Thermal insulation

Thermal insulation is the reduction of the passage of thermal energy through an envelope in order to protect a room or body from cooling or heating. It has developed in the course of evolution in warm-blooded (endothermic) animals, but is also used in many areas of technology with the help of natural or man-made materials.

Thermal insulation is also used as heat insulation or thermal insulation called (English: thermal insulation ). In technical terms, the term insulation is used more for protection against the transmission of electrical current or vibrations .

principle

Heat is transferred through three mechanisms:

- Thermal conduction : The heat is passed on through the movement of molecules . Materials with a high density usually conduct heat better than materials with a low density. Steel conducts heat better than wood . Thermal insulation is achieved by lengthening or interrupting the molecular cascades responsible for heat conduction using suitable materials and their arrangement.

- Thermal radiation : The heat is passed on by electromagnetic waves . Thermal insulation with regard to the prevention of warming is achieved primarily through reflection ("mirroring") of incident thermal radiation, with regard to the prevention of cooling by reducing the surface temperature of the body by reducing the heat conduction in the outer shell of the body, so that as little heat as possible can be radiated.

- Convection : The heat is transported by currents in gases or liquids. Thermal insulation is achieved by interrupting the flow of heat. A special form of this heat transfer, which is often overlooked, is the thermal binding by water vapor, i. H. the enthalpy of evaporation of the water (steam) binds thermal energy.

History

In the course of the development of refrigeration processes, the development of thermal insulation was advanced and in 1918 the Research Home for Thermal Protection (today: Research Institute for Thermal Protection e.V. Munich, abbr.FIW) was founded in Munich. The leading figure here was Professor Carl von Linde , who taught at the Technical University for several decades from 1868 and founded the Gesellschaft für Linde Eismaschinen Aktiengesellschaft (today: Linde AG ) in the south of Munich in 1879 .

Thermal insulation in technology

General

In the art thermal insulation is used to enable industrial processes or to minimize their energy needs. Other areas of application are, for example, the prevention of frost damage or the protection of food , but also the protection of spacecraft with a heat shield . Particularly effective thermal insulation is called super insulation .

Plant engineering

The protection against heat losses or cold losses through "heat gains" in chillers and their pipelines ( chillers ) is in many cases necessary for operation both for energy efficiency and for the function of the system itself. The increased costs of fossil fuels add an economic incentive.

Thermal insulation of buildings

Thermal insulation is used to minimize the cooling of heated buildings. Up until the middle of the 20th century, the thermal insulation of buildings was of little importance. One made do with warm clothing and moving closer together in a few rooms that were heated during the day. Most people worked physically and were therefore less chilled than is the case with desk work. In the 1960s, heating oil became affordable and competed with hard coal . Numerous new apartments and houses were built, the construction of which was seldom paid attention to energetic aspects. In the course of the first oil crisis in 1973/74, the oil price quadrupled ; In 1979/80 it tripled. In the 1970s and 1980s - also in connection with the discussion about global warming and sustainability as well as with forest dieback - an awareness of the necessity and rationality of energy-saving measures such as B. Thermal insulation.

In Germany, the first thermal insulation ordinance for buildings came into force in November 1977 ; At the beginning of 2002 it was replaced by the Energy Saving Ordinance (EnEV).

Building physics parameters

|

This describes the specific heat-insulating properties of a material under the assumption that there is no draft (convection). The smaller the value, the better the thermal insulation effect. |

|

|

This describes the specific heat-insulating properties of a component , including the heat transfer resistance to the adjacent air layers . The component can consist of several substances that are arranged one behind the other or next to one another. An example would be the outside wall of a building or a window . The smaller the value, the better the thermal insulation effect. The reciprocal value is the heat transfer resistance . |

|

This corresponds to the heat transfer coefficient , but without including the heat transfer resistance to the adjacent air layers. The reciprocal value is the thermal resistance . |

|

|

In North America , components are usually characterized with the R-Value and building materials with the R-Value per inch . This corresponds to the thermal resistance with Anglo-American units of measurement . The thermal resistance in the metric variant is referred to there as RSI or R ( SI ). An RSI value [m² · K / W] corresponds approximately to 0.176 times the conversion factor for R-Value to RSI-Value, for example for: an R-Value [h · ft² · ° F / Btu] The 0.144-fold reciprocal of the R-Value per inch [h · ft² · ° F / (Btu · in)] or the 0.0254-fold reciprocal of the RSI-Value per inch [m² · K / (W · in) ] of a substance gives the thermal conductivity λ [W / (m · K)] . |

How fast a temperature change spreads in a material depends not only on its thermal conductivity, but also on its heat storage capacity. The thermal diffusivity is decisive for this .

Types of thermal insulation

In buildings, building materials , components and other constructive methods are used to limit the passage of heat due to heat conduction and heat radiation through the building envelope. In many cases, this also involves ensuring airtightness .

- Thermal insulation materials are materials whose specific thermal conductivity λ is particularly low (less than 0.1 [W / (m · K)]) and whose main purpose is thermal insulation.

- Typical types of thermal insulation in relation to the building part are: roof insulation , wall insulation, facade insulation , perimeter insulation and ceiling insulation. With regard to the location in the building part, typical types of construction are: interior insulation, partition insulation , core insulation, external insulation.

- Construction materials with thermal insulation properties . The focus here is on the load-bearing effect or protection from the weather. Examples are heat-insulating exterior plaster , heat-insulating bricks such as vertically perforated bricks , solid wood and wood-based materials . Thermally insulating walls or ceilings made of homogeneous mineral building materials , without any significant use of insulating material , are referred to as monolithic construction.

Special case of interior insulation

Interior insulation is usually carried out in order to be able to preserve a historical facade, e.g. B. in half-timbered houses . They are also suitable if, for architectural reasons, the load-bearing wall shell should also form the visible outer surface and a double-shell wall would be too complex, for example with natural stone , clinker brick or exposed concrete walls , as well as log houses .

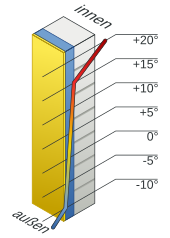

Interior insulation is more problematic, as the dew point is shifted inwards when the insulation is installed. The moist indoor air, which diffuses into the insulation layer in the winter months, condenses; this can lead to damage to the structure if the moisture content permanently exceeds certain maximum values.

The interior insulation is therefore often protected from penetrating water vapor by a vapor barrier . Using a separate, thin vapor barrier layer has some disadvantages:

- At transitions to walls, ceilings, projections and recesses and wall openings as well as penetrations for sockets, heating pipes, etc., completely airtight connections are difficult to produce. Vapor barrier films are susceptible to later damage. Since penetrating air moisture can hardly dry off towards the inside wall side due to the vapor barrier, larger amounts of moisture can accumulate, especially when using non-capillary insulating material such as mineral wool that is easy to flow through . Smaller amounts of moisture can dry out through the outer wall if only capillary-active building materials are used.

- The vapor barrier prevents the outer walls, which are often affected by driving rain on the weather side, from drying out towards the inner wall side.

Since the vapor barrier hinders the exchange of moisture with the indoor air, a layer of at least 2 cm thick made of vapor-permeable, storable material such as plaster or wood should be provided in front of the vapor barrier in order to enable the desired buffer effect of the wall surface.

In the meantime, we have many years of experience with interior wall insulation that do not require a classic vapor barrier layer. The prerequisite is the rapid drainage of the condensation water that forms in the insulation layer to the inner and outer wall surface through the continuous capillarity of the entire wall structure. For this purpose, capillary-active insulation and wall building materials are connected to one another without voids . In damp rooms and kitchens, it is advisable to limit the amount of water vapor penetrating the wall, for example by using an interior plaster containing synthetic resin with a defined diffusion resistance . Wood fiber insulation boards are also available with a special integrated mineral vapor barrier, which hardly restricts capillarity. In addition to light clay and wood fiber insulation , a large number of new types of insulation have been developed that are suitable for interior insulation. These include thermal insulation plasters , mineral foam boards , calcium silicate boards and composite materials with light mineral additives such as perlite and expanded clay .

In any case, interior insulation should be connected to the wall construction without cavities and in a flow-tight manner against the room air, in order to avoid both rear ventilation and convection currents within the wall construction, which would lead to locally increased condensation in winter .

Thermal insulation and moisture

Insufficient thermal insulation can cause condensation to form during the heating season . If a building structure is soaked through over a longer period of time, this can cause fungal growth ( mold ) and promote fogging effects, with corresponding dangers for the health of the residents as well as the functionality and intrinsic value of the building fabric. These undesirable effects can be reduced or avoided by using suitable materials, construction methods and additional measures.

The physical effects of thermal insulation cannot be viewed separately from other (structural) thermal insulation measures . Thermal insulation is only fully effective when the ventilation heat losses in a building are reduced by improving the airtightness of the building envelope.

Condensation caused by indoor air

Thermal insulation increases the temperature differences within a certain distance. If indoor air or water vapor penetrates into cold areas, this can lead to condensation. The lower the temperature there and the higher the room humidity, the more likely condensation will occur. With an airtight seal, the so-called vapor barrier , the direct inflow of interior air and the diffusion of water vapor can be made more difficult, but in practice they can hardly be prevented entirely. As a rule, therefore, additional precautions are taken so that the moisture that has nevertheless entered is transported away again or can be absorbed harmlessly to a certain extent.

Relocation of the condensation

Condensation mainly occurs at the coldest point. The coldest point can be relocated to less favorable areas by means of thermal insulation measures, for example from the glass pane to the reveal of the window . It is therefore desirable to achieve a surface temperature above the dew point in all areas accessible to the indoor air , to reduce the humidity by means of domestic ventilation or to use less problematic building materials in these areas.

Moisture transport, hygroscopic storage capacity and capillarity

Every building material is in a moisture equilibrium with its surroundings. Depending on the location where it is used, the moisture equilibrium and the level of water content will change quickly.

The ability to absorb water for a short time and thus avoid critical moisture penetration in situations such as driving rain or the formation of condensation is called hygroscopic storage capacity (see also w-value , water absorption coefficient ). Capillary-active building materials (see, for example, capillary-active clothing) then ensure that moisture is transported away within the construction. Building materials that combine both properties include bricks, gypsum, wood fiber materials, clay and calcium silicate boards . Although aerated concrete has a high storage capacity, it lacks the property of quickly releasing the water again. It is important that the constructions do not hinder the transport of water with unsuitable wall coatings ( emulsion paints , wallpaper , vapor barriers ).

In addition to water conduction through capillarity, there is also water vapor conduction through diffusion (see also water vapor diffusion resistance and breathing wall ).

Moisture damage

It should be checked whether water is produced by condensation in the indoor air, by leaks in the water supply or from outside. With humidity in summer, ventilation on humid or hot days can condense warm air on surfaces in cold rooms (cellars, churches). If there is moisture in winter, cold spots can be identified by measuring the internal surface temperature (infrared thermometer). Is z. B. a window reveal near the frame over a large area or unusually cold in individual places, the frame insulation may have defects. If necessary, the joint between the frame and the masonry must be opened at this point to check the insulation. In the case of a built-in vapor barrier such as foils, it must be considered beforehand to what extent this can be damaged and weighed against the effects of clarifying the cause of the mold infestation. In the case of larger defects in the frame insulation, so much water can condense between the masonry and frame that this increases the humidity of the room. The condensed water can escape at other points of the masonry on the wall and form mold (lower lying, also lower lying laterally). A renovation by introducing foam between the frame and masonry can be attempted in a cost-saving manner for owner-occupied property. In fact, a professional renovation of the frame installation with vapor barriers is necessary. In the case of massive insulation defects, it should be considered whether the structure under window sills and, if necessary, external door sills should also be examined.

Airtightness

Increasing the airtightness of the building envelope prevents the ingress of cold (and therefore usually less humid) outside air, which forces more humid air out. By means of a controlled ventilation , the humidity can be reduced with simultaneous supply of fresh air, whereby heat energy is recovered in the condensation of air humidity.

The level of airtightness is the interior plaster.

Therefore, the airtightness of a building is not changed by the insulation, but usually by the airtight connection of new, joint-free windows to the interior plaster, a measure that is often associated with thermal insulation. This correlation leads laypeople to the wrong assumption that the insulation board is the cause of a change in airtightness (see also Breathing Wall ).

Thermal insulation and economy

It is extremely difficult to make a general statement about the profitability of thermal insulation measures, as there are many influencing factors. The climatic boundary conditions, the outside and inside climate and the energetic state of the components before and after the renovation are decisive for determining the energetic saving potential. But the financial boundary conditions are also of great importance, including the actual renovation costs, loan costs and terms as well as the intended useful life. In addition to this project-specific information, general but unsteady parameters such as energy price and energy price increase as well as real interest rate developments are also important.

Due to the strong influence of uncertain boundary conditions, the amortization period of energetic measures should be specified in time periods. According to a study commissioned by the General Association of the Insulation Industry, the amortization times listed in the following table result for the heat protection measures typically carried out on a building.

| Component insulation |

Typical initial U-value [W / (m² · K)] |

Payback period [a] | |

|---|---|---|---|

| Average | Area with 95% probability |

||

|

External wall ETICS (EPS and MW) energy-related costs |

1.4 |

6th |

4 to 10 |

|

Basement ceiling from below with clothing without clothing |

1.3 1.3 |

8 6 |

6 to 13 4 to 10 |

|

Pitched roof (renovation from the outside including complete new roofing) energy-related costs |

0.9 |

10 |

6 to 16 |

|

Flat roof energy-related costs |

0.9 |

7th |

5 to 13 |

|

Top floor ceiling accessible not accessible |

0.9 0.9 |

10 3 |

6 to 15 2 to 5 |

In the case of non-transparent building parts, part of the incident solar radiation energy is reflected on the outside surface and part is converted into thermal energy . The resulting increase in temperature on the outside reduces the temperature difference between the (warm) inside and the (colder) outside of a building, so that less heat flows out of the building. Critics of thermal insulation argue that it is more energy efficient to counter the solar radiation input with the lowest possible thermal insulation resistance and instead provide a sufficiently high thermal capacity of the outer wall to store enough solar energy. There is also the opinion that the heat demand of a house can even be higher with thermal insulation than without. A survey by the Hamburg GEWOS Institute from 1995 is cited as evidence for this, but it shows considerable deficiencies, for example the failure to check the losses in the heating systems.

In a field test for the energetic renovation of residential buildings, almost 180 objects (single-family / two-family / multi-family house) were examined in which the boiler was replaced and / or the thermal insulation improved after 2006. The focus was on the question of how big the discrepancy is between the technical potential of renovation measures and the successes in practice, and which levers could be used to increase the effectiveness of renovations. With the combination of measures roof-outer wall-window, savings between 21 and 48 percent could be proven. It was noticeable that the insulation of distribution lines and fittings in the unheated area leaves much to be desired in many cases. Defects in quality assurance before, during and after the renovation are seen as the main reasons for the lack of success in the renovation. For example, after insulation measures, just 10 percent carried out heating optimization. With partly simple optimizations and improvements, an additional 25 to 30 kWh / m²a could be saved in the area of room heating and hot water preparation.

Problems and criticism

Fire protection

For fire protection and related problems with polystyrene foams, see Polystyrene # Fire behavior and thermal insulation composite system # Fire behavior .

Airtightness and forced ventilation

With increasing airtightness of the building envelope in order to avoid ventilation heat losses, sporadic manual ventilation, the existing uncontrolled exchange of air and diffusion processes are no longer sufficient to remove sufficient moisture from the building. In addition to the aspect of fresh air supply for the residents, controlled living space ventilation is essential from a certain level of thermal insulation. Since the increase in the thermal insulation standard was a continuous development, but controlled living space ventilation represented a sudden change in the previous building technology, this accompanying development step was not always carried out and is usually hardly possible if the ventilation heat losses are subsequently reduced. Occurring moisture damage - due to lack of knowledge of the interrelationships - attributed to the thermal insulation. Critics complain here that the forced ventilation of a building is an unnatural condition that was never necessary in the past. The argument is also made that diffusion-open and capillary-active building materials make an otherwise necessary forced ventilation unnecessary. Furthermore, construction errors such as leaks or holes in the frame insulation are not recognized and ventilation errors are held responsible.

Algae infestation on components in the outside climate

The better the thermal insulation, the smaller the temperature differences to the adjacent air layers, and the lower the heat storage capacity, the faster the temperature is adjusted. In the case of components whose surface temperature is close to the outside temperature during the night-time cooling phase, condensation water can occur and this promotes algae growth. Shaded external walls with high thermal insulation and low heat storage capacity of a thin external plaster on a layer of insulation are particularly prone to algae growth. According to a report by the NDR , 75% of the thermally insulated houses would be affected, and mixed algicides and fungicides would already be banned in agriculture.

Structural damage

When installing insulation materials, the fundamental building physics principle of the water vapor diffusion resistance, which decreases from the inside to the outside, must be observed. Particularly glaring structural damage occurs when the mineral wool , which is often very air-permeable , is permeated by moist room air due to leaks in the inner cladding. Mineral wool is not able, in the winter in the insulation layer condensing humidity capillary , so that complete wetting takes place dissipate under unfavorable circumstances. As a result, adjacent building materials can get wet and rot and mold can develop. In the case of poorly executed interior insulation , mineral wool can become humid even without air flow if there is insufficient ventilation for longer periods of time .

Thermal insulation in animals

The body's own thermal insulation of endothermic animals ranges from the naturally existing hair or fletching , through the fatty tissue to the fat layer of warm-blooded (endothermic) vertebrates (especially with a polar or marine lifestyle). In addition, many animals use insulating materials when building their nests. In the absence of dense hair growth as most other mammals have, to serve people of clothing from plant or synthetic fibers and animal skins to protect against heat loss (see nudity ).

See also

Individual evidence

- ^ Friedrich Tables of Construction Engineering, Ferd. Dümmlers Verlag Bonn, thermal engineering basics.

- ^ Hans-Liudger Dienel: Engineers between university and industry. Vandenhoeck & Ruprecht, 1995, ISBN 3-525-36047-9 , p. 398.

- ↑ The basement drying and drying of the walls as well as the causes of the moisture in the masonry .

- ↑ FIW Munich: Report FO-2015/02 “Economic efficiency of heat insulating measures” . April 2015.

- ↑ Sebastian Knauer: Windy business with climate protection . Spiegel Online , October 27, 2006, accessed April 10, 2013.

- ↑ Richard Haimann: Thermal insulation can drive up heating costs . Die Welt , October 8, 2012, last accessed on September 4, 2014.

- ↑ GEWOS Institute for City, Regional and Housing Research GmbH: Analysis of heating energy consumption of existing apartment buildings. Hamburg, November 1995.

- ↑ G. Hauser, A. Maas and K. Höttges: Analysis of the heating energy consumption of multi-family houses on the basis of the GEWOS survey . German construction magazine 3/97.

- ↑ Study “Effective renovation: Opportunities for climate protection - field test for the energy-efficient renovation of residential buildings” . co2online non-profit GmbH, Berlin, August 2015.

- ↑ Güven Purtul, Jenny Witte: House insulation: poisons in the facade . TV report from October 9, 2012, accessed on September 4, 2014.

- ↑ On the sense and nonsense of facade insulation . Immowelt AG website. Retrieved February 16, 2015.

Web links

- Energy saving guide for testing and modernizing residential buildings , climate seeks protection

- Brochure "Thermal insulation - speaks against it?" , Consumer Advice Center Rhineland-Palatinate - Energy Advice (PDF; 2 MB)

- U-value calculator for calculating the heat transfer coefficient, u-wert.net