Pizza box

The pizza box or the pizza box is a folding box made of cardboard in which hot pizza from a delivery service or from the pizzeria can be transported. The pizza box must have a high mechanical strength, be stackable, thermally insulated with simultaneous moisture regulation and suitable for food. It also offers space for advertising. The pizza box differs from the packaging of frozen pizzas . This contains the frozen product welded in foil and is similar to the outer packaging of other frozen products.

history

Containers for the delivery of fresh pizzas have been around since at least the 19th century, when Neapolitan pizza bakers packed their products in multi-layer metal containers, so-called stufe (singular stufa , 'oven'), and used them to send sellers out onto the streets. The ventilated container was round and made of tin or copper.

The development of disposable packaging for pizza began in the United States after World War II . At that time, pizza was gaining popularity there, and the first pizza delivery services arose. There have been attempts to deliver pizzas in simple cardboard boxes, similar to those used by pastry shops. However, these often got damp, dripped, bent or broke through completely. Other pizza makers tried to put the pizza on a platter and put both together in a paper bag. This did less damage. However, it was almost impossible to transport more than one pizza at the same time in one bag. In this method, the top pizzas will damage the surfaces of the lower ones.

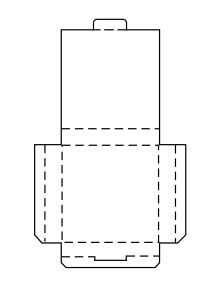

The first patent for a pizza box made of corrugated cardboard was applied for in 1963. It already describes the basic features of today's pizza boxes: flat blanks, foldability without glue, stackability and ventilation slots. By combining ventilation slots with a material that absorbs water vapor ( adsorbent ), the moisture build-up in conventional transport packaging for fresh pizza can be reduced.

According to his own statement , the first pizza boxes in Germany were used by Nicolino di Camillo , who opened Germany's first pizzeria "Sabbie di Capri" in Würzburg in 1952 and, according to the House of Bavarian History, also the inventor of the pizza box, which is available in two sizes.

It is also claimed that Domino's Pizza (founded in 1960) was the inventor of the pizza box, but without having registered a patent for it. In the pizza box variant used by this pizza chain until 1988, there was no direct connection between the corners created during the folding between the front wall and the two side walls. Rather, only the tabs attached to the wall surfaces were folded inwards under the lid. This design is also known as the "Chicago Fold". Domino's was the first pizza maker to use pizza boxes on a large scale and understood how to use them to expand its delivery area over the area immediately around the pizzeria. With the introduction of heat-insulating bags for pizza boxes, the delivery range was further expanded at the end of the 1960s.

conditions

Mechanical stability and stackability

Most transport packaging for pizza is made of cardboard , as this material is inexpensive and has various functional properties. Both solid cardboard and single-wall corrugated cardboard are used . E-corrugated cardboard (micro or fine flute with a corrugation pitch of 3.0 to 3.5 mm and a flute height of 1.0 to 1.8 mm) is often used as corrugated cardboard, but the somewhat thicker B corrugated cardboard is also used processed with a wave height of 2.2 to 3.0 mm. It is not just the geometric structure of the corrugated cardboard that determines the strength of the cardboard, but above all the type and weight of the paper used. As cover layers usually come in the carton inside kraftliner used. These not only make the cardboard stable, but also more resistant to moisture and oil.

In order to keep the storage space for packaging small, the pizza boxes are mostly folded from flat blanks shortly before use. Different material thicknesses are clearly noticeable in the storage space requirements. Pizza boxes made of solid cardboard require around half of the storage space compared to pizza boxes made of E-corrugated cardboard and around a quarter of storage space compared to pizza boxes made of B-corrugated cardboard. The stability of the cardboard is determined not only by the material itself but also by the shape of the fold. Cardboard boxes in which flaps that are firmly connected to the side walls are folded into the front wall have become popular. As a result, the walls of the box are connected to one another at the corners and the stability increases. Traditional folding is an example of this type of folding. The disadvantage of this folding is that the walls of the carton stand vertically upwards and it is more difficult to cut the pizza inside the carton with a pizza roll cutter .

Thermal insulation and moisture regulation

The pizza box should enable the transport of a baked pizza with the least possible loss of quality. It should fulfill two tasks that are difficult to reconcile with one another: On the one hand, the carton should insulate as well as possible - against cold outside air, possibly wind and radiation - so that the pizza stays hot. To reduce the flow of heat, the box must close as tightly as possible in order to keep the warm air inside. The temperature range that consumers consider optimal for tastings is between 70 and 85 ° C. On the other hand, it should prevent moisture penetration so that the pizza base is crispy and the topping is crisp when it reaches the consumer. To do this, the water vapor emerging from the pizza must be discharged to the outside (ventilation holes and some diffusion through the box) or absorbed by the box. In pizza boxes made of corrugated cardboard that are not provided with additional insulation, the transported goods cool down too much after around ten minutes.

If it comes into contact with untreated corrugated cardboard, the oil from the pizza dough can penetrate it and dissolve flavors from the pulp. In order to prevent a change in the taste of the pizza due to the ingredients of the pizza box and at the same time the cardboard material from soaking through, some pizza boxes have a thin aluminum foil coating on the inside. Another option is to lay the pizza on aluminum foil, a bonded carrier material made of corrugated cardboard and blotting paper or wax paper. However, this changes the thermodynamic properties of the pizza box considerably. The pizza base can no longer release moisture downwards, the underlay not only acts as a fat barrier , but also as a kind of vapor barrier .

Exterior surface and advertising

Usually the outer surface of the carton is either provided with a generic pizza image or with advertising for the supplier or is unprinted. The colors red and green, which are reminiscent of the colors of the flag of Italy, are often used for the printing . White cover paper is often used to produce higher-contrast printing, but brown recycled paper is also used as the outer layer. Individual pizza chains use the lid of the box to characterize the pizza topping using a list of ingredients that can be marked. This enables identification without opening the packaging.

However, the cardboard surface can also be used for other purposes. The pizza boxes can be used as a special form of advertising in the context of ambient media campaigns. They are also considered to be unusual and unexpected ad space for guerrilla marketing . For example, in 2008 the Economist magazine in Philadelphia worked with pizza delivery services near universities. They printed advertisements for the Economist on their pizza boxes . This essentially consisted of a pie (/ pizza) diagram that linked pizza consumption with the global economy and aimed specifically at students.

In 2001 the pizza box with third party advertising was patented. Third-party advertising pressure means that advertising is not for pizza or the manufacturer of the product or packaging, but for products from third parties, for example mobile phone providers or movies. The registering company provides pizza delivery services free of charge and is financed by the advertising printed on the pizza boxes. In 2017, for example, the Ministry of Defense of the Federal Republic of Germany had a total of 725,000 pizza boxes with advertising for the Bundeswehr printed and distributed to pizza bakers for around 200,000 euros.

variants

Most of the pizza boxes used today have a square or a hexagonal base with the two front corners bevelled. The latter variant is often referred to with the model name "Treviso". Compared to the square version, it is somewhat more torsion-resistant, but the corners make it a little slower to assemble. Pizza boxes are offered in different sizes. The commercially available dimensions range from around 20 × 20 cm (for very small pizzas) to 60 × 60 cm, or as a rectangular shape 40 × 60 cm (for party or family pizzas). In order to prevent the pizza from sticking to the lid, the standard height of the boxes for smaller variants is usually 3 cm. For particularly high-baked pizzas, however, special sizes from 4 to 5 cm in height are also available. For the larger boxes, heights of 4 cm, but also 5 cm, are typical. There are also special sizes (e.g. for pizza calzones) with a carton height of 7 to 10 cm and a mostly rectangular base.

The smallest packaging unit usually consists of 100 or 200 boxes, depending on the size and provider. In the case of special sizes, 50 or 100 boxes can also form a packaging unit. The price per box depends among other things on the size, the printing, the quality and the purchase quantity and is around 10 to 20 cents for typical pizza box sizes.

Most pizza boxes have the front and side flaps of the lid tucked inwards into the base. If the box is closed carelessly, there is a risk that the tabs will press on the edge of the pizza. In some cardboard boxes, cutouts are therefore provided on the flaps to prevent this. An internal closure can have advantages in terms of folding and handling.

While most pizza boxes are square, e.g. B. Domino's Pizza octagonal cardboard boxes that enclose the pizza more closely and thus minimize the pizza slipping. This also reduces the need for packaging material by 10 percent. The American delivery service Papa John's, on the other hand, has separated the corners within the square box; On the one hand, this prevents the pizza from slipping; on the other hand, the resulting compartments can also accommodate sauce or other side dishes. Another version is the triangular single slice pizza carrier modeled on a piece of cake , which was developed around 1990 by Stephen L. France and Gregory P. Phelps , was patented in 1992 and is used to transport a piece of pizza.

A cardboard variant has been on the market since 2009 in which the pizza box can be closed in a space-saving manner after half a pizza has been removed. Furthermore, the lid can be divided into four parts by perforations in order to pass the pizza on in portions.

Aids for pizza delivery

Pizza saver

In the USA, many pizza boxes now have a spacer (reminiscent of a three-legged table) made of heat-resistant plastic (usually polypropylene ), the so-called pizza saver (also known as package saver , box tent , pizza table or pizza lid support ) in the middle of the lid . . This prevents the lid of the box from touching the pizza and the topping (such as cheese ) from sticking to the lid during delivery .

The pizza saver goes back to a patent granted in 1985 by the American Carmela Vitale .

The use of this small piece of plastic is also often criticized as a waste of resources, as it is only used once and then usually thrown away. Therefore ideas for its reuse are developed.

Transport bags and boxes

For the delivery of pizzas in pizza boxes, there are lined transport bags and boxes that are adapted to the typical sizes of the boxes. Some bags can be actively heated to maintain the temperature. These can usually be operated either with electricity from the socket or with the 12-volt car power network. With the use of these aids, the requirement regarding the thermal insulation of pizza boxes themselves is no longer so important.

Pizza boxes with their contents must be transported horizontally throughout and protected from excessive lateral acceleration and impacts. For this purpose, carrier bags usually have a longer carrying loop on both sides, which together allow the bag to be carried slightly to the side of the body with one hand. Carrying bags insulate best when they are closed with a horizontal 3/4 all-round zipper. One bag holds around 3–5 boxes, which is usually sufficient for one delivery address. If there is more demand, a higher bag is selected or two lower bags are placed on top of each other and carried in front of the body with both hands.

Pizza box with thermal indicator

Pizza boxes the chain Pizza Hut in Morocco and other countries included on the outside of a thermal indicator , intended to provide a color coding statements about the temperature of the pizza. If the pizza is hot when it is delivered, the indicator shows the red lettering 'HOT' on a white background; if, on the other hand, the pizza falls below a certain temperature, the 'Hot Dot' turns black and the writing is no longer legible. If the pizza is too cold for the recipient, he will receive a free pizza with the next delivery. The indicator is intended for single use.

Possible contamination

The European Regulation No. 1935/2004 regulates that the contact of packaging materials with food may not transfer substances in such quantities that a health hazard or an unacceptable change or impairment of the food occurs. In the recommendations of the Federal Institute for Risk Assessment (BfR), all permitted ingredients for paper, cardboard and cardboard are compiled. In particular, in the BfR recommendation, fibers recovered from waste paper are also allowed as paper raw material for the production of food contact materials, provided that they meet certain conditions. Depending on the source and type of waste paper, raw materials can be contained in waste paper, which z. B. come from books, magazines or office waste and were not intended to come into contact with food. Not all of these substances can be removed during the recycling process, or individual cleaning steps may have been omitted to reduce costs. Known possible contaminants are diisopropylnaphthalene (DIPN) from carbonless paper, benzophenones from printing inks, phthalates (DiBP) from adhesives and mineral oils ( MOSH / MOAH ) from newspaper printing.

mineral oil

In 2009, studies by the Zurich Cantonal Laboratory (Switzerland) showed that recycled cardboard can contain high levels of mineral oil . The mineral oils came from printing inks that are customary for newspaper printing and were not completely removed in the recycling process. Animal studies show that mineral oil mixtures with low viscosity are stored in the body and can lead to deposits and damage in the liver, the heart valves and the lymph nodes. The Federal Institute for Risk Assessment therefore came to the conclusion that the transfer of mineral oil to food must be minimized.

In 2012, the consumer magazine Öko-Test ordered several salami pizzas from large pizza service providers and had them examined in the laboratory. Mineral oil could be detected in two of the three pizzas. One of these samples even contained an increased amount. The color of the pizza box is no guarantee that the cardboard will also consist of new paper on the inside.

In 2017, the Association of Cantonal Chemists in Switzerland, VKCS, examined food packaging made of paper and cardboard . Eleven of the 78 packagings examined (14%) contained substances in quantities that exceeded the maximum values applicable to food packaging . The laboratory found high levels of mineral oil residues in 42 samples (62%), which can be assumed to be transferred to the food during storage.

Diisopropylnaphthalene (DIPN)

Diisopropylnaphthalene (DIPN) is used as a solvent in carbonless papers . These, in turn, can be part of the waste paper that is used to recycle raw materials in the manufacture of packaging materials such as pizza boxes. The DIPN can be transferred from the packaging to the food packed in it through direct contact or evaporation. In particular, fatty foods such as pizza with cheese toppings can absorb DIPN. According to the current state of knowledge, there are no concerns with regard to health risks for consumers. Nevertheless, DIPN-contaminated papers may not be used in the area of foodstuffs and consumer goods due to the general minimization requirement for the transfer of substances to food.

In 2004, the Rhineland-Palatinate State Investigation Office was able to detect increased levels of the solvent diisopropylnaphthalene (DIPN) in pizza boxes and snack packaging . Over 30 percent of the samples contained more than 50 milligrams of DIPN per kilogram of carton. In studies by the Lower Saxony State Office for Consumer Protection and Food Safety , a content of 107.7 to 232.2 mg / kg was even detected in five pizza box samples. In later reports of the state investigation offices there are no more reports of such finds.

Diisobutyl phthalate (DiBP)

With regard to diisobutyl phthalate (DiBP), findings have been available since 2007 for a transfer of the chemical compound from recycled paper / cardboard to food. DiBP is used as a plasticizer in dispersion adhesives (e.g. in corrugated cardboard, the adhesive backing of magazines, books) and entered via the recyclate. The state investigation facilities regularly check packaging and report the results to the Federal Office for Consumer Protection and Food Safety (BVL). The industry's minimization strategies to avoid DiBP are having an effect, so that the proportion of suspicious samples continues to decrease and the BfR guideline value could be reduced from 1 to 0.3 mg / kg in 2011.

Fluorotelomer Alcohols (FTOH)

So that pizza boxes do not soften during use, they can be coated with perfluorochemicals. These grease and water-repellent chemicals can contain certain amounts of fluorotelomer alcohols (FTOH) as impurities or decomposition / conversion products from the manufacturing process of the perfluoro compounds, which in turn can be partially converted in the body into perfluorooctanoic acid (PFOA). The European Food Safety Authority (EFSA) has given PFOA a very critical assessment due to the toxicological findings in animal experiments and the long half-life in human blood. Investigations at paper mills in North Rhine-Westphalia showed increased levels of fluorine compounds in individual cases, although in these cases no fluorine compounds had been actively added. According to the Federal Environment Agency (2009), contaminated waste paper would be a possible entry path . A pollutant depletion in the waste paper cycle usually takes several years even after the cause has been clarified.

Packaging Ordinance

In Germany, pizza boxes represent sales packaging according to Section 3 of the Packaging Ordinance, as they are offered as a sales unit and are incurred by the end consumer. Sales packaging or service packaging within the meaning of the ordinance is packaging for retail , catering and other service providers that enable or support the transfer of goods to the end consumer. Put simply, it is service packaging if a seller only packs the goods immediately before they are handed over to the consumer.

According to § 12 , “General requirements” are presented for the packaging. "Packaging is to be manufactured and sold in such a way that

- The packaging volume and mass are limited to the minimum that is appropriate to maintain the necessary safety and hygiene of the packaged product and to ensure its acceptance by the consumer;

- their reuse or recovery is possible and the environmental impact of recovery or disposal of packaging waste is limited to a minimum;

- harmful and dangerous substances and materials are limited to a minimum when disposing of packaging or packaging components in emissions, ash or leachate. "

The Packaging Ordinance regulates the recycling of packaging in Section 6 . According to this, there is a licensing requirement for the first distributor of packaging and goods, i.e. those who first market the packaging as a unit of pizza box and pizza, i.e. pizzeria and delivery service. The initial distributor participates in the dual system for recycling the cardboard boxes through licensing . If, as in the case of the pizza box, the packaging typically comes from the private end consumer, the pizzeria can transfer the licensing to the manufacturer or distributor of the service packaging. This is to prevent the large number of small and medium-sized companies from having to make license agreements with dual systems themselves.

recycling

There are different regulations for disposal in the individual municipalities in Germany. Clean, uncoated cardboard boxes should usually be disposed of with the waste paper. For the disposal of soiled pizza boxes with buildup, either the organic waste bin or the residual waste is suggested. Pizza boxes coated with aluminum are composite materials that are fed into the yellow sack .

The problem with recycling pizza boxes is sticky food residue such as cheese and fat, as well as oil that has been absorbed by the paper fibers of the box. While such residues are not a problem when recycling plastic, metal or glass, the process of waste paper recycling is very sensitive. This is due to the fact that primarily water is used to break down the paper fibers into a paper pulp . However, water and oil do not mix and the oil floats together with the paper fibers on the surface. If the excess water is pressed out of the pulp, the oil causes voids and stains, which reduce the paper quality of the entire batch or even make it unusable. In addition, stickers on the pizza boxes can also disrupt the recycling process. Contamination is a big problem in the recycling process. The damage is estimated at around $ 750 million per year worldwide.

Over a billion pizzas are shipped in pizza boxes every year. In the United States, one percent of corrugated cardboard production is used for pizza boxes. There are now separate collection points for used pizza boxes.

There are also coated pizza boxes in the United States that are easier to recycle. Some pizzerias use round polystyrene containers . However, these are significantly more expensive than the corrugated cardboard variant, ventilate more poorly and are more difficult to recycle. Round corrugated cardboard boxes are discussed [receipt?] , But not yet used.

Pizza boxes in art and culture

The British painter and conceptual artist Adam Neate uses corrugated cardboard from cardboard boxes and specially folded pizza boxes as an inexpensive substitute for canvas. The American artist John Landsiedel also uses closed pizza boxes reinforced with an internal wooden frame as a substitute for canvas. By painting all six sides, his works of art stand between conventional images and sculpture. He paints exclusively with acrylic paints ; Landsiedel covers the finished works with an epoxy layer to preserve paints and pizza boxes .

Various artists designed the design of their CD sleeves as pizza boxes, including the band Die Ärzte mit Jazz ist anders (2007), Brimstone Howl with European Tour 2008, Cam Deas with My Guitar Is Alive And It's Singing (2009) or Andrew Coltrane with Refuse (2009). The Jon Spencer Blues Explosion named a promo album released in 1997 as the Pizza Box Promo after it was packed in a pizza box .

Metaphor in information technology

Some personal computers and servers were also referred to as “ pizza boxes ”. Well-known examples are the "Pizzabox Workstations" ( SPARCstation ) from Sun Microsystems from 1989 and the Macintosh LC II from Apple from 1992. Both are reminiscent of a pizza box due to their shape and size.

literature

- Patrizia Fava, Luciano Piergiovanni, Ella Pagliarini: Design of a functional box for take-away pizza. In: Packaging Technology and Science. To International Journal. Volume 12, No. 2, March / April 1999, pp. 57-65, doi : 10.1002 / (SICI) 1099-1522 (199903/04) 12: 2 <57 :: AID-PTS447> 3.0.CO; 2- R (summary).

- XXXVI. Papers, cardboard and cardboard for food contact . ( Memento of August 10, 2014 in the Internet Archive ) Federal Institute for Risk Assessment, as of January 1, 2012; Retrieved May 26, 2012.

Web links

- History of pizza boxes (english)

Individual evidence

- ^ A b Heston Blumenthal : In Search of Perfection. Bloomsbury Publishing, 2006, ISBN 0-7475-8409-5 , p. 63.

- ↑ a b c d Alexis Madrigal: The 3 Big Advances in the Technology of the Pizza Box . In: The Atlantic . July 18, 2011.

- ↑ a b Abraham L. Tunick, Container, US Patent 3,163,344 ( Memento of the original dated August 14, 2016 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. issued December 29, 1964.

- ↑ Ralph Bauer: GIs fought over the first pizza in Germany . In: The world. (March 26, 2012).

- ↑ Berliner Zeitung (counter statement): The Italians Giuseppe and Nicola di Camillo opened Germany's first pizzeria 50 years ago .

- ^ House of Bavarian History: Janina Camillo: ballet dancer and restaurateur .

- ^ A b John Correll: Pizza Packaging, Overview & History. Archived from the original on August 25, 2012 ; accessed on March 11, 2012 (English).

- ^ Matt Haig: Brand Success: How the World's Top 100 Brands Thrive and Survive. Kogan Page Publishers, 2011, ISBN 0-7494-6287-6 , p. 241. ( Google Preview )

- ↑ Jean L. Walsh, Insulated Container for Pizza Pies, US Patent 3,428,103 ( Memento of the original from September 24, 2015 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. issued February 18, 1969.

- ^ A b c d e f John Correll: Pizza Packaging, Structural Options, Pros & Cons. Archived from the original on August 19, 2012 ; accessed on March 11, 2012 (English).

- ↑ Patrizia Fava, Luciano Piergiovanni, Ella Pagliarini: Design of a functional box for take-away pizza . In: Packaging Technology and Science . tape 12 , no. 2 . Wiley, March 1, 1999, ISSN 1099-1522 , pp. 57-65 , Table 4 , doi : 10.1002 / (SICI) 1099-1522 (199903/04) 12: 2 <57 :: AID-PTS447> 3.0.CO; 2-R .

- ↑ Patrizia Fava, Luciano Piergiovanni, Ella Pagliarini: Design of a functional box for take-away pizza . In: Packaging Technology and Science . tape 12 , no. 2 . Wiley, March 1, 1999, ISSN 1099-1522 , pp. 57-65 , Figure 2 , doi : 10.1002 / (SICI) 1099-1522 (199903/04) 12: 2 <57 :: AID-PTS447> 3.0.CO; 2-R .

- ↑ Norbert Drees and Markus Jäckel: Guerilla Marketing - Basics, Instruments and Examples. In: transfer - Advertising Research & Practice. 2/2008, p. 32, transfer-zeitschrift.net (PDF)

- ↑ E1132304 A1 ( Memento from January 26, 2013 in the web archive archive.today ) Packaging with third-party advertising , accessed on July 14, 2012.

- ↑ Fast Food: Bundeswehr exercise on pizza packs costs 202,000 euros. Accessed January 1, 2018 (German).

- ^ Kye-Sung Chon, Thomas A. Maier: Welcome to Hospitality: An Introduction . Cengage Learning, 2009, ISBN 1-4283-2148-9 , p. 263.

- ^ Shri L. Henkel, Douglas Robert Brown: How to Open a Financially Successful Pizza & Sub Restaurant . Atlantic Publishing Company, 2006, ISBN 0-910627-80-0 , p. 321.

- ↑ Single Slice Pizza Carier, 1992 patent, USA , accessed November 10, 2011.

- ^ "50 Best Inventions 2009" ( Memento from November 1, 2011 in the Internet Archive ) Time , accessed on October 31, 2009.

- ↑ About.com: Package Saver .

- ↑ Product description: Pizza Lid Support .

- ↑ European Patent Office , accessed on October 26, 2011 (English).

- ^ A b Henry Petroski: A Round Pie in a Square Box. In: American Scientist. July – August 2011.

- ↑ Critique of the Pizza saver (English).

- ↑ Tool Time Tuesday… Recycled Pizza Box Support (English).

- ↑ Scott Wiemer: Take a 'Tour' of Pizza Boxes of the World , private video about special pizza boxes from different countries (English), accessed on July 15, 2012

- ↑ Food Safety & Hygiene Thermometers & Temperature Indicators. In: www.lcrhallcrest.com. Retrieved February 25, 2016 .

- ↑ REGULATION (EC) No. 1935/2004 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of October 27, 2004 on materials and objects intended to come into contact with food (PDF) , paragraph 3

- ↑ Federal Institute for Risk Assessment, BfR Recommendations on Materials for Food Contact : XXXVI. Papers, cardboard boxes and cardboard for food contact ( Memento from March 7, 2014 in the Internet Archive ), as of March 1, 2011, accessed on January 2, 2012

- ↑ a b c Beate Brauer (Chemical and Veterinary Investigation Office Münsterland-Emscher-Lippe): Contaminants in recycled paper - problematic substances, problem solutions -. (PDF; 2.2 MB) Federal Institute for Risk Assessment (BfR), October 28, 2010, pp. 1–25 , accessed on May 26, 2012 (presentation at the 9th BfR Consumer Protection Forum).

- ↑ Transfer of mineral oil from packaging materials to food. (PDF; 76 kB) BfR Opinion No. 008/2010 of December 9, 2009. Federal Institute for Risk Assessment (BfR), December 9, 2009, pp. 1–6 , accessed on May 26, 2012 .

- ↑ Mineral oil from the pizza box. ÖKO-TEST, April 18, 2012, archived from the original on August 9, 2014 ; Retrieved May 26, 2012 .

- ↑ Association of Cantonal Chemists in Switzerland: Many deficiencies in food packaging made of paper Media release (PDF), April 25, 2018, accessed on April 26, 2018.

- ↑ a b Lower Saxony State Office for Consumer Protection and Food Safety: Core solvent DIPN in packaging: 8 of 128 samples objected to , press release No. 063 of December 17, 2004, accessed on January 5, 2012

- ↑ Report on the 109th meeting of the commission / expert group for the health assessment of plastics and other materials within the framework of the Food and Commodities Act of the Federal Institute for Consumer Health Protection and Veterinary Medicine (plastics commission / expert group of the BgVV) on 25/26. April 2001 in Berlin: Diisopropylnaphthalene (DIPN) in paper, cardboard and cardboard for food contact (PDF; 84 kB), accessed on January 5, 2012

- ↑ State Investigation Office Rhineland-Palatinate: Annual Report 2004, II Food, Drugs & Commodities ( Memento of the original from February 5, 2013 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. , accessed March 24, 2013

- ↑ Di-isobutyl phthalate in paper and cardboard for contact with food. (PDF; 100 kB) Short minutes of an extraordinary meeting of the “Paper, Cardboard and Cardboard” working group on July 5, 2007 at the BfR. Federal Institute for Risk Assessment (BfR), July 5, 2007, pp. 1–2 , accessed on May 26, 2012 .

- ^ Initiative to reduce di-isobutyl phthalate in paper, cardboard and cardboard. (PDF; 233 kB) Voluntary commitment to reduce di-isobutyl phthalate (DiBP). Federal Institute for Risk Assessment (BfR), November 15, 2007, pp. 1–3 , accessed on May 26, 2012 .

- ↑ Karla Pfaff: Perfluoro compounds in food contact materials. (PDF; 144 kB) Federal Institute for Risk Assessment (BfR), March 23, 2006, pp. 1–13 , accessed on May 26, 2012 (advanced training for the public health service).

- ↑ Perfluorochemicals in papers and cardboard for food packaging. (PDF; 52 kB) Health assessment No. 049/2005 of the BfR of October 27, 2005. Federal Institute for Risk Assessment (BfR), October 27, 2005, pp. 1–5 , accessed on May 26, 2012 .

- ↑ Almut Reichart: Perfluorinated organic compounds (PFC) in the paper industry. (PDF; 88 kB) Health assessment No. 049/2005 of the BfR of October 27, 2005. Federal Environment Agency, June 19, 2009, pp. 1–9 , archived from the original on May 29, 2012 ; accessed on May 26, 2012 (technical discussion of the UBA and MUNLV June 19, 2009).

- ↑ Service packaging: packaging and law. Special regulation for service packaging. PRO-S-PACK Working Group for Service Packaging e. V., accessed on May 27, 2012 .

- ^ Supply and disposal company for the district of Ostvorpommern mbH: What belongs where? - waste paper. Archived from the original on July 17, 2013 ; Retrieved January 5, 2012 .

- ↑ a b Waste disposal and city cleaning company Paderborn: Abfall MP ( Memento from February 29, 2012 in the Internet Archive ), accessed on January 5, 2012

- ↑ Waste Management Company of the City of Mainz: Alphabetical guide with tips on avoiding waste , accessed on January 5, 2012

- ^ Kreis Kleve Abfallwirtschafts GmbH, Uedem: Wertstoff- & Abfall - ABC , accessed on January 5, 2012

- ^ Office for waste management of the Plön district: Waste ABC (P). Archived from the original on August 21, 2009 ; Retrieved January 5, 2012 .

- ↑ James L. Hanson, Nazli Yesiller, Jagjit Singh, Greg M. Stone, Adam Stephens: Beneficial Reuse of Corrugated Board in Slurry Applications . In: American Society of Civil Engineers (Ed.): Geoenvironmental Engineering and Geotechnics . Proceedings of Sessions of GeoShanghai 3-5 June 2010, Shanghai, China. tape 2014 . ASCE Publications, 2010, ISBN 0-7844-1105-0 , pp. 132-139 ( (Google Books) [accessed October 3, 2011]).

- ↑ Thinking 'round the Box, ( Memento of September 3, 2011 in the Internet Archive ) Pizza marketplace.com, June 4, 2004.

- ↑ Shona Fairweather: Adam Neate . From Street Art to the Gallery. In: Aesthetica . The Art & Culture Magazine. tape 20 , 2007, p. 24-25 .

- ↑ Die ärzte - Jazz is different

- ↑ Brimstone Howl - European Tour 2008 at discogs.com

- ↑ Cam Deas - My Guitar Is Alive And Its Singing at discogs.com

- ↑ Andrew Coltrane - Refuse at discogs.com

- ↑ The Jon Spencer Blues Explosion - Pizza Box Promo at discogs.com

- ↑ My first Mac never comes off on einestages.spiegel.de, accessed on October 22, 2011.