V engine

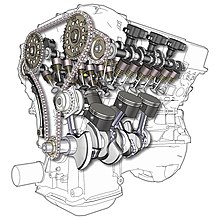

A V-engine (formerly also called fork engine ) is a design of a reciprocating piston engine with several cylinders . These are divided into two cylinder banks that are at an angle ( "bank angle" ) to each other. After the in- line engine , it is the most widespread engine design.

description

In the classic V-engine, the two cylinder banks “stand” on the crankcase below, inclined to one another by the bank angle . In the case of aircraft engines , the reverse installation was also common, with the cylinder banks “hanging”, as this keeps the center of gravity low. In older descriptions, in particular, this is often referred to as "A-motor", although it is not a separate motor design. The pilot's view is less obstructed by exhaust gases and the landing gear is less high for a given propeller diameter.

The bench angle has a strong influence on the size of the inertia forces and is limited by the installation space available on the side. In practice, a minimum bank angle is required to take advantage of the V-arrangement. In order to keep the bench angle small, the cylinder feet can be offset outwards; the cylinder axes then intersect under the crankshaft. The bench angles shown so far start at around 10 ° in the Lancia Appia and in Röhr 8 . With the so-called VR engines , i.e. V engines with a very small bank angle (<15 °), the two banks usually have a common cylinder head.

The bench angle can be up to 180 °. Then one speaks of a 180 ° V-engine. Such engines differ from boxer engines in that the crankshaft has a different offset (see next section ).

In a V-engine, the connecting rods of two opposing cylinders are mounted next to each other on the crank pin of a crankshaft offset, which results in a slight offset of the cylinders. Exactly opposite cylinders require the use of fork connecting rods ( Harley-Davidson ) or coupling rods . Due to the kinematics , coupling rods cause an unequal piston stroke in the two cylinder banks. The resulting difference in compression can, however, be compensated for using the pistons. Fork connecting rods are more complex and therefore more expensive.

Occasionally, V-engines with an uneven number of cylinders were also built, with motorcycles as V3 ( Honda NS 400 R ) and V5 ( Honda RC211V ). VW used in the Golf IV a process called V5 five-cylinder - VR engine .

In the case of passenger car engines, the aim was always to keep the ignition intervals between the cylinders uniform for reasons of smoothness. In four-stroke engines - given as the crank angle - these are 720 ° divided by the number of cylinders, since each cylinder fires once with two crankshaft revolutions. With a V8 the ignition interval is 90 °, with a V6 120 °. If the bank angle is not a multiple of the ignition interval, you need different crank pins. These can sit right next to each other if they are not offset too much ( PRV engine from 1985), are connected with an intermediate cheek (Ford V4), sometimes a separate crankshaft offset is made for each cylinder ( Lancia Aurelia , Mitsubishi 3000GT), what the length of the engine increased.

The most common bank angle is 90 ° for almost all V8 and V4, many V6 (ideal would actually be 60 °) and some V10 engines (ideal would be 72 °). For manufacturing reasons, it is advantageous if a V8 engine with a bank angle of 90 ° is used as the basis of a V engine series with different numbers of cylinders (for example V6, V8 and V10), as all engines can largely be manufactured on the same production lines and there are cost advantages as a result of identical parts. Examples include the V6, V8 and V10 FSI engines from Audi and V6 and V8 engines from Mercedes-Benz ( Mercedes-Benz M112 ). Various V6 and almost all V12 have 60 ° bank angles. There are hardly any V6s with 120 °, because the engine is then very wide.

In the case of large engines and engines for special applications (for example in racing), other aspects are often decisive for the choice of the bench angle, such as accessibility for maintenance work, space requirements or the height of the center of gravity. In connection with the firing order, the bank angle also influences the engine characteristics (either broad usable speed range or maximum engine power).

180 ° V engine

In addition to the VR engine, the V engine with a 180 ° bank angle is also a special case. In the typical V-engine mounting of two connecting rods on a common crank pin, it is referred to as a "180 ° V-engine". If, on the other hand, the connecting rods of opposing cylinders are mounted on their own crankshaft throws, which are offset by 180 ° from one another, it is a boxer engine . Because of the better mass balance of the boxer engine, 180 ° V engines are rarely built, mostly as high-revving racing engines with many cylinders.

In the case of twelve-cylinder engines, the crankshaft throws are arranged analogously to an in-line six-cylinder. Therefore, regardless of the cylinder bank angle, all inertial forces and moments of first and second order are completely balanced, since the engine can be viewed as a double R6. The bank angle must be a multiple of 60 ° for even firing intervals. (60 ° are common for cars, 180 ° for racing and sports cars. 120 ° are not used because two cylinders would then fire at the same time). Examples of sports cars with 180 ° -V12 are the Mercedes-Benz C291 , the Ferrari Testarossa or the Porsche 917 .

Designations

V-engines are usually referred to with the specification of the number of cylinders, with a preceding "V" for the design of the engine and an appended number for the number of cylinders. “V12” thus designates a twelve-cylinder V-engine. In contrast, a number followed by a “V” usually designates engines with multi-valve technology , i.e. more than two valves per cylinder, e.g. B. “16V” stands for a four-valve, four-cylinder engine . Since multi-valve technology has become more and more widespread in the last two decades, this information is now rarely highlighted as a special feature, but only used as a reference in the technical data.

Cylinder arrangement

3 6 2 5 1 4

The arrangement is seen from the front of the vehicle in a V8 engine installed lengthways at the front (DIN 73 021):

Kraftabgabe 4 8 3 7 2 6 1 5

application

V-engines are widely used, especially with a higher number of cylinders and limited installation space. Vehicle engines with 8 or more cylinders are now almost exclusively V-engines.

V6, V8 or V12 engines are predominantly used in automobiles with V engines. V4 engines have not been able to establish themselves in the passenger car sector due to the poorer mass balance and the higher production costs compared to in-line engines, as have V2 engines, even if earlier V4 (Ford, SAS ) and occasionally V2 engines (mainly in Voiturettes and other small vehicles like the Morgan Threewheeler) were used. The first mass-produced V4 engines were in the Lancia Lambda from 1922 and the first V6 engines from 1950 in the Lancia Aurelia . The V-engine was also used in US vehicles such as the Ford V8 from 1932, right up to the muscle cars of the 1960s such as the Ford Mustang , Pontiac GTO or AMC Javelin . V10 engines are used in individual car models such as the Lamborghini Gallardo or VW Touareg V10-TDI - even more frequently in motorsport . The BMW M5 of the E60 / E61 series also had a V10.

V4 engines are found quite frequently in motorcycles, including the Yamaha Vmax , the Honda Pan European , the Honda VFR 1200 F or the Aprilia RSV4 . The Motus MST / MSTR, currently only available in the USA , is driven by a longitudinally installed 90 ° V4 engine with OHV valve control , the technical concept of which corresponds to a V8 engine of American design that is halved and reduced to 1650 cm³. The Laverda V6 , which was manufactured in just two prototypes, is an exception .

V2 engines are typically found in Ducati , Moto Guzzi , Harley-Davidson and Indian motorcycles . The irregular firing order of V-engines contributes significantly to the characteristic running noise of motorcycles. The special construction of the V2 engine of the historic Iver Johnson motorcycle enables an even firing sequence and thus generates the exhaust sound of a parallel twin engine.

In commercial vehicles (trucks, buses) the proportion of V-engines is greater, here mainly V6 and V8 engines, occasionally also V10 engines, are installed. V8, V12, V16, V18 and V20 engines are used for ship and locomotive drives, the V18 version being the rarest variant. V12 diesel engines were common in tanks for a long time and some still are ( Leopard 2 , T-90 ). V-engines were also used in airplanes, sometimes in an inverted manner: the cylinder banks are suspended, the crankshaft is on top.

V2 engine of a Mazda R360 Coupé

V4 engine of a SAS-965A "Saporoshez"

V6 engine of a Lancia Flaminia Coupe

air-cooled Tatra 87 V8 engine

cut open Daimler-Benz DB 601 , a V12 engine with hanging cylinders.

Advantages and disadvantages

The advantages of the V-engine compared to an in-line engine with the same number of cylinders include:

- Shorter overall length

- Half the number of crankshaft throws (except for some V4 and V6 engines) compared to the in- line engine and thus

- lower friction, which is seen as an advantage, especially with racing engines

- better cooling, especially of the cylinder heads and especially with air cooling

The compact design saves material and thus weight. A V12 with a six-cranked crankshaft is only slightly longer than an in-line engine with six cylinders.

A V-engine is more complex than an in-line engine with the same number of cylinders, because:

- some assemblies must be duplicated, for example the cylinder head and the camshafts (if on top)

- more complex shape of the crankcase .

- Frequently, two exhaust lines are required in cars, which take up additional space

- poor balance of inertia forces (up to V4) and moments of inertia (V4 and V6).

Disadvantages are mitigated by VR engines, for example in the Lancia Fulvia (bank angle 13 °) or the VW VR6 engine (bank angle 15 °) with a common cylinder head for both cylinder banks and only one manifold.

American V8 engines of the usual design ( "Big Block" and "Small Block" ) have only a single central camshaft, which is positioned in the top of the engine block between the cylinder banks and operates the valves via tappets , bumpers and rocker arms.

V4 and V6 engines are often used in passenger cars instead of R6 in- line engines because they are shorter and not so tall. The disadvantages are vibrations and a rougher sound at high engine speeds due to free mass moments. Due to the not longitudinally symmetrical crankshaft, free mass moments of the first and second order occur. A counterbalancing shaft can compensate for the first-order free moment of inertia. The remaining second-order free moment of inertia is relatively small. Since compensation would be excessively costly, it is dispensed with.

With four-stroke V8 engines, with a bank angle of 90 °, the inertial forces and moments of the first and second order can be completely compensated, as well - regardless of the bank angle - with the V12 and the very rare V16. The almost complete balance of masses leads to a very smooth run.

The original V8 design has a cylinder bank angle of 90 ° and a crankshaft with four cranks that are offset by 180 ° in one plane (hence the name flat-plane design, crankshaft corresponds to the R4 design). The crankshaft is simple and inexpensive to manufacture. It requires fewer counterweights, which makes the engine lighter and revs up further. With this design, however, free inertia forces of the second order and thus more vibrations occur. All V8 engines up to 1925 were flat-plane engines. Today the design is still used in racing and consistently by Ferrari .

In the cross-plane design of the V8, the first and last crankings of the crankshaft lie in one plane and the two middle cranks in a plane perpendicular to it. In the direction of the longitudinal axis, the cranks form a cross. Cross-plane -Kurbelwellen are much more difficult in the die to forge a flat-plane and are usually cast . However, they offer the advantage that the free inertia forces of the 1st and 2nd order and the free moment of inertia of the 2nd order balance each other out independently. A free moment of inertia of the first order occurs, which can be compensated by a pair of counterweights on the crankshaft. The complete balance of inertia forces and moments results in very smooth engine running. The design was introduced in 1915, but it was not until 1923 that Cadillac and 1924 Peerless brought the first production engines of this type onto the market. It has the disadvantage that the ignitions - and thus also the intake and exhaust strokes - do not take place alternately in the left and right cylinder banks, but rather irregularly. This is unfavorable for a good cylinder filling and an even distribution of the mixture or the combustion air to all cylinders, but this can be managed by appropriate design of the intake manifold . This also creates the acoustically distinctive exhaust noise ("V8 babbling"). With high engine performance, such as in racing, this design requires a complex exhaust system .

"Irregular" V-engines

In order to achieve a uniform firing sequence despite the bank angle not matching the ignition interval, some designs deviate from the usual requirement of arranging two connecting rods on a wide crank pin - for one piston in each bank.

Instead, these motors guide each piston on its own crank pin. This requires an interlaced, more complex crankshaft, although in most cases no additional main bearings are arranged between the connecting rods of the offset crank pins.

Examples of such V-engines with separated crankpins are almost all V4 and many V6 engines. Four-cylinder four-stroke engines have an ignition interval of 180 °, with the V-type the bank angle should be 180 °. The V4 engines from Ford therefore have a crank pin offset of 120 ° at a bank angle of 60 °. The V4 engine of the SAS-965 of the Saporisky Awtomobilebudiwny Sawod has a 90 ° bank angle and a corresponding 90 ° crank pin offset. Six-cylinder engines have an ignition interval of 120 °. As V-engines with a 120 ° bank angle, they would be awkwardly wide. Six-cylinder engines were built with smaller bank angles of around 60 ° and the ignition interval was made even by means of a corresponding crank pin offset.

Many six-cylinder V-engines were designed with a 90 ° bank angle because the blocks were to be processed on transfer lines planned for V8 engines; For example the PRV engine , the Citroën Maserati engine of the Citroën SM and Maserati Merak or the Mercedes-Benz M112 . If such an engine had no crank pin offset, the ignition interval would be uneven. In 1985, 9 years after its appearance, the PRV engine got the Mercedes-Benz M112 crankpins offset by 30 ° to compensate. The Citroën-Maserati engine had no crank pin offset and therefore ran comparatively rough.

In the V6 diesel engines of the Mercedes-Benz OM642 series , the cylinder bank angle has been increased from the 60 ° usual for V6 engines to 72 ° in order to better accommodate auxiliary units such as the water-oil cooler in the wider space between the banks; Here, too, the crank pins are offset accordingly in order to achieve a uniform ignition interval.

The V8 engines of the same construction period do not have this feature. Regular V-constructions with a 90 degree bank angle and unmounted crank pins of the crankshaft were used here.

The V8 diesel engines of the OM 628 and OM 629 series, on the other hand, have a bank angle of just 75 degrees instead of 90 so as not to be too wide. Therefore the crank pins of your crankshafts are also offset. The engines also have a balance shaft.

Sometimes irregular V-engines are also used in motorcycles , for example in the V-4 the Honda VFR 750 and 800 with a crank pin offset of 180 degrees.

literature

- Jan Drummans: The car and its technology. 1st edition, Motorbuch-Verlag, Stuttgart 1992, ISBN 3-613-01288-X .

- Hans Jörg Leyhausen: The master's examination in the automotive trade part 1. 12th edition, Vogel Buchverlag, Würzburg 1991, ISBN 3-8023-0857-3 .

- Gert Hack: make cars faster. 11th edition, Motorbuch-Verlag, Stuttgart 1980, ISBN 3-87943-374-7 .

- Richard van Basshuysen, Fred Schäfer: Handbook Internal Combustion Engine Basics, Components, Systems, Perspectives. 3rd edition, Friedrich Vieweg & Sohn Verlag / GWV Fachverlage GmbH, Wiesbaden 2005, ISBN 3-528-23933-6 .

Web links

Remarks

- ↑ This does not correspond to the definition in DIN 1940, December 1976 edition.

- ↑ In the standard DIN 1940 internal combustion engines; Terms, signs, units from March 1958, there is no such distinction, there the V-engine and the V-in-line engine are explained as follows: Arrangement of the cylinders in two planes which form an angle with each other and whose intersection line goes through the crankshaft axis or parallel to it lies.

Individual evidence

- ^ J. Königstedt et al .: The new V10 FSI engine from Audi. 27th International Vienna Motor Symposium 2006.

- ↑ Michael Trzesniowski: drive . Springer Fachmedien Wiesbaden GmbH, Wiesbaden 2017, ISBN 978-3-658-15534-6 , 3 losses, paragraph "Friction in the crank drive" , doi : 10.1007 / 978-3-658-15535-3 .

- ↑ flat crankshaft. Ferrari, accessed January 16, 2014 .

- ^ A b Eduard Köhler, Rudolf Flierl: Combustion engines . Engine mechanics, calculation and design of the reciprocating engine. 6th edition. Vieweg + Teubner Verlag, Wiesbaden 2011, ISBN 978-3-8348-1486-9 , 5.2 The crank drive, paragraph “g) Notes on the V8 engine” .

- ↑ https://www.e31.de/engines.html Section: The six-cylinder V-engine

- ↑ http://www.joe-ca-r.de/resources/_wsb_503x449_IMG_0088.JPG opened Ford-Essex-V6 with 60 ° bank angle and offset crank pins

- ↑ https://shop.bergmann-motorentechnik.com/media/catalog/product/cache/1/small_image/170x/9df78eab33525d08d6e5fb8d27136e95/z/_/z_ndverteilerkappe_merak_2.jpg Distributor cap for uneven ignition interval