Gülitz brown coal mines

As Gülitzer lignite mines several smaller brown coal mines in the northwest were Brandenburg referred. To the communities Gülitz (earlier spelling "Gühlitz") and Pirow in Prignitz was from 1848 to 1949 in Day and civil engineering lignite mined.

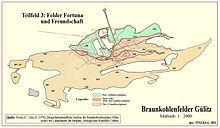

Divided into four subfields , lignite was extracted from two lignite seams, the upper and lower seam, via 68 mining, driving, weather and artificial shafts . The approx. 105 hectare mining area is divided into subfields 1 (Ottiliengrube field), 2 (Louise, Sophiensglück, and friendship fields), 3 (Fortuna and friendship fields) and 4 (Sophiensglück field). Today the quarry fields of the earlier mining form the Schönholz pit ponds .

Two seams from a lower Miocene lignite series were mined: seam 1 (upper seam) and seam 2 (lower seam). These are distributed over an area approx. 700 m wide and 1.8 km long west of the village of Gülitz, mainly in a large forest area between the villages of Gülitz in the east, Wüsten-Vahrnow in the south, Bresch in the west and Burow in the north. A small part of the mining area is used for agriculture. The village of Schönholz lies roughly in the middle of the old mining area.

| Gülitz lignite mines | |||

|---|---|---|---|

| General information about the mine | |||

| Removal of overburden using a bucket chain excavator in opencast mine A | |||

| other names | Gülitz mines, Gülitz lignite deposits, Westprignitz lignite | ||

| Mining technology | Broken piers | ||

| Information about the mining company | |||

| Operating company | Different societies | ||

| Start of operation | 1848 | ||

| End of operation | 1949 | ||

| Successor use | forestry | ||

| Funded raw materials | |||

| Degradation of | Brown coal | ||

| Mightiness | 3 m | ||

| Geographical location | |||

| Coordinates | 53 ° 12 '6 " N , 11 ° 55' 46" E | ||

|

|||

| Location | Gülitz / Schönholz | ||

| local community | Gülitz-Reetz | ||

| District ( NUTS3 ) | Prignitz | ||

| Federal Republic | Federal Republic of Germany | ||

| Country | Germany | ||

history

Lignite extraction in the Gülitz area took place from 1848 to 1905 and in a smaller subfield in the south of the deposit from 1946 to 1949. The lignite was mainly extracted underground using the pillar excavation method. In some places where the coal seam was almost exposed, it was extracted in open-cast mining.

Extraction period from 1848 to 1905

The Gülitz lignite deposit has been known since 1847. The assumption was made on December 10, 1847, and the award was made on July 12, 1848.

The following is known about the discovery of the lignite stocks there: “Tradition has it that one day Hansen, the owner of the manor at the time , had a cattle trough dug on his field in the so-called“ Plagried ” . Johann Pröpper was entrusted with this. At work the day laborer found deep black earth. That struck him as strange. After completing the job, he took home a sackcloth full of this conspicuous soil. He wanted to show the unique find to his landlord . But he met his daughter Ottilie. He gave her the unusual soil sample - brown coal, as it turned out later. As a reward, the day laborer Johann Pröpper received a few bushels of peas. "

| Name of the courage | Ottilie | Sophiensglück | unity | Friendship | Louise | Nobility | Fortuna | total |

|---|---|---|---|---|---|---|---|---|

| Award day | December 7, 1848 | October 25, 1849 | October 29, 1849 | December 20, 1849 | December 31, 1850 | March 18, 1851 | March 16, 1853 | |

| Field size | 54,000 m² | 54,400 m² | 54,050 m² | 31,600 m² | 54,400 m² | 54,100 m² | 54,400 m² | 356,950 m² |

| Expansion size | 60,300 m² | 59,800 m² | 60,100 m² | 82,900 m² | 59,990 m² | 60,050 m² | 60,000 m² | 443,140 m² |

| Total field size | 114,300 m² | 114,200 m² | 114,150 m² | 114,500 m² | 114,390 m² | 114,150 m² | 114,400 m² | 800,090 m² |

The location of the former point of discovery can be seen on the general plan (see appendix). Under mining law, there was the right to speculate, d. H. lignite not belong to the landowner, but was able to presumption be purchased as mine property sqm within a maximum field of 2,189,000.

| date | Pit field | Lender |

|---|---|---|

| July 12, 1848 | Ottilie, Gühlitz field hall | Landowner FL Hansen in Gühlitz |

| Oct 25, 1849 | Sophiensglück, Feldflur Vahrnow | Oeconom A. Tromann in Vossberg near Pritzwalk

Oeconomist Friedrich Gericke in Perleberg Butter merchant Joachim Schultze in Perleberg |

| Oct. 29, 1849 | Unity, Feldflur Vahrnow | Economist Friedrich Gericke in Perleberg, reindeer Joachim Schultze in Perleberg |

| December 20, 1849 | Friendship, Feldflur Gühlitz | Oeconomist Friedrich Gericke in Perleberg |

| Dec 31, 1850 | Louise, Gühlitz field corridor | Friedrich Gericke in Perleberg, reindeer Joachim Schultze in Perleberg |

| March 18, 1851 | Nobility, Feldflur Gühlitz | Friedrich Gericke in Perleberg, reindeer Joachim Schultze in Perleberg, merchant W.Herz in Berlin |

| March 16, 1853 | Fortuna, Gühlitz field | Landowner FL Hansen in Gühlitz |

In the period from 1848 to 1853, seven individual fields were awarded (see table above): The fields were consolidated on December 22, 1859 under the name "Gühlitzer Gruben" and expanded on November 26, 1866.

The mining of the lignite took place in the years 1848-1856 in the field Ottilie in the open pit.

In the Sophiensglück field there was also an open-cast mine from 1850 to 1851.

In 1856 it is reported: “The mines near Gülitz and Vahrnow, on the other hand, have forfeited their previous sales to Mecklenburg due to the lignite works ( Malliss ) , which recently came into operation near Dömitz in the immediate vicinity of the Prussian border and on the Elbe stream ; Only through the final completion of the construction of an artificial road from Putlitz, via the above-mentioned pits, first to Karstedt for connection to the Berlin-Hamburg railway and on to Lentzen, can these works be brought back to sufficient sales. The administration of the last-mentioned railway, as in almost the same measure that of the Wittenberge-Magdeburg railway, had already taken significant quantities of lignite from the pits near Gühlitz in 1854, partly for experiments, for the firing of locomotive boilers, partly for heating the station buildings. "

In 1858 another opencast mine was set up on the friendship mine, which however had to be abandoned two years later, probably because of the added groundwater.

In 1858, the royal government in Potsdam approved the issuance of shares in the newly founded Gühlitz-Varnower Braunkohen Actiengesellschaft . From the name it can be concluded that several mine owners had come together at that time.

After the high altitudes of the lignite deposits had been dismantled, the seams were traced with numerous shafts of several tons (1853–1905). There was a test shaft in the Louise field, which had been mined here since 1864. The production from both seams from 1848 to the closure in 1905 totaled 1,413,214.2 t (see section Statistics ).

Annual production had reached its maximum in 1875 at around 68,000 t. The workforce was at times up to 250 men. In 1905 mining came to a standstill and on September 25, 1905, the mine was auctioned off. The cessation of operations at the "Gühlitz-Vahrnower Braunkohlengruben A.-G." is essentially due to the fact that the operation, especially its operating resources, were out of date and new investments would have been necessary. This made no economic sense against the background of cheaper Bohemian competing coal.

The manual of the German stock corporations , edition 1902/1903 (1) or edition 1906/1907 (2) lists: The Gühlitz-Vahrnower Braunkohlen-A.-G. in Gühlitz b. Perleberg with the following information:

In (1) : “ Founded: 1858. Last amendment to the statute on June 9, 1900. Funded from 1899–1901: 139 993, 147 940, 150 865 hl, 94 166, 95 138, 91 970 hl lignite sold: sales price per hl 54.82, 66.79 , 72.10 Pfg. 1901 average workforce 44 man capital: M. 232 200, - in 387 shares a. M. 600, -. Direction: Herzog. Supervisory board: Chairman Neuhaus, Komm.-Rat Runge "

In (2) : “ Founded: 1858. The shareholders' meeting on June 11, 1904 resolved to dissolve the company. Mined 1900–1903: 147 940, 150 865, 127 985, 133 555 hl, sold 95 138, 91 970, 82 199, 79 668 hl lignite; Selling price per hl 66.79, 72.10, 68.68, 67.05 Pfg. 1903 average workforce of 45 men. Capital: M. 232 200, - in 387 shares a. M. 600, -. From 7./8. 1905 Payment of the 1st liquidation installment of 50% = M. 300, - per share, from June 30th 1906 payment of the final quota of 23.96%. Liquidator: Factory owner Max Herz Supervisory board: Komm.-Rat Runge, lawyer Busch, manor owner Bartels ”. The table below shows an overview of the daily openings in the old mining area of Gülitz that were researched for the existing mine work :

| Shaft designation | number | Dimensions | Remarks |

|---|---|---|---|

| Art shafts | 12 | 2.4 × 1.6m to 4.8 × 2.4m or d = 4.0m | with route connection |

| Drainage shafts | 3 | 2.4 × 1.2m to 3 × 2m | without route connection |

| Conveyor shafts | 35 | 1.2 × 1.2m to 4.8 × 2.4m | - |

| Lift shafts | 9 | 1.2x × 1.2m to 2 × 1.4m | - |

| Auxiliary shafts | 2 | 1.6 × 1.6m to 3.6 × 2.4m | - |

| Weather shafts | 5 | 1 × 1m to 3.2 × 1.6m | - |

| Weather boreholes | 42 | - | - |

A few years later, at the end of 1919, the then district builder of the Westprignitz district initiated exploratory drilling, which should clarify whether the district could be electrified on the basis of an electricity plant to be built that would be fed with the locally occurring brown coal. This would have meant the revival of the Gülitz mining industry. The investigations dragged on until 1923 and were finally discontinued.

Extraction period after the Second World War

The enormous shortage of fuel after 1945 led to the revival of Gülitz lignite mining. “After 1945, Mayor Kraft was in office in Gülitz. He found an excellent specialist in the head climber Johannes Porwik - a resettler from the Silesian mining area. Initially there were only eight men in the force, which mainly exposed the brown coal with spades, shovels and hoes, that is, removed the surface layer and cleared away some boulders in the process. The lignite was brought to the place by muscle power and a wheelbarrow, from where it could then be picked up by horse-drawn cart or truck - some with wood gas drive ". JAHNCKE goes on to say: “And in autumn the Siemens-Bauunion started open-cast mining with a larger excavator system. This of course meant an increase in overburden and lignite mining. On average, 55 tons were conveyed per shift, which is more than 1000 quintals a day. ... With the intensification of the downsizing, the number of workers increased. About 60 to 80 people were employed. The deployment then took place in three shifts. Coal was extracted in a second open pit. The pit was laid deeper and deeper. Later, two tunnels were driven from the open pit, sloping into the ground, which reached a length of 200 meters. From the two tunnels there were several side tunnels that were perhaps ten meters. Main and secondary tunnels were laid out with rails. The miners went into the tunnels with their mining lamps . The side tunnels were mostly very low. On site was a pick or with the wedge pick coal resolved. Then the hunt was loaded. The mate who worked as a tug had to pull or drag the loaded hunt with the greatest effort to the main tunnel. Only in exceptional cases was it possible to move the freight forward with a reel (winch). With the help of a sheet metal plate it was inserted into the track of the main gallery. Once again, enormous muscle strength was required to transport it to the daylight. Here the truck was emptied , and the shovel was now used to load the damp raw lignite into the carts. These were then pulled to the surface of the earth with a reel on the slope. "

Coal mining began in 1946 in the opencast mining operation in subfield 4. Later the seams were tracked with collapsing stretches. Depending on the building quality , both the upper and the lower seam were extracted.

“On October 2, 1946, coal mining was started by the“ Braunkohlenwerk Gülitz ”company. The excavation operation in the open pit was stopped again on August 28, 1947. While civil engineering field A was only opened up over daily stretches, civil engineering field B was opened up via shafts in addition to 2 daily stretches. Three of the four planned shafts were sunk . The shaft I had on the 7-m- sole a querschlägige conjunction with shaft II, which was geteuft 1948 to the 15-m level. Plots B 1 to B 5 were intended for mining operations. However, construction site B 5 was discarded due to the strong influx of water. The workforce of the entire mine had a workforce of 49 in September 1946 and 95 in December 1948, of which around 40 worked underground. Apart from the operations manager, there was no trained miner among them. The supervisors were shift leaders who had worked as prisoners of war in the Belgian coal mining industry. Correspondingly, the pit lining was adapted to that which is usual in hard coal mining. The production took place in two shifts and amounted to 15-20 t of lignite per day. The annual production in 1948 was around 11,000 tons. The mine was connected to the “Cottbus state-owned brown coal works”. In March 1948, the state government of Brandenburg assessed the Gülitz mine as unprofitable. On September 30, 1949, activities in the Gülitz lignite mine were finally stopped according to the notification from VVB Bergbau to the council of the Westprignitz district. "

Geological deposit conditions

general overview

The old mining area of Gülitz is geographically part of the hill country and heathland of West Prignitz . Morphologically , the study area is a large part of the North Brandenburg plateau and hill country. The area belongs to the West Prignitzer plateau. It is located south of the terminal moraine of the Ruhner Berge and represents a wash-off area of the meltwater that flowed south from the terminal moraine, leveled the terrain and deposited huge masses of sand. Larger standing waters are missing. The area is crossed by the Schlatbach in a north-south direction. There is a lack of constantly flowing watercourses and the existing rivulets dry up even with moderate summer drought. The entire study area has a flat wave design with maximum height differences of approx. 15 m at elevations between +55 m and +70 m above sea level . The height differences are compensated for by gently climbing the terrain. The mining fields of the lignite civil engineering are located approx. 800 m west of Gülitz in the area of the Gülitzer saddle (measuring table sheet 2737 Hülsebeck and 2837 Bäk). The east-west trending saddle is about 2 km long and about 1 km wide. At the eastern end it divides into two partial saddles (partial field 2b and 3). The Gülitzer Sattel is located in the area of warthestadial plateau sands. Among these thin Pleistocene sands, the Tertiary stands in the form of the sub-Miocene lignite series (Märkische lignite formation). The Märkische lignite formation can be divided into a hanging and a lying group. The layers of the hanging part are made up of fine sand, clayey sand, sandy clay, Latvian and brown coal, while in the lying group the molding sands are replaced by coal sand, a light or mica-rich quartz sand that is light or, due to the increasing content of carbon particles, dark to black in color . In some cases there are pronounced floating sands. The Tertiary of Gülitz is assigned to the hanging or molding sand group of the Frankfurt education. The Gülitz strata represent an alternating layer of clays and sands with embedded brown coal seams. For the most part, they dip very shallowly (about 15 ° on the flanks) and only occasionally very steeply or even overturned.

Generally there are two seams of brown coal, but they often disappear completely.

The upper seam (seam 1) carries friable, earthy coal of inferior quality. It reaches a thickness of up to approx. 3.0 m (on average 2.1 m).

In contrast to the upper seam, the lower seam (seam 2) consists of solid, lumpy coal of good quality. The maximum thickness of the lower seam is 3.6 m (average 2.4 m).

The intermediate section is 12–26 m thick. In the southern area, the seams are discarded for about 20 m along a 250–260 ° trending fault.

For the footwall of the Tertiary there are no exact statements because in the field Ottilie mine in 19.35 m depth intersected chalk marl there should be a carryover, sediment, since the extension field of Louise the Tertiary at a depth of 125.3 m not was penetrated. The hanging wall of the Tertiary forms the thin Pleistocene (up to 15 m). In places between the Pleistocene and Lower Miocene lignite series, Upper Miocene marine deposits with remains of marine fauna were observed (southeast of Burow). The emergence of the tertiary culmination of Gülitz is associated with saline movements (structure Marnitz) north of the current location. It is assumed that the Gülitz lignite series is a clod that came into the area of influence of the ice through halokinesis and was dragged south by it. This hypothesis is supported by the sometimes complicated storage conditions, numerous faults, folds and the sudden immersion of the tertiary at the edges of the saddle. In the core area of the saddle, the seams were folded so high that they were eroded during the Quaternary.

The entire Gülitz mining area is divided into four subfields.

Geology of the individual subfields

Subfield 1 (Ottilienzeche field)

Subfield 1 comprises an edge clod located approx. 550 m west-southwest of the Schönholz district; immediately north of the way from Bresch. This has an east-west extension of about 160 m and is about 220 m long in north-south direction.

The mining to the lower seam took place in the years 1878 to 1882. The seam rises from west to east with a slope of approx. 3 ° and is slightly wavy. No mining was carried out east of production shaft 23, as the average thickness of the seam decreased from 2.80 m to 1.25 m. The depth of the excavation varied between 7 m in the east and 17 m in the west. On the surface there is yellow plateau sand. This sand is underlain by tertiary black to black-gray sands. This is followed by black clay, which is partly mixed with sand. This cohesive layer complex is about 2.20 m thick in the east and 6.00 m in the west and directly forms the hanging wall of the lower seam. Subfield 1 was made accessible by a so-called artificial shaft, two conveying shafts and a driving shaft.

Subfield 2

Due to its geological formation, subfield 2 is divided into subfield 2a north of the L13 Karstädt-Putlitz road and subfield 2b in the east-southeast.

Subfield 2a (field Louise, Extended Louise, Extended Ottilienzeche)

Subfield 2a lies in the area of the western part of the Gülitzer saddle that swings to the north, north of the L13 Karstädt-Putlitz. The main saddle divides here north of the Brescher Weg into two narrow north-south trending partial saddles. The maximum east-west extension of the subsoil mining is approx. 500 m and the north-south extension approx. 1000 m. Between the two partial saddles north of the Brescher Weg, the mining of the upper seam began in 1848. The mining field of the upper seam is approx. 170 m long in east-west direction and has a north-south extension of approx. 540 m. The Pleistocene cover varied between 1.50 m and 15.00 m. To the north, the collapse of the seam rises from 12 ° to 85 °. In the area of the east saddle, both seams have even overturned. In the area of the western part of the saddle, the lower seam has a trough-shaped bearing. The outcrop of the western flank of this hollow is about 550 m west of the Schönholz location. The eastern flank of the hollow, on the other hand, only rises to a depth of 13.50 m (in the area of artificial shaft VII). In an easterly direction, the hollow joins the two partial saddles, which reaches its greatest depth of 34.50 m at artificial shaft X. The deepest trough of this lignite floe was not mined. The eastern part of the saddle is narrow (approx. 80 m) with very steep flanks. In the northern part the layers have overturned. The entire upper parts of this brown coal floe were eroded during the Quaternary. The outcrops of the seams are in places only covered by a 5 m thick Pleistocene layer.

The mining in subfield 2a took place in the years 1866 to 1884.

Subfield 2b (Ottilienzeche field, Sophiensglück, friendship, Louise)

The mining area to the east of the L13 Karstädt-Putlitz road, extending up to approx. 700 m west of Gülitz, is referred to as subfield 2b. It includes the east-west trending main saddle and has an east-west extension of approx. 1500 m and a north-south extension of approx. 650 m. The layers are arched according to the course of the saddle structure. The dip here is 10–20 °. The lower seam falls from 5 to 6 m in the west to a depth of approx. 37 m in the eastern part of the mining field. In the area of the top of the saddle, the upper seam was removed during the Quaternary. It reappears on the north and south flanks of the saddle as well as in the lower part of the village (in the area of the former coal removal path), where it was also partially dismantled. The hanging wall of the upper seam is largely composed of fine sand. Cohesive layers (black clay) are predominantly involved in the further petrographic structure of the intermediate agent. The maximum thickness of this cohesive layer complex varies between 5 m and 11 m. At Art Shaft V, an approximately 5.5 m thick layer of gray slate forms the bottom of the upper seam. The small overburden thickness led to the opening of several small opencast mines between 1847 and 1848 . The part of the field east of Art Shaft V was charred between 1863 and 1873. The extensive pit drivings indicate that the deposit was shallow.

The production shaft 27, built on the southern edge of the subfield, opened up the deposit over an extension of almost 400 m. The collapse of the upper seam here was 4 to 12 °. It was dismantled between 1885 and 1894.

Subfield 3 (Fortuna field, Friendship field)

This separate mining field is located about 150 m south of the eastern area of subfield 2b and has an east-west extension of approx. 900 m and a north-south extension of approx. 260 m. Its geographical location is approx. 300 m south of the county road K 7025 Schönholz-Gülitz and approx. 750 m west of the road L13 Karstädt - Putlitz .

The seams in this sub-field are deeper than in the other mining fields. On the northern flank of this partial saddle at Art Shaft XII, the upper seam is at a depth of 28.40 m and the lower seam at 47.00 m. The upper seam was mined in the eastern area of subfield 3. The construction limits reached 400 m in an east-west direction; in north-south extension approx. 140 m.

The structure of the overburden shows the following normal profile:

| Normal profile |

|---|

| Plateau sand |

| Alternating sandy and cohesive layers |

| sand |

| volume |

| sand |

| Upper seam |

| sand |

| volume |

| sand |

| Under seam |

The maximum thickness of the cohesive layer complex fluctuates between 21.00 m at borehole B 136 and only 4.00 m at artificial shaft XII. His average value can be given as 12.10 m.

Subfield 4 (Sophiensglück)

Subfield 4 is located on the southern edge of the mining area and includes the two mining areas A and B of mining after 1945. Here, lignite was extracted both in open pit and underground mining. From a geographical point of view, the two mining fields A and B are approx. 300 m east of the L13 Karstädt-Putlitz road and approx. 20 m south of sub-field 2b.

Geologically, subfield 4 forms a small floe with very little Pleistocene cover. It is characterized by its severe positional disturbance, characterized by numerous faults and thrusts with amounts of several meters. The brown coal seams are folded flat and narrow. The average seam thickness is only 1.80 m to 2.00 m. The upper seam extends up to 5 m below ground in places. Of the three existing seams, only the middle seam 2 generally proved to be worth building. This east-west trending camp is folded and broken up into several small individual clods by cracks. The adjacent rock consists of a more or less clayey-silty fine sand with Latvian deposits.

Due to these complicated storage conditions, subfield 4 is divided into:

Mining field A

It connects to the south of the opencast mine A and has an east-west extension of 110 m and is 60 m long in north-south direction. The hanging wall forms an alternating layer of cohesive, brown-black clays and non- cohesive materials (silty to medium-sized fine sand).

Coal mining took place between 1947 and 1949.

Mining field B

In this mining field, the seams dip at approx. 12 to 15 ° to the east. Longitudinal faults have broken them up into individual clods of different depths. Shaft II opened up the upper seam at 7 m and the lower seam at 17 m. The structure of the petrographic composition of the host rock corresponds to that of field A.

Hydrogeological reservoir conditions

The Gülitz old mining area is hydrographically located in the Elbe catchment area. The general direction of groundwater flow is south to south-west.

“A groundwater level of approx. 55 m above sea level can be taken from the basic hydrological map HK 50 for the middle mining area. While there is an increase to almost 60 m above sea level in an easterly direction, to the west there is a drop to about 52 m above sea level. It is interesting that to the east and west of the mining area a presumed groundwater divide of the 2nd order runs roughly in the NS direction. "

The flat, undulating area has no noteworthy drainage, it is only crossed by a few smaller drainage ditches. The surface drainage of the wider area takes place to the east to the Stepenitz and to the west to the Schlatbach .

"The pits of Perleberger coalfield generally have artificial in the great flatness of the area drainage necessary service, accompanied for part of the-constructed by Hoppe in Berlin locomobilen steam engines, by making them easy to move."

In the western excavation field of civil engineering from 1905, there were two drainage shafts, so-called artificial shafts. This designation goes back to the water art that was still common at the time to raise the mine water . These were small, movable high-pressure steam engines, sometimes also called locomobiles . “Essentially, they consist of a boiler that is screwed lengthways onto two strong bearing beams and is set up in the manner of a Locomotive steam boiler with many fire tubes on which one or two horizontal cylinders with the control devices, the guide rails of the piston rods and other accessories are attached to cast-iron stands. With the head of the piston rod, which goes between horizontal rails, the blue rod is connected, which by means of a crooked pin drives a small flywheel, of which 2 cylinders are also on a common shaft. The artificial crosses above the shaft are moved by tie rods. ... Such a machine of 12 horsepower ... has 2 cylinders with a piston diameter of 8 inches attached to the right and left of the boiler, also 2 feet of stroke length, makes 30 strokes per minute and lifts the pit water from a depth of 7 puddles by means of a lifting pump. "

These dealt with the pit water from 2.0 to 2.2 m³ / min. In the eastern part of the field, the sink shaft from 1885 pumped 2.1 m³ of pit water per minute from a depth of 45 m. The tributaries increased with increasing mining depth, so that mining was limited to a depth of around 50 m. In addition, there were confined groundwaters in the lying area of the deposit. In 1855 it is reported: "On the Cäcilie mine near Rambow, the locomobile steam engine had to be relocated to another point and the sinking of a new art shaft started, which resulted in an interruption in production."

The shallow excavations of civil engineering after 1945 brought only 50–60 liters of water per minute. The strong water inflow when sinking shaft 4 in 1949 in the projected field C is likely to be due to the proximity to the old construction field of the Ottilienzeche .

Mining and offsetting procedures

Approx. 70 different shafts were sunk on the brown coal deposit, most of which opened up the lower seam. The entire area used by civil engineering covers around 68.5 hectares. In addition to pure production shafts with up to three headers - with the exception of one shaft with a round cross-section (diameter 4 m), rectangular or square shafts were sunk - these were weather, water management and , Driving and auxiliary shafts. In some places, the civil engineering work was tackled from an open-cast mine base through inclined stretches . The shafts were in bolt-fired timber or, in some cases, in brickwork. If these sunk through both seams, two filling sites were also created. The floors of the shafts or the stretches of the investigation were generally 1.80 to 2.00 m wide. Their height was up to 2.20 m, so that a largely sufficient levitation could be left against the hanging sand. They were provided with door frames. The length of such floors, such as those of artificial shafts 3, 5, 7 and 8, was several kilometers. They were not only significant for promotion, driving experiences, Ventilation and drainage, but also for mine survey innovative measurement of the workings and other Auffahrungen as well as escape routes.

Cross-passages, mountains of brakes and reels, as well as floating investigation sections, were used to drive traversing device sections. The general mining method was the broken pillar construction. The complicated storage conditions did not allow the seams to be regularly broken down into fracture fields. The seam sections were broken up into individual breaks of approx. 3 m × 5 m by means of mining and fracture sections. These were basically broken by robbing the carpentry , as were most of the fixtures . In the parts of the field in which both seams were to be mined, the upper seam was first prepared and mined. Only those stretches were relocated which either passed under particularly endangered surface objects, e.g. B. the streets Karstädt – Schönholz and Gülitz – Schönholz or above-ground watercourses. Backfill materials were presumably accruing secondary rock or tailings. Manual offset can be assumed as the offset method .

Characteristics of the Gülitz brown coal

“The lignite is blackish brown, indistinctly slatey and very firm. On the schistungsflächen one sees quite often lighter brown colored remains of plants that seem to belong to leaves and stems, but are only very indistinctly preserved. Where the latter are absent, the coal is thoroughly dense, homogeneous, without a trace of vegetal structure, with uneven, earthy transverse cracks. Bituminous wood is found in considerable quantities in the dense coal; it is long-fiber and strong. The annual rings can still be clearly distinguished on the transverse fracture, together with the medullary rays, but instead of being circular, the former always show a long, elliptical course as a sign of a strong compression of the wood masses. The resin dots that have already been mentioned so often can also be found in the Perleberg coals, and they are quite numerous. It was first mentioned when Mr. Girard was mentioned, but the assumption that it might be amber has not been confirmed by the chemical examination of the distillation products. Apart from isolated dots, the resin can also be found in individual cases in parallel strips between the carbon substance, indistinctly recognizable plant residues, which cover the layers of the coal in abundance. Since the pits are very far away from larger towns and the means of communication are only very mediocre, attempts have been made to make the coals suitable for railroad operations and thus for further transport by coking them in piles. But these attempts have so far not given any favorable result. The charred brown coal is as light as the charred fresh wood, but it is so easily friable that it can withstand transport even less than the non-charred one. The bituminous wood can hardly be distinguished from charcoal in the caked state, only that it tears into a multitude of thin, strongly curved and easily fragile chips after the longitudinal fiber. "

This quality description from 1852 undoubtedly relates only to the lignite of the upper seam (seam 1) that had been mined up to that point.

It was later reported that the Gülitz brown coal was of high quality and lumpy and was used for a long time to fire the locomotives of the state railway. It is therefore reasonable to assume that it was coal from parts of the lower seam (seam 2).

Statistics of lignite mining 1848–1894

| year | 1848 | 1849 | 1850 | 1851 | 1852 | 1853 | 1854 | 1855 | 1856 | 1857 | 1858 | 1859 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| pit | Ottilienzeche | Ottilienzeche, Sophiensglück, unity |

Ottilienzeche, unity, happiness in Sophia, friendship |

Ottilienzeche, friendship |

Ottilienzeche, friendship, nobility |

Ottilienzeche, friendship, nobility |

Ottilienzeche | Ottilienzeche | Ottilienzeche | Ottilienzeche | Ottilienzeche | Ottilienzeche, friendship, nobility |

| advancement | 8,887 | 30,354 | 48.505 | 46.171 | 31,180 | 31,229 | 47,782 | 49,645 | 55,235 | 55,057 | 114,335 | 91,282 |

| Miners | 10 | 38 | 85 | 64 | 36 | 28 | 54 | 49 | 48 | 66 | ? | ? |

| year | 1860 | 1861 | 1862 | 1863 | 1864 | 1865 | 1866 | 1867 | 1868 | 1869 | 1870 | 1871 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| pit | United Gühlitz pits | United Gühlitz pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits |

| advancement | 133,466 | 207,661 | 222,865 | 226,592 | 265.011 | 337.726 | 262,957 | 294,899 | 342,623 | 259,348 | 253,599 | 265,470 |

| Miners | 79 | 156 | 204 | 198 | 161 | 181 | 157 | 174 | 181 | 152 | 124 | 146 |

| year | 1872 | 1873 | 1874 | 1875 | 1876 | 1877 | 1878 | 1879 | 1880 | 1881 | 1882 | 1883 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| pit | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits | Gühlitz club pits |

| advancement | 550.980 | 534.973 | 520.833 | 566,350 | 488,574 | 402,529 | 456.469 | 520,545 | 540,624 | 504.463 | 400.464 | 324.046 |

| Miners | 165 | 213 | 146 | 137 | 144 | 158 | 147 | 138 | 162 | 167 | 153 | 123 |

| year | 1886 | 1887 | 1889 | 1890 | 1891 | 1893 | 1894 |

|---|---|---|---|---|---|---|---|

| pit | cons. Gühlitz pits | cons. Gühlitz pits | cons. Gühlitz pits | cons. Gühlitz pits | cons. Gühlitz pits | cons. Gühlitz pits | cons. Gühlitz pits |

| advancement | 290,882 | 16,483 | 14,166 | 14,318 | 14,415 | 11,889 | 10,216 |

| Miners | ? | ? | ? | 64 | 58 | 55 | 54 |

literature

- Handbook of German stock corporations, issues 1902/1903 and 1906/1907. Verlag für Börsen- und Finanzliteratur A.-G., Leipzig.

- Günter Pinzke: Lignite mining in the Prignitz. In: Association of Friends of Art and Culture in Mining e. V. (Ed.): THE ANSCHNITT . 64th volume, No. 4 , pp. 160-171, 2012.

Appendix: Overview plan of the entire Gülitz mining area and the former site

Web links

- Günter Pinzke: The Gülitz brown coal mines. (PDF, 3.8 MB) Retrieved July 4, 2011 .

- Günter Pinzke, D. Ehle: Analysis of mining damage in the Gülitz lignite mining. (PDF, 3.4 MB) Retrieved July 4, 2011 .

Individual evidence

- ↑ Prignitzer wetlands around Putlitz and mountains - circuit 4. (No longer available online.) Formerly in the original ; Retrieved May 27, 2011 . ( Page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ a b JAHNCKE, G .: Schwarzes Gold in Prignitzer Erde (mining history in 12 episodes), in: Heimatgeschichte aus der Prignitz, 2002.

- ↑ a b c d magazine for mining, metallurgy and saltworks in the Prussian state, published in the Min. public works, publishing house of the Royal Secret Ober-Hofbuchdruckerei, Berlin 1854–1908.

- ^ Official Journal of the Government in Potsdam 1858; Page 329. Retrieved September 22, 2018.

- ↑ a b DMT-Leipzig: mining damage hazard analysis for the former "Gühlitz brown coal mines" near Gülitz, Prignitz district, Brandenburg, September 30, 2005.

- ^ Plettner, F .: The brown coal in the Mark Brandenburg, published by Wilhelm Hertz , Berlin 1852.

- ↑ a b 1 Prussian ton = 4 bushels (salt, coal, etc.) = 219.85 liters

- ↑ a b 1 hectolitre (1 hl) = 100 liters

- ↑ from 1887 onwards in metric tons