Potash works unions Richard and Reichskrone

| Potash works unions Richard and Reichskrone | |||

|---|---|---|---|

| General information about the mine | |||

| other names | Reichkrone and Richard trade unions | ||

| Mining technology | Chamber construction | ||

| Funding / total | around 105,000 t | ||

| Information about the mining company | |||

| Operating company | Mining trade unions Reichskrone and Richard | ||

| Employees | to 170 | ||

| Start of operation | 1913 | ||

| End of operation | 1916 | ||

| Successor use | no | ||

| Funded raw materials | |||

| Degradation of | Carnallitite | ||

| Greatest depth | 560 m | ||

| Geographical location | |||

| Coordinates | 51 ° 13 '36 " N , 11 ° 23' 40" E | ||

|

|||

| Location | Lossa | ||

| local community | fin | ||

| District ( NUTS3 ) | Burgenland district | ||

| country | State of Saxony-Anhalt | ||

| Country | Germany | ||

| District | Kali Unstrut district | ||

The shafts and mine workings of the Richard and Reichskrone potash works are located about one kilometer northwest of the Lossa district of the municipality of Finne . The distance between the shafts is only 30 m. Thus, by definition, they represent a double shaft system.

The underground facilities have an area of approx. 850 m × 750 m. Both shafts were tackled in 1909 and 1910 and opened up the Staßfurt potash seam on the southwest flank of the Roßlebener saddle. In addition to the tailgating of exploring routes attracting carried carnallite only four Abbauörtern in the years 1913 to 1916. A total of 6,600 are t K 2 O ) * have been deposed. If one calculates with a K 2 O content of the extracted salts of 9% and a processing loss of 30%, the result is the calculated amount of carnallitite extracted from only about 100,000 t.

The pits were finally shut down in 1921.

*) For the qualitative and quantitative calculation of the various potash salts (here extrapolated to the amount of carnallitite extracted), their fictitious K 2 O content is used as a basis: 100% KCl = 63.17% K 2 O; 100% K 2 SO 4 = 54.05% K 2 O.

The situation of the justified (also known as the justified )

Search and exploration work

A number of deep boreholes were carried out in the vicinity of the former Richard and Reichskrone pits.

These boreholes are compiled in the following table according to location and depth as well as the possibility of a geological statement for the pit fields of these shafts:

| Name of the hole: | Richard I | Richard II | Richard III | Richard IV | Richard V | Richard VI | Richard VII | Finn II | Finn V | U 41 | U 44 | U 45 E | U 46 | U 70 | U 79 E | U 100 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Drilling period | unknown | unknown | unknown | unknown | unknown | unknown | unknown | unknown | unknown | 1959 | 1959 | 1960 | 1960 | 1957 | 1961 | 1959 |

| Final depth (in meters) | 334.0 | 406.2 | 437.2 | 331.6 | 321.3 | 315.3 | 304.3 | 600.8 | 558.4 | 762.7 | 949.7 | 772.2 | 1,098.45 | 655.5 | 1,229.8 | 936.8 |

| Formation of the Staßfurt potash seam | drained | Carnallitite | Carnallitite | Carnallitite | Carnallitite | Carnallitite | Carnallitite | Carnallitite | Carnallitite | drained | drained | Carnallitite | Carnallitite | drained | Carnallitite | Carnallitite |

Geological and hydrogeological reservoir conditions

The geological conditions

The pits Richard and imperial crown were to Kalisalzgewinnung on the southwest edge of the herzyn trending set Roßleben saddle. Both shafts reached the potash store at the same depth (528.0 m). The potash deposit is limited in the northeast by the leaching of the Staßfurt potash seam from the Sattelkern. In the southwest, the Finns fault is to be understood as a natural limitation, as the potash deposit continues at a greater depth beyond. A north-westerly boundary is given by the leaching boundary of the potash deposit against the Unstrut valley and the pit fields of the former Heldrunger shafts. In the southeast is the former Burggraf-Bernsdorf mine near Kahlwinkel . The former Finne mines were only mined insignificantly.

As a result of the excavations made by the Richard and Reichskrone pits, a flat-lying carnallitite deposit with an average content of 9-10% K 2 O was found everywhere , which fell 3 to 4 degrees to the south in a preferred east-west strike direction. The buildable thickness should have been 14 m.

The hydrogeological conditions

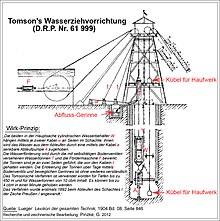

The strong water flow of the red sandstone caused considerable difficulties when sinking the shaft and made it necessary to secure the shaft tubes in two areas between 155 m and 240 m and between 278 m and 375 m by means of tubbing . Particularly strong inflows occurred when sinking both shafts in the Lower Buntsandstein in a rye-leading zone between 156 m and 178 m, where a cleft running perpendicular to the stratification at a depth of 168 m caused considerable difficulties. The "Tomson's water drawing device" was used to manage these tributaries (see figure below right). It is not known exactly how high the tributaries were. The water barrels used to raise the water had a volume of at least 8 m 3 . The closure only succeeded after extensive cementing work . Other strong tributaries, probably from a Rogenstein bank, have been documented from a depth of 335.5 m.

The upper area of the main anhydrite was found fissured but dry, so that the shaft could only be secured in this horizon by masonry . Later, in the lower part of the main anhydrite, between 510 m and 520 m in both shafts, saturated saline solution inflows emerged which, despite careful sealing work, could not later be closed within the shaft. The amount to be added was approximately 12 l / min at a pressure of 10 bar. The composition of the salt solution also remained unchanged. Their mineralization was as follows:

MgCl 2 = 269 g / l; CaCl 2 = 109 g / l; NaCl = 21 g / l; KCl = 38 g / l with a specific weight of 1.28 g / ml. Baumert calculated that in the period from the Teufen (1911) to the shutdown of the mine in 1925, around 85,000 cubic meters of lye leaked, which dissolved and carried a fixed component of 350,000 dz of salts.

The operation of the potash plant

The company formation

The construction of the Richard and Reich crown pits took place after the first Reich Scale Law , which came into force on May 25, 1910. The consequences for the potash industry in general were the compulsory membership in the newly founded potash syndicate and the allocation of a certain share of the total sales of this syndicate (the so-called sales quota ). A (mostly group-controlled) race to found more potash plants began everywhere; not ostensibly about further raw material extraction, but merely about achieving a production quota . The Richard and Reichkrone pits are also part of such “ quota pits ”.

Kaliwerk Reichskrone (former Reichskrone Union):

Foundation: On November 20, 1911 as a Gothic 1) union.

Number of Kuxe : 1,000, of which 850 have been with Kali-Industrie-Aktiengesellschaft since 1920.

Field location: In the districts of Lossa, Baden near Eckartsberga, district Halle. Neighboring union Walter, Burggraf and Rastenberg.

Justice: The pit field has a size of 13,496,017.3 m 2 = 7 Prussian maximum fields (compare the map above).

Shaft: Started in 1909, 560 m deep. Closed on November 8, 1921 to December 31, 1953. The water inflows that occurred in early 1921 were reduced by installing cement plugs.

Two -way question 2) : see Richard union.

Sales: 1913 = 9,424 dz K 2 O, 1 914 = 10,695 dz K 2 O, 1915 = 12,537 K 2 O. Operations have been inactive since 1916.

Closure of operations in accordance with § 83a 3) : In 1922, the potash inspection agency granted the union, on its voluntary closure application, a participation rate of 86% of the average participation of all plants.

Liquidation and transfer of ownership to Kali-Industrie (later Wintershall) A.-G .: The trade union meeting on September 20, 1926 decided to liquidate the union and sell the entire assets to Kali-Industrie A.-G. In exchange, Kali-Industrie Aktiengesellschaft offered the trades pro Kux a nominal 400 RM Kali-Industrie-Aktien. The exchange offer came into effect on December 8, 1927.

Richard Potash Works (former Richard Union):

Foundation: September 4, 1909 as a Prussian 1) trade union.

Number of Kuxe: 1,000, of which 850 were owned by Kali-Industrie A.-G. before the final transfer of ownership. have found. In October 1920 the Rastenberg trade union offered the Richard trade unions the exchange of 3 Kuxes plus 4,500 M bar for a Kux "Rastenberg". In November 1920, Wintershall AG then acquired the ¾ majority.

Location of field ownership: In the districts of Garnbach, Wiehe , Allerstedt , Lossa , Langenroda , Hechenroda, Kleinroda and Berndorf, district Halle aS, with the unions Reichskrone, Burggraf and Walter.

Lawful : The pit field has a size of 18,644,169.7 m 2 = 8 Prussian normal fields.

Interest group: existed with the Reichskrone trade union, Kassel .

Two- shaft question : was solved through a connection with the shaft of the Reichskrone trade union (incorrectly it says : " Riedel trade union " in the " Handbuch der Kali-Bergwerke, Salinen und Tiefbohrunternehmungen 1936 ").

Shaft construction: on July 25, 1910 about 575 m deep.

Facilities: Together with the Reichskrone union: mill system, electrical center, narrow-gauge railway to the Rastenberg union. The facilities were demolished until the end of 1933 when the shaft was closed. The machines, apparatus and materials were usefully given away.

Sales: 1914 = 18,839 dz K 2 O, 1915 = 12,535 dz K 2 O.

Shutdown:

Closure of operations in accordance with § 83a 3) : In 1922, the potash testing agency granted the union, on its voluntary closure application, a participation rate of 87.5% of the average participation of all plants. Liquidation and transfer of ownership to Kali-Industrie (later Wintershall) A.-G .: The trade union meeting on September 20, 1926 resolved to liquidate the union and sell the entire assets to Kali-Industrie A.-G. In exchange, Kali-Industrie Aktiengesellschaft offered the trades pro Kux a nominal 400 RM Kali-Industrie-Aktien. The exchange offer came into effect on December 13, 1927.

1) The right to found a mining union was regulated differently according to state law. According to Prussian mining law, it was enough for two people to submit an application fora unionto be awarded , by speculating with the mining office based on their findings.

2) Even before the turn of the century, there was a provision in the Clausthal district of the Oberbergamt, according to whichthere should betwo separate mobile exits to above the day for all miningfacilities, i.e. a target regulation. Here, in the Upper Mining District of Halle, it was reserved for salt mines to a special regulation of the Upper Mining Office, whether and by what time they were to be provided with a second exit. The result was that most of the potash mines under construction in the Halle district initially only had one shaft. However, when a firedamp explosion occurredat the Frisch-Glück potash mine near Eime in 1902, the Prussian Minister for Trade and Industry urged the upper mining authorities in Halle and Clausthal to generally demand the second exit in potash mining as well. Since the shaft of a neighboring mine could be viewed as a second mobile exit, provided a connection was made underground to the neighboring mine field, the requirement for a second exit was satisfied.

3) In § 83a of the so-called decommissioning ordinance ofOctober 22, 1921, it says: “A change in the conditions relevant for the assessment remains without influence until December 31, 1953 on the continued existence and the amount of the participation figure of those works, which up to this point in time be voluntarily shut down. An irrevocable declaration to this effect must be submitted to the potash inspection office by April 1, 1923 (extended to December 31, 1926). Taking into account the economic circumstances, in particular the salt reserves, this determines the point in time by which the shutdown must be carried out; an extension of this period beyond April 1, 1924 is not permitted. A shutdown within the meaning of this paragraph requires that any extraction of usable minerals from the shutdown shaft ceases. Exceptions can only be granted by the Reich Minister of Economics after hearing the Reichskalirat and the potash testing office ”.

Here are some excerpts from statistical yearbooks (1910–1914):

Union "Reichskrone" to Lossa:

1911: Board of Directors: Privy Councilor Kempner in Berlin. Director: Nolting. Operations manager : Honigmann. The Reichskrone union sinks two shafts in the field of the Finne V union near Lossa. Depth about 150 or 100 m. Opencast structures are being built. Average number of workers: 80 men.

1912: Board of Directors: Privy Counselor Kempner in Berlin. Director: Nolting. Operations manager: Honigmann. The Reichskrone union sinks two shafts in the field of the Finne V union near Lossa. Depth about 300 m. Opencast structures are built. Average number of workers: 170 men.

1913: Board of Directors: Privy Councilor Kempner in Berlin. Director: Nolting. Operations manager: Honigmann. The shaft will be sunk by the end of the year. Opencast structures have been erected, salt mill under construction. Light railway connection to the light railway of the Bernsdorf union. Workforce: 170 men.

1914: Board of Directors: Privy Councilor of Justice Kempner in Berlin, chairman. Director: Nolting. Operations manager: Honigmann. Finishing and fitting work. Opencast structures are built. Salt mill. Light rail connection to the light railroad of the Bernsdorf union. Workforce: 170 men.

"Richard" union in Lossa:

1913: The shaft will be completely sunk by the end of the year. The other information as for the “Reichskrone” union.

1914: The final conveyor system will be completed by the end of the year. The other information as for the “Reichskrone” union.

The shaft construction work

The suspended lawn bench of the Reichskrone shaft is at +343.77 m above sea level ( sea level ). The digging of the shaft began on December 28, 1909. The middle red sandstone proved to be particularly rich in water. By the end of 1910, the Reich crown had reached a depth of 168 m and was walled up to 156 m. However, the inflows increased as the river went deeper. At a depth of 178 m, a vertical crevice was approached through the shaft, from which so much water leaked that conventional pumps could no longer cope with the remaining amount. The "Tomson's water drawing device" was used (see illustration on the right), with which the inflows were kept short and ultimately the gap area could be sealed with cement paste. However, the sinking work was interrupted at a depth of 335.5 m due to renewed water ingress. The added amount of water was so great that the pump system was no longer sufficient for the sump . First a 15 m thick concrete plug was placed. After the completion of this work, “petrification holes” were made on the concrete plug and cement paste was pressed into the water-bearing layers through these. In this way the water seal succeeded. The shaft was then secured in this zone (between 287 m and 375 m) by lining segments. In September 1912, rock salt was reached at depth of 558.3 m . The shaft was lined up to the final depth of 576 m.

The following table shows the diameter , depth and extension of the Reichskrone shaft:

| diameter | Depth | Expansion type |

|---|---|---|

| 5.50 m | 0-156 m | Masonry |

| 4.20 m | 156-241 m | German segments |

| 4.20 m | 241-287 m | Masonry |

| 4.20 m | 287-375 m | German segments |

| 4.20 m | 375-576 m | Masonry |

Reichkrone shaft kept its wooden sinking structure; after its completion it served as a cableway, material pulling in weather shaft . The turf hanging bank of the Richard pit is at +344.02 m above sea level. Sinking of the shaft began on June 25, 1910. It reached its final depth of 576 m in 1910. Due to the short distance from the Reichskrone shaft, the geological profiles of the two shafts hardly differ . The same difficulties arose when sinking as when sinking the Reichskrone shaft. But with the same work and measures applied there, these could also be overcome here in the Richard shaft. The following table shows the diameter, depth and expansion of the Richard shaft:

| diameter | Depth | Expansion type |

|---|---|---|

| 3.50 m | 0-155 m | Masonry |

| 3.50 m | 155-240 m | German segments |

| 3.50 m | 240-278 m | Masonry |

| 3.50 m | 278-365 m | German segments |

| 3.50 m | 365-576 m | Masonry |

After completion, Schacht Richard received a steel headframe and a one-day rack conveyor . At the same time it served as an extending weather shaft. The breakthrough in both pits took place on June 5, 1913, at the devil level of the 545 m level.

Removal and installation, dismantling and relocation processes

Were in the depths 537 of the two shaft tubes m (= -194.20 m NN) and 545 m (= -202.02 m NN) shaft landings injured and the only two of these sole developed. Both levels were connected to one another by a large number of upheavals or dies (the exact number cannot be determined unequivocally from the existing mine drawings; it could be up to 56!). These high fractures or hollows were probably used for driving and weather management . To the east of the shafts, on the 545 m level, three mining chambers were excavated . With a chamber length of 100 m, the chamber width was 10 m and the pier width 7 m. These excavations should presumably reach both levels in height, which would have resulted in a mining height of 10 m. Since two of the three excavations were only 80 m long, they probably only reached the jacking height of 2.5 m. At the level of the 537 m level, a further excavation of 100 m length and 10 m chamber width is shown on the crack work. A total of almost 7 km of routes were excavated in the mine field. Between 1913 and 1916, approx. 150,000 t of carnallitite were extracted from the Richard mine. No offset was introduced into the mine workings. The open cavity was determined based on the ground plan:

Routes: 71,000 m 3 , dismantling: 9,000 m 3 , total: estimated 80,000 m 3 .

The manufacturing processing of the crude salts

The Richard and Reichskrone pits did not have their own factory for processing the extracted potash salts. The raw salt was simply ground here and then transported by light rail to the Rastenberg union's potash factory.

Special occurrences

There are no indications of the occurrence of gases during and after the operating period.

After the end of World War II battle were ammunition (flak projectiles and detonators ) and over 2,000 phosgene bombs in two shaft tubes sunk. The resulting explosions led to massive destruction of the shaft cladding and the shaft head protections. Later, the shafts were secured with so-called orlas locks (see above photo from 1978).

The closure of the potash works

After the First World War and the "loss" of the Alsatian potash mines, the German potash monopoly was broken. In order to curb the overproduction of potash salts, on October 22, 1921 , the Reichstag issued the “Ordinance on the Amendment of the Regulations of the Law on the Regulation of the Potash Industry” of July 18, 1919 (“KWG”), or “Decommissioning Ordinance” for short. With this ordinance, the potash plant operators were offered to voluntarily shut down less profitable plants by the end of December 31, 1953. The participation figure previously granted to such works, the so-called sales quota , could be transferred (read: sold) to other works. In response to a request for closure by the Reichskrone trade union assembly, the potash testing office granted the trade union a participation rate of 86% of the average participation of all plants in 1922. The same application from Richard's trades was approved with a participation figure of 87.5%. Subsequent meetings of both trades, each dated September 20, 1926, decided to liquidate the trade unions themselves and to sell their entire assets to "Kali-Industrie A.-G." (later Wintershall AG).

Current condition (2012)

The two shafts belonged to Wintershall AG until 1945. After 1945 they became “the property of the people”. As of September 21, 1955, they became the legal entity of VEB Kaliwerk "Heinrich Rau" Roßleben. With the issue of the GDR's safekeeping order of October 10, 1971 (GDR GBl. II No. 73), the Halle District Council was responsible for a large number of old potash pits, so-called “pits of old mining without legal successors”; thus also for the old potash shafts Richard and Reichskrone. With the accession of the GDR to the area of application of the Basic Law , these closed mines were also regarded as " closed facilities of a mining operation for which a legal successor does not exist or can no longer be determined ".

After the GDR acceded to the area of application of the Basic Law of the FRG, the state government of Saxony-Anhalt took the place of the council of the Halle district until the relevant regulatory authority regulations were issued (for the state of Saxony-Anhalt: Law on Public Safety and Order of the State of Saxony-Anhalt (SOG LSA) in the version published on September 23, 2003 (GVBl. LSA p. 214), last amended on May 18, 2010 (GVBl. LSA p. 340)). This ensures that these mines are to date regulatory law of respect. Duty of care in order to security in the jurisdiction of the municipality . In order to guarantee public safety , the shafts have now been stored and secured by a cover (see photos above). The manhole safeguards are secured against unauthorized entry by means of a chain link fence .

Bibliography

- Baumert, B .: About caustic and water inflows in German potash mining. Dissertation, Technical University of Aachen, 1927. Verlag Gebr. Gerstenberg, Hildesheim, 1928.

- Nagel, Lobert, Schwarzer: Analysis of mining damage of the mine systems of the Richard and Reichskrone unions in Lossa, Nebra district. Roßleben, August 1970. Archives of the LAGB Saxony-Anhalt, archive no. 922.5D.

- J. Mossner (Hrsg.): Handbook of the potash mines, salt pans and deep drilling companies . Finanz-Verlag, Berlin 1936.

- oV: Yearbooks of the German lignite, hard coal and potash industries . Wilhelm Knapp publisher in Halle / Saale.

Individual evidence

- ↑ PDF at www.gesetze-im-internet.de

- ↑ Law on Public Safety and Order of the State of Saxony-Anhalt (SOG LSA)

literature

- J. Löffler: "The potash and rock salt deposits of the Zechstein in the GDR. Part III: Saxony-Anhalt" . Freiberg research books C 97 / III, Akademie-Verlag, Berlin 1962.

- E. Loock: "Disused shafts - a problem for the potash industry" . Freiberg research books, A 136 series, Akademie-Verlag, Berlin 1960.