Gas engine

(of Innio Jenbacher for power generation of wood gas in the thermal power station transmitting )

The gas engine , a subset of internal combustion engines , is a generally as a gasoline engine , rare as diesel engine operating internal combustion engine , the gaseous fuel ( fuel gases ) such as natural gas , liquid , wood , bio , landfill , pit , blast furnace gas or hydrogen used ( instead of liquid fuels such as gasoline , diesel , heavy oils , etc.). Historically, the first reciprocating piston engines were mainly designed as stationary gas engines before liquid fuels became generally commercially available towards the end of the 19th century.

Gas engines are mainly used as stationary engines to generate electricity in block-type thermal power stations (CHP) or as emergency power units, and increasingly as less environmentally harmful ship engines with LNG as fuel for ships . Automobiles are increasingly being equipped with bi-fuel engines (natural gas and petrol) or retrofitted for additional operation with CNG or L PG . Gasoline-Otto engines with external mixture formation ( naturally aspirated engines ) only require minor modifications. In times of need with a limited oil supply, motor vehicles were operated with a wood gasifier .

history

In 1791, John Barber was the first to investigate the mode of operation of an engine operated by the explosive force of a gas. He received a patent for a device in which wood, coal, oil or other fuels should be gasified in a retort with external firing, the product should be mixed with air in a second vessel and ignited when it escapes. A paddle wheel should then be driven by the emerging jet of fire .

In another patent, Robert Street 1794 describes a reciprocating engine in the cylinder of which tar oils or turpentines are first gasified and then ignited by a flame which burns outside the cylinder and which can be connected to the gas to be ignited at a suitable time.

The Frenchman Philippe Lebon designed a machine that should be operated with coal gas . Air and gas were pressed separately into a reservoir by means of two pumps, in which they combine and ignite. The products of combustion were supposed to drive the piston of a double-acting cylinder. Lebon recommended an electrical machine for ignition, which should be operated by the gas engine itself. Further improvements came from Samuel Brown in 1823 and Lemuel W. Wright , an American from New Hampshire (1833).

The Frenchman Pierre Hugon developed a commercial gas engine, the Hugon engine, in 1858 , which, however, was not widely used.

Lenoir engine

The gas engine only acquired real practical value through the invention of the Luxembourg native Étienne Lenoir , after whose patent on January 24, 1860, the Paris industrialist Marinoni initially produced a few of these machines. When sales of these machines rose rapidly after a cleverly staged advertising campaign, a company for the construction of gas engines, Société Lenoir, was founded . Although it turned out over time that the maintenance costs of the Lenoir motors were disproportionately high, the demand remained at a high level, especially because they were extremely quiet.

Gasoline engine

In 1867 Nikolaus Otto showed his newly designed aero piston engine at the second Paris World Exhibition . As a result, he devoted himself to the development of a four-stroke engine powered by luminous gas , which was produced from 1877 and marketed as "Otto's new engine". He made 3 HP (2.2 kW) at 180 min -1 . The licensee Crossley Brothers in Manchester advertised it as an Otto Engine . About 5000 copies were built by Deutz and its licensees. After many further improvements and the repeal of patents in 1886, the " Otto engine " was built as a gas engine as well as a carburettor engine for liquid fuels in many variations and was thus widely used.

Applications

Small and medium-sized gas engines in the power range of 20–1500 kW are mainly used today to generate electricity and heat in systems with combined heat and power, such as combined heat and power plants (CHP), as well as for the energetic use of lean gases , such as those produced during the fermentation of organic waste ( Bio and landfill gases ), or wood gas . Increasingly larger gas engines are being developed for gas-fired power plants , which with exhaust gas turbines and turbochargers in the power range of a few megawatts often achieve better efficiencies and can be operated more economically than classic gas turbines .

The relatively simple retrofitting of car gasoline engines for economic (currently approx. 50% of the other fuel costs) and ecological motives is also becoming increasingly widespread.

functionality

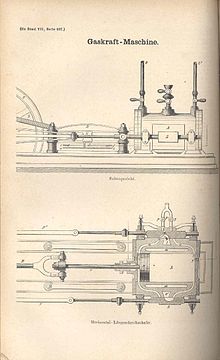

In contrast to the gas turbine , the gas engine is constructed as a reciprocating piston engine . An external mixture formation can take place by means of gas mixing units before or after a possible turbocharger ; internal mixture formation is possible through separate gas inlet valves or injection needles. The fuel-air mixture is ignited in systems based on gasoline engines through external ignition using a spark plug , in systems based on diesel engines through self-ignition with a pilot jet of pilot oil (mostly diesel fuel ) injected in small quantities .

Gas injection

With higher compression, an attempt is made to achieve better efficiency by igniting the mixture with direct injection, similar to the diesel engine , in order to optimize the control of the combustion in the sense of a Seiliger cycle . The company MAN Energy Solutions has now successfully tested the PGI process "Performance Gas Injection", in which a pilot jet (consisting of a mixture of a gas pilot quantity and air) is used. Similar to the diesel engine with pre-chamber injection , part of the fuel gas is injected into a pre-chamber by means of a high pressure injector and ignited with a glow plug, which then ignites the gas-air mixture in the main combustion chamber. The glow plug can be switched off in continuous operation, as it maintains its high temperature through the heat supply from the antechamber.

The Wärtsilä company uses a diesel engine for high-pressure gas injection, i.e. with auto-ignition of the fuel gas injected directly into the combustion chamber at high pressure. The engines working according to this process achieve the highest mean pressures of all internal combustion engines.

economics

When operated with high-quality fuel gases such as methane (CH 4 ), the main component of natural gas , higher levels of efficiency are possible, resulting in clean combustion and a good CO 2 balance . Stationary operated systems for combined heat and power are subject to the TA Luft and thus considerably stricter limit values than motor vehicles. In small engines that work according to the λ = 1 process, exhaust gas is cleaned by means of three-way catalytic converters; medium-speed systems in the lean process (λ = 1.4–2.5) require oxidation or NO x storage catalytic converters or optionally urea or Ammonia injection for NO x reduction.

Manufacturer

Important manufacturers for gas engines are

- Caterpillar Energy Solutions (formerly MWM) in Mannheim

- Innio Jenbacher in Jenbach , Austria

- MAN Energy Solutions in Augsburg

- MTU Friedrichshafen , MTU Onsite Energy GmbH (formerly MDE Decentralized Energy Systems)

- Wärtsilä in Helsinki , Finland

Other manufacturers are 2G , Ford , Perkins Engines , Blohm + Voss Energie und Umwelttechnik, Maschinenbau Halberstadt GmbH, Rolls-Royce Marine , Waukesha Engines , Iveco Aifo , Liebherr , Kubota, Schnell, agrogen and others.

See also

- Étienne Lenoir built the first usable gas engine in 1860.

- George Brayton patented an atmospheric internal combustion engine without spark plugs in 1872

- Natural gas vehicle

- LPG vehicle

- Liquid gas

- Wood gas

- Hydrogen combustion engine

- Heat engine

- Hot air engine (no gas engine)

literature

- The big book of technology . Publishing house for knowledge and education, Bertelsmann publishing group, Gütersloh 1972.

- Peter A. Wellers, Hermann Strobel, Erich Auch-Schwelk: Vehicle technology expertise . 5th edition. Holland + Josenhans Verlag, Stuttgart 1997, ISBN 3-7782-3520-6 .

Web links

Individual evidence

- ↑ a b Chronicle, Motor of Progress ( Memento of the original dated February 6, 2009 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , Website of Deutz AG.

- ^ Gustav Goldbeck: Tamed power: The history of the invention of the Otto engine . Moos, 1965. p. 17

- ↑ Horst Hardenberg: "Siegfried Marcus, Mythos and Reality, page 185 ff., Deutzer rasselling monsters".

- ^ Decisions in nullity proceedings against the patents of the Deutz'er Gasmotorenfabrik number 532, 14254, 2735 ; in: Patentblatt and excerpts from the patent specifications, January 30, 1886, accessed on April 6, 2014.

- ↑ See the article: Wärtsilä to supply major gas engine power plant to Russia. 22th May 2013.

- ↑ See 5th Dessau Gas Engine Conference - The 32/40 PGI - The new gas engine without spark plug from MAN Diesel SE