Composite bow

As composite bow (of lat . Compositio , "composition", "composition") are all hunting, war or sports arc referred consisting of several (at least two) different types of materials are composed, thereby efficiency and durability of the sheet can be increased. For this purpose, other materials are glued onto the core, which is mostly made of wood, such as horn, bone, metal, sinews or other types of wood that are resistant to tension.

Material construction

Under the umbrella term composite arches, a distinction is made between two types of arches that are assembled:

1. The horn bow consists only of horn and a glued-on tendon covering , a kind of natural fiber composite material made from animal tendons. Some Indian bows were made this way.

If several thin layers of horn are glued on top of each other and provided with a tendon coating, it is called a layered horn arch (or horny layer arch). These were only used for medieval crossbow weapons (see cross-sections on the right). The layered construction is too cumbersome for hand bows. Such crossbow bows could instead consist of toothed and glued horn rods with a sinew coating. If a horn bow consists exclusively of horn, it is referred to as a pure horn bow (horn selfbow). However, this type of construction is rare.

2. The actual composite bow is mostly as manual arc of archers used: it contains sinew and horn also a bamboo or wood core to mass to save ( sandwich construction ). With these bows, horn strips are glued to a wooden core, which is then glued with a tendon covering on the tension side (see cross section below). To save weight, the ends of the bows are usually made of wood.

The high price has a disadvantage - a copy can require the Achilles tendons of around 50 cattle . Since the production of a composite bow is much more complex than that of a horn bow, the costs are much higher. The construction cannot be used in very damp weather .

In the English-speaking world, the two terms horn bow and composite bow are synonymous.

The bone arch is a special form of the composite arch : it is an arch made of pieces of antler ( caribou , elk ) or ribs ( whale , bison ) and a tendon covering. Usually this had no wooden core, but the cancellous bone of the antlers / bones served to save weight.

A distinction is made between composite arches and lamellar arches that consist of several layers of the same material, e.g. B. several woods. The Japanese Yumi bow, on the other hand, is a composite bow, as it is made of different materials (wood and bamboo).

Those with fiberglass or carbon fiber reinforcement are also not referred to as composite arches in the traditional sense . These are called custom bows if they look like traditional bow shapes, otherwise fiberglass bows .

Designs

Deflex bow

A deflection bow remains D-shaped even when the bowstring is relaxed. This construction was only used for composite bows for the bone bows and bows made of brittle or soft woods mentioned above, as z. B. antlers and bones are not very elastic, even if a tendon cable or tendon coating is applied. It is the simplest form of the composite bow, it is considered a technological archetype. Deflex bows have about the same range and penetration power as normal wooden bows. A lack of raw materials in the bow makers is assumed to be the reason for their construction, as is conceivable for steppes or polar regions. But these bows were already as durable as all composite bows.

Deflex composite bows were mainly known to the Eskimos and related tribes, but they also knew reflex bows with horns.

Recurve bow

With the recurve bow, the relaxed bow ends are bent forward ( recurved ), i.e. H. to the side facing away from the archer or the string. The wooden core and the horn strips are made flexible with steam , then the ends of the arches are bent over a round wooden shape. This rounding of the arch ends is finally fixed by gluing on the tendon covering. Such a recurve bow could also be made without a horn, only with an elastic wood such as yew and tendon covering, or just made of wood; in the latter case, however, it was not a composite bow.

Examples of a recurve composite bow are the Scythian bow or some Cupid bow with rounded ends depicted on Greek vases .

The bowstring first rests on the curved ends of the bow, only when the bow is pulled does it gradually lift off the curve. As a result, the bow stores more energy at the beginning of the draw because the bowstring makes it behave as if it were shorter. As you continue to pull, the bowstring lifts more and more from the recurves , the bow becomes longer and longer as you pull it out, making it easier to pull ( longer lever , see graphic). During the shot, the opposite happens: the arrow still receives the energy supply that the recurves had stored at the beginning of the draw; This increases the arrow speed and range noticeably. But not the accuracy: if the arrow is loosened improperly, the recurves can vibrate during the shot and the accuracy decreases. Recurves require a very clean dart release.

Arch with end stiffeners

For an arch with end stiffeners (Arabic: Siyahs ), two separate wooden arch ends are glued to the wooden core at an angle. The horn strips on the back and the tendon covering on the front overlap the glue joints so that the parts do not break off. Such bows, like recurve bows, can also be made without horn, only from wood and sinews.

Examples of bows with Siyahs are the Mongol , Huns , Turks , Koreans and the Indian crab bow. The effect of the stiff ends is similar to that of the recurve: First, the bowstring rests on the angle where the stiffener is glued, usually on a special bed. When the bow is drawn, it becomes more and more strict as soon as the bowstring lifts off the angles, the knees, but the leverage of the Siyahs sets in suddenly and not gradually as in the recurve. The pull-out is felt to be pleasantly soft towards the rear, the more the longer the end stiffeners are. End stiffeners have a similar effect on arrow speed and range as the recurves described above: they make the arrows faster, but more forgiving of mistakes in loosening the arrow than these, which could be the reason why bows with Siyahs at the end of the Roman Empire interspersed with those with recurves. In addition, the bow maker saves himself the trouble of having to laboriously bend the recurves with steam: wooden parts for Siyahs in particular grow in the wild, finished recurves tend not.

The point of the extension at which the draw weight reduction begins can be set by the bow maker using the angle between the limb and the stiffener.

Reflex arc

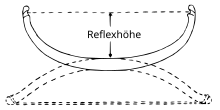

In the case of a reflex bow, the entire unstressed bow stick has an extreme counter-curvature, i.e. H. a curve towards the back of the bow (to the side that points away from the archer). This forward curvature, also known as a reflex, is then held by the glued-on tendon covering. The stripes of horn on the back, the arch belly, are indispensable in this case; Without a pressure-resistant horny layer, a reflex bow would break immediately because the elasticity of the wood would be fully exhausted by covering the bow. The opposite curvature is of course only visible when the bowstring is relaxed, the bow looks like any other when it is strung. The distance between the middle of the bow and the imaginary straight line between the tendon cams (in the case of an untensioned bow) is called the reflex height; they are given in centimeters or inches.

Pure reflex bows without end stiffeners or recurves are rare, because of the high pull weights they are mostly medieval crossbow bows . The purpose of the counter-curvature is to take full advantage of the elastic properties of the horn / tendon construction. These materials would not be challenged in a straight arch, so a non-reflective arch is usually only made of wood. The result is that such a reflex arc is very short and narrow, but has the same length as a normal arc with the same energy storage capacity. The stronger pre-tensioning reduces the dead weight of the limbs: equally strong, but shorter and narrower limbs weigh less, when the bowstring is loosened they react faster because of the lower mass inertia, the arrow speed increases, the range and penetration of the weapon increase. The efficiency of the arc can be increased up to 90% with a strong reflex (usually around 70% -80%). The bullet's trajectory is noticeably flatter, which also makes aiming easier.

A no less remarkable advantage of the reflex is this: If the bow is strained, it bends into the typically reflex C-shape. Since part of this C-curvature was created when the freshly glued-on tendon covering was drying (dry tension), it lengthened the horn belly on the opposite side of the bow. During the production of the bow, the horn belly came under tension, which then remained frozen in the finished, dried bow. If the reflex arc is now stretched after days or weeks of use and it has lost its strength due to the long period of stringing and the permanent pressure on the horn, it bends back into a C-shape, which immediately puts the horn belly under tension, which has been weakened by pressure. It is precisely the dry tension of the tendon covering that was built up during production in the bow; now she pulls the horn again, over and over again, hundreds of times, every time the reflex arc is released. As a result of this pulling apart, the horny layer quickly regenerates to its old shape, which gives the arch its old elasticity in a short time. This also explains the long lifespan of reflex composite bows, which can sometimes be centuries, especially with Asian and Islamic reflex bows.

Overall, most composite / horn bows are medium to strong reflex, as the bow maker deliberately brings them into this shape. A very slight reflex of a few centimeters reflex height can of course also occur with non-composite bows if the piece of wood has grown into this shape by itself. It can be assumed that the advantages of the reflex design were first discovered as a light natural reflex in simple wooden arches and then later deliberately artificially incorporated into composite arches. When used as a hand bows, almost all reflex bows have recurves or end stiffeners due to the high tension to make it easier to pull out. All bows of Asian origin with stiffeners are reflex bows.

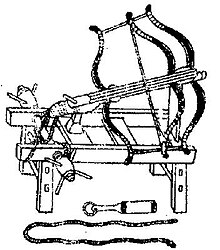

As a typical example of a reflective composite bow with end stiffeners, the Huns bow shown on the right , which was in use between 200 and 500 AD , is explained . Due to the strong reflex, it has the shape of the character "{" without a bowstring. This bow has a wooden core over its entire length, which consists of five parts, namely a handle in the middle with the two flexible limbs glued to it at an angle. The two stiff limb ends (Siyahs), which hold the bowstring, are also glued to the limbs .

On the inside of the arms you can see the two black stripes of horn that are glued to the wooden core. The outside of the weapon is covered with several layers of tendon fibers along its entire length. That is, dry animal tendons were frayed and glued to the wooden core with warm hide glue like fiberglass (see production of tendon coverings ). The white on the sides of the Siyahs and the handle are bone plates, which are glued to the sides of the wooden core to stiffen these areas. Since the bowstring does not lie at the angles of the limb-siyah connections, the pull weight reduction of the siyahs starts from the beginning and is evenly distributed over the extension length, which the bow maker probably intended.

The wood core itself is nowhere to be seen, as it was covered with horn, tendons or bone everywhere.

The four angled connection points, the knees, are also tightly wrapped with tendon fibers or silk soaked in glue, because this is where the connection points of the wood, horn and bone parts are.

The lower limb is intentionally a bit shorter in order to be able to shoot better with the device from the horse's back (rider's bow).

raw materials

Tendon covering: The raw materials for the tendon covering of composite bows are already described in the article of the same name, tendon covering , see there.

Horn: There is no shortage of horn that can be used for composite bows in the animal kingdom; throughout Asia, the preferred material has been the horn of the water buffalo for millennia . In addition, yak and ibex horns (with the Mongols ) are also used. In the Middle Ages, the Japanese occasionally used whalebones for short bows.

Ibex horn was also used in Europe; it is mentioned e.g. B. in the production of a composite bow by the Greek Pandaros in the Iliad . A ram's horn was also used here , perhaps also from the billy goat. Long cattle horns could also be used, but they are more delicate to work with as they tend to delaminate (layer separation). The Magyars (Hungarians) knew a special breed of cattle with gray horn, which is said to be more reliable. The ancient Egyptians could neither use ram nor cattle horn, both animals were considered sacred to them; instead they used horns from the oryx and other antelopes . In the Islamic culture, however, as in Asia, water buffalo horn was used. The Muslims had copied Asian arch designs. The American Indians preferred horn from mountain sheep, also ram horn (bison horns are too short), sometimes the Eskimos used horn from musk ox . Technically, water buffalo horn is still preferable to the best for composite bows and other types of horn.

Horn from rare albino water buffalo was processed by the Chinese, Tibetans and Koreans into particularly valuable bows with a transparent horn belly so that the core of the bow could be seen through the horn. Before the bow maker glued these transparent stripes of horn onto the wooden core, he painted the wooden surface with colorful characters, hunting scenes and mythical figures. Once the strips were glued on, one could see the colorful pictures enlarged through the convex, polished horn as if through a reading stone . Such master bows were a worthy gift for emperors and kings.

Wood: Almost every people had their own preference for wood, which was used for bow cores and bow ends. The Turks almost exclusively used maple , rarely yew or cornel cherry for the handle section. The Mongols now make the flexible part of the limb out of bamboo, the ends of the bow and the handle out of birch . Most of the Siberian peoples also used birch. The Koreans today make their bow cores from bamboo, with handles and bow ends from mulberry tree . With the ancient Egyptians and Assyrians, the arch cores were often made of imported elm or ash.

Glue: Isinglass from swim bladders was preferred, especially from sturgeon , tendon glue from animal tendons and hide glue . Casein glue was rarely used. In some of the composite bows that have been preserved, substances with a tanning effect such as white lead or tannin have been detected in the glue, probably to reduce the sensitivity to moisture.

Cover material: Finished horn and composite bows were usually pasted over with a layer to protect against moisture, often only the tendon covering, whereby the horn remained visible. The most popular material to this day and at all times the most widely used material for this in all regions is birch bark. In composite arches found in Egyptian graves around 1400 BC. BC the birch bark strips were glued across the arch so that they covered the horn, no doubt to keep the construction a secret. In later Asian reflex arcs, paper-thin strips of birch bark were typically glued diagonally, more rarely lengthways, over the tendon covering. The horn remained visible.

Medieval crossbow bows were usually completely sewn into a piece of leather , sometimes wrapped in a spiral with a long strip of it. In the case of Turkish bows, the tendon covering was pasted over with a continuous strip of thin rawhide ( parchment ) or with thin tanned leather, more rarely with birch bark. The horn belly remained free.

American Indians sometimes wrapped composite bows spirally with the thin bark of the young cherry tree .

Manufacturing

The assembly of the individual components usually went like this: First, the bow maker made the wooden cores for the bows he wanted to build by sawing , planing and rasping . If the arches were strongly curved (e.g. Scythian arches), the wooden boards were bent into the appropriate shape using hot steam. In Asian reflex bows, the wooden cores were composed of several parts, usually five. They were glued together with dovetail grooves .

Then the Bogner sawed off the horn strips, the outer curves of the animal horns . They were then glued onto the bow in such a way that the horn tips of both horns met in the handle of the bow. If the strips were to get a special shape, this could be made by boiling and then bending. Then the horn strips had to be thoroughly degreased. The Turks and Arabs put the horn strips in naphtha , a kind of gasoline, for several weeks .

Once the wooden cores were ready and the horn parts degreased, assembly could begin: in order to be able to glue the horn strips onto the wooden core, the closest possible fit had to be achieved between them. There was also a special scraper holder . It resembled a wooden bicycle handlebar with a sharp, replaceable scraper attached in the middle. Horn strips and wood core were then clamped in a vice or the like, and the scraper holder was drawn with both hands like a pulling knife with the scraper lengthways over the surfaces to be glued until they fit together smoothly. If the horn strip was to be glued flat to the wood, a flat blade was first used to smooth the horn strip. The wood core has also been smoothed. If the horn strip should have a crescent-shaped cross-section, a round scraper was used for it, but a bay-shaped blade that exactly matches the former was used for the surface of the wooden core.

If the cores and strips were now smoothed and matched, the longitudinal grooves had to be cut into them: To do this, other scraper blades were clamped into the above-mentioned tool, which had sharp teeth approx. 1.5 mm long and 2 mm wide. For a flat fit, a flat blade with teeth was used, for a crescent-shaped fit again a round one for the horn and a curved one for the wood, both provided with teeth, whereby the teeth of the bay and the curve had to fit exactly into one another when held against one another. With the blade holder, these blades were drawn lengthways over the surfaces to be glued, creating very precisely fitting grooves. The purpose of these was to enlarge the surface to be glued: the glue cannot penetrate the horn well because it is not very porous . The surface, which is enlarged by longitudinal grooves, helps the adhesive force of the glue.

When the wood and horn surfaces were finished and perfectly fitting, they were briefly degreased again (fingerprints) and then immediately impregnated with a thin glue solution so that the glue was not so absorbed into the wood later when glued. The parts were then preheated to glue them together so that the hide / isinglass did not gel as quickly and the Bogner had more time to work. The warm wooden cores and horn strips were now generously coated with rather thick glue and immediately pressed together. Then another tool was used: a wooden lever about a cubit length, at the lower end of which a wooden block with a guide groove or a hole was formed. A thin rope of great length was tied to the preheated arch, then pulled through the guide groove on the wooden lever and fastened with a couple of turns up the lever, from where the rest of the rope hung to the ground. The lower end of the wooden lever was now pressed onto the clamped bow and moved around it in such a way that the rope wrapped itself tightly around the wooden core and horn strips. The lever itself pulled the rope with much more tension than would have been possible with bare hands. So the whole horn strip to be glued was wrapped with rope and fixed. By wrapping the parts to be glued with a rope, the wood and horn strips were pressed together with such great force that the excess glue oozed out of the joints and pressed out all the enclosed air bubbles. The last inaccuracies in the wood-horn fit were also eliminated by the high contact pressure. A wafer-thin, highly resilient adhesive joint was created between the wooden core and the horn belly of the composite bow.

Wrapped in rope in this way, the sheets were briefly heated again so that the glue in the glue joint could liquefy one last time. Then they were dried for a few weeks.

When the cores covered with horn were completely dry, the press rope was removed. They were cleaned of glue residue, then the outer surface of the horn belly was smoothed, again with the scraper holder, depending on the desired profile, flat, convex, pyramidal, etc. In the middle of the handle of the bow, where the horn tips met, there was now a gap in the horn belly of the bow. In order to close this, it was sawn a few millimeters into the wood core in such a way that the saw gap widened slightly inwards. The sawn-in material was then carved out. A small, precisely fitting wedge made of bone or ivory was hammered into the gap with glue from the side into this gap, which tapered slightly towards the outside. So the horn strips in the middle of the handle met this transversely inserted plate, which the Turks called Chelik. Other peoples also used wood for this, some also have several such wedges made of horn and bone next to each other, e.g. B. the Chinese. This was superfluous if a single, very long strip of horn that went right through from one end of the arch to the other had been used from the start.

Next, the other side, the wooden arch back, was brought into the right shape with rasps, files and the pulling tool described above. The finished wood surface was roughened a little, and then you started with the application of the tendon covering (see there for production).

The tendon covering was often built up on the wood in such a way that it ran down the sides of the bow a bit to a few millimeters on the horn of the bow belly. The tension created during the drying of the glue and the tendon fibers was used in a clever way: after drying, the radial dry tension of the tendon covering held the horn strip in place, so that it could not be blasted off the wood, as the covering overlapped the glue joint between wood and horn , while the tangential dry tension of the covering caused the reflex and put the horn stripe under tensile stress. The bogner also took care to thin out the tendon coating towards the ends of the bows; it should be thickest in the bending parts of the limbs. In this way, mass could be saved towards the ends of the bow, which later did not have to be accelerated with each shot.

After the tendon coating was applied, a longer drying time followed, which could be several months up to two years depending on the type of bow.

Once the bow blanks were well dried, the fine work began: Now every single bow had to be milled as follows: The bogner took one of his bows and first bent it a little by hand. He looked closely at the curvature of the bow stick to find places that did not bend enough. If he found a point that was too stiff in the curve, he took a knife, a file or the like and carefully scraped some horn away from the bowels, but definitely not from the tendon coating. Then he bent the arch again to see whether the patched area was bent correctly, at the same time keeping an eye out for other areas that were too stiff, which he then also patched, etc. So the archer felt his way slowly and patiently until the arch bent correctly enough that a bowstring could be stretched. Now he no longer had to bend the bow by hand; He carefully plucked the bowstring, paying close attention to the curvature, corrected it, pulled the string again, repaired it again, and so on, until he could almost completely extend the bow. In the end, the Bogner only worked with sandpaper, at the very end of the Tillern only with the warmth of a small flame. In the end, he did not scrape the horn away, but rather warmed the horn (but by no means the tendon covering) in the area of the bow that did not bend properly, whereby the horn softened and gave way due to the heat. After this work step, which lasted several hours, the raw bow could now be fully drawn out and shot; it now flexed exactly where it should, and was stiffer where it should. Then the next sheet blank was cut.

With the medieval crossbow bows, the procedure was somewhat different up to this point, as they did not have a wooden core: Here the horn strips / plates were boiled and bent into the correct shape, grooved with scrapers and, during and after drying, initially only temporarily String tied together. Then the bogner first tillered this horn core by bending it and unwinding the cord at the too stiff places, grinding away the horn, rewinding the cord and bending the horn core again, etc. If the horn core bent correctly, the cord winding was removed and the degreased horn parts firmly glued together, the parts being held together by a new spiral wrapping, this time made from animal tendons or tendon cord soaked in glue, which then remained on the horn core. The horn core also had transverse furrows for the firm fixation of this wrapping, which were made with a rasp before wrapping. After drying, a tendon covering was glued to it lengthways (over the first wrapping), which in turn was held by a second, spiral wrapping of glue-soaked tendon fibers / cord. The individual horn parts in the crossbow bow were not allowed to move against each other when the finished bow was curved. Otherwise, small air pockets were probably less of a problem. With such pure horn tendon bows, which did not contain a wooden core, the meticulously clean degreasing of the horn was particularly important.

After that, strips of birch bark, leather, etc. could be pasted onto the bow to protect the tendon covering from water. After several days of drying time, the arch was then painted, gilded and varnished, usually not by the Bogner, but by a specialist; Paints and varnishes had to be very elastic, because the arch bent back and forth a lot.

Most composite / Hornbogen were due to the complex method of production in factories manufactured with a masters, servants, apprentices and slaves in series. The long duration of the multi-year manufacturing process was mostly due to the many drying times anyway. While the first series z. B. dried with the finished tendon coating for many months, the horn strips were glued to a second series, after which this also had to dry for a few weeks, and during the third series horn strips and wooden cores were cut, animal tendons tapped into fibers, etc.

We know from the Turks that the apprenticeship period for an apprentice bow maker was up to 10 years, whereby in the first year he was only allowed to watch at work. A lot of experience and physical understanding was and is required to be able to build a composite bow. In particular, a composite bow must be able to glue well.

In this way, composite bows were produced in large quantities and with standardized, constant quality in ancient times and the Middle Ages; The main customer was the military. Today there are still a few such traditional manufacturers (but without slaves) in Korea and China, which can produce several hundred sheets per year in series. Bow makers in Mongolia used to work that way, but these days they rarely make more than a dozen bows a year, mostly for tourists. In Europe and the USA, however, a number of bow makers have recently sprung up again to meet the growing demand from western archers.

The prices for composite bows are roughly the same as for good swords , depending on where they were made and what type of bow it is. For centuries-old bows, there is also the collector's value. A new Mongolian bow built in Mongolia costs around 1,300 euros today, a new Turkish bow built in Europe can cost up to 8,000 euros.

history

Emergence

A distinction is made between old-world and new-world composite bows (American Composite):

Images of recurve bows (with a very likely composite construction) have been on rock art in Spain since the early Neolithic . The composite bows of the old world can therefore have their origin there. Other rock carvings of arches with reflex limbs come from the early Copper Age in Europe, for example from Alta in Norway. In this case, however, it cannot be decided on the basis of the images whether it is a question of curved selfbows (under steam) or real composite bows.

The oldest example of an angular bow with strongly reflective limb ends (with a very likely composite construction) comes from Göhlitzsch, a suburb of Leuna in Saxony-Anhalt. This stone box grave from the time of the late Neolithic megalithic culture, discovered in 1750, shows an arch 1.20 m long carved on the inside of the stone sarcophagus . The author Leif Steguweit suspects that, despite the arrows, which are only approx. 50 cm long, the substitutive grave goods were actually related to the size of the arrows and that these short arrows (carved in the rock art without stone points) may have been poisoned.

The oldest archaeological evidence of composite construction (found in the ground) comes from the late Neolithic from the Pribaikalja region near Lake Baikal (antler arch). From there, the then new type of bow is said to have spread to the Bronze Age Middle East and Europe, where the further development of the composite bow then took place separately from one another. The Naram Sin stele (around 2200 BC) shows the king of Akkad with a short reflex arc, for which a composite construction is obvious. In the period that followed, typically western (e.g. Persian and Assyrian bows ) and typically Asian-Eastern forms ( Chinese and Yumi bows etc.) emerged, whereby the transitions between East Asian and West Asian construction methods were quite fluid (e.g. Mughal and Scythian Arch ).

After the advent of the crossbow in Europe and China in antiquity, the foundation stone for artillery was laid with the invention of the crossbow guns (see bow artillery ). The composite bow first came to Africa in antiquity through the ancient Egyptians , who copied it from their enemies at that time, the Assyrians, at the beginning of the Iron Age and then developed it independently; in the early Middle Ages , Islamic African peoples such as the Moors and the (now Islamic ) Egyptians and Arabs ( Saracens ), but now in typical Asian (Kipchak / Persian) design and no longer in Assyrian design, whereby foreign mercenary armies from Central Asia ( Mamelukes ) probably influenced the design.

In the rest of Africa and in Australia / New Zealand, the composite bow was never introduced or invented according to the current state of knowledge.

The origin of the New World composite bow is more difficult to define. When the European invaders attacked America, some of the indigenous people were already fighting them with simple composite bows, e.g. B. from the Eskimos . As the Native Americans claim, these bows were developed by them on their own. This is supported by the often rather idiosyncratic design of these arches and the fact that a simple form of the composite arch was also developed in the Amazon region . On the Orinoco , cables made of plant fibers were / are tied to the back of a wooden bow stick, so that they fulfill the same function as, for example, a tendon cable in the Eskimos. Another theory suggests that composite construction found in North America originated in Asia, although it may be difficult to find evidence for it.

Bow artillery

After the invention of the crossbow in Greece and China in the 3rd and 2nd centuries BC. BC, apparently, an upgrade began in both regions. The aim in both cases was to build ever larger and more powerful crossbow guns, i.e. bow artillery, with correspondingly strong bows.

In China, the development was that several, usually two or three, very strong reflex bows, but also hand bows of the infantry, were attached one behind the other to a common crossbow barrel. Small bronze pulleys were attached to the arch ends. A common, extra-long bowstring was now passed through the pulleys so that all three bows were pulling on the same bowstring. This enabled a number of composite bows to be connected in parallel, with their pull-out weights adding up on the common bowstring. Due to the very high pulling weights, larger arrows with a correspondingly greater range and penetrating power could be shot. However, the extension length of the individual sheets did not add up; every single sheet had an extract of z. B. 71 cm, the finished weapon with three bows had a maximum extension of only a little more than 71 cm, but almost three times the draw weight. As a result, an enlargement of the weapon z. B. Limits to ten sheets: the draw weight would have been almost ten times as high, but the maximum extension would not have been significantly more than 71 cm. The machine was usually mounted on a table-like carriage and was tensioned with a winch , which, strangely enough, was located on the carriage and not on the gun itself.

The smaller version with two bows was called Shoushe-Nu by the Chinese , it was portable and, after the bows had been drawn by the winch, could be taken from the mount and shot from a standing position like an ordinary crossbow (but with double the firepower). We know from pictorial representations of the Khmer that it and its mount could also be mounted and shot on the back of a war elephant. This can be seen on the Bayon Bas relief in Cambodia (picture on the right).

Chuangzi-Nu

The larger version with three arcs was called Chuangzi-Nu in Chinese . The Persians also knew this weapon, they called it Kaman-i-Gav. Such devices were used as fortress guns for walls and towers, as well as siege weapons and field artillery . These were permanently mounted on the carriage on which the winch was located, but there are also said to have been mobile guns with wheels. The appearance of such weapons has been handed down through contemporary Chinese illustrations and texts. (Note: The illustration on the right shows a Chuangzi-Nu, in which only two bows are drawn by a common string. The third bow is apparently built in to cushion the impact of the bouncing shock when it is fired. Bouncing strikes occur particularly when the projectile is in proportion is too light for the bow to perform.)

There is also an archaeological find: it is the trigger mechanism (lock) of the crossbow with a bronze casing; the functionality of the mechanism corresponds to that of ordinary Chinese hand crossbows of the Song dynasty (11th century), but the bronze case is a proud 39 cm long and weighs several kilos, which suggests a Chuangzi-Nu of 1.5 to 2 meters in length lets than on a crossbow. Modern replicas with simple wooden arches are said to have had high firepower. A comparison with modern compound bows suggests itself because of the roles, but it is lagging because the roles of the Chinese bow guns should only deflect the bowstring over to the next bow. They weren't eccentric like the compound bow rolls either.

Another idea came up in the Mediterranean culture: Here the bow guns were provided with a single, but greatly enlarged composite bow on a large crossbow barrel. The high pull weights of the Chinese bow artillery could thus be exceeded, and the draw length and penetration power of a single large composite bow were correspondingly greater than those of several smaller bows.

Oxybeles

This type of weapon was called Oxybeles ( Oxy sharp, shooting beles ) by the Greeks , in the plural Oxybelei . These devices were also tensioned with a cable winch and were mounted on a mount. The Oxybelei were used like their Chinese counterparts as fortress guns, light field artillery and for sieges. However, it is not known how such enormous composite arches were built. There are no archaeological finds (other than arrowheads) and we only know of the Oxybeles from descriptions in ancient texts. Obtaining the raw materials must have been very difficult, as the arches are said to have been almost two meters long and more than a hand's width. We can only speculate about the structure of this enormous arch. It is assumed, however, that they were made in composite construction. However, the oxybeles bows cannot have been made exactly the same as the hand and crossbow bows. The unusual size certainly caused new problems to arise in purely mathematical terms:

They must have a wooden core, because the dead weight of a bow increases to the power of three, i.e. eight times, each time its dimensions are doubled. Without a wooden core, a bow with z. B. three times the mass of a normal crossbow bow made of horn and string, much too heavy to effectively accelerate an arrow . Only with a wooden core can the sluggishness of the mighty limbs be reduced. Since the wood core is also heavily stressed with such a large arch, it must have been made from a flawless piece of a very elastic type of wood or even in layered construction from different woods.

For the horn belly of the bow, if horn was used, only the longest horns of a few animal species were considered, such as ibex horns , if several of them were used as horn sticks, or whale whiskers as individual continuous strips.

The problem mentioned above must have reappeared when the tendon covering of such a large bow: In the tendon covering of a hand crossbow bow, many small tendon strips overlap like roof tiles. Each time the dimensions of a bow are doubled, its own weight increases to the third power, so it is eight times as heavy, has eight times as much volume, and thus its tendon covering also has eight times as many junctions at which the tendon strips overlap. At the same time, the strength of the bow increases every time it doubles its size: a composite bow that is twice as large is four times as strong, but contains eight times as many connection points in the tendon covering, which are also four times as stressed by the quadrupled forces of the larger weapon. The connections between these small glued-on tendon strips in the larger gun bow are not stronger than in the hand bow, which makes them possible break points because of the higher forces. The tendon coating component becomes eight times more inhomogeneous with every doubling of the bow , has more and more overlaps, which influence the immensely higher forces of the gun as defects and endanger the bow.

Now if the arch of an Oxybeles z. For example, four times the size of a crossbow bow, it would be 16 times as strong as this one, but would have 64 times as many connection points in the tendon covering that would be stressed 16 times more! It would no longer work.

The Chinese bowmakers may not have been able to solve this problem, and for their Shoushe and Chuangzi Nu's they therefore opted for the method with several smaller bows and pulleys.

The Greeks seem to have got the problem of the increasing inhomogeneity of the bow stick in the cube under control. Some kind of homogenization of the tendon covering is conceivable , for example by using longer (and more valuable) animal tendons, which would have produced fewer, but longer (and thus firmer) overlaps. Or with normal-length tendons by first spinning the tendon fibers into string and then using many such parallel tendon strings and glue to glue a homogeneous covering onto the back of the arch, which would then no longer have any overlaps. It is also conceivable to first weave the tendon fibers into a kind of fabric and then glue on several layers, which would also take account of the lateral forces increasing in the square .

The Oxybelei were the largest and strongest composite bows ever built. To date, no experimental archaeologist or bow maker has succeeded in recreating an Oxybeles in composite construction, as there are hardly any or no records of the manufacture of these siege weapons.

In Europe, the bow artillery went seamlessly into the torsion artillery in antiquity (approx. 200 BC) , i.e. the first real catapults with torsion springs, which finally replaced the oxybelei (see ballista ). It wasn't because of the power of oxybelei, but catapults were easier and cheaper to build in larger numbers, and larger guns were possible than with a bow. The knowledge learned from the bow guns about the correct position and shape of the limbs remained important with the torsion catapults, since the two limbs together also formed an arc (although they hardly bent, but turned), which was correctly adjusted and brought to maximum performance had to become.

The Chinese bow guns, on the other hand, remained in use until the Middle Ages, as the Chinese never really got to know the torsion catapult. After normal arrows and those with gunpowder charges (explosive projectiles) had been successfully fired at enemy targets with the crossbow guns there, they were slowly replaced there by the firearms and rockets . Christian missionaries showed the Chinese the principle of torsion guns in the Middle Ages, but the Chinese had long been familiar with gunpowder and rockets, which were then adopted by the Europeans.

In the form of the ancient crossbow guns, the composite bow was the origin of the torsion guns and the first powder weapons, and thus also of all later generations of artillery weapons.

literature

- Volker Alles (Ed.): Reflexbogen. History and manufacture. Angelika Hörnig, Ludwigshafen 2009, ISBN 978-3-938921-12-8 .

- Steve Allely: The Bible of Traditional Bow Making . Volume 1. Angelika Hörnig, Ludwigshafen 2003, ISBN 978-3-9808743-2-8 .

- G. Fred Asbell: The Bible of Traditional Bow Making . Volume 2. Angelika Hörnig, Ludwigshafen 2004, ISBN 978-3-9808743-5-9 . (Includes chapters on composite bows)

- Tim Baker: The Bible of Traditional Bow Making. Volume 3. Angelika Hörnig, Ludwigshafen 2005, ISBN 978-3-9808743-9-7 .

- Steve Allely: The Bible of Traditional Bow Making . Volume 4. Angelika Hörnig, Ludwigshafen 2008, ISBN 978-3-938921-07-4 .

- Holger Eckhardt: bow and arrow. An archaeological-technological investigation. International archeology. Volume 21. Marie Leidorf, Espelkamp 1996, ISBN 3-924734-39-9 .

- Liang Jieming: Chinese Siege Warfare. Mechanical Artillery & Siege Weapons of Antiquity. Leon Kit Meng, Singapore 2006, ISBN 981-05-5380-3 .

- Holger Richter: The horn bow crossbow. History and technology. Angelika Hörnig, Ludwigshafen 2006, ISBN 3-938921-02-1 .

- Richard Kinseher: The bow in culture, music and medicine, as a tool and weapon. Kinseher, Kelheim 2005, ISBN 3-8311-4109-6 .

Web links

- ATARN (English)

- International Hornbow Society (English)

- Drawing of presumed oxybelei and [1]

- Diodorus von Sizilien 14,42,1 and the invention of the artillery in the Mediterranean area (with a bibliography on ancient artillery; PDF; 209 kB)

Individual evidence

- ↑ M.-S. Hernández Pérez, P. Ferrer Marset, E. Catalá Ferrer: Arte rupestre en Alicante. Alicante (Center d'Estudis Contestans), 1988.

- ↑ a b c d Leif Steguweit: Evidence for recurve bows in the European Neolithic. In: Volker Alles (Ed.): Reflexbogen. History and manufacture. Angelika Hörnig, Ludwigshafen 2009. pp. 10–25

- ↑ AP Okladnikov: Neolit i Bronsovij vek Pribaikalja. Materialij i isledovania po archeologij SSSR 18 (Moscow and Leningrad, 1950).