Flettner rotor

The Flettner rotor is a rotating cylinder exposed to the wind flow . It acts like a sail and generates a force across the flow through the Magnus effect . It is named after Anton Flettner , who patented it as a ship propulsion system.

The Flettner rotor is mainly used in rotor ships . A single rotor drive is generally not possible, as it does not ensure maneuverability in the absence of wind.

The Flettner rotor should not be confused with the Flettner double rotor by the same inventor, a rotor configuration for helicopters.

construction

As a ship propulsion system , a Flettner rotor consists of a vertical, high, rotating cylinder made of sheet metal or composite materials, the larger end plates of which keep the flow on the tube and thus prevent an otherwise significant reduction in efficiency at the end of the rotor. The rotor is rotated at a speed adapted to the prevailing wind speed. An electric drive is common.

principle

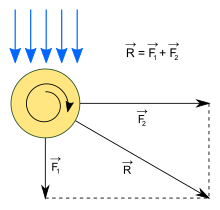

- A rigid cylinder exposed to a flow would only generate force through the wind resistance of the projected area, namely in the direction of the flow.

- A rotating cylinder, on the other hand, uses the Magnus effect from suction and dynamic pressure forces to generate a far greater deflection force directed at right angles to the flow.

- An equipped exclusively with Flettner rotors ship must therefore similar to a sail boat against the wind to show up and remains in doldrums unmotivated.

If wind blows against a rotating cylinder, the air is accelerated where the direction of rotation of the cylinder and the wind direction come together. It is braked on the opposite side of the cylinder, so it flows more slowly. This creates underpressure (faster flow) and overpressure (slower flow), in total a force acting across the flow (dynamic lift, in graphic F), similar to a stationary (aircraft) wing, but with far better efficiency - around ten times that of a sail or rigid wing with the same wind resistance. This (partial) force acts in the direction in which the direction of flow and direction of rotation of the body are in the same direction and depends (like ultimately the driving speed) on the flow velocity, the rotational speed of the rotor and, crucially, on the relationship between the two. The speed of the rotor surface is often around three to four times the wind speed in order to enable a very efficient drive, which was previously in the range of roughly 100 revolutions per minute in ship drives.

A change in the direction of rotation of the rotor reverses the force component F2 generated thereby. In any case, however, a second force component, which arises from the resistance, acts in the direction of flow: F1. The sum (resultant R) of these two partial forces is used.

The drive forces of the rotors, which are generated by the rotation, act transversely to the wind, like normal sails, have no propulsion on in-wind courses and - in contrast to normal sails - hardly on courses in front of the wind.

The speed of the rotor must be increased with the wind speed, so that when there is high wind energy, high drive energy must also be provided for the rotors, but when the wind energy is low, there is a relatively greater effort to operate the rotors.

Sigurd Savonius researched to drive the cylinders with wind power and invented and developed the Savonius rotor . Another wind turbine with a vertical shaft would also be suitable for the drive .

Even Laurence J. Lesh tinkering around on a rotor ship with wind driven rotors. The Lesh rotor was a lens-shaped aerodynamic profile that could not rotate by itself, but could be started in both directions of rotation. According to model tests, the rotor promised almost four times more advance than a sail. A jibe could also be driven with the rotor without converting the rotor, as is necessary with the Savonius rotor or other turbines with a vertical axis. The profiles could also be stopped completely at higher wind speeds and used like a sail. A test boat for a full-size rotor was built in Chicago in 1933.

According to the experience of the operator Norsepower, using a modern Flettner rotor in lightweight construction with an electrical energy consumption of less than 90 kW for the electric motors of the rotor can replace a conventional machine output of up to around 3 MW.

use

Rotor ships were first developed during the 1920s and by Flettner himself, but could not prevail and in the years after 1930 lost the economic competition against heat engines ( steam engines and turbines as well as diesel engines ) to the same extent as sail drives.

It was not until the early 1980s that Jacques-Yves Cousteau had a research vessel built with cylinders derived from the Flettner drive that act as an additional drive: the Alcyone . On August 2, 2008, the E-Ship 1 was launched in Kiel, using real Flettner rotors in a size that had not been used until then.

Ships

- Buckau (later renamed Baden-Baden ): With the three-masted schooner Buckau , which wasconverted into a rotor ship by the Germania shipyard in Kiel, Flettner gained his first practical experience with the new type of propulsion he had developed. The Buckau , which set out for its test run with two rotors in 1924, was drivenby an auxiliary motor thatactedon a propeller when there was no wind and the fairway was restricted. After various tests under variable weather conditions, Flettner's rotor ship, now renamed Baden-Baden , reachedNew York on May 9, 1926after successfully crossing the Atlantic .

- Barbara : For the Rob. M. Sloman Jr. Shipping company in Hamburg was put into service on July 28, 1926 at the AG "Weser" shipyard in Bremen , 2077 GRT and 87 meters long Barbara . On behalf of the Reichsmarine , the cargo ship was equipped with three Flettner rotors as an additional drive. It cruised against the windat wind speeds around Beaufort 4 at four knots, and before the wind the ship allegedly even cruised at nine knots. Nevertheless, in the years after 1930, Flettner rotors lost the economic competition against purely mechanical drives to the same extent as the sail drives themselves.

- The Flettner yacht was a 6 or 7 meter recreational boat, equipped with an approximately 6 meter high Flettner rotor with two end disks and another disk, the fence , between the lower third and the upper two thirds of the cylinder. The boat was rebuilt in the spring of 1925 and sailed in the waters near Berlin. Flettner's fence was already in the patent from 1928 and was calculated by A. Thom in 1934 using uneconomical speeds. At these speeds, the Flettner Fence achieves an enormous transverse drive coefficient. The work generated a lot of attention, which is why the fence became known as the Thom Disk .

- Flettner's racing yacht was an 11 meter sports boat with a 5.8 meter high aluminum rotor. It was the second yacht to have a rotor in 1925. With a 4 hp engine, 300 rpm were achieved. In the summer of 1925 it lost the race against a sailing boat on the Wannsee, but the heel was significantly less.

- An unnamed 30-foot marine cutter was tested with a Flettner rotor in 1925 by US shipbuilding students at MIT , Navy lieutenants J. Kiernan and W. Hastings, shortly after the first reports about the Buckau. The rotor was 2.9 m high, 1.07 m in diameter and was driven by a 5 HP motor. The end disk was larger than in the Flettner designs and was attached to the boat instead of to the rotor.

- Rotorboat : A 3.6 m long dinghy with a dead weight of 40 kg without a sail was first equipped by Stephen Thorpe in 2004 with a 2.5 m high, slim, conical Flettner rotor without an end plate on the tip and later with a 3 m high rotor. It consumed 25 watts to reach the hull speed with 800 / min at wind force 4 . It sailed off the British coast until at least 2007.

- Uni-Kat Flensburg : The Uni-Kat Flensburg was developed at the Institute for Physics and Chemistry and its Didactics at the University of Flensburg under Professor Lutz Fiesser as part of the PROA project. The ship was christened at Flensburg Nautics 2006. The rotor was made of plastic film with reinforcing aluminum rings.

- E-Ship 1 : In 2006, the wind turbine manufacturer Enercon commissioned the Lindenau shipyard in Kiel todesign and build a 130 m long cargo ship. Its main drive is diesel-electric and it also has four Flettner rotors. It was launched on August 2, 2008, in the middle of the 2007 Great Recession . Due to the bankruptcy of Lindenau, the hull of E-Ship 1 was transferred to Emden and completed there in the Cassens shipyard . The loading space was specially equipped for the transport of parts from the owner Enercon's wind turbines. The maiden voyage of E-Ship 1 from Emden to Dublin took placeon August 9, 2010. In October 2010, the savings in fuel consumption on a Mediterranean cruise should be determined.

- Cloudia : The 2008 presented cloudia is a converted trimaran type Searunner 34 . It is equipped with an 8.24 m and a 6.4 m high Flettner rotor with a core diameter of 1.37 m for a maximum of 400 rpm. Several horizontal disks, so-called fences or thom disks , with a diameter of 2.44 m and a distance of 0.92 m between the disks are installed on their surface in order to increasethe transverse drive coefficient . It is a demonstration boat on behalf of the 1500 needed saltwater particle-releasing autonomous boats of the Brighter World project by John Latham and Stephen Salter to combat global warming . The project aims toimprovethe energy reflectivity ( albedo ) of ocean surfaces by generating deep stratus clouds (high fog) . This would increase the earth's radiation by approx. 2% and cool the atmosphere at a bit. The technology of the Flettner rotors is used because they are easier to operate than rigging andcan be operatedentirely with electricity from solar cells .

- Estraden : The Estraden is the second RoRo freighter in the world with a Flettner rotor. The ship, built in 1999 andsailing in the North and Baltic Seasfor Mann Lines , was equipped with the first rotor in 2014 and a second rotor in 2015 and now hasa rotor at the stern and one in the middle inaddition to the normal drive via diesel engines . Thedrive system developedby the Finnish company Norsepower under the name Norsepower Rotor Sail is said to differ from earlier Flettner rotors in terms of its higher performance. Six percent fuel is saved every year.

- MV Afros : The bulk carrier of the SDARI 64 Ultramax seriesbelonging to Blue Planet Shipping (Piraeus, Greece)was delivered by the Jiangsu Haitong Offshore Engineering (China) shipyard in January 2018 with four Anemoi Wind Engine rotors that can be moved on the starboard side on rails. The rail system enables the rotors made of GRP to be moved out of the crane's working area while the cargo holds are being loaded and unloaded. It is the first bulk carrier with Flettner rotors and wasnamed the winner of the 'Ship Of The Year' categoryat the Greek Shipping Awards 2018.

- Viking Grace : Thispassenger ferry, which has been in servicewith Viking Line in the Baltic Sea since 2013, received a Flettner rotor in 2018 to save fuel. The rotor is 24 meters high and has a diameter of 4 meters. It was a practical test from April 2018 to the end of 2019 to see how much fuel savings would be possible on the route. The savings were too small, so Flettner rotors are notinstalledon the Viking Glory .

- Whirlwind : Under the project name “Eolos”, students at ETH Zurich developed and built a 3.8 m high and around 65 cm wide inflatable rotor for leisure use in 2016. The system was installed in the 6.3 m long sailing boat Whirlwind . The foldable rotor, which can be retracted up to 80 cm , has a telescopic axis inside. The surface consists of a three-ply laminated canvas that is glued to the only slightly larger end caps. The internal pressure during operation is 0.2 bar .

- Maersk Pelican , the tanker of the Danish shipping company AP Møller-Mærsk , was retrofitted in 2018 with two Flettner rotors 30 meters high and 5 meters in diameter. These are 'Rotorsails' modules from the manufacturer Norsepower. The first test was successfully completed in October 2018.

- In June 2018 the 4200-ton multi-purpose freighter Fehn Pollux (built in 1996) from Fehn Ship Management GmbH & Co. KG in Leer was equipped with an 18-meter-high rotor sail of the Eco Flettner type. This comes from the Wind Hybrid Coaster project of the University of Emden / Leer , the Maritime Competence Center (Mariko) and regional companies. According to the evaluation of the measurement results, depending on the speed of the ship, between 10 and 20 percent fuel can be saved. It is important that the deck surface is free for the flow to the rotor.

- Viking Glory , a ferry operated by the Finnish shipping company Viking Line , was keeled by Xiamen Shipbuilding Industry Co. on June 3, 2019. For the first time, the installation of two Flettner auxiliary drive modules was already taken into account when planning a ferry. The ferry is designed for the Turku - Åland - Stockholm route. The practical experience with the Flettner rotor of the Viking Grace on the same ferry route led to the decision to prepare the ship for the installation of Flettner rotors, but not to install the rotors.

- Copenhagen : The RoPax ferry of the Scandlines shipping companyon the Rostock - Gedser route was retrofitted with a Flettner rotor from Norsepower . This is expected to reduce CO 2 emissions by a further 4–5%.

Planes

The Flettner rotor generates a force perpendicular to the direction of the incoming air. This means that it can be used as a wing for an aircraft. With the same flow velocity, a Flettner rotor even generates significantly higher lift than a rigid profile. This allows a particularly low airspeed. This principle proved to be functional on model aircraft with a wingspan of around one meter . However, the models also showed problems with regard to the flight attitude: The Coriolis force of the rotors couples rotations around the vertical axis with rotations around the roll axis .

One problem is that if the rotor drive fails, a Flettner aircraft no longer has any lift and crashes.

Around 1930, the Plymouth AA-2004 (approval 921-V ) was the prototype of a seaplane with rotors instead of wings. However, it is not clear if this aircraft ever flew. Human aircraft designs based on this principle are sometimes proposed but have not yet reached the full-size airworthy prototype stage.

Wind turbines

The Polish Acowind A-63 wind turbine has three Flettner rotors instead of rotor blades.

literature

- The Flettner ship. In: Marine-Rundschau, magazine for marine life. 1924, ISSN 0025-3294 , pp. 361-371.

- Anton Flettner: The application of the knowledge of aerodynamics to the wind propulsion of ships. In: Yearbook of the Shipbuilding Society . Vol. 25, Julius Springer, Berlin 1924, pp. 222-251.

- German patent 420840: Method for generating the transverse drive on transverse drive bodies, e.g. B. on sailing ships. November 4, 1925, online on Google Patent Search, accessed January 19, 2017.

- Josef Esser: The Flettner ship. GD Baedeker, Essen 1925.

- Kurt Graffstädt: The Flettner rotors in a generally understandable form. Polytechnische Verlagsgesellschaft M. Hittenkofer, Strelitz in M. 1925.

- Anton Flettner: My way to the rotor. Köhler & Amelang, Leipzig 1926.

- U.S. Patent 1674169: Arrangement for exchanging energy between a current and a body therein. June 19, 1928, online on Google Patent Search, accessed January 19, 2017.

- Heinrich Croseck: From sailing ship to rotor ship . In: Institut für Meereskunde, Berlin (Ed.): Meereskunde . tape 16 , no. 3 . ES Mittler & Sohn, Berlin 1928.

- Hans-Jürgen Reuß: Flettner rotor ships: Old technology for new ships. In: The technical development of the German merchant fleet in the 1920s and 1930s. Internet project of the German Maritime Museum, at DSM.Museum, accessed on January 23, 2017 (PDF; 2.5 MB)

- Felix von König: Wind power from the Flettner rotor: boats, yachts, ships and wind turbines with rotors. Pfriemer, Munich 1980, ISBN 3-7906-0095-4 .

- Claus D. Wagner: Further development of the Flettner rotor into a modern auxiliary wind drive. (BMFT report MTK 03084, 2 volumes) Blohm + Voss, Hamburg 1985.

- Ekkehard Büge: Investigations on a Flettner rotor pair. University of Hamburg, diploma thesis 1986.

- Claus D. Wagner: The sailing machine. Kabel Verlag, Hamburg 1991, ISBN 3-8225-0158-1 .

- Uwe Greve: Ships - People - Fates: Buckau and Barbara. The experiment of the rotor ships. No. 20, Volume 3, DBM-Media, Berlin 1995.

- Christian Mähr: Forgotten Inventions. 2002, ISBN 3-8321-7816-3 .

- Frank Grotelüschen: Torque: Anton Flettner succeeds in 1924, what all sailors dream of: his rotor ship sails against the wind. In: Mare - the magazine of the seas. No. 45, August 2004, Dreiviertel-Verlag, Hamburg 2004, ISSN 1432-928X , pp. 38-41. Online at mare.de, accessed on January 8, 2017.

- Reiner Höhndorf: Flettner rotor ship. Gadebuscher Strasse 270a, Schwerin 2004.

- Reinhold Thiel: The history of the Actien-Gesellschaft "Weser" 1843–1983. Hauschild, Bremen 2006, ISBN 978-3-89757-338-3 .

- Egg yolk meadow: full pipe. In: Deutsche Seeschifffahrt. Issue 3/2010, Storck-Verlag, Hamburg 2010, ISSN 0948-9002 , pp. 50-53.

- Karl-Heinz Hochhaus: STG consultation day “Innovative Ships” in Kiel. In: Hansa . Issue 4/2010, Schiffahrts-Verlag Hansa, Hamburg 2010, ISSN 0017-7504 , pp. 44–47, online at Hochhaus-Schiffsbetrieb.jimdo.com, accessed on January 19, 2017.

- P. Schenzle: Back to sailing? From the empirical “know-how” to the rational “knowing-why”. In: Yearbook of the Shipbuilding Society 2010. pp. 33–44.

- P. Schenzle: Windships in the 21st Century? Current approaches in the wind propulsion of ships. In: Yearbook of the Shipbuilding Society 2010. pp. 55–65.

- German utility models 20 2007 009 278.4 and 20 2007 009 279.2.

- Michael Vahs, Jann Strybny, Thomas Peetz, Moritz Götting, Marcel Müller, Sascha Strasser: Flettnerrotor cuts fuel costs . In: Schiff & Hafen , issue 2/2019, pp. 12–20

- Michael Meyer: New EcoFlettner company is looking for shipping companies . In: Hansa , issue 10/2019, pp. 54/55

Web links

- Private page about the Flettner and Savonius rotor (and others)

- "Das Flettner-Schiff" , Albert Einstein's manuscript from 1925, Einstein Archives Online

- Flettner rotor information on windschiffe.de (website about wind propulsion for merchant ships)

- Can modern cargo ships sail with the wind again? DLR blog

- Report on the christening of the Uni-Kat Flensburg in the broadcast series Research News of Deutschlandfunk

- Frank Grotelüschen: Advertising pillar as a sail: The Flettner rotor in the research series of Deutschlandfunk

- Pillars as sails - wind propels a ship with Flettner rotors ( memento from June 10, 2015 in the Internet Archive ), Nano (3sat) on September 21, 2010 video on YouTube

Individual evidence

- ↑ New Rotor Ship Sails in Lightest Wind . (JPG) In: Popular Science . July 1933, p. 45.

- ↑ a b Katherine Kornei: Spinning metal sails could slash fuel consumption, emissions on cargo ships . In: Science . 2017, doi : 10.1126 / science.aap8915 .

- ↑ Buckau. The test ship 'Buckau'. In: Flettner-Rotor.De. Ingenieurbüro Böger, accessed on November 20, 2019 .

- ↑ Barbara. The rotor ship 'RMS Barbara'. In: Flettner-Rotor.De. Ingenieurbüro Böger, accessed on November 20, 2019 .

- ↑ a b Rotor Yacht. Equipping modern sailing yachts with Flettner rotors. In: Flettner-Rotor.De. Ingenieurbüro Böger, accessed on November 20, 2019 .

- ↑ The Flettner Rotor - An Invention Ahead of Its Time? (Special exhibition in the shipping section of the German Museum of Technology; February 2 to August 1, 2010). In: SDTB.de. Stiftung Deutsches Technikmuseum Berlin, 2010, accessed on November 20, 2019 (English).

- ↑ a b America’s First Rotor Boat . Naval Officers Embody New Ideas in Odd Craft. In: Popular Science Monthly . September 1925 (English, ed.ac.uk [accessed November 20, 2019]).

- ↑ Toby Heppell: Think you understand how rigs work? ( English ) In: The Daily Sail - The racing sailor's homepage . Sailing Media Ltd. October 13, 2006. Retrieved January 7, 2019.

- ↑ a b Stephen Thorpe: Rotorboat . (PDF, 594 kB) In: Catalyst: Journal of the Amateur Yacht Research Society . No. 24, April 2006, pp. 26-30.

- ↑ Stephen Thorpe: Rotor home ( English ) In: rotorboat.com . Stephen Thorpe. 2007. Archived from the original on May 26, 2010.

- ↑ Angelika Hillmer: With wind power over the oceans , Hamburger Abendblatt, September 8, 2010, accessed on June 15, 2018.

- ^ FAZ , October 12, 2010, page T5

- ↑ picture of Cloudia

- ^ A b John R. Marples: Project Brighter World . In: Michael Barker (Ed.): Epoxyworks . Building, Restoration & Repair with Epoxy. tape 29 . Gougeon Brothers, Bay City 2009, pp. 8–11 (English, com.au [PDF; 4.3 MB ; accessed on November 19, 2019]).

- ↑ TJ Craft, H. Iacovides, N. Johnson, BE Launder: Back to the future: Flettner rotors Thom for maritime propulsion? In: Turbulence, Heat and Mass Transfer 7 . Begell House, 2012 (English, ed.ac.uk [PDF; 1.9 MB ; accessed on November 23, 2019] Lecture script, 7th International Symposium, September 24-27, 2012 in Palermo, Italy).

- ↑ Holger Dambeck: 1500 robot ships to stop global warming , Spiegel Online - Wissenschaft , September 3, 2008.

- ↑ Stephen Salter, Graham Sortino, John Latham: Sea-going hardware for the cloud albedo method of reversing global warming . In: Royal Society (Ed.): Philosophical Transaction of the Royal Society A - Mathematical, Physical and Engineering Sciences . tape 366 , no. 1882 , August 29, 2008, ISSN 1364-503X , online ISSN 1471-2962 , section 4 , doi : 10.1098 / rsta.2008.0136 (English, royalsocietypublishing.org [accessed November 24, 2019]).

- ↑ Frank Binder: "Estraden" with Flettner rotor on the move · New rotor with better performance . In: Daily port report from December 8, 2014, pp. 1 + 4

- ↑ Flettner rotors: How ships with steel sails save fuel - Golem.de . ( golem.de [accessed on October 22, 2017]).

- ↑ a b c d Werner Pluta: Norsepower. Steel sails help the environment and save fuel. In: golem.de, Golem Media, Berlin, Version: October 12, 2018, accessed on October 19, 2018.

- ↑ a b Platsidakis, Palios, Frangou and Kassidokostas-Latsis win awards in front of over 1,000 at annual shipping gala ( English ) In: greekshippingawards.gr . Informa PLC, London (UK). December 7, 2018. Accessed December 21, 2018.

- ↑ a b Flettner Rotor-Fitted Ultramax Wins Ship of the Year Award ( English ) In: worldmaritimenews.com . Navingo BV, Schiedham (Netherlands). December 14, 2018. Accessed December 21, 2018.

- ↑ Michael art: Energy from the tube . In: segelreporter.com . SegelReporter Verlag (Hamburg). December 20, 2018. Accessed December 21, 2018.

- ↑ Peter Kleinort: Flettner rotor for passenger ferry for the first time · “Viking Grace” already runs with LNG propulsion · Potential savings are 900 tons of CO 2 and 300 tons of LNG annually . In: Daily port report from February 8, 2017, pp. 1 + 4

- ^ Viking Grace - maiden voyage with Flettner rotor ( memento from April 12, 2018 in the Internet Archive ), Hansa , April 11, 2018.

- ↑ a b New building for Viking Line is named Viking Glory: Flettner rotors are initially not installed . In: SeereisenMagazin, issue 3/2019 (May-June) . Sea travel magazine media. May 1, 2019. Retrieved July 17, 2018.

- ↑ Inken De Wit: Recovering Treasures and Building Ships. In: ethz.ch. President of ETH Zurich, May 31, 2016, accessed on December 7, 2019 (further information in the comments section).

- ↑ crooked (nickname): Showcasing Student Innovation - Foldable Flettner Rotor. National Instruments, January 30, 2017, accessed December 7, 2019 .

- ↑ Franz Radke, Sebastian Krummenacher. (May 31, 2016). Eolos presentation focus roll-out (HD). Department of Mechanical and Process Engineering (DMAVT), ETH Zurich. 7th December 2019.

- ↑ Conversion diary: Installation of the Eco-Flettner on the MS “Fehn Pollux”. Retrieved June 14, 2018 .

- ↑ André Germann: "Fehn Pollux" gets rotor sails . In: Daily port report of May 29, 2018, p. 14

- ↑ project "MariGreen" test Flettner rotor . In: Schiff & Hafen , issue 9/2018, DVV Media Group, Hamburg 2018, pp. 54/55

- ↑ Michael Vahs, Jann Strybny, Thomas Peetz, Moritz Götting, Marcel Müller, Sascha Strasser: Flettnerrotor cuts fuel costs . In: Schiff & Hafen , issue 2/2019, pp. 12–20

- ↑ Wolfhart Fabarius: Thrust for Flettner rotor · Power higher than expected · Up to 20 percent less fuel · Suitable for ships with free deck area . In: Daily port report from December 6, 2019, p. 3

- ↑ a b MarEx (editor): Construction Starts on Viking Line's New Passenger Ship ( en ) In: maritime-executive.com . The Maritime Executive. September 3, 2018. Retrieved November 18, 2018.

- ^ Keel laid for new eco ship Viking Glory ( en ) In: safety4sea.com . SAFETY4SEA. June 7, 2019. Retrieved July 17, 2019.

- ↑ Werner Pluta: Norsepower. Steel sails help the environment and save fuel. First new build with Rotorsails. (Part 2) In: golem.de, Golem Media, Berlin, Version: October 12, 2018, accessed on October 19, 2018.

- ^ André Germann: Environment package for "Viking Glory". In: THB - daily port report. DVV Media Group, October 29, 2019, accessed on February 1, 2020 .

- ↑ Scandlines installs rotor sails from Norsepower on board the hybrid ferry “Copenhagen”. Scandlines press release, August 14, 2019, accessed on August 28, 2019 .

- ↑ Video of a flight model with a Flettner rotor as a wing

- ↑ Krzysztof Baranowicz: Silniki WIATROWE: Wiatraki Z ROTORAMI MAGNUSA. In: DARMOWA ENERGIA. FUNDACJA EKOROZWOJU (KRS 0000178876), August 2, 2001, accessed April 4, 2019 (Polish).