Fabric (textile)

Woven fabric is a flat textile structure that consists of two thread systems , warp ( warp threads ) and weft ( weft threads ), which, when viewed from the fabric surface , cross at an angle of exactly or approximately 90 ° . Each of the two systems can be made up of several types of warp or weft (e.g. basic, pile and filler warp; basic, tie and filler weft). The warp threads run in the longitudinal direction of the fabric, parallel to the fabric edge, and the weft threads in the transverse direction, parallel to the fabric edge. The connection of the threads to the fabric is mainly done by friction . In order for a fabric to be sufficiently resistant to sliding, the warp and weft threads usually have to be woven relatively tightly. Therefore, with a few exceptions, the fabrics also have a closed appearance. The fabric is produced either by hand weaving on a hand loom or by machine on a loom . A historical name for textile fabrics made of linen and cotton is stuff. (see also kit maker , kit printer )

Distinguishing features

Depending on requirements or agreements, the following characteristics must be specified to describe tissue:

- Type of fiber , if necessary separated according to warp and weft, whereby in the case of fiber blends the blend components are given in percent based on the dry matter (e.g. 50% cotton , 50% polyester )

- Type of yarn , possibly separated according to warp and weft, e.g. B. Fineness , yarn twist ( twist direction and number of twist ), spun fiber or filament yarn

- Basis weight

- Fabric thickness (distance between the top and bottom of the fabric)

- Thread density (number of warp and weft threads per unit of length)

- Weaving technology, e.g. B. shaft or jacquard technique

- Binding type

- Fabric width and length

Properties of tissues

The structure of the fabric has a decisive influence on its properties. Tissues are anisotropic in nature. In addition, most tissue structures are asymmetrical, which increases the anisotropy. This means that the mechanical properties of a tissue depend on the direction in which a force acts. With tensile load in the warp or in the weft direction, fabrics stretch e.g. B. only a little. If, on the other hand, the tensile load acts diagonally, e.g. B. at 45 °, so fabrics are very stretchable, even if they were woven from non-stretchable threads.

Furthermore, the tensile force-elongation curves of fabrics have two different areas. The initial area is relatively flat, so the initial modulus is low, ie a relatively high elongation is achieved with a relatively low force. The reason is that initially only a structural deformation takes place, whereby the threads are aligned in the direction of the applied tensile force, their material properties do not yet come into play. This initial stretch depends on the weave of the fabric. Only after the end of the structural deformation, when the loaded threads are almost stretched, the material properties of the threads become effective. The tensile force-elongation curve rises more steeply. To achieve the same elongation as in the initial area of the tensile load, a higher tensile force is necessary. The fabric appears stiffer.

With high thread counts, fabrics are particularly resistant and hard-wearing. This effect is increased if twisted threads are used instead of simple yarns . Important properties of a fabric are also the single thread pull-out force and the slip resistance. The former is the force that has to be used to pull the thread out of the tissue parallel to its longitudinal axis. A measure of the slip resistance is the force that is required to move a thread perpendicular to the longitudinal axis in the fabric plane. The pulling out of a thread is opposed to the frictional resistance of the thread crossing points, which is determined by the wrap angle at the crossing points and the coefficient of friction. These two properties are a measure of the manageability of the tissue. The higher both values are, the worse the drapability , i. H. the possibility of shaping into three-dimensional textile structures.

Classification of tissues

The classification aspects for fabrics are very diverse and differ significantly in terms of quality. A single classification scheme is therefore not possible. Classification aspects such as fabric weave or fabric technology, color pattern, figurative pattern, fiber type, thread type and thread count, intended use, production-related aspects and the like are useful. a.

After the weave

The way in which warp and weft threads cross in a fabric is called a weave. Depending on which warp threads are raised or lowered during weaving , the result is a different distribution of binding points and thus different weaves , which determine the appearance of the fabric. The part of the weave that specifies the type of crossing of the warp and weft threads until they are repeated is called the repeat . Depending on the basic weave , there are names such as linen , twill or atlas fabric . Extended basic weaves, which are created by adding tie points to twill and atlas basic weaves, wide-burr twill and multi-burr twill fabric as well as reinforced atlas fabric. Derived weaves are weaves developed from a plain weave or extended plain weave that give the fabric a different structure. These include a. Zigzag twill, corrugated burr twill, reps. Combined weaves of at least two different weaves can be used to produce fabrics with stripes, checks and jacquard patterns, such as those used for table linen, bed linen, tea towels and handkerchiefs. These bonds influence the properties of a fabric such as its appearance, slip resistance or drapability.

According to the color pattern

If the color of the warp material is the same as that of the weft material, the fabrics are referred to as plain fabrics. If different colored yarns are used, colored fabrics are created. If the warp threads and the weft threads are different in color, the result is a mixed color in the fabric or, if the weave is appropriate, a two-tone pattern. Depending on the incidence of light, the color of the warp or the weft dominates. If the colors differ greatly from one another, a shimmer is created by different light refraction. These fabrics are called changeant fabrics. Another class of colored fabrics is created when working with a single-colored weft and with a colored pattern in the warp. The color sequences of the warp threads are called the warp sequence. These include, for example, awning fabrics. Another type of colored fabric is created when the warp is monochrome and the weft is two or more colored. The result is tissue with horizontal stripes. Fabrics with a checkered pattern are formed when the warp and weft have a color pattern, the number of colors per thread system being at least two (e.g. pepita ).

According to the figurative pattern

Fabrics with small repeat figurative patterns, so-called shaft-patterned fabrics, are created through the pattern-like joining of different weaves. These include fabrics with diamonds, dots, rectangles or small flowers. Large repetitive figurative patterns are produced with jacquard machines. Fabrics without figurative patterns are called plain fabrics. The surface parts of the fabric surface are similar in appearance. Representatives of this type of fabric are cotton nettle, shirt poplin and side taffeta.

According to the technical aspects of the fabric and the surface properties

Fabrics can be divided into flat fabrics and pile fabrics according to their surface properties. In flat woven fabrics, the warp and weft form a closed surface without tufts sticking out. In the case of pile fabrics, the surface is characterized by closed and / or open tufts of one of the two thread systems.

Flat weave

Both the single-chain and the multi-chain flat woven fabrics can be single-section or multi-section. With multi-chain or multi-ply fabrics, the pattern options are many times higher than with single-warp, single-ply fabrics

Reinforced fabric

Fabrics in which three or more thread systems are closely and inseparably connected with each other are referred to as reinforced fabrics. The two fabric sides can be different in color, handle and material. They have a higher total thread density, but still do not look sticky to the touch. Fabrics with two weft systems and one warp system are referred to as weft double (two weft fabric, double weft fabric), with only the upper weft on the top of the fabric and only the short weft on the underside of the fabric. Soft and slightly twisted weft yarns are often used, so that these fabrics can be napped. These rough fabrics thus created include z. B. Molton and Beaver . Furniture cover and decorative fabrics are also produced as fabrics with two weft thread systems and one warp thread system. Fabrics with two warp systems (upper and lower warp) and one weft system are called warp double. Due to the second warp system, such reinforced fabrics have a high warp thread density, which are suitable for solid suit fabrics, dresses and costumes. They show a good case despite the high density.

Double weave

In contrast to the reinforced fabrics, in which several thread systems are integrated into one fabric layer, double fabrics are fabrics that consist of two independent fabrics lying one above the other, which are firmly connected to one another during the weaving process. The result is a very heavy woven fabric, which can be completely different in appearance and material on both sides of the fabric. For example, they are made into jackets and coats (with woven lining). For production, two warp thread systems and two weft thread systems are required that form the two fabric layers. The layers are connected by:

- Connection: connection of weft of the lower and warp of the upper fabric.

- Tie: connection of warp of the lower and weft of the upper fabric.

- Binder weft or binding chain shows a further thread system connects the two fabric as a weft or chain.

- Change of fabric : lower and upper fabric alternate with one another at the edge of the fabric. In the middle of the double fabric there is a cavity, hence the name hollow fabric .

Openwork fabric

If so-called leno healds are used instead of the usual healds, in which the warp threads z. B. wrapped around the sides in pairs, the result is called leno fabric . By twisting 2 warp threads towards each other, the weft threads are bound in a non-slip manner. In contrast to the aforementioned, this type of fabric can form open, net-like surfaces. Leno fabrics are u. a. used for curtains or to reinforce the back of carpets.

Pile fabric

Pile fabrics are the three-dimensional special form of fabrics in which one or two pile thread systems are also firmly integrated into the base fabric, which are processed either as loops (terry cloth) or as an open pile (pile fabric / velvet).

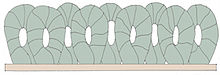

Terrycloth

Terrycloth fabrics are a type of fabric in which an additional warp thread system is thrown up to form pile loops. This is done by combining binding technology (rep weave) with a special weft beating technique, for example a sley with a so-called suggestion function. In terms of weaving technology, a group of, for example, three weft threads with a spacing from the fabric edge is first formed, which firmly bind the pile warp thread. When this group hits the fabric edge, these three weft threads take the pile warp thread with them and throw it up perpendicular to the pile loop.

Pile fabric

Typical pile fabrics are:

The way in which the pile thread is introduced gives the types their names. Viewed from the side, the cut pile thread looks either like the letter V or W, so the knobs are then named after their letters. The double W-nub is a modification of the W-nub.

Warp velvet fabrics are textiles that are mostly made up of two superimposed base fabrics and an additional pile thread fabric. In addition, rod looms and lancet looms are used, which use an additional pile / warp thread system to form pile loops that are perpendicular to the base of the fabric.

Weft velvet fabrics are formed by an additional pole weft system. Cord fabrics are typical representatives of this type of fabric. First, a fabric is formed with more or less long weft floats, which are then cut open and brushed so that they are again perpendicular to the base.

If so-called leno healds are used instead of the usual healds, in which the warp threads z. B. wrapped around the sides in pairs, the result is called leno fabric . In contrast to the aforementioned, this type of fabric can form open, net-like surfaces. Leno fabrics are u. a. used for curtains or to reinforce the back of carpets.

According to the type of fiber used

The fabrics can be divided into fabrics made from natural fibers, man-made fibers and fiber mixtures, with the latter becoming increasingly important. In the warp and / or weft, mixed yarns made from natural fibers and man-made fibers, or natural fibers in one of the thread systems or partial thread systems, and man-made fibers in the other thread system. The fabrics produced from it then have properties and utility values that they would not have without a blend partner and which thus bring improvements for the actual improvements for the consumer. Particular importance for outerwear fabrics have z. B. the mixtures of 55% PES and 50% wool or 70% PES and 30% wool, which are very hard-wearing, dimensionally stable and low-maintenance.

Classification according to the purpose

Fabrics are often used according to their intended use in fabrics for clothing (e.g. outerwear and underwear, which can also be separated into daywear and nightwear), for laundry, for interior decoration and furniture, for technical purposes and for other purposes (e.g. . Toys, sports).

Further classifications

Fabrics can also be divided into narrow fabric or band fabric and wide fabric according to their width. Ribbons such as belts or rubber bands are produced on ribbon looms, which differ significantly from wide looms. Wide fabrics range from a width of 40 cm (narrow fabrics that are used in the clothing industry) to wide sail fabrics that can be woven in one piece over the entire width of up to 20 m. A subdivision according to the mass per unit area into light, medium-weight and heavy fabrics and the fabric shape created during the weaving process into flat and tubular fabrics is also possible.

Types of fabric, product knowledge

- batiste

- Brocade (atlas)

- Canvas (canvas)

- chiffon

- chintz

- Clydella

- Cord

- damask

- denim

- Donegal

- Drill ( drill )

- Duchess

- Enoa

- Etamin (sieve cloth)

- Chambray

- Fil-à-fil (end-on-end)

- flannel

- gabardine

- Gauze (Mull)

- Georgette

- Jacquard

- Jersey (fabric) (no fabric!)

- Crepe (crepe)

- Twill (twill)

- Loden

- Mesh

- muslin

- Natté

- nettle

- Oxford

- Pinpoint

- Piqué (pique)

- Pleated

- Poplin (Poplin)

- satin

- Seersucker

- Slubyarn

- Taffeta

- cloth

- tweed

- Valves®, Shirley Cloth

- Viyella

- Voile

- Two-ply

- Boiled wool

- Zendaline ( half crepe )

- Zephyr (Zephyr)

See also the category flat weave .

See also

literature

- Ernst Hecht: Which fabric is that? Franckh'sche Verlagshandlung, Stuttgart 1956, DNB 451885112 .

- Iris-Elisabeth Karl: The fabrics guide. 2., rework. Edition. Creative Medien, Bonn 2007, ISBN 978-3-00-020493-7 .

Web links

Individual evidence

- ↑ DIN 61100, Part 1: Fabric-Characteristic Features. Beuth Verlag, Berlin January 1976.

- ↑ Alois Kießling, Max Matthes: Textile specialist dictionary. Verlag Schiele & Söhne, Berlin 1993, ISBN 3-7949-0546-6 , p. 153.

- ^ Heinz Hollstein, Hanskarl Hahn, Rolf Meixner: Manufacturing technology weaving. Volume 1: Basics of tissue formation and working element for tissue production. Fachbuchverlag Leipzig, 1987, ISBN 3-343-00338-7 , p. 10.

- ↑ Thomas Meyer to Capellen: Lexicon of tissues. 3rd, expanded edition. Deutscher Fachverlag, Frankfurt am Main 2006, ISBN 3-87150-893-4 , p. 450.

- ↑ DIN 61100, Part 1: Fabric-Characteristic Features. Beuth Verlag, Berlin January 1976.

- ↑ DIN 61100, Part 2: Fabric-technological information for the description. Beuth Verlag, Berlin January 1976.

- ^ Heinz Hollstein, Hanskarl Hahn, Rolf Meixner: Manufacturing technology weaving. Volume 1: Basics of tissue formation and working element for tissue production. Fachbuchverlag Leipzig, 1987, ISBN 3-343-00338-7 , p. 13.

- ↑ Jinlian Hu: Structure and mechanics of woven fabric. Woodhead Publishing, Cambridge 2004, ISBN 1-85573-904-6 , p. 102.

- ↑ Ralf-Dieter Reumann (Ed.): Test methods in textile and clothing technology . Springer, 2000, ISBN 3-540-66147-6 , p. 64.

- ↑ Chokri Cherif (Ed.): Textile materials for lightweight construction - Techniques - Process - Materials - Properties. Springer-Verlag, Berlin / Heidelberg 2011, ISBN 978-3-642-17991-4 , p. 182.

- ↑ Chokri Cherif (Ed.): Textile materials for lightweight construction - Techniques - Process - Materials - Properties. Springer-Verlag, Berlin / Heidelberg 2011, ISBN 978-3-642-17991-4 , p. 183.

- ^ Heinz Hollstein, Hanskarl Hahn, Rolf Meixner: Manufacturing technology weaving. Volume 1: Basics of tissue formation and working element for tissue production. Fachbuchverlag Leipzig, 1987, ISBN 3-343-00338-7 , p. 14.

- ^ Heinz Hollstein, Hanskarl Hahn, Rolf Meixner: Manufacturing technology weaving. Volume 1: Basics of tissue formation and working element for tissue production. Fachbuchverlag Leipzig, 1987, ISBN 3-343-00338-7 , p. 25.

- ^ Alois Kießling, Max Matthes: Textile - specialist dictionary. Fachverlag Schiele & Schön, Berlin 1993, ISBN 3-7949-0546-6 , p. 43.

- ^ Heinz Hollstein, Hanskarl Hahn, Rolf Meixner: Manufacturing technology weaving. Volume 1: Basics of tissue formation and working element for tissue production. Fachbuchverlag Leipzig, 1987, ISBN 3-343-00338-7 , p. 38f.

- ^ Alois Kießling, Max Matthes: Textile - specialist dictionary. Fachverlag Schiele & Schön, Berlin 1993, ISBN 3-7949-0546-6 , p. 59.

- ^ Heinz Hollstein, Hanskarl Hahn, Rolf Meixner: Manufacturing technology weaving. Volume 1: Basics of tissue formation and working element for tissue production. Fachbuchverlag Leipzig, 1987, ISBN 3-343-00338-7 , p. 29ff.

- ^ Heinz Hollstein, Hanskarl Hahn, Rolf Meixner: Manufacturing technology weaving. Volume 1: Basics of tissue formation and working element for tissue production. Fachbuchverlag Leipzig, 1987, ISBN 3-343-00338-7 , p. 31.

- ↑ Thomas Meyer: Lexicon for Capelles of the tissues. 3rd, expanded edition. Deutscher Fachverlag, Frankfurt am Main 2006, ISBN 3-87150-893-4 , p. 129.

- ^ Heinz Hollstein, Hanskarl Hahn, Rolf Meixner: Manufacturing technology weaving. Volume 1: Basics of tissue formation and working element for tissue production. Fachbuchverlag Leipzig, 1987, ISBN 3-343-00338-7 , p. 31ff.

- ^ Paul-August Koch, Günther Satlow: Large Textile Lexicon: Specialized lexicon for the entire textile industry. Volume L - Z. Deutsche Verlags-Anstalt, Stuttgart 1965, p. 555.

- ↑ Fabia Denninger, Elke Giese: Textile and Model Lexicon. Volume L - Z. 8th, completely revised and expanded edition. Deutscher Fachverlag, Frankfurt am Main 2006, ISBN 3-87150-848-9 , p. 758.

- ↑ Fabia Denninger, Elke Giese: Textile and Model Lexicon. Volume L - Z. 8th, completely revised and expanded edition. Deutscher Fachverlag, Frankfurt am Main 2006, ISBN 3-87150-848-9 , p. 636f.

- ↑ Author collective: Gewebetechnik. Fachbuchverlag Leipzig, 1975, p. 125.

- ^ Paul-August Koch, Günther Satlow: Large Textile Lexicon: Specialized lexicon for the entire textile industry. Volume A - K. Deutsche Verlags-Anstalt, Stuttgart 1965, p. 284.

- ↑ Fabia Denninger, Elke Giese: Textile and Model Lexicon. Volume L - Z. 8th, completely revised and expanded edition. Deutscher Fachverlag, Frankfurt am Main 2006, ISBN 3-87150-848-9 , pp. 158f.

- ↑ textillexikon.de ( memento of October 24, 2011 in the Internet Archive ) accessed on October 5, 2011.

- ↑ Ursula Völker, Katrin Brückner: From fiber to fabric - Textile materials and goods. 35th, updated edition. Publishing house Dr. Felix Büchner, Hamburg 2014, ISBN 978-3-582-05112-7 , p. 143.

- ↑ Ursula Völker, Katrin Brückner: From fiber to fabric - Textile materials and goods. 35th, updated edition. Publishing house Dr. Felix Büchner, Hamburg 2014, ISBN 978-3-582-05112-7 , p. 144.

- ^ Heinz Hollstein, Hanskarl Hahn, Rolf Meixner: Manufacturing technology weaving. Volume 1: Basics of tissue formation and working element for tissue production. Fachbuchverlag Leipzig, 1987, ISBN 3-343-00338-7 , p. 27.

- ↑ Ursula Völker, Katrin Brückner: From fiber to fabric - Textile materials and goods. 35th, updated edition. Publishing house Dr. Felix Büchner, Hamburg 2014, ISBN 978-3-582-05112-7 , p. 95.

- ^ Heinz Hollstein, Hanskarl Hahn, Rolf Meixner: Manufacturing technology weaving. Volume 1: Basics of tissue formation and working element for tissue production. Fachbuchverlag Leipzig, 1987, ISBN 3-343-00338-7 , pp. 25f.

- ^ A b N. AG Johnson, I. Russell: Advances in Wool Technology. Elsevier, 2009, ISBN 978-1-84569-546-0 , p. 286.

- ↑ a b c d Phyllis G. Tortora, Ingrid Johnson: The Fairchild Books Dictionary of Textiles. A&C Black, 2014, ISBN 978-1-60901-535-0 .

- ↑ Etamin on stoff4you.de, accessed on July 29, 2016.