Tanker

A tanker is a ship designed to transport liquids or gases . Typical transport goods are crude oil , oil as a finished product, fuel, liquid gas , water , juice .

A tanker can easily be distinguished from other ships by its silhouette. It has a flat deck that has hardly any superstructure apart from the bridge . It does not require any loading gear (deck-mounted cranes), with the exception of the crane mounted amidships on all tankers, with which hoses can be lifted on board from shore to connect them to the ship's pipeline system. Tankers have several connection stations ( manifolds ) for hoses.

Tankers have pumps on board for unloading ( nautical for "unloading") the cargo. The loading and unloading operations are controlled and monitored with a loading computer (as with almost all cargo ships). This makes it possible to calculate the distribution of the forces acting on the ship (weight of the cargo and buoyancy).

The main components of the ship technology are the main engine with ancillary units, boiler system, auxiliary diesel with generators for power generation, inert gas system, tank washing facilities and the loading pumps with an individual output of over 10,000 t per hour.

In the case of flammable tank loads, ship fires and explosions are nowadays caused by filling the empty spaces in the tanks, e.g. B. above the load, avoided by inert gas . The inert gas replaces the previous, oxygen-containing tank atmosphere with almost oxygen-free gas in order to prevent the cargo gases from igniting. The inert gas can be a specially prepared combustion gas (exhaust gas) produced on the ship; however, any other gas that does not form a reactive mixture with the respective charge can also be used.

Oil tankers

Oil tankers are ships that are specially built to transport petroleum .

Oil tankers that transport crude oil from oil-producing countries to other countries are almost always over 100,000 GRT in size . Today's oil tankers have a heavy oil powered ship engine with direct drive of the drive shaft with a fixed propeller . The two-stroke diesel engine is often a slow runner (around 100 revolutions per minute). Medium-speed four-stroke engines can also be found in smaller ships, as well as diesel-electric drives in which the main engine drives a generator and the electricity generated is also used to drive the propeller. The steam turbine drives that were common in the past are no longer built due to their low level of efficiency and the increased fuel prices. There is also currently a search for alternatives in propulsion, for example there is a concept study on environmentally friendly oil tankers with natural gas propulsion. Crude oil is loaded in a heated state and continues to be heated during the entire sea voyage so that it can be pumped out in the port of discharge. Sufficiently dimensioned boiler systems are installed on board to heat the cargo. The largest oil tanker ever built, the Years Viking , could carry 652,000 cubic meters of crude oil.

The tanker also plays a major role in inland shipping , mainly product tankers . Oil is hardly ever transported in inland shipping. The Vorstenbosch , which went into service in 2011, is the largest inland tanker in the world and has a loading capacity of 13,889 m³. Before that it was the Dutch tanker Vlissingen with a loading capacity of 9,297 tons. It is used for the bunkering of seagoing vessels in the port of Rotterdam.

Since speed is not particularly important when transporting oil, oil tankers are relatively slow ships at around 15 knots (28 km / h) (see also slow steaming ).

Oil tankers (like many other cargo ships) are scrapped after 20 to 25 years of operation. For this purpose, they are used at scrapping yards such. B. in Alang at spring tide with swing on the beach, then dismantled and largely recycled.

Size growth

Since the transport costs per ton of cargo are lower for larger ships, larger and larger oil tankers have been built.

| year | description | Load capacity tdw |

Length ü. a. Width side height draft |

image |

|---|---|---|---|---|

| The first oil tanker was the converted sailing ship Andromeda by WA Riedemann , who in 1890 co-founded the German-American Petroleum Society (DAPG) (since 1950 Esso, today Exxon Mobil ). | ||||

| 1878 | The Zoroaster was an oil-fired, steam-powered oil tanker owned by the Swedish entrepreneur Ludvig Nobel , built in Sweden in 1878, delivered to the Volga in dismantled barges and commissioned in 1879. Initially with upright cylindrical cistern tanks, but later sealed off areas of the ship's hull were used as tanks. | 250 | ||

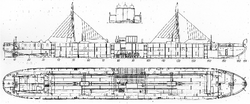

| 1886 | The first machine-driven oil tanker was the Glückauf . It was built by Wilhelm Anton Riedemann on behalf of the German forwarding company; Maiden voyage on July 13, 1886. | 3,000 | L = 97.00 m W = 11.40 m D = 5.80 m |

|

| 1887 | The first inland tanker was the converted barge Carolina from the Mannheim entrepreneur Fendel. He transported crude oil from the Rhine estuary ports to the port of Mannheim . | |||

| 1903 | The Vandal , an inland tanker, was the world's first diesel motor ship with diesel-electric propulsion . |

|

||

| 1913 | The Hagen of DAPG was the first Seetanker with diesel engine | |||

| 1914 | The DAPG's Jupiter was the largest tanker in the world to date. | 12,000 | ||

| 1928 | The CO Stillman was delivered from Bremer Vulkan with 23,060 tdw as the largest tanker in the world (also the world's largest tanker with a diesel engine drive); this size was only exceeded in 1949. | 23,060 | L = 172.44 m W = 23.00 m |

|

| 1953 | The Tina Onassis was launched in Hamburg as the largest tanker in the world at the time. | 48,000 | ||

| 1959 | The first tanker with over 100,000 tdw was the Universe Apollo, built in Japan . | 100,000 | ||

| 1962 | The Nissho Maru was built in Japan. | 110,000 | ||

| Jan. 1966 | The Tokyo Maru became the world's largest tanker. With a measurement of 90,000 GRT, it also surpassed the largest ship in the world to date, the English passenger ship Queen Elizabeth with 83,673 GRT. | 150,000 | ||

| Dec 1966 | The Idemitsu Maru was the first tanker with over 200,000 tdw. | 200,000 | L = 344.28 m B = 48.84 m |

|

| 1968 | The 300,000-tonne limit was exceeded with the six Japan-built Universe Ireland- class ships . | 326,000 | ||

| 1971 | The at IHI; Kure in Japan-built Nisseki Maru became the new record holder. | 372,000 | ||

| Feb./Oct. 1973 | This is followed by Globtik Tokyo and Globtik London from Globtik Tankers Inc, London, built by IHI; Kure in Japan. A geared turbine had 33,000 kW. | 478,000 | L = 378 m B = 62 m S = 35.9 m D = 28 m |

|

| 1975 | The Nissei Maru was the largest tanker in the world, built by IHI in Kure, Japan for Tokyo Tanker Co, Japan. Dimensions like Globtik Tokyo . | 484,000 | L = 378 m B = 62 m S = 35.9 m D = 28 m |

|

| Dec 1975 | The Emperor Mountains were built at Mitsui Heavy Ind., Japan . The ship had a maximum draft of only 22 meters, but its length and width exceeded the largest tankers in the world to date. | 413.999 | L = 391.8 m B = 68.1 m S = 29.8 m D = 22 m |

|

| 1976 | With the Batillus for Shell France, a tanker with more than 500,000 tdw was put into service for the first time. At the same time it was also the first ship in the world to exceed the 400-meter mark. It was a two-screw turbine tanker that was built in France at Chantiers de l'Atlantique in St. Nazaire. Another three sister ships followed with Bellamya at the end of 1976 (Shell France), Pierre Guillaumat ( largest and longest ship ever built in one piece in the world ) in October 1977 and Prairial 1979 (both for Compagnie Nationale de Nav.) | 553,000 |

L = 414.2 m B = 63.05 m S = 36.00 m D = 28.5 m |

|

| Sept. 1976 | The tanker Bonn was handed over from the AG “Weser” shipyard in Bremen to the Hapag-Lloyd subsidiary Kosmos Bulkschiffahrt . For less than a month, the Bonn was the largest tanker sailing under the German flag until then, but was then trumped by the Esso Deutschland . A total of six copies of this size were manufactured by the AG “Weser” shipyard in Bremen, also known as the so-called “ Europe Tanker ” at the moment. Two of these ships (the Shat-Alarab and also the Bonn ) later even returned to the shipyard up the Weser in Bremen for final equipment or guarantee work; a rarity for the port of Bremen that ships of this size returned. | 393,000 | L = 370.23 m B = 64 m S = 28.60 m Tmax = 22.58 m |

|

| Oct 1976 | The Esso Deutschland was built by Kawasaki Heavy Ind. In Sakaide (Japan) and delivered to Esso AG, Hamburg, as the largest tanker ever to sail under the German flag . | 415,020 421,681 (according to main article) | L = 378 m W = 69 m S = 28.70 m D = 22.92 m |

|

| Aug./Dec. 1977 | Hitachi Heavy Industries, Ariake Yard in Japan, built two single-screw turbine tankers for Esso Tankers Inc., Esso Atlantic and Esso Pacific . | 516,000 | L = 406.6 m W = 71.00 m S = 31.20 m D = 25 m |

|

| 1978 | The Swedish Uddavalla shipyard built the twin-screw turbine tanker Nanny for a Swedish shipowner. It is still the widest monohull ship to this day . | 499,000 | L = 365 m W = 79 m S = 30.50 m D = 22.3 m |

|

| 1980 (1975) | In 1975/76 Sumitomo Heavy Industries built the 420,000 tdw single-screw turbine tanker Porthos for a Greek shipowner. The ship was completed in 1976, but not accepted by the client. The Hong Kong shipowner C. Y. Tung acquired the ship in 1979 and had it extended in 1980 by an 81-meter midship section from Nippon Kokan. It was the largest and longest (but not built in one piece) (tank) ship in the world to this day . On December 22, 1987, the ship was attacked off the island of Larak in the Persian Gulf by Iraqi Mirage fighter planes and badly damaged in another attack on May 14, 1988. Despite the damage, the ship was bought in 1991 by an owner from Norway and refitted and renamed Years Viking . In 2004 the ship was renamed Knock Nevis and has since served as a stationary crude oil interim storage facility. In 2010 the ship was renamed Mont and scrapped in Alang, India . | 564,650 |

L = 458.45 m B = 68.86 m S = 29.80 m D = 24.61 m |

|

| 1980/1981 | The tankers Berge Pioneer and Berge Enterprise were sold as the world's largest diesel-powered tankers to the Norwegian shipping company Sig. Bergesen d. Y. delivered. | 360,000 | ||

| Dec 1992 | The Danish Odense Yard delivered the world's first VPlus double-hull tanker Eleo Mærsk to the shipping company A. P. Møller, Copenhagen, a total of 6 sister ships by June 1995. Another 3 almost identical, about 1/2 percent more load-bearing sister ships to Star. | 300,000 | ||

| 2001-2003 | After a break of more than 20 years, tankers over 400,000 tdw were built again for the first time. The four ships of the Hellespont Alhambra class were built at Daewoo Heavy Ind. In South Korea for a Greek shipowner. They are the largest double-hulled tankers in the world . | 450,000 | L = 380 m B = 68 m S = 34 m D = 24.5 m |

|

Note on the table: Records / maximum values in the respective categories and their explanations are highlighted in bold .

Oil tankers over 200,000 tons are referred to as VLCC (Very Large Crude Carrier), and tankers over 320,000 tons as ULCC (Ultra Large Crude Carrier). With a load capacity of over 250,000 tons, one speaks of a super tanker . Despite their size, even the largest tankers usually get by with a crew of 15 to 25 men. Double-hull tankers more than 300,000 tons as VPlus referred

However, the growth in size not only brings benefits, it also creates problems. When constructing ships of this size, it is important to avoid structural problems, as the high loads would otherwise lead to deformations and cracks on the hull. Due to the great draft, only a few ports can be entered, and they are too big for the Panama Canal . The Suez Canal, on the other hand, can also be navigated by 450,000 tdw ULCC tankers when empty. In order to be able to earn money from loaded ULCC, a pipeline tank system was installed along the canal, so that at the beginning the oil is pumped out to the permitted depth and after the canal is kept in tanks for resumption. The idea of building such large ocean-going vessels is u. a. can also be traced back to the closure of the Suez Canal in the years 1967-1975. During this time, all ships from the Persian Gulf on their way to the USA or Europe had to bypass the Cape of Good Hope in South Africa.

Two-hull tankers or double-hull tankers

A two-hull tanker is a transport ship for the transport of liquid goods that has a double outer hull. The distance between the two shells is usually 2-3 meters.

In contrast to conventional single-hull tankers, these should offer greater security against the leakage of the transported goods when operated properly. The double hull of the tanker must, however, be usable as a ballast tank in order to be able to trim the ship according to the current load ( sea water is used as ballast on ships, which is pumped into the corresponding tanks).

Due to the seawater plus atmospheric oxygen, the inner walls of the hull are exposed to an extreme risk of corrosion, so that regular checks and renewals of the protective coating are necessary so that the two-hull tankers can really offer increased safety.

After the Exxon Valdez disaster in March 1989, the International Maritime Organization (IMO), as the regulatory authority, decided that all tankers built from 1996 and with a transport weight of over 5,000 tonnes must be double-hulled.

After the Erika disaster (1999), the IMO decided that from 2015 only oil tankers with double-walled outer hulls would be allowed to sail the world's oceans.

Originally, double-walled tankers were not developed for safety reasons, but to save energy (and therefore costs) when transporting hot goods such as bitumen , molasses or paraffin . Because a double shell (filled with air or inert gas) offers good thermal insulation .

With the 88th amendment to the fifth version of SOLAS coming into force on July 1, 2006, the double hull construction is also a mandatory element in the construction of bulk carriers for the purpose of the safety of life at sea (and, as a side effect, also for the protection of life on land). But as a result of the express resistance of Greece, this was still not prescribed on board pure tankers, but only on board ships that either only carry dry bulk cargo (e.g. ores, soy, scrap etc.) or as "combination ships" have both cargo holds and tanks on board so that liquid (e.g. crude oils) and dry bulk goods can be transported at the same time.

Liquefied gas tankers

Liquid gas tankers are used to transport liquefied gases by sea in bulk in fixed cargo tanks. Transported gases in addition to industrial gases, especially liquefied natural gas (LNG liquefied natural gas ) and LPG (LPG liquefied petroleum gas ). Liquid gas tankers are a flexible alternative to transport in pipelines . The efficient transport of gases requires liquefaction . This liquefaction causes a considerable reduction in volume (LPG: 1/260, LNG: 1/600) and, depending on the type of gas, can be achieved both by increasing the pressure and lowering the temperature. The Methane Pioneer was the world's first LNG gas tanker. Since the various types of liquefied gases differ, specific tankers are built for the various types of gas.

The IMO has set internationally binding standards for the construction and equipment of liquid gas tankers in the IMO Gas Code (IGC) . This code typifies the ships based on their ability to withstand certain damage (e.g. caused by collision or stranding). Type 1G tankers are the safest ships with regard to a possible escape of cargo.

The following liquefied gases are z. B. transported by:

- Type 1G tanker: chlorine , ethylene oxide , methyl bromide

- Type 2G tanker: ethane , ethylene , methane (LNG), typical for LNG tankers

- Type 2G / 2PG tankers: acetaldehyde , ammonia , butadiene , butylene , dimethylamine , ethylamine , ethyl chloride , methyl chloride , propylene , vinyl chloride and butane , propane (LPG), typical for LPG tankers

- Type 3G tanker: nitrogen , various safety refrigerants (Rxx)

The shape characteristic of LNG liquid gas tankers is characterized by several spherical tanks, the upper half of which is always above the deck, making this type of ship very clearly recognizable. The spherical shape of the individual tanks is the best possible design for both pressure load (LPG) and thermal insulation . However, there are also LNG tankers in which the almost rectangular tanks are almost completely in the hull and can therefore easily be confused with oil tankers. These are so-called membrane anchors . An LPG tanker is used to transport liquid gas, which, like lighter gas, can be liquefied at room temperature under moderate pressure (max. 20 bar). Cooling is not necessary with LPG.

In contrast, LNG tankers transport liquefied natural gas through freezing in highly insulated tanks. The first ship of this type was the Methane Pioneer, converted from the C1 ship Normarti to a tanker (aluminum tanks with wood insulation, 5123 m³ total tank volume, maiden voyage on January 29, 1959 from Lake Charles, Louisiana).

This transport method, which has become increasingly evident in recent years, shows a trend towards larger units. In addition to the currently predominant LNG tankers with a total tank volume of 125,000–147,000 m³, divided into mostly 4 to 6 tanks, ships with up to 250,000 m³ tank capacity are planned. The liquefied natural gas is transported at a slight overpressure ( membrane tank e.g. max. 230 mbar) and the corresponding temperature of −164 ° C to −161 ° C.

Despite the insulation ( pearlite insulation ) of the LNG tankers, the slow heating of the tanks leads to the evaporation of part of the cargo, the so-called “boil-off”. The vaporized gas must be able to escape so that the pressure in the tank does not assume impermissibly high values. This boil-off gas is energetically used to generate steam and, ultimately, to propel it and generate electricity ( LNG as fuel for ships ). For this reason, LNG tankers are mainly designed as turbine ships for heavy oil and / or natural gas operation. If there is an excess of boil-off gas, the overproduction of steam in the auxiliary or main condenser is condensed against seawater, so that methane (as a main component of natural gas) does not have to be released into the atmosphere during normal ship operating conditions. When the capacitance limits of the capacitors are exceeded, the boil-off gas is blown into the atmosphere through a mast (vent raiser) in order to keep the tank pressure within the permissible range and, on the other hand, to keep the deck outside the suffocating, flammable to explosive, rising plume of exhaust gas.

A few new builds are equipped with diesel-electric drives , with natural gas and / or diesel fuel or heavy oil being burned in the engines. In the long term, the turbine ships in LNG shipping will be displaced by the motor ships with gas reliquefaction systems. This trend can be found in the new construction business.

The renewed deep freezing, i.e. reliquefaction, of LNG on board was considered too expensive until recently. Some older ships are equipped with reliquefaction systems, but these were never used properly due to technical problems and a lack of profitability. Some modern LNG tankers are prepared for the installation of a reliquefaction system in anticipation of rising natural gas prices and can thus be retrofitted without any problems (e.g. TGT "British Trader", foundations, flanges and a comparatively large heavy oil tank capacity are available).

Around 470 LNG tankers with a total capacity of 75 million cubic meters were in use worldwide in 2018, mostly in Asia. New ships of this type are primarily being built in South Korea, but also in Spain and France. Due to the high construction costs (typically US $ 200 million), LNG tankers are constructed for a service life of around 40 years and are usually only put on keel when a long-term charter (20 years) is available. But here too there has recently been a tendency towards the formation of a spot market (as in the oil business).

The largest LNG tankers currently being planned will be equipped with a tank volume of 266,000 m³. These ships are driven by diesel engines (DRL drive system). The boil-off gas is reliquefied and returned to the cargo. The first ship of this so-called Q-Max class went into service in 2009 for the Qatar Gas Transport Company .

Environmental hazards

The oil that leaks in the event of a tanker accident causes great damage to nature (“ oil spill ”). Waterfowl and mammals living in the water get stuck together in their plumage or fur, fish, mussels and crustaceans perish due to toxic components, which deprives many other animals of their nutritional basis.

In order to reduce the risk of oil spillage in the event of a ship collision or when running onto a reef, the International Maritime Organization (IMO) decided that only two-hull tankers may be built. All single-hull tankers are to be decommissioned by 2015.

Technical improvements and stricter safety rules are now having an effect: of the roughly three million tons of oil that end up in the oceans every year , only about thirteen percent come from tanker accidents (as of June 2005). Far larger amounts of oil, on the other hand, get into the oceans from the engines of boats , cars , oil platforms at sea, illegal discharges and other oil-lubricated machines and devices. The ecologically particularly sensitive coastal areas and estuaries are the most affected by pollution.

The use of ballast water represents an increasing ecological problem. With the seawater, animals and plants living in it are transported between the world's oceans. As early as the beginning of the 20th century, this brought the Chinese woolly crab into European waters. When the tanks are emptied at the destination, the organisms find their way into new habitats, where natural enemies may be lacking. If these neobiota can survive under the new maritime climatic conditions, they pose a threat to the ecological balance .

At the end of their lifespan, ocean-going ships are scrapped, especially in India, Pakistan and Bangladesh. A ship is put on the beach with a call and dismantled under extremely harsh, high-risk working conditions. Because of dangerous environmental pollution there was resistance against ships with built-in asbestos, radioactive smoke alarms and of course oil, fuel and cargo residues are also problematic.

Stopping distance

The International Maritime Organization stipulates that ships must come to a stop within 15 (in exceptional cases 20) ship lengths during an emergency stop maneuver from full speed. Such an emergency stop maneuver loads the main engine , its foundations and the shaft so heavily that this is only practiced in exceptional cases, with the exception of technical acceptance. With a maximum length of 450 m, the regulations result in a maximum distance of 9 km (4.9 nm) to stop the vehicle. Longer stopping distances arise if the ship is not braked or steadily slows down.

Series of tests with unloaded large tankers with a load capacity of 250,000 and 390,000 tons resulted in stopping distances between 1.32 nm (2.45 km) and 3.4 nm (6.3 km), which were reached in periods of between 12 and 27 minutes.

Other forms

- Water boat

- Asphalt tanker

- Fruit juice tanker

- Product and chemical tankers

- Tankers with icebreaker skills

See also

- Tank wagon (railway)

- Tanker aircraft

- Tank truck

literature

- Peter Baumann: Oil tankers. Giants of the oceans. Polydruck AG, undated (around 1970).

- Jochen Brennecke: Tanker. From the petroleum clipper to the super tanker. Koehlers Verlagsgesellschaft, Herford 1975.

- Gert Uwe Detlefsen: Shipping in the picture. Tanker (I). Publisher HM Hauschild, Bremen 2000.

- Gert Uwe Detlefsen, Rudi Kleijn: Shipping in the picture. Tanker (II). Publisher HM Hauschild, Bremen 2003.

- Gert Uwe Detlefsen, Rudi Kleijn: Shipping in the picture. Tanker (III). Publisher HM Hauschild, Bremen 2008.

- Karsten Kunibert Krüger-Kop: German tankers: An illustrated fleet list of tankers in German management after the Second World War - as of the end of 2005. Koehlers Verlagsgesellschaft, Hamburg 2006.

- Joachim W. Pein: Giants of the oceans. The history of the supertanker. Koehlers Verlagsgesellschaft, Hamburg 1996.

- Joachim W. Pein: Giants of the Seas. The largest tankers in the world. Koehlers Verlagsgesellschaft, Hamburg 2011.

Web links

Individual evidence

- ↑ http://www.miramarshipindex.org.nz/ship/show/314460 ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ^ A b c Felix Sutton: WAS IST WAS, Volume 1, Our Earth , Tessloff Verlag, Nuremberg • Hamburg 1981, ISBN 3-7886-0241-4 , p. 36.

- ^ The natural gas explosion. In: The Economist . February 28, 2005, accessed November 4, 2012 .

- ↑ Note: Methane has about 55% the density of (dry) air.

- ↑ Wolfhart Fabarius: Study: LNG tankers benefit from China · KfW Ipex expects increasing demand - currently 470 units with more than 100,000 cubic meters of capacity . In: Daily port report of October 29, 2018, p. 16

- ↑ article about future Qmax LNG carriers (English)

- ↑ Documentary film "Eisenfresser"

- ↑ R. Brenke: The stopping behavior of large tankers . In: Ship & Harbor / Command Bridge . Vol. 29, No. 6 , June 1977, p. 603-605 .