Potash works union Walter

| Potash works union Walter | |||

|---|---|---|---|

| General information about the mine | |||

| View of the potash pits of the Walter and Irmgard unions around 1914 | |||

| other names | Walter potash pit | ||

| Mining technology | Chamber construction | ||

| Information about the mining company | |||

| Operating company | Walter union | ||

| Employees | up to 300 (including the Irmgard union) | ||

| Start of operation | 1912 | ||

| End of operation | 1922 | ||

| Successor use | no | ||

| Funded raw materials | |||

| Degradation of | Carnallitite, hard salt and rock salt | ||

| Geographical location | |||

| Coordinates | 51 ° 16 '37 " N , 11 ° 17' 23" E | ||

|

|||

| Location | Skin soda | ||

| local community | On the jewelry | ||

| District ( NUTS3 ) | Kyffhäuserkreis | ||

| country | Free State of Thuringia | ||

| Country | Germany | ||

| District | South Harz district | ||

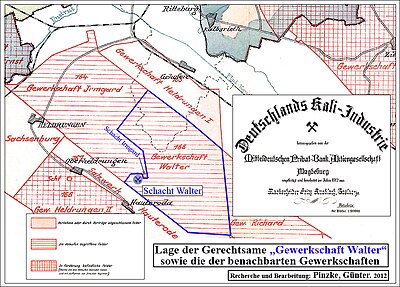

The disused potash mine union Walter is located about 1.4 km northeast of Hauteroda , a district of the city of An der Schmücke in the Thuringian Kyffhäuserkreis (see map below). Shaft Irmgard of the union of the same name is only about 225 m as the crow flies from the Walter shaft . Both unions built on the southern edge of the Hohe Schrecke a gently undulating, mostly from konglomeratischem carnallite existing potash from. Although both pits were mutually effective , the legally independent “Walter Union” with its mine building from the currently accessible archives and statistical yearbooks is to be presented below for reasons of commercial law .

Sinking of the Walter shaft began in 1910, and in November 1911 it had reached its final depth of 430.5 m. The extraction of carnallite and hard salt was made from 1912. The mining mining method was the room and pillar method. The processing of the extracted salts took place in factories of the "Union Heldrungen II" . In 1924, the Walter and Irmgard pits were finally shut down in accordance with Section 83a of the Decommissioning Ordinance (for more detailed explanations of the relevant legal provisions: see the section on “Shutting down the potash plant”).

Search and exploration work

In 1861, chemical factories in the Staßfurt area, which were described as “unclean”, succeeded in sinking the vd Heydt / v shafts, which were originally only sunk for the extraction of rock salt to enrich the weak brine of the Staßfurt salt works. Manteuffel to make carnallitic salts available for technical use. It had become possible to dissolve the potassium chloride (KCl) contained in these salts and ultimately to market it as a fertilizer in agriculture . And the discovery of these potash salts - the “Staßfurter Berggeschrey ” - encouraged Unstrut and Finne to search for such salt deposits . The brine springs in the near and far, known and also partly used since time immemorial , suggested the presence of salts in the deeper subsurface. An industrialist named Emil Sauer 1 was initially involved in the search for and exploration of potash deposits suitable for mining . With the establishment of the "Kalibohrgesellschaft Heldrungen" in 1897, he began extensive and ultimately successful geological exploratory drilling. A borehole, deep borehole VII, drilled northeast of Hauteroda in Dornbachtal, drilled from 355.24 m to 403.00 m depth of potash salts with a content of 23.82% to 26.98% potassium chlorine; Furthermore, from 396.01 m to 403.15 m and from 407.59 m to 413.00 m depth, high-percentage sylvinite with a content of up to 43% potassium chloride. This borehole lies between the shaft starting points of the Walter and Irmgard shafts, which were sunk later .

1 Emil Sauer from Berlin founded the Wilhelmshall trade union near Anderbeck in 1887, the Heldrungen potash drilling company in 1897 and subsequently the Heldrungen I and II, Walter and Irmgard unions, and later, in 1905, the Neuhof potash drilling company , which was established on December 1, 1905 by a notarial act in the Neuhof union was converted.

The geological and hydrogeological reservoir conditions

The mine field of the Walter union is located on the southwest flank of the Heldrunger saddle. This strikes parallel to the Roßlebener Sattel , which is included in the northeastern part of the Hermandurian plaice. The Walter shaft reached the Staßfurt potash seam at a depth of 364.2 m. The upper parts of this 44 m thick seam with storage almost at the bottom consist of hard salt with an average content of 21% potassium chloride (KCl).

Individual lots reached up to 30% KCl. The lying facies of the Staßfurt potash seam with a thickness of 2 m in the immediate vicinity of the shaft also consist of hard salt with an average chlorine potassium content of 19.1%. The intermediate layer consists of carnallite with up to 18.4% KCl (compare the adjacent layer profile). Hydrogeologically, the entire area of the potash shafts on the Unstrut and Finne is characterized by the strong water flow of the Buntsandstein , especially the Rogenstein zones of the Lower Buntsandstein. Inflows of up to 4 m³ / min when sinking the shafts were not uncommon.

The operation of the potash plant

The financial and business situation

Foundation: The "Walter Union" was only founded in 1910. The “founding father” was the industrialist Emil Sauer from Berlin, who, with the establishment of the “Kalibohrgesellschaft Heldrungen” in 1897, devoted himself to the search and exploration of potash deposits suitable for mining. From a large number of pit fields awarded to him, u. a. the mine- friendly Walter with 2,210.7145 ha in the districts of Oberheldrungen and Bretleben . The southern part of the field was later separated from this and transferred to the "Irmgard Union" . This rather complicated construction under mining law presumably served to obtain additional participation quotas, a process that was not unusual at the time (see map on the right).

Number of Kuxe : 1,000 pieces, of which 251 pieces were owned by Deutsche Kaliwerke and 250 pieces were owned by the Hedwigsburg union based in Hedwigsburg in Lower Saxony before the transfer of ownership by the union to Kali-Industrie AG .

Interest and operating community: With the trade unions Heldrungen II and Irmgard there was an operating community with a term of 50 years. By resolution of the trade union meeting on December 17, 1924, this joint venture was dissolved.

Daytime facilities: Chew building with office, workshops with storage, a pumping station, the definitive hoisting machine building with electric hoisting machine with buffer battery, ventilator building with ventilator (so-called main pit ventilator ), connecting railway with the Heldrungen II shaft of 3.5 km in length, residential building for the operator, two pieces of land with apartments for nine workers. The electricity is obtained from the headquarters of the Heldrungen II trade union. Also via Heldrungen II overland connection to the overland plant in Bretleben. This union had also taken over the processing of the salts obtained on Walter. [From: Mossner ]

Here are some statistical figures from 1912 to 1914:

1911: The Heldrungen I trade union cut off part of its fields and formed a new "Walter trade union" . This sinks a shaft near Hauteroda. Depth currently about 150 m. Opencast structures are being built. Electric power from Heldrungen II. Operations manager for Walter: Obersteiger Klaube. 1912: Board of Directors: Emil Sauer in Berlin. Director: Franke in Oberheldrungen. Operator: Obersteiger Schulze (in other sources Obersteiger Krämer). 1913 as 1912: Furthermore: fitting out and fixtures. The salts are processed on Heldrungen II. Sidings to Heldrungen II. Electric power from Heldrungen II. Workforce: 100 men. 1914 as in 1913. [from: Mossner ]

The shaft construction

The sinking was initially started with provisional means; At the end of August 1910, the machine was fully advanced. How in detail and which shaft construction company carried out this work still needs to be researched. The shaft was lined up to a depth of 80 m , as this part was free of water. Later, water inflows set in and so the shaft had to be expanded to 245 m with segments . At this depth the waters were locked. To be on the safe side, another wedge was laid at 251 m and a short set of segments was installed. From then on the shaft was lined up again.

Height of the hanging lawn bench : + 222.05 m above sea level . Total depth : 430.5 m. 1. Sole : - 153.7 m above sea level (376 m level). 2nd level : - 187.1 m above sea level (409 m level). The distance to the Irmgard shaft is about 225 m as the crow flies .

Removal and installation, dismantling and relocation processes

The actual mining field is located southeast of the shaft on a midsole below the 1st level and comprises 10 mining chambers (no. 6 to 16) of different lengths. The longest extraction chamber, mine No. 14, was 240 m long and 15 m wide. The width of the safety pillars between the excavation chambers was 10 m. Information on the ridge height is missing. On the other hand, the extraction chambers No. 8 and 9 were only up to 40 m long, which can indicate the strongly changing thicknesses of the Staßfurt potash seam.

From the first floor almost straight a 400 m long double track after NordNordWest was to investigate mineral deposits advanced. No extraction took place here. The route of this bed to the south and south-east, however, is highly variable, which was probably due to the bedding conditions of the seam. Here, too, the preserved mineworks show no mining activity . A straightening section was driven from this level in a westerly direction to the neighboring Anna shaft of the Heldrungen II trade union. Its length is approx. 490 m. The total distance that would have to be covered is around 3 km.

As already mentioned at the beginning, the pit fields of both unions, the Walter and Irmgard unions, actually form a unit. However, they are dealt with separately here for commercial and mining law reasons (details on the mine field of the “Irmgard Union” can be found in the Wikipedia article of the same name). Both shaft safety pillars also border the limits of the respective mountain fair (see map above). Nuancinal differences between these two shaft systems are, for example, the depth of the respective first levels (in the Walter shaft 376 m depth or - 153.7 m NN ; in the Irmgard shaft 384 m depth or - 158.6 m NN). Furthermore, Schacht Walter was used exclusively for extraction, Schacht Irmgard, on the other hand, was the moving weather - and common driving shaft.

No information is available about the type and quantity of the backfill material introduced . The crack work also shows mining sites in rock salt . Archive information on numerical values about the order of magnitude of the quantities of mined rock salt which was sold and how much rock salt was used as backfill material for the mining chambers in carnallitite or hard salt are not known. Thus, the pit cavity that remained open at the time the mine was shut down cannot be precisely quantified. According to the existing mine workings, the open pit cavity of both shafts at the time of closure is estimated to be around 125 Tm 3 . The extent to which later or still active subrosive changes as a result of drowning these mines caused an increase in the cavity configuration cannot be assessed at this point.

Manufacturing processing

The extracted salts were transported by track to the factories of the "Heldrungen II trade union" and processed there. The table on the right shows some sales figures for the potash salts extracted in the Walter and Irmgard mining fields (in quintals (dz) K 2 O):

In 1922 the sales quota was assigned to other plants.

The closure of the plant

At the beginning of the 20th century, drilling activities in Germany to search for potash salt and hard coal experienced a real boom . In order to prevent the proliferation of new potash works (as well as coal mines) and thus overproduction, the Prussian state parliament decided at the request of MP Karl von Gamp-Massaunen u. a. the "Law, regarding the amendment of the General Mining Act of June 24, 1865/1892, of July 5, 1905 (GBS 265)" , referred to as Lex Gamp . It initially led to a temporary ban on speculation of potash salts and hard coal for two years. This meant that only the state could acquire mining property. The latter was able to transfer it to third parties in the form of a time-limited real extraction right.

The Lex Gamp was the beginning of further state interventions to avoid the formation of monopoly up to the regulation of prices and the overproduction caused by the excessive increase of potash mines. The latter was also served by the so-called decommissioning ordinance of October 22, 1921 ("Ordinance on the amendment of the regulations for the implementation of the law on regulating the potash industry of July 18, 1919", (Reichs-Gesetzbl. P. 663)) .

In § 83a of this ordinance it says: “A change in the conditions relevant for the assessment remains without influence until December 31, 1953 on the continuation and the amount of the participation figure of those plants which are voluntarily shut down up to this point in time. An irrevocable declaration to this effect must be submitted to the potash inspection office by April 1, 1923 (extended to December 31, 1926). Taking into account the economic circumstances, in particular the salt reserves, this determines the point in time by which the shutdown must be carried out; an extension of this period beyond April 1, 1924 is not permitted. A shutdown within the meaning of this paragraph requires that any extraction of usable minerals from the shutdown shaft ceases. Exceptions can only be granted by the Reich Minister of Economics after hearing the Reichskalirat and the potash inspection office. "

In 1924, the potash inspection agency granted the Walter union, on its application for closure, a participation rate of 97.5% of the average participation of all potash plants.

Condition of the mine after its closure

The shaft diameter of the Walter shaft, originally 5.25 m, increased as a result of the collapse of the gray salt clay to 10.5 m at depth 333 m, 12.0 m at depth 345 m and an extreme 34.0 m at depth 361 m. The cause is probably the saline dissolution in the carnallitite area below by water entering the upper shaft area.

In 1939 the disused mine was to be used for storage purposes. The manhole, which had already broken at this point in time - that is only around a decade and a half after the last cable trip - was only able to be overcome with great effort . The shaft extension could be secured again up to the depth of 349 m . However, the increasing technical difficulties in the mountain finally led to the abandonment of this undertaking in 1940. The shaft tube was then m up to a depth of 330 filled . It is not documented which backing materials were used. Measurements after 7 months showed a drop in this offset column by an amount of 6 m.

The investigations carried out in 1978 at the Walter shaft (see picture gallery below) showed u. a. the height of the water or solutions in the shaft at + 147.65 m above sea level. The bottom of the shaft was plumbed at - 110.12 m above sea level. The chemical analysis from a depth of 330.17 m at the in-situ temperature of + 21 degrees showed the following content of individual salts (all in g / l): CaSO 4 0.17; CaCl 2 87.10; MgCl 2 201.00; KCl 45.40; NaCl 38.70; Density 1.267 g / ml. Similar solution compositions can be found in caustic reservoirs of the main anhydrite .

After 1945 the mine was declared property of the people ; In 1953 it was taken over by VEB Kaliwerk " Heinrich Rau " Roßleben in legal ownership. With the issue of the GDR's safekeeping order of October 10, 1971 (GDR GBl. II No. 73), the Halle District Council was responsible for a large number of old potash pits, so-called “pits of old mining without legal successors ”; thus also for Schacht Walter. The condition of the shaft area in 1978, on the occasion of investigation work on the shaft, is shown in the following photos:

With the accession of the GDR to the scope of the Basic Law , these disused shafts were also regarded as "disused facilities of a mining operation for which a legal successor does not exist or can no longer be determined" . Instead of the councils of the districts, the respective state governments acted until the relevant regulatory authority regulations were issued ( "Thuringian law on ensuring public safety and order in objects of old mining and in underground cavities (Thuringian old mining and underground cavities law - ThürABbUHG)" from 23 May 2001 (published in ThürGVBl No. 4 of May 31, 2001, p. 41) as amended by the "Amendment by the Thuringian Law on the Adaptation of Authorities in the Mining Administration of December 3, 2002" (GVBl p. 430, 431)) a. Thus, up to now this decommissioned mine has been the responsibility of the Thuringian State Mining Office with regard to the duty of care for the purpose of averting danger (see also “Guide to safekeeping day shafts”). To ensure public safety , the shaft tube was covered in 1940/41 (see photos above). Compared to 1978, this shaft head protection already showed major weathering damage in 2010. The immediate access is secured against unauthorized entry by means of a chain link fence. Schacht Walter and other of these relics from earlier mining activities continue to require special care.

Bibliography

- J. Mossner (Hrsg.): Handbook of the potash mines, salt pans and deep drilling companies. Finanz-Verlag, Berlin 1936.

- G. Pinzke: files relating to the investigation of closed potash mines in the Halle district . Council of the Schwerin District, Geology Department, 1978, unpublished.

- oV: Yearbooks of the German lignite, hard coal and potash industries. Wilhelm Knapp publisher in Halle / Saale.

- o. V .: Handbook of the potash mines, salt pans and deep drilling companies 1924-25 . Finanz-Verlag, Berlin.

Individual evidence

- ↑ Eckart Frischmuth, Lothar Rudolph: Excursion in the catchment area of the Middle Saale with the tributaries Ilm and Unstrut

- ↑ On the development of mining law in the western part of the Prussian state. In: rheinkamp.com. Retrieved January 11, 2015 .

- ^ Arndt, Adolf: General mining law for the Prussian states, 5th, verb. u. verm. ed., Leipzig 1907, page: 284. In: dlib-pr.mpier.mpg.de. Retrieved January 11, 2015 .

- ^ Harm Peter Westermann: Property law. Hüthig Jehle Rehm, 2011, ISBN 978-3-8114-7810-7 , p. 76 ( limited preview in the Google book search).

- ^ Gerhard Leibholz: Yearbook of the Public Law of the Present. New episode. Mohr Siebeck, 1965, ISBN 978-3-16-615942-3 , p. 207 ( limited preview in Google book search).

- ^ Order on the safekeeping of underground mining facilities (safekeeping order) Safekeeping order dated October 19, 1971 (Journal of the GDR 1971 II p. 621) (PDF file)

- ↑ Thuringian law on the guarantee of public safety and order in objects of the old mining and in underground cavities ( Memento of the original from April 20, 2014 in the Internet Archive ) Info: The archive link was inserted automatically and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. (Thuringian Old Mining and Underground Cavities Act - ThürABbUHG) of 23 May 2001 (PDF file)

- ↑ Guide for the safekeeping of day shafts in Thuringia ( Memento of the original from April 20, 2014 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. dated August 8, 2008 (PDF file)

literature

- E. Loock: Disused shafts - a problem for the potash industry. Freiberg research books, A 136 series, Akademie-Verlag, Berlin 1960.

- J. Löffler: The potash and rock salt deposits of the Zechstein in the GDR. Part III: Saxony-Anhalt. Freiberg research books C 97 / III, Akademie-Verlag, Berlin 1962.

Web links

- Günter Pinzke: Gallery II: Photos of shafts in Saxony-Anhalt and the Teutschental shaft. In: guenter.pinzke.de. July 31, 2009, accessed January 11, 2015 .