Casting (metal)

The casting (also the casting or the work ) of metals and alloys is a manufacturing process in which work pieces ( cast pieces ) are made from liquid metal - the melt . In the most common process - die casting carried out in foundries - the melt is poured into a hollow mold in which it then solidifies . The inner surface of the hollow mold is the negative of the outer surface of the casting.

Casting belongs to the main group of primary forming and is the most important process group within this. For the casting of non-metallic materials, see Casting (archetype) .

The process of pouring the melt into the molds is called casting . The entire process chain of mold casting from the raw material to the casting also includes mold construction , the production of models , melting of the materials and melt treatment, as well as post-treatment: demolding, heat treatment and fettling . The latter includes the removal of gates and feeders that are only used to supply melt but are not part of the cast part , desanding , deburring , descaling and the repair of casting defects .

When iron is extracted from ore , the liquid metal is poured into bars or pigs ( ingot casting ) or into endless strands ( continuous casting ). The pigs are further processed in the foundries, where the iron is melted down again. Of the casting processes used there , the most important are sand casting , where molds made from sand are used, and pressure casting , in which the melt is pressed by a piston into a permanent mold that is used several times.

The most important casting materials for castings are cast iron with a mass fraction of the total production in foundries of around 75% and aluminum alloys . The material properties that are important for casting are summarized in castability .

The casting as well as the supplying companies are grouped under the term "foundry industry", which in turn is bundled in Germany in the Federal Association of the German Foundry Industry .

history

Prehistory and early history

The casting originates from the Copper Age , the transition period from the Neolithic to the Bronze Age . The first metals were already known in the Stone Age. Gold , silver and copper occurred in nature in a dignified , i.e. metallic form . Copper was initially worked by hammering, which made it very brittle and brittle. Therefore it was initially only used as jewelry; All known metals could not be used for tools because of their low hardness and strength. With the development of melting furnaces (so-called crucible furnaces ) around 3000 BC. BC - first in China and India - it became possible to cast metals and to extract copper from copper ore. However, copper has been a problem in casting because it has a tendency to bubble. It also has a high melting point and is relatively viscous. Since 1500 BC Therefore bellows were used instead of blowpipes in Egypt. The decisive breakthrough came with the technique of alloying: the alloying of tin resulted in bronze , which is excellent for casting, is significantly harder and stronger than copper and is therefore also suitable for tools. Bronze thus replaced stone as the most important tool material. Bronze, silver and gold were used for art casting, bronze also for the manufacture of weapons and tools. These metals were also processed by forging and driving , but the most important process was casting. Since the melting furnace evolved from the ceramic furnace, the early metalworkers were also familiar with building ceramic molds.

Antiquity

In antiquity, bronze was replaced by iron as the most important material, which could not be cast in Europe until the Middle Ages, while the Chinese had used the technology since around 500 BC. Ruled. Bronze casting was still used and further developed in handicrafts . The bronze statues became larger and more complex in the course of antiquity. Initially, only massive figures about 30 cm high were made. Later, the casting of hollow castings ( hollow cast ) succeeded, which saved a lot of material and thus enabled significantly larger workpieces, including life-size equestrian statues. The lost wax process was used : a wax coat was placed over a clay base into which the shape to be manufactured was incorporated. Then this layer was surrounded with another layer of clay. The melt was poured into the intermediate layer of wax, causing it to burn. In a further development of the process, the statues were potted in individual parts such as arms or heads and soldered together. If the individual parts failed, the entire mold did not have to be remade.

middle Ages

In the High Middle Ages, thanks to the new shaft furnaces , the forerunners of the cupola furnaces , the production of cast iron (castable but not malleable iron), which was now used in art casting, was successful for the first time . In addition, the bellows were increasingly driven by water power. In some cases, cast iron and forgeable iron were produced in the same shaft furnaces. Some of the molds were built in the foundry and transported to the furnaces, and some of the cast iron was melted down again in the foundries. The bell casting achieved special importance .

Early modern age

The first cannons of the early modern era were forged from wrought-iron sheet metal strips, but this was expensive. After that, bronze casting gained in importance. The bronze cannons were first made in full cast and then drilled, later they were cast over a core and the existing hole was only drilled out, which saved casting mass and machining time. Shortly before industrialization, cast iron cannons were also cast over a core and then drilled out.

Baroque

Industrial age

During industrialization, cast iron became an important construction material . Sometimes entire bridges were made from it. Towards the end of the 19th century, new cast materials were discovered with aluminum and magnesium . As early as 1900 series parts for the automotive industry were cast from aluminum, but larger applications did not appear until the middle of the 20th century.

In the 1970s, the development of modern FEM simulation made it possible to simulate and optimize the casting process .

Competing procedures

Many manufacturing processes can be used alternatively. Casting competes primarily with forming ( forging ) and machining (turning, drilling, milling, grinding). However, these require raw material in solid form, which was usually produced by casting. Very complex shapes can also be produced during casting and it is suitable for large series. Small and medium-sized workpieces are more likely to be forged or machined.

Materials with a very high melting point are often manufactured using powder metallurgy . Instead of a melt, metal powder is used. 3D printing is an alternative for individual pieces .

Economical meaning

The casting of complex workpieces has the advantage over other production methods that it only involves relatively few process steps and reduces the material consumption that B. arises when milling. Even with weight-optimized component geometry, as is required in aircraft construction or in medical technology for titanium casting, casting is becoming increasingly important compared to machining. The share of the production of the foundries in the total production of the manufacturing industry in Germany makes up only about one percent, but there are numerous industries that the foundries need as suppliers. The main customers are the vehicle industry (with a strong upward trend in the last few decades) and mechanical engineering with over 50%. In contrast, the demand of the coal and steel industry for cast parts fell sharply.

The number of employees in Germany was 78,000 in 2011, working in around 500 foundries. The production volume is given in the foundry as the total mass of the workpieces. In 2011 it was 5.8 million tons for Germany. The worldwide annual production of castings in 2013 was over 100 million tons. In 2013, China was the most important producer with 42.5 million tons, followed by the USA (12.8 million tons) and India (9.3 million tons). This is followed by Japan, Germany and Russia with 5.3 to 4.3 million tons.

- Development prospects

The German vehicle manufacturers alone get around 3 million tons from the production of the German foundries. This shows that the industry is likely to be severely affected by the implementation of electromobility , which will lead to the elimination of heavy mechanical components (engine, transmission, etc.). The focus of automobile production is also shifting to Asia. Another important trend is the development of lightweight cast parts. The hand-molded casting of large individual pieces and small series has largely been discontinued in Germany for reasons of efficiency, which means that large, hand-cast individual pieces now often have to be obtained from abroad (e.g. Brazil).

Achievable accuracies and productivity

The accuracies that can be achieved are generally low. The ISO tolerances are between IT16 to IT11 (small ones are more precise), with special measures also IT10. The accuracies in forging are comparable ( precision forging up to IT8) in machining significantly better with IT7 to IT6, which is why cast parts are often reworked. Further developments in foundry technology try to keep this rework as low as possible. As with forging, the surface roughness is relatively poor, with mean roughness depths of 63 µm to 1000 µm; for machining, it is between 10 µm and 0.25 µm.

The series casting processes like die casting are very productive. In contrast, vacuum casting is a process for precision casting of individual pieces, small batches or prototypes made of plastic.

Energy balance and material utilization

The material utilization is very good in casting as well as in forging. Only about 10% of the material is lost; during machining, sometimes over half of the raw part is removed in the form of chips. Despite the large amounts of energy required for melting, casting, like forging, is therefore very energy-efficient if the entire process chain to the finished component is considered, while machining requires around three times the energy.

Workpiece range and areas of application

A wide range of workpieces can be produced with casting. Some small parts weigh only a few grams, the largest over 200 tons. The variety of shapes that can be produced is hardly limited, especially free-form surfaces, i.e. three-dimensional curved surfaces are possible. Important products are bells (made by bell casting ), implants and prostheses , bronze statues (made by bronze casting ) and other artificial castings , housings for pumps, gears and electric motors, impellers , ship propellers and turbine blades for the aerospace industry made of titanium or nickel. For the foundry's most important customer industry, the automotive industry, car rims , engine blocks , crankshafts , cylinder heads , exhaust manifolds and many other parts are manufactured, often by sand casting (with cast iron) or die casting (with aluminum).

Part of a turbocharger .

Auto part made of aluminum ( strut support )

Material spectrum - cast materials and castability

Materials that are used in the foundry are referred to as cast material or cast alloy, their suitability for casting as castability .

By far the most important cast material with a share of 75% is cast iron , an iron alloy with at least 2% carbon (mostly around 4.3%). At 1200 ° C, it has a significantly lower melting point than steel (1500 ° C), which contains less than 2% carbon. In addition, cast iron is very easy to cast: The melt is very thin and has good mold filling properties. The shrinkage and shrinkage on cooling and solidification are low. In addition, cast iron has very good performance properties, including wear resistance and vibration damping. Most types of cast iron still contain around 2% silicon, which improves castability. Cast iron is preferably cast in sand molds ( sand casting ).

The second most important cast material, measured as the mass fraction of total production in foundries, is cast aluminum , an aluminum alloy that still contains silicon, magnesium or copper. They melt at around 570 ° C and are also very easy to cast. Cast aluminum alloys can also be used for filigree components whose shapes would not be completely filled by other materials. Aluminum alloys are preferred for die casting .

Cast steel and the various copper alloys ( brass , bronze , gunmetal ) still have single-digit percentages . Medical implants, but also aircraft parts are partly cast from titanium , but the cast titanium part runs under "Other" in the foundry statistics and on the other hand only about 2% of the titanium is processed by casting because it has a very high melting point and its melt tends to absorb oxygen which leads to embrittlement in the solid state.

Casting process

There are numerous different casting processes that can be classified according to several criteria.

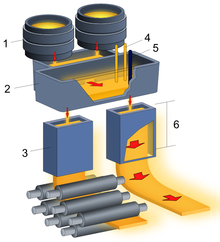

Pouring into molds, which largely correspond to the shape of the finished part, the molding , which is used most often. There is also the casting of bars or slabs , ingot casting and the casting of continuous, theoretically endless strands, the continuous casting .

Depending on the type of mold filling, a distinction is made between gravity casting , the standard process in which the melt falls into the mold through the action of gravity, as well as centrifugal casting with centrifugal forces (for rotationally symmetrical parts) and pressure casting , in which the melt is pushed into the mold by piston pressure is pressed.

A particularly important division distinguishes between processes with molds that are only used once and are destroyed when the cast pieces are removed ( lost mold ) and permanent molds that are used multiple times:

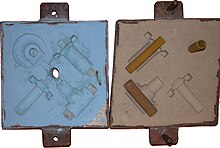

- Casting with lost forms. Models are used to manufacture the molds. A further distinction is made as to whether the models can be used once ( lost model ) or multiple times ( permanent model ) .

- Casting with lost molds and permanent models: It is also known as sand casting because the molds are made from sand. Depending on the type of mold production, it is suitable for individual parts and series pieces as well as any workpiece dimensions and is therefore of great economic importance. Numerous vehicle components are manufactured in this way. Since sand is very temperature-resistant, it is mainly used for pouring cast iron and cast steel.

- Casting with lost molds and lost models: These include the lost wax process ( investment casting ) and full mold casting . With investment casting, the models are made of wax and covered with clay or ceramic. Then the wax is melted out and the mold is filled with melt. It is only suitable for smaller quantities and small workpiece dimensions, but achieves high quality. With full mold casting, the molds are made of Styrofoam , surrounded with any molding material and then, without removing the models, poured melt over them, which burns the models. It is suitable for small quantities and also very large castings.

- Casting with permanent molds. They are mostly made of steel. When they come into contact with the melt, they wear out, which means that the workpieces have a poorer surface quality and shape accuracy than lost shapes. In the case of low-melting materials such as aluminum, they can be poured very often, but less often in the case of high-melting materials such as copper. Since the permanent forms are very expensive, the number of pieces has a strong effect on the unit price.

- Chill casting : gravity casting with permanent molds

- Die casting : Here the melt is pressed into the mold by means of a piston. The time to fill the mold is reduced, which is why it is well suited for large series of small workpieces. It is particularly often used to cast aluminum, die-cast aluminum .

- Centrifugal casting

- Continuous casting

- Low pressure casting : Here, the air pressure around the melt is increased in order to force it into a riser pipe that leads to the mold.

There are also a number of special processes such as Thixocasting , Vacuralgießen and squeeze casting .

Process chain in casting

The process chain in casting consists of

- the preparation with the production of the molds and the melting of the materials,

- the casting, which includes the filling of the mold and the solidification of the melt, as well as

- post-treatment: demoulding, plastering and heat treatment.

preparation

To prepare for the actual casting process, the casting, the molds are built for which models are made beforehand. In order to be able to produce cavities in the workpieces, cores are produced and placed in the molds. The melt is prepared in parallel to these tasks.

Modelling

The wax models for investment casting are either carved manually from a wax model or made by casting using a master model. With full mold casting, the styrofoam models are cut from blocks and sometimes also assembled from individual parts and glued. Permanent models for sand casting can be made of wood, ceramic or metal, which can be used differently. Cheap wooden models can sometimes only be used five times, metal models significantly more often.

Mold making and preparation of molding materials

Permanent forms are forged or milled from steel and can cost several 100,000 euros. Lost forms are made of molding material , mostly sand is used, which is held together with small amounts of clay and water. The shapes can be milled out of solidified sand ( direct molding material milling ). Some of them are made by 3D printing. Usually, however, models are used for mold construction, over which the molding material is placed. The still loose molding material then has to be solidified, for which numerous different processes can be used. This includes simple shaking and pressing, which is used in series production because it can be automated ( machine molds ). When molding a mask , a relatively thin layer of molding material is placed over the model and saturated with resins. These harden in the oven.

The molds not only have to contain the shape of the workpieces to be manufactured, but also further openings for feeding in the melt. The cavity into which the melt is poured is called the gate . After the mold has been filled, the volume of the liquid, cooling melt decreases, which is why more material has to flow into the mold. A single gate is often not enough, which is why so-called feeders are added, which are removed again with the gate after solidification. In the simplest case, the gate consists of an opening directly above the cavity for the workpiece. Better workpiece quality can be achieved if the melt falls on the floor in a separate shaft and flows into the workpiece from the side. There are numerous variants for the shape, size and number of feeders and gates, as they have a great influence on the component quality.

Core production and core molding material preparation

Cores are necessary to be able to manufacture cast parts with cavities. The cores are placed in the molds and removed after they have solidified. In the case of permanent molds, the cores are usually also made of metal, in sand molds of sand. They are also destroyed after pouring. Cores are also required for undercuts .

Melt preparation

The preparation of the melt includes the composition of the raw materials, the melting in furnaces and the treatment of the melt.

Metals can be used as raw materials directly by the smelting works, but larger amounts of scrap are processed in the foundry . The industry is characterized by a high recycling rate. Some of the scrap is produced in the foundry itself; this includes defective castings as well as the removed feeder and gate systems that function as cycle material. Old scrap from used and shredded components is also processed.

In order to obtain an alloy with the desired composition, different raw materials have to be mixed. This mixture is called charge make designated. Special software can be used to calculate which quantities are required in which proportions for the cheapest charge.

Various industrial furnaces are used to melt the metals . The cupola furnace , the electric arc furnace and the induction furnace are of particular importance . They are differently suitable for different materials. Cupolas are used for ferrous materials, arc furnaces for steel and non-ferrous metals, but both are only used for melting. Induction furnaces and resistance furnaces are also suitable for keeping the melt warm. About 60 to 70% of a foundry's energy requirement is due to melting.

Then the melt treatment takes place . Various substances are added to the melt that prevent it from reacting with the oxygen in the air and otherwise changing unintentionally. During the inoculation of the melts , foreign substances are added that affect the solidification and thus the hardness and strength of the finished casting.

Most of the time, the metals are melted in the foundry, sometimes in the steelworks or smelting works and then transported to the foundry by liquid metal transport .

Cast

The process of pouring the melt into the mold is called casting. Thereafter and in some cases parallel to this, the melt solidifies. These processes have a decisive influence on the quality of the cast parts. The melt can be poured into the mold directly from the furnace, but it can also be poured into ladles or ladles and only then into the molds.

Mold filling

The melt can be poured directly into the molds, which is mainly done with molds that are open at the top. Potting in a special pouring system is common . The melt can fall into the mold from above or flow into it from the side or from below. Falling melts lead to eddies and turbulent flows. The melt mixes with air and absorbs unwanted gases that later remain as pores in the casting. The forms are filled relatively quickly. With increasing mold filling, there is little or no turbulence, which leads to laminar flows. The castings then contain only a few pores. Both variants are combined with tilt casting .

The melt cools when it comes into contact with the mold. The solidification should only begin when the mold is completely filled, otherwise there may be defects. Some melts become viscous when they cool, which favors imperfections. The corresponding casting property is the mold filling capacity . Some molds are heated to keep the melt warm longer, or molds with low thermal conductivity are used. However, this prolongs the subsequent solidification. Other forms, especially permanent forms, are cooled in order to speed up the process and reduce the temperature load.

Cooling and solidification of the melt

At the latest after the mold has been completely filled, the melt cools and reduces its volume, which is known as (liquid) shrinkage . Melt must flow in from the gate and the risers until it solidifies. Volume changes also occur during solidification due to shrinkage . This can no longer be compensated by feeders. The volume then continues to decrease until the casting has reached room temperature (solid body shrinkage).

The exact course of solidification and subsequent cooling has a decisive influence on the microstructure and thus on the hardness and strength of the cast parts. Various substances are dissolved in the melt. Since the solubility decreases on cooling, these substances are excreted. In the case of cast iron, for example, graphite (carbon) is precipitated. The types of cast iron are classified according to the (microscopic) form of graphite: cast iron with lamellar graphite , cast iron with vermicular graphite (worm graphite ) and cast iron with spheroidal graphite , which differ in their hardness and strength. Dissolved gases can also be separated from the melt. If they cannot escape from the mold, they remain as pores or cavities . The cooling rate also has an influence on the hardness and strength of the cast parts. With slow cooling, for example, the easy-to-work gray cast iron is created, with faster chill casting .

Aftercare

Post-treatment includes demolding, in which the castings are removed from the molds. This can be done after they have cooled to room temperature or right after they have solidified. In series production in particular, the castings are removed from the molds as early as possible, because on the one hand further shrinkage is not hindered by the mold and on the other hand the molds are quickly available again for re-casting. With permanent molds , the cast pieces are removed with ejectors, with lost molds the mold is destroyed.

Further post-treatment mainly includes cleaning and sometimes heat treatment.

Cleaning

The fettling involves separating the gate and Speißern, removing seeds, Ent -temperature oxidation (scorch), sand removal (removal of molding material residues), repair of casting defects and the cleaning of the surface. Machining allowances are sometimes also removed. The cleaning work accounts for a large part of the total costs in the foundry, since it can only be partially automated. A plaster-friendly construction of the casting is therefore decisive for the unit costs .

Heat treatment

The heat treatment is intended to improve the mechanical properties of the casting. In malleable cast iron (a type of cast iron) it is a fixed component ( tempering is a form of heat treatment). Also cast steel is usually annealed because the cast structure is very coarse. With other materials, the heat treatment can also be omitted.

Casting process simulation

The casting process simulation uses numerical methods to predict the entire casting process, including mold filling, solidification and cooling of cast parts, and also allows the quantitative prediction of mechanical properties, thermal stresses and warpage of the cast parts. By means of simulation, the quality of a cast part can be precisely described before production begins, and the casting technology can be tailored to the desired part properties. This not only eliminates expensive test casts in development. The precise design of the entire casting system also saves energy, material and tool costs.

Software for the simulation of casting processes supports the user from the design of the component, the definition of the melting practice and casting technology, through model construction and mold production to heat treatment and post-processing. This means that costs can be consistently saved along the entire production chain.

The casting process simulation was first developed at universities, especially in Europe and the USA, since the 1970s and is considered to be the most important innovation in foundry technology of the last 50 years. Commercial programs have been available since the late 1980s that give foundries the first insight into casting technology that was previously a black box. However, optimizing the geometry of the casting mold and determining the correct casting configuration (material, temperature, duration of casting, etc.) are relatively complex processes for which exact mathematical models are not always available. Therefore, the use of experimental methods is still necessary for the development of simulation methods.

education

The place of work is called the foundry, the worker is called the foundry . The official job titles are:

- Foundry mechanic (apprenticeship period 3.5 years) specializing in hand molding , die casting, permanent mold and machine molding.

- Metal and bell caster (training period 3 years) specializing in art, bell, metal and tin casting technology

Despite the mechanical aids, relatively high physical demands are placed on the foundrymen and their helpers.

Foundry technology has been an apprenticeship in Austria since July 1, 2010. This replaces the previous apprenticeships foundry mechanic, former and foundryman. The apprenticeship foundry technology distinguishes iron and steel casting from non-ferrous metal casting. Both training courses have a dual training duration of four years. Foundry technicians with a focus on iron and steel casting work in companies in the foundry trade and the iron, steel and mechanical engineering industries. They make castings from iron and steel. Foundry technicians with a focus on non-ferrous metal casting work in companies in the foundry trade and in the light metal, non-ferrous metal foundry and mechanical engineering industries. They make castings made of non-ferrous metals and alloys, such as B. aluminum, brass, bronze, copper.

See also

- Foundry (magazine)

- Konstruieren + Gießen - trade journal

Web links

- Video documentation of the casting process of gray cast iron (GJL), nodular cast iron (GJS) and Ni-Resist

- “Constructing and casting” - technical online portal of the Federal Association of the German Foundry Industry

- Federation of the German Foundry Industry

- Association of German Foundry Experts

- Association of the foundry industry of the Austrian Chamber of Commerce

- Professional and industry information foundry technology - iron and steel casting from the Austrian Chamber of Commerce

- Professional and industry information foundry technology - non-ferrous metal casting from the Austrian Chamber of Commerce

literature

- Andreas Bühring-Polaczek , Walter Michaeli , Günter Spur (eds.): Handbuch Urformen, Edition Handbuch der Fertigungstechnik , Hanser, Munich 2014, ISBN 978-3-446-42035-9 .

- Paul Schimpke : Technology of machine building materials. 17th edition. Hirzel, Stuttgart 1968, DNB 458836591 .

- Karl Stölzel: Foundry for thousands of years . German publishing house for basic industry, Leipzig 1978, DNB 800185536 .

- Günter Spur, Theodor Stöferle : Handbook of manufacturing technology . Volume 1: Archetypes . Hanser, Munich / Vienna 1981, ISBN 3-446-12532-9 .

- A. Herbert Fritz, Günter Schulze : Manufacturing technology . Springer, Berlin / Heidelberg 2012, ISBN 978-3-642-29786-1 .

- Rolf Roller (Hrsg.): Expertise for foundry-related professions, technology of molding and casting . 5th, revised. and extended edition. Verlag Europa-Lehrmittel Nourney, Vollmer Haan-Gruiten 2007, ISBN 978-3-8085-1795-6 .

Individual evidence

- ↑ Günter Spur: On the change in the industrial world through machine tools. Carl Hanser Verlag, Munich, Vienna 1991, pp. 38, 42, 44 f.

-

↑

- Günter Spur: About the change in the industrial world through machine tools. Carl Hanser Verlag, Munich, Vienna 1991, p. 51.

- Wolfgang König (Ed.): Propylaea History of Technology - Volume 3. Propylaea, Berlin 1997, p. 104 f.

- ^ Johann Mehrtens: The foundry shaft furnace in the construction and operation. Berlin 1942, p. 4. Digital Archive Springer Books, see Google Books .

- ^ Fritz Klocke: Manufacturing process 5 - casting, powder metallurgy, additive manufacturing , 4th edition, Springer, 2015, p. 5 f.

- ^ Alfred Herbert Fritz, Günter Schulze: Manufacturing technology. 11th edition. Springer, 2015, pp. 2, 8.

- ↑ Andreas Bühring-Polaczek, Walter Michaeli, Günter Spur (ed.): Handbuch Urformen , Hanser, 2014, p. V, 7.

- ↑ Heiko Lickfett: Economic importance of the foundry industry , in: Andreas Bühring-Polaczek, Walter Michaeli, Günter Spur (ed.): Handbuch Urformen , Hanser, 2014, p.

- ↑ The worldwide foundry industry. (PDF; 709 KB) In: get-in-form.de. Hüttenes-Albertus Chemische Werke GmbH, accessed on February 7, 2017 .

- ^ Alfred Herbert Fritz, Günter Schulze: Manufacturing technology. 11th edition. Springer, 2015, p. 4

- ^ Alfred Herbert Fritz, Günter Schulze: Manufacturing technology. 11th edition. Springer, 2015, p. 5.

- ↑ Andreal Bühring Polaczek: Technological and economic importance in: Andreas Bühring-Polaczek, Walter Michaeli, Günter Spur (ed.): Handbuch Urformen , Hanser, 2014, pp. 7–9, 85, 91, 96, 101, 216, 224 .

- ↑ Fritz Klocke: Manufacturing process 5 - casting, powder metallurgy, additive manufacturing , 4th edition, Springer, 2015, pp. 6 f, 9 f.

- ↑ Ilschner, Singer: Material Science and Manufacturing Technology 5th Edition, Springer, 2010, p. 455.

- ↑ Fritz Klocke: Manufacturing Process 5 - Gießen, Powder Metallurgy, Additive Manufacturing , 4th Edition, Springer, 2015, p. 4.

- ^ Fritz Klocke: Manufacturing process 5 - Gießen, powder metallurgy, Additive Manufacturing , 4th edition, Springer, 2015, p. 20.

- ^ Fritz Klocke: Manufacturing process 5 - casting, powder metallurgy, additive manufacturing , 4th edition, Springer, 2015, p. 13.

- ^ Böge: Handbuch Maschinenbau , Springer, 21st edition, p. M1 f.

- ↑ Matthias Blünkin: Andreas Bühring-Polaczek, Walter Michaeli, Günter Spur (eds.): Handbook archetypes , Hanser, 2014, pp 252, 272.

- ↑ Hartmut Polzin: Rapit prototyping with molding materials in: Andreas Bühring-Polaczek, Walter Michaeli, Günter Spur (eds.): Handbuch Urformen , Hanser, 2014, p. 237.

- ^ Böge: Handbuch Maschinenbau , Springer, 21st edition, p. M3f.

- ↑ in: Andreas Bühring-Polaczek, Walter Michaeli, Günter Spur (Ed.): Handbuch Urformen , Hanser, 2014, p. 112.

- ^ Fritz Klocke: Manufacturing Process 5 - Gießen, Powder Metallurgy, Additive Manufacturing , 4th Edition, Springer, 2015, p. 15.

- ↑ Veronika Groten: Technology of melting and casting in: Andreal Bühring Polaczek: Technological and economic importance in: Andreas Bühring-Polaczek, Walter Michaeli, Günter Spur (ed.): Handbuch Urformen , Hanser, 2014, p. 112.

- ↑ Eike Wüller, Bin Lao, Benjamin Schelnberger: Melt treatment in: Andreal Bühring Polaczek: Technological and economic importance in: Andreas Bühring-Polaczek, Walter Michaeli, Günter Spur (ed.): Handbuch Urformen , Hanser, 2014, p. 21.

- ^ Fritz Klocke: Manufacturing Process 5 - Gießen, Powder Metallurgy, Additive Manufacturing , 4th Edition, Springer, 2015, p. 2.

- ↑ Roland Kahn: Melt transport and pouring equipment and dosing technology both in: Andreal Bühring Polaczek: Technological and economic importance in: Andreas Bühring-Polaczek, Walter Michaeli, Günter Spur (ed.): Handbuch Urformen , Hanser, 2014, pp. 171, 175.

- ↑ Veronika Groten: Technology of melting and casting in: Andreal Bühring Polaczek: Technological and economic importance in: Andreas Bühring-Polaczek, Walter Michaeli, Günter Spur (ed.): Handbuch Urformen , Hanser, 2014, p. 13.

- ^ Alfred Herbert Fritz, Günter Schulze: Manufacturing technology. 11th edition. Springer, 2015, p. 18 f.

- ^ Alfred Herbert Fritz, Günter Schulze: Manufacturing technology. 11th edition. Springer, 2015, p. 15.

- ↑ Rüdiger Bähr, Stefan Scharf: Casting aftertreatment and completion of the cast parts for Versnad in: Andreas Bühring-Polaczek, Walter Michaeli, Günter Spur (ed.): Handbuch Urformen , Hanser, 2014, p. 348.

- ↑ Andreas Bühring-Polaczek, Walter Michaeli, Günter Spur (ed.): Handbuch Urformen , Hanser, 2014, p. 358.

- ↑ Federal Employment Agency, job descriptions at BERUFENET

- ↑ Job and branch information: Foundry technology - iron and steel casting on the website of the Austrian Chamber of Commerce.

- ^ Job and industry information: Foundry technology - non-ferrous metal casting on the website of the Austrian Chamber of Commerce.