytic hydrogenation ) is heated with 10 times the amount of hydrochloric acid for 24 hours, isomannide is formed, which is initially obtained as a syrupy liquid that solidifies into a crystalline mass.

The isomannide yield in the acid-catalyzed dehydration of mannitol can be increased to 63% when using crystalline acidic zeolites .

Mannitol is dehydrated even without the addition of acid at high temperatures (573K) in liquid water, whereby the monoanhydrohexitols 1,4- and 2,5-anhydromannitol are formed by splitting off a water molecule, which with further splitting off of water in a modest yield (approx %) react to isomannide.

Instead of the relatively expensive mannitol, isosorbide, which is available on an industrial scale, can also be used as a raw material for isomannide. During the catalytic isomerization of isosorbide with hydrogen (10.3 MPa) in the presence of a nickel catalyst at 200-230 ° C, an equilibrium mixture of the three dianhydrohexitols is formed, in which, however, only less than 10% isomannide is present.

The most efficient is the oxidation of isosorbide with oxygen in the presence of a platinum catalyst or with nitrates and nitrites , as well as the oxidizing agent 4-acetamido- TEMPO (AA-TEMPO) to the diketone 2,6-dioxabicyclo- (3.3.0) -octane 4,8-dione in high yields of over 95%.

The diketone can e.g. B. with sodium borohydride NaBH 4 in aqueous solution in 90% yield can be selectively reduced to the diol isomannide.

properties

Isomannide is a white to light yellow, slightly hygroscopic solid that dissolves very well in water. In aqueous solution the substance shows optical activity and is clockwise (α D = 91 °, 6% in H 2 O). Isomannide is also readily soluble in polar alcohols such as methanol or ethanol. At 86 ° C, its melting point is significantly higher than the other isohexides isoidide (64–65 ° C) and isosorbide (61–64 ° C). According to Arthur C. Cope , the two hydroxyl groups are in the endo configuration and form intramolecular hydrogen bonds .

Applications

The mono- and dinitrates of isomannide have a significantly less vasodilatory effect than the corresponding isosorbide nitrates ISMN ( isosorbide mononitrate ) and ISDN ( isosorbide dinitrate ) and are therefore therapeutically insignificant.

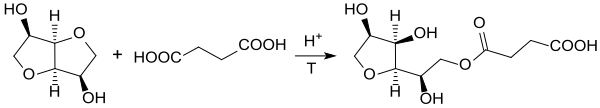

Analogous to the sorbitan fatty acid esters , nonionic surfactants are formed from isomannide by esterification with long-chain carboxylic acids .

The chiral and rigid “sugar diol” isomannide is interesting as a monomer component for polycondensates , e.g. B. polyester and for polyadducts such. B. Polyurethanes. However, the endo - endo diol isomannide shows significantly lower reactivity in polycondensation reactions with dicarboxylic acids and lower molar masses of the polyesters formed than the isohexides isosorbide and isoidide. The thermal instability with discoloration and the branching and crosslinking due to partial cleavage of a tetrahydrofuran ring from the bicyclic isomannide system are also disadvantageous.

The gentle enzymatic esterification by means of lipases provides polyesters with unsatisfactorily low molecular weights .

The ring-opening polymerization of cyclic oligomeric isomannide- 2,5-furandicarboxylic acid esters with cyclic oligo (butylene-2,5-furandicarboxylate) has recently been described, which under tin (II) -2-ethylhexanoate catalysis to form completely bio-based copolyesters with high glass transition temperatures T g and good biodegradability can be implemented.

Diamines are of isomannide starting as molecular building blocks for polyamides and polyurethanes of interest. In a Gabriel synthesis , the ditosylate (2) of isomannide (1) can be converted with phthalimide potassium with Walden inversion to diphthalimidoisoidide (3), which is acid-catalyzed to form a mixture of monoaminoisoidide hydrochloride (4) and predominantly diaminoisoidide dihydrochloride (5) responds. The 2,5-diamino isoidide (6) can be obtained from (5) in a total yield of approx. 50%.

This multistage synthesis is unsuitable for the industrial production of diamine, as is the possible alternative route with sodium azide in ionic liquids via the diazide.

The direct amination of the dianhydrohexitols isosorbide or isomannide by means of ruthenium- phosphine complex catalysts in a homogeneous phase, which originated from the working groups of Matthias Beller and Dieter Vogt , provides practically quantitative yields of isohexide diamine mixtures - in the case of isomannide as the starting material in the composition 14.9% diaminoisomannide + 36.1% diamino isoidide + 44.7% diamino isosorbide. However, the (laborious) isolation and purification of the target product 2,5-diaminoisomannide which is formed the least percentage is not indicated.

The synthesis from the diketone via the diimine and its hydrogenation at a nickel contact appears to be the most powerful for generating the diaminoisomannide .

A mixture of a significantly higher proportion of diaminoisomannide (60%) in addition to diaminoisosorbide (35%) and diaminoisoidide (5%) is obtained in 96% yield. A separation of this mixture is also not described.

In addition, with diaminoisomannide as the diamine component, polyamides with the lowest molar masses of all diaminoisohexides were obtained, which are technically uninteresting.

The poorer accessibility compared to isosorbide and the resulting higher price, but especially the significantly lower reactivity of the two secondary hydroxyl groups, make isomannide less attractive as a starting material for further syntheses. Thermal instability (discoloration) and the tendency to side reactions (branching and crosslinking) under polycondensation conditions further limit the potential of isomannide as a monomer and raise doubts about the future of isomannide as a relevant synthetic and polymer building block made from renewable raw materials.

Individual evidence

- ↑ a b c d Entry on isomannides at TCI Europe, accessed on January 15, 2019.

- ↑ a b c Data sheet 1,4: 3,6-Dianhydro-D-mannitol from Sigma-Aldrich , accessed on January 15, 2019 ( PDF ).

- ↑ a b U. Koert: Isomannide and Isosorbide . In: e-EROS Encyclopedia of Reagents for Organic Synthesis . 2012, doi : 10.1002 / 047084289X.rn01380 .

- ↑ a b c d e f g A. Fauconnier: Anhydride de la mannite . In: Bull. Soc. Chim. France . tape 2 , no. 41 , 1884, p. 119-125 ( bnf.fr ).

- ↑ a b c d F. Fenouillot, A. Rousseau, G. Colomines, R. Saint-Loup, J.-P. Pascault: Polymers from renewable 1,4: 3,6-dianhydrohexitols (isosorbide, isomannide and isoidide): a review . In: Progress Polym. Sci. tape 35 , no. 5 , 2010, p. 578-622 , doi : 10.1016 / progpolymsci.2009.10.001 .

- ↑ H. Yokoyama, H. Kobayashi, J. Hasegawa, A. Fukuoka: Selective dehydration of mannitol to isomannide over Hβ zeolite . In: ACS Catal. tape 7 , no. 7 , 2017, p. 4828-4834 , doi : 10.1021 / acscatal.7b01295 .

- ↑ A. Yamaguchi, O. Sato, N. Mimura, M. Shirai: Intramolecular dehydration of mannitol in high-temperature liquid water without acid catalysts . In: RSC Adv. Band 4 , no. 85 , 2014, p. 45575-45578 , doi : 10.1039 / C4RA09198A .

- ↑ a b M. Rose, R. Palkovits: Isosorbide as a renewable platform chemical for versatile applications - quo vadis? In: ChemSusChem . tape 5 , no. 1 , 2012, p. 167-176 , doi : 10.1002 / cssc.201100580 .

- ↑ a b K. Heyns, W.-P. Trautwein, H. Paulsen: About catalytic oxidations, XX. Selective catalytic oxidation of 1.4; 3.6-dianhydrohexites . In: Chem. Ber. tape 96 , no. 12 , 1963, pp. 3195-3199 , doi : 10.1002 / cber.19630961214 .

- ↑ a b Patent EP2393817B1 : Process for the production of 2,6-dioxabicyclo- (3.3.0) -octane-4,8-dione. Filed on Jan. 26, 2010 , published on March 27, 2013 , Applicant: Evonik Degussa GmbH, inventors: U. Dinger Dissen et al ..

- ↑ Patent WO2018112774A1 : Process for preparing isomannide, monoketones and mixtures thereof. Registered on December 21, 2016 , published on June 28, 2018 , applicant: Rhodia Operations, inventor: M. Corbet, J. Lai.

- ^ AC Cope, TY Shen: The stereochemistry of 1,4: 3,6-dianhydrohexitol derivatives . In: J. Amer. Chem. Soc. tape 78 , no. 13 , 1956, pp. 3177-3182 , doi : 10.1021 / ja01594a055 .

- ↑ MG Bogaert, MT Rosseel: Vascular effects of the dinitrate and mononitrate esters of isosorbide, isomannide and isoidide . In: Naunyn-Schmiedebergs archive . tape 275 , no. 3 , 1972, p. 339-342 , doi : 10.1007 / BF00500061 .

- ↑ TVK Reddy, GS Ravi, RBN Prasad, BLAP Devi: Green recyclable SO3H-carbon catalyst for the selective synthesis of isomannide-based fatty acid monoesters as non-ionic bio-surfactants . In: RSC Adv. Band 5 , no. 51 , 2015, p. 40997-41005 , doi : 10.1039 / C5RA03605D .

- ^ HR Kricheldorf: “Sugar Diols” as building blocks of polycondensates . In: J. Macromol. Sci., Part C . tape 37 , no. 4 , 1997, p. 599-631 , doi : 10.1080 / 15321799708009650 .

- ↑ MD Zenner, Y. Xia, JS Chen, MR Zenner: Polyurethanes from isosorbide-based diisocyanates . In: ChemSusChem . tape 6 , no. 7 , 2013, p. 1182-1185 , doi : 10.1002 / cssc.201300126 .

- ↑ Bart AJ Noordover: Biobased step-growth polymers: chemistry, functionality and applicability . Ed .: Eindhoven University of Technology , dissertation. Eindhoven 2008, doi : 10.6100 / IR631662 .

- ^ AF Naves, HTC Fernandez, APS Immich, LH Catalani: Enzymatic syntheses of unsaturated polyesters based on isosorbide and isomannide . In: J. Polym. Sci. tape 51 , no. 18 , 2013, p. 3881-3891 , doi : 10.1002 / pola.26789 .

- Jump up ↑ JC Morales-Huerta, A. Martinez de Illarduya, S. León, S. Munoz-Guerra: Isomannide-containing poly (butylene-2,5-furandicarboxylate) copolyesters via ring-opening polymerization . In: Macromolecules . tape 51 , no. 9 , 2018, p. 3340-3350 , doi : 10.1021 / acs.macromol.8b00487 .

- ↑ M. Janvier, S. Moebs-Sanchez, F. Popowycz: Nitrogen-functionalized isohexides in asymmetric induction . In: Chimia . tape 70 , no. 1/2 , 2016, p. 77-83 , doi : 10.2533 / chimia.2016.77 .

- ↑ S. Thiyagarajan, L. Gootjes, W. Vogelzang, J. Wu, J. van Haveren, DS van Es: Chiral building blocks from biomass: 2,5-diamino-2,5-dideoxy-1,4-3, 6-dianhydroiditol . In: Tetrahedron . tape 67 , no. 2 , 2011, p. 383-389 , doi : 10.1016 / j.tet.2010.11.031 .

- ^ TG Barros et al .: Pseudo-peptides derived from isomannide: inhibitors of serine proteases . In: Amino Acids . tape 38 , no. 3 , 2010, p. 701-709 , doi : 10.1007 / s00726-009-0273-4 .

- ↑ S. Imm et al .: Improved ruthenium-catalyzed amination of alcohols with ammonia: Synthesis of diamines and amino esters . In: Angew. Chem. Int. Ed. tape 50 , no. 33 , 2011, p. 7599-7603 , doi : 10.1002 / anie.201103199 .

- ↑ D. Pingen, O. Diebolt, D. Vogt: Direct amination of bio-alcohols using ammonia . In: ChemCatChem . tape 5 , no. 10 , 2013, p. 2905-2912 , doi : 10.1002 / cctc.201300407 .

- ↑ Patent US9029412B2 : Method for preparing diamino-dianhydro-dideoxyhexitols, particularly preferably 2,5-diamino-1,4: 3,6-dianhydro-2,5-dideoxy-D-hexitol. Registered on June 28, 2011 , published on May 12, 2015 , applicant: Evonik Degussa GmbH, inventor: G. Streukens, C. Lettmann, S. Schneider.

- ↑ J. Thiem, F. Bachmann: Synthesis and properties derived from anhydro- and dianhydroalditols . In: Macromol. Chem. Band 192 , no. 9 , 1991, pp. 2163-2182 , doi : 10.1002 / macp.1991.021920922 .