Mercedes-Benz OM 470 / OM 471 / OM 472 / OM 473

| Mercedes Benz | |

|---|---|

Six-cylinder in-line OM 471 in a Mercedes-Benz Actros 1845. |

|

| 47x series (BlueEfficiency Power) | |

| Construction kit | 4 variants (OM 470–473) |

| Displacement | 10677/12809/14841/15569 cc |

| drilling | 125/132/139/139 mm |

| Hub | 145/156/163/171 mm |

| Design |

Inline six cylinder 4 valves (2 I / 2 O) |

| Valve train | 2 overhead camshafts ( DOHC ) |

| compression ratio |

17.0: 1 |

| cooling | Water cooling |

| fuel | Diesel min. 51CZ |

|

Fuel preparation |

Common rail - direct injection |

| Emission standard | EU 5, EEV, EU 6 |

| Charging |

Turbocharger with asymmetrical air supply or Turbo compound technology |

| Application area |

Commercial vehicle engine , built-in engine |

| predecessor | OM 500 series |

| Range of services | |

| OM 470 to 473 | 240-460 kW (326-625 hp) |

|

Tabular overview of the 47x series |

|

The OM 47x diesel engine family developed by Mercedes-Benz under the initially internal name HDEP (Heavy Duty Engine Platform) consists of a total of four different engines and represents the current expansion stage in the line-up of Mercedes-Benz commercial vehicle engines All of them designed as long - stroke in- line six - cylinder engines, the only differences between the individual engines are in terms of bore and stroke . Two types of engine each use a standardized construction kit with regard to important components ( pistons , connecting rods , fuel preparation , etc.). Special feature of the new engines is the soft and quiet engine running, the first and foremost by the high-pressure common rail - direct injection is achieved. In addition to acoustic advantages, the row construction offers the advantage of a high level of mechanical running smoothness (largely vibration-free) due to the very good mass balance.

Like its predecessors, the OM 47x series also follows the usual nomenclature of Mercedes-Benz engines, with the letters OM standing for oil engine ( i.e. diesel engine). The new generation of engines replaces the previous V-engines in the Mercedes-Benz Actros ( OM 501 V6 and OM 502 V8 ) as well as the six-cylinder OM 457 (h) LA of the Mercedes-Benz ( Citaro -, Tourismo - and Travego -) and Setra - (Series 400) buses and OM 460 LA , the z. B. is used in some models of the German agricultural machinery manufacturer Claas (models Jaguar and Xerion ).

Generation world engine

Since December 2007, three of the four engine series developed largely under the leadership of Stuttgart have been introduced by the US subsidiary Detroit Diesel and have been running there since then as DD13 (OM 471; presented 01/2009), DD15 (OM 472; 12/2007) and DD16 ( OM 473; 12/2009) from the tape. In March 2010, Daimler's Japanese subsidiary Mitsubishi Fuso Truck and Bus (MFTB) began converting to the 6R10 (OM 471). Production takes place in the Mannheim and Redford (USA) plants. Various components are manufactured centrally in one factory in order to achieve maximum economies of scale and then exchanged with one another. The Mercedes-Benz plant in Mannheim produces the world's camshafts, while all connecting rods are manufactured at Detroit Diesel in Redford. The engines for Mitsubishi Fuso are largely completely manufactured in Mannheim and completed in Kawasaki (Japan). Cylinder heads and cylinder crankcases are cast in the Mannheim plant, while the subsidiary Atlantis Foundries in Cape Town ( South Africa ) casts the cylinder crankcases for the North American market. In terms of construction, the German, US and Japanese variants differ in more than 200 components, including a. regarding the injection nozzles , turbocharger, control electronics and the air compressor .

The earlier use in the USA and Japan is due to the stricter emissions standards applicable there ( US EPA 10 and JP09 , the latter currently being the world's most stringent emissions standard). To date, around 70,000 OM 47x engines have been sold in the USA and Japan. Overall, the engines have covered several million test kilometers (around 50 million in total) on the road and on the engine test bench . The use in Japanese and American vehicles also made it possible to take into account the experiences of the drivers with regard to the design of the German counterparts. Compared to the previous 500 series, the stability increased by 20% to now 1.2 million kilometers (without fundamental overhaul). The maintenance intervals have now been extended to 150,000 kilometers.

The design as a global engine results in the wide-ranging use of the modern series. While the two largest engines are reserved for the new Actros long-haul truck (and in the specific designs for the USA and Japan the corresponding Freightliner , Western Star and Mitsubishi Fuso trucks), the two smaller in-line six-cylinder units are also used in various other Mercedes-Benz commercial vehicles , for example will be used in the new model series for heavy-duty distribution transport Antos , the successor to the Axor series . Following the announcement by Daimler AG that the new Citaro public service bus presented in May 2011 was already prepared for the Euro 6 standard, which will become mandatory from 2012, it has been available with the OM 936 (7.7 liter displacement) and OM 470 (10 , 7 liters). The same applies to the Travego (the touring coach from MB) and the current Setra 500 series, which includes buses, intercity buses and coaches. The OM 470 and OM 471 engines have been used in these types since mandatory Euro 6. Up to the Euro 5 standard, the OM 457 LA series (11.97 liter in-line six-cylinder with pump-line-nozzle injection) was used in the buses mentioned .

Basic construction

The basic construction of the crankshaft housing, the crankshaft , the cylinder head with four (4) vertically hanging valves per cylinder (24-valve) and the valve train with two (2) overhead camshafts ( DOHC ) are the same for all versions . For the rigid one-piece cylinder head, Mercedes-Benz relies on the gray cast iron material with vermicular graphite (MB patent), which was specially developed for the long-stroke in-line six-cylinder . This new material enables particularly high stability and rigidity. The higher strength is also necessary due to the higher ignition pressures compared to the predecessor. In favor of a higher efficiency, these are from 180 to max. 230 bar increased.

Turbocharger , crankcase ventilation and starter are mounted on the hot side of the engine, while the air compressor , engine control, fuel pumps for the high and low pressure system and the oil / coolant module with filter and coolant pump are placed on the cold side. On the front of the engine there are three poly-V belts in different levels, which are used to drive the alternator , the cooling water pump, the hydraulic fan and the air conditioning compressor . The design of the levels is configuration-specific, with the third level being available for driving optional ancillary units . On the output side of the engine is the gear drive , which drives the oil pump , the common rail high pressure pump, the optimized two-cylinder air compressor, the steering servo pump and the two overhead camshafts.

Weight problems and fuel consumption

What is striking, however, is the significantly higher weight of the new OM-47x series compared to the predecessor series OM 501 LA (11.95 liter V6) and OM 502 LA (15.93 liter V8). While the old V6 only weighs 885 kg dry weight, the 471 now weighs 1,156 kg. The larger OM 472 weighs 1,306 kg, the roughly equivalent OM 502 V8 weighs around 1,125 kg.

When asked about the weight problem, Hubertus Troska , Head of Mercedes-Benz Trucks ( Europe / Latin America ) explained that "the OM 471 [...] has huge advantages in terms of fuel consumption and reliability". The question of the use of a significantly heavier engine than the previous OM 501 V6 was therefore never asked. Reliability and consumption are essential for Troska. A comparison with competitor engines shows that the new OM 471 is definitely in the usual weight class.

The six-cylinder in-line OM 471 compared to the competition

| Manufacturer | Mercedes Benz | Scania | MAN | DAF | Volvo / Renault | Iveco | |

|---|---|---|---|---|---|---|---|

| Engine designation | OM 471 | DC 13th | DC 12 | D2676 | Paccar MX | D13C / DXi 13 | Cursor 13 |

| Cylinders / valves | Row 6/24 | ||||||

| Displacement | 12,809 cc | 12,742 cc | 11,705 cc | 12,419 cc | 12,902 cc | 12,777 cc | 12,882 cc |

| Bore × stroke | 132 × 156 mm | 130 × 160 mm | 127 × 154 mm | 126 × 166 mm | 130 × 162 mm | 131 × 158 mm | 135 × 150 mm |

|

Compression ratio (ε) |

17.0: 1 | 17.3: 1 or 18.0: 1 |

18.1: 1 | 19.0: 1 | 16.4: 1 | 17.8: 1 | 17.0: 1 |

| Fuel preparation |

X-Pulse Common Rail |

Scania XPI Common Rail |

Common rail | Common rail | Pump nozzle | Common rail | |

| Range of services | 310-375 kW (421-510 hp) |

265–353 kW (360–480 hp) |

280–309 kW (380–420 hp) |

338–397 kW (460–540 hp) |

265–375 kW (360–510 hp) |

279–397 kW (380–540 hp) |

301–412 kW (410–560 hp) |

| Torque | 2100-2500 Nm | 1850-2500 Nm | 2200-2500 Nm | 2300-2500 Nm | 1775-2500 Nm | 1900-2600 Nm | 2300-2500 Nm |

| Dry weight, DIN 70020-A |

1156 kg | 1000 kg | 980 kg | 1015 kg | 1055 kg | approx. 1050 kg | 1006 kg |

The OM 47x has already proven the lower fuel consumption mentioned by Troska. The Actros 1845 (OM 471 with 330 kW / 449 hp) with a StreamSpace driver's cab (2,500 mm wide) consumed an average of 7.6% (Euro 5) on a 10,000 km long consumption journey in commuter traffic (Record Run 2011) between Rotterdam and Stettin. Version; 25.1 liters of diesel) or 4.5% (Euro 6; 25.9 liters) less diesel fuel than its direct predecessor, the Actros 1844 MP 3 LS (L-cab) with the V6 engine OM 501 LA III (320 kW / 435 PS, consumption: 27.1 liters). Similar to the current Mercedes-Benz passenger car engines, the OM 47x series also bears the suffix BlueEfficiency Power, which refers to the favorable fuel consumption and emission control with the help of AdBlue (see section " Emission control ").

The higher weight of the new series is partly offset by the restructuring of the engine range. The largest expansion stage of the OM 471 (375 kW / 510 PS) will replace the smallest eight-cylinder in the future. The following table provides information about the versions available.

The individual engines at a glance

| Engine code: Mercedes-Benz ... |

cylinder | Displacement | Bore × stroke | Range of services | Torque | Fuel processing | Similar variants |

|---|---|---|---|---|---|---|---|

| OM 470 | Row 6 | 10,677 cc | 125 × 145 mm | 240 kW (326 hp) -315 kW (428 hp) at 1800 min -1 | 1700-2100 Nm at 1100 min -1 | Common Rail , X-Pulse Pressure Boost | MTU 6R 1100 |

| OM 471 | 12,809 cc | 132 × 156 mm | 310 kW (421 hp) -375 kW (510 hp) at 1800 min -1 | 2100-2500 Nm at 1100 min -1 | Detroit Diesel DD13, Mitsubishi Fuso 6R10, MTU 6R 1300 | ||

| OM 472 | 14,841 cc | 139 × 163 mm | 335 kW (455 hp) -448 kW (615 hp) at 1800 min -1 | 2100-2500 Nm at 1100 min -1 | Detroit Diesel DD15 | ||

| OM 473 | 15,569 cc | 139 × 171 mm | 380 kW (517 hp) -460 kW (625 hp) at 1600 min -1 | 2600-3000 Nm at 1100 min -1 | Detroit Diesel DD16, MTU 6R 1500 | ||

| For comparison: the previous series | |||||||

| OM 501 | V6 | 11,946 cc | 130 × 150 mm | 235 kW (320 hp) -350 kW (476 hp) at 1800 min -1 | 1650-2300 Nm at 1080 min -1 | Pump-line-nozzle | MTU 6V 501 |

| OM 502 | V8 | 15,928 cc | 370 kW (510 hp) -480 kW (653 hp) at 1800 min -1 | 2400-3000 Nm at 1080 min -1 | MTU 8V 502 | ||

| OM 457 (h) | Row 6 | 11,967 cc | 128 × 155 mm | 220 kW (299 hp) -335 kW (456 hp) at 1800 min -1 | 1250-2200 Nm at 1100 min -1 | HAF 6 R 12, MAN D2866 | |

| OM 460 | 12,816 cc | 128 × 166 mm | 295 kW (394 hp) -390 kW (490 hp) at 2000 min -1 | 1900-2200 Nm at 1200 min -1 | Detroit Diesel MBE 4000, MTU 6R 460, MAN D2876 | ||

The smallest engine in the new series is the OM 470 (dry weight 990 kg), which with a displacement of just under 10.7 liters covers the power range between 240 kW / 326 hp and 315 kW / 428 hp. Above this is the OM 471 with a displacement of 12.8 liters. The engine, which was presented to the public in March 2011, is available in power classes from 310 kW / 421 PS to 375 kW / 510 PS. The 14.8-liter OM 472 covers the power spectrum for which the 15.9-liter V8 of the OM 502 series was previously responsible: 400 kW / 544 hp to 448 kW / 615 hp. The largest member of the new engine family is the OM 473, a 15.6-liter engine with outputs of up to 500 kW (680 hp) for heavy-duty applications. All engines are available in Euro 6 configuration, and some variants of the OM 471 also with Euro 5 standard or EEV certification, a homologation that has not yet been legally stipulated .

Innovations

In total, various innovations are used in the OM 47x:

One of these is the assembled camshaft, which, unlike the previous OM 457/460 and OM 501/502 series, is not machined from the full material. Instead, the shafts are made hollow and the cams are then shrunk on. The process was developed around 1986 by the company Emitec / the former managing director Wolfgang Maus , but was no longer pursued because the focus was on metal catalysts. The hollow camshaft is cheaper to manufacture and a few kilograms lighter. Nevertheless, the new in-line six-cylinder units have over 200 kg more dry weight than the previous V-type six-cylinder units .

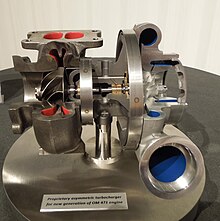

The asymmetrical turbocharger is also new. The exhaust gases from cylinders four to six are routed directly into the turbine without a detour to quickly build up the boost pressure and thus a rapid increase in power and torque. In contrast, a defined amount of exhaust gas is diverted from the exhaust gases from cylinders one to three for exhaust gas recirculation. It is used to reduce NOx emissions. Instead of the previous EGR flap, there is now an EGR flap in the exhaust manifold that has been moved far forward, well before the hot exhaust gases enter the turbocharger. As a result, the distribution can now be regulated steplessly and very precisely in the entire area of the engine map and you get effective thermal management and a generally lower EGR rate with advantages in fuel consumption.

The newly developed, asymmetrical injection ensures good regeneration of the diesel particle filter even at low loads by significantly increasing the EGR rate and thus the exhaust gas temperature of cylinders four to six. In comparison, the amount injected for the first three cylinders can be reduced to zero. The power output and fuel consumption should not be influenced by this reduction until the cylinder is deactivated, but the exhaust gas quality increases and soot particle emissions decrease. If the driver steps on the accelerator again and the load increases, the injection is automatically repeated for all cylinders.

The concept of the OM 47x also includes a three-stage supercharged decompression brake . In the first stage, only three cylinders work, while in the second stage all six cylinders act as decompression brakes. At the highest level, the turbocharger is also charged, so that the maximum braking power is up to 340 kW / 462 hp in the case of the OM 470 or 400 kW / 544 hp in the OM 471. The full braking power is available within 150 milliseconds.

Second generation OM 471

On July 3, 2015, Mercedes-Benz presented the second generation of the OM 471 series to the national and international trade press, which, thanks to a number of technical changes, uses around three percent less fuel than the first generation. With an annual mileage of 130,000 km, Mercedes-Benz speaks of around 1,100 liters of fuel savings.

The technical changes include a. the new geometry of the piston bowls, the significantly increased compression ratio from 17.3: 1 to 18.3: 1 and a reduced rate of exhaust gas recirculation (EGR). All measures lead to a further improvement in efficiency across the entire engine map.

A new air conditioning system that saves fuel, the omission of a failure-prone wastegate valve for the turbocharger and the lack of the usual boost pressure control ensure greater comfort and, at the same time, greater reliability.

In contrast to the first generation, the second is now available in five power levels between 310 kW / 421 PS and 390 kW / 530 PS. Both the maximum output and the highest torque are available almost constantly over a wide speed range in all engines of the new generation, which further improves drivability.

The new heavy-duty diesel engine OM 471 has been delivered since October 2015.

Technical design

As has long been the norm with truck engines, the OM 47x is a turbodiesel - direct injection with four-valve technology. The fuel is processed via a high-pressure injection system with multi-hole nozzles and common rail technology, which delivers a maximum pressure between 900 and 2500 bar (2nd generation OM 471 between 1160 and 2700 bar). A control of the fuel quantity adapted to the engine load ensures efficient use of the energy contained in the diesel fuel ( calorific value 45.4 MJ / kg at 25 ° C ).

The combustion process is divided into pilot , main and post-injection. A maximum of two pilot injections serve to gently increase the pressure and thus reduce the noise level. In the main injection , the pressure level and pressure build-up can be individually adjusted with the help of two solenoid valves . If necessary, post-injection enables extensive combustion of the particles or regeneration of the particle filter (by increasing the exhaust gas temperature). The active regeneration of the particle filter takes place via a separate injection valve in the exhaust port, the so-called HC Doser.

The injection pressure of the common rail system developed jointly with Robert Bosch GmbH - with pressure boosting in the injector itself - can be freely modulated and flexibly adapted to current conditions. This system, known at Mercedes-Benz as X-Pulse (designation at Bosch: APCRS (Amplifier Piston Common Rail System) and at Detroit Diesel: Amplified Common Rail System) enables the effective control of the injection quantity and timing depending on the operating state of the engine. The injection nozzle is an eight-hole nozzle (previously seven holes), which increases the maximum flow rate by around ten percent. The maximum rail pressure is 900 bar (2nd generation OM 471: 1160 bar), which results in a maximum injection pressure of 2500 bar (2700 bar).

Three different profiles are available for the purely electronic Motor Control Management (MCM): Boot (pressure increase that starts late), Square ( pressure increase that starts early) and Ramp (a mixture of both). The Profil Boot is characterized by two successive plateaus, the former being lower than the latter. With the Ramp profile , the pressure increase occurs in two phases in order to reach a specific plateau. The last profile, Square , is characterized by a rectangular pressure curve in which the plateau level is maintained longer. The MCM engine control decides, depending on the engine load and operating status, whether the pressure boost takes place early, late or not at all. In the latter case it remains at 1160 bar inlet pressure. Together with the freely formable main injection, complete control of the injection quantity and timing is guaranteed.

Further measures to reduce fuel consumption

Since the standard axle ratio in the new Actros to reduce fuel consumption is longer than before (2.611: 1, previously 2.846: 1), the three smaller versions of the OM 471 have Top Torque Electronics, which generate an additional 200 Nm of torque in the highest gear (approx 23 kW / 31 hp at 1100 min -1 is) available. Thus, the motor has the speed range from 800 min -1 and 1400 min -1 more pulling power, and the driver can drive longer top gear. In addition, the asymmetrically designed turbocharger and load-controlled auxiliary units (water and power steering pump) ensure further increased efficiency.

The engine brake is supported by a water retarder from Voith , which is attached to the rear of the transmission. This runs at roughly twice the speed of the cardan shaft and achieves up to 600 kW braking power or 3500 Nm braking torque. The secondary water retarder (BWR) uses the coolant (also for lubrication) instead of an oil filling, which absorbs the thermal energy and transfers it to the engine cooling system via a heat exchanger. The new retarder weighs around 30 kilograms less than the previous oil retarder (65 kg instead of around 100 kg).

Exhaust gas cleaning

In order to achieve the Euro 6 emissions standard, various emission reduction devices for exhaust aftertreatment are necessary. Mercedes-Benz therefore uses a combination of cooled exhaust gas recirculation (EGR), particulate filters and SCR technology ( Selective Catalytic Reduction ) to clean the exhaust gases . To reduce nitrogen oxides ( NO , NO 2 ), Daimler relies on the 32.5 percent urea solution AdBlue, which has been used since 2005 . This addition (chemical catalyst ) enables the chemical reaction to take place at lower temperatures. With Euro 5, on the other hand, Mercedes-Benz dispenses with the particulate filter and relies on a lower exhaust gas recirculation rate. This means that the Euro 5 variants require less cooling air to lower the temperature of the EGR system.

Smaller series OM 93x

One year after the introduction of the OM 471, in March 2012 Mercedes-Benz presented the new generation of four- and six-cylinder in-line engines that will power the Atego models and the solo bus versions of the Citaro series (C2). The heavy Transporter Vario will no longer receive this engine family as its production will be discontinued in the 2014 model year. In this series too, the B10 durability increased by 20 percent to 750,000 kilometers (previously 625,000 km).

These medium-weight engines of the OM 93x series have a displacement of 5.1 (four-cylinder, OM 934) or 7.7 liters (six-cylinder, OM 936) and are only available with Euro VI homologation . In the medium term, they will replace the current OM 904/924 (4.25 and 4.8 liter displacement) and OM 906/926 (6.37 and 7.2 liter displacement) series as part of the changeover to upcoming emissions standards. Like the OM 47x series, they have common rail injection, but with an injection pressure of up to 2500 bar and without X-Pulse technology. They are available in four (OM 934) or five performance levels (OM 936). The dry weight (according to DIN 70020-A) of the engines is 495 kg (four-cylinder) or 650 kg (six-cylinder) and thus, similar to the big brother OM 47x, in the standard range.

The series in comparison with competitors (Euro 6 standard)

| Manufacturer | Mercedes Benz | MAN | DAF | Iveco | Renault | Volvo / Renault | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Engine designation | OM 934 | OM 936 | D0834 | D0836 | Paccar FR | Paccar GR | Tector 4 | Tector 6 | DXi 5 | DXi 7 / D7F |

| Cylinders / valves | Row 4/16 | Row 6/24 | Row 4/16 | Row 6/24 | Row 4/16 | Row 6/24 | Row 4/16 | Row 6/24 | Row 4/16 | Row 6/24 |

| Displacement | 5,132 cm³ | 7,698 cc | 4,580 cc | 6,871 cm³ | 4,460 cc | 6,690 cc | 4,485 cc | 6,728 cm³ | 4,764 cc | 7.145 cc |

| Bore × stroke | 110 × 135 mm | 108 × 125 mm | 107 × 124 mm | 104 × 132 mm | 108 × 130 mm | |||||

| Compression ratio (ε) |

17.0: 1 | 18.0: 1 | 16.4: 1 | 17.0: 1 | ||||||

| Fuel preparation |

Common rail | |||||||||

| Range of services | 100-170 kW (136-231 hp) |

175–260 kW (238–353 hp) |

110–162 kW (150–220 hp) |

184–240 kW (250–340 hp) |

103–152 kW (140–207 hp) |

160–235 kW (220–320 hp) |

118–152 kW (160–206 hp) |

162–235 kW (220–320 hp) |

132–162 kW (180–220 hp) |

177–250 kW (240–340 hp) |

| Torque | 650-900 Nm | 1000-1400 Nm | 570-850 Nm | 1000-1250 Nm | 550-760 Nm | 800-1100 Nm | 580-750 Nm | 800-1100 Nm | 660-815 Nm | 940-1300 Nm |

| Dry weight, DIN 70020-A |

495 kg | 650 kg | 458 kg | 625 kg | 316 kg | 522 kg | 400 kg | 529 kg | no information | |

Technical differences

As a technical innovation in diesel engines , the small series has adjustable camshafts for the first time , which enables variable control of the valve times, which can also be used to regenerate the particle filter . By opening the exhaust valves earlier , hotter exhaust gases get into the exhaust tract, which burns the filter free.

The maximum output range of the new engines is between 115 kW / 156 PS and 260 kW / 354 PS. In the smaller four-cylinder engines of the OM 934 series up to 130 kW / 177 hp, Mercedes-Benz uses a single-stage turbocharger , while the two larger versions have two-stage turbocharging. For the six-cylinder OM 936 up to 220 kW / 299 hp, an asymmetrical turbocharger with two exhaust gas flows is used; the two largest expansion stages have two of these turbochargers (biturbo).

An electronically controlled wastegate valve is used in all four versions, which on the one hand limits the maximum boost pressure and on the other improves the response time of the engine when accelerating and when using the engine brake . The output of the four-cylinder OM 934 is between 145 kW (standard) and 170 kW (premium), and the six-cylinder OM 936 between 235 and 300 kW. In both cases, operation is via a steering column lever, which is two-stage in the four-cylinder engine and three-stage in the six-cylinder engine.

The engines at a glance

| Engine code: Mercedes-Benz ... |

cylinder | Displacement | Bore × stroke | Range of services | Torque | Fuel processing specialty |

Similar variants |

|---|---|---|---|---|---|---|---|

| OM 934 | Row 4 | 5,132 cm³ | 110 × 135 mm | 115 kW (156 hp) -170 kW (231 hp) at 2200 min -1 | 650-900 Nm at 1200 to 1600 min -1 | Common-Rail (max. 2500 bar), adjustable camshafts (variable valve timing) | MTU 4R 1000 |

| OM 936 | Row 6 | 7,698 cc | 175 kW (238 hp) -260 kW (354 hp) at 2200 min -1 | 1100-1400 Nm at 1200-1600 min -1 | MTU 6R 1000 | ||

| For comparison: the previous series | |||||||

| OM 904 | Row 4 | 4,249 cc | 102 × 130 mm | 95 kW (129 hp) -130 kW (177 hp) at 2200 min -1 | 500-675 Nm at 1200 to 1600 min -1 | Pump-line-nozzle | MTU 4R 904 |

| OM 924 | 4,801 cc | 106 × 136 mm | 115 kW (156 hp) -160 kW (218 hp) at 2200 min -1 | 580-810 Nm at 1200 to 1600 min -1 | MTU 4R 924 | ||

| OM 906 | Row 6 | 6,374 cc | 102 × 130 mm | 175 kW (238 hp) -210 kW (286 hp) at 2200 min -1 | 850-1120 Nm at 1200-1600 min -1 | MTU 6R 906 | |

| OM 926 | 7,201 cm³ | 106 × 136 mm | 240 kW (326 hp) at 2200 min -1 | 1300 Nm at 1200-1500 min -1 | MTU 6R 926 | ||

Modifications of the series

Natural gas engines

The six-cylinder engines OM 906 and OM 939 are also supplied as natural gas petrol engines. The data:

- M 904 LAG (6.9 l): 205 KW and 1050 Nm

- M 939 G (7.7 l): 222 KW @ 2000 min −1 and 1200 Nm @ 1200 - 1600 min −1 .

MTU engines

The new engine family is also offered by Rolls-Royce Power Systems (formerly Tognum ) under its own nomenclature: MTU 6R 1100 C (OM 470), MTU 6R 1300 C (OM 471) and MTU 6R 1500 C (OM 473). These engines are homologated according to EU Stage IV and US EPA Tier 4 final ( off-highway engines) and have been available for agricultural and construction vehicles since 2014 .

The corresponding engines of the MTU 1000 series (OM 93x) for on- and off-highway applications (drive of harvesters , harvesters and mobile forage harvesters ) will also be offered. In addition to power units for driving buses, Mercedes-Benz also offers all of the engines in the new series as built-in engines . At RRPS, these new engines are named MTU 4R 1000 C and MTU 6R 1000 C and are offered with an output of 100 kW / 136 hp or more.

Omnibus engines

The Euro 6 diesel OM 471 is also available for Mercedes-Benz and Setra buses in two versions with 350 kW / 476 hp and 375 kW / 510 hp as well as 2300 and 2500 Nm. In order to be able to install the unit in the flatter engine compartments of the buses, a special, particularly low oil pan was constructed. EvoBus (including Mercedes-Benz Buses and Setra) presented the Travego “Edition 1” as the first bus with the new Euro 6 OM 471 engine at the Busworld trade fair in Kortrijk, Belgium (October 21-26 , 2011). The Setra TopClass 500 is also equipped with this engine.

The OM 470 is available in two versions with 265 kW / 360 PS and 290 kW / 394 PS as well as 1700 and 1900 Nm for use in buses, but only in articulated buses (Citaro G, Citaro GÜ, CapaCity, CapaCity L) and im Citaro LE MÜ low-entry intercity bus (optional). There is an option of 315 or 335 kW for intercity buses and coaches . The new 7.7-liter six-cylinder in-line engine OM 936 is available in vertical and horizontal versions as a drive for city buses and most intercity buses. This unit is available with 220 kW / 299 PS and 1200 Nm as well as 260 kW / 354 PS and 1400 Nm.

Web links

swell

- Bernd Bertsche, Gisbert Lechner: "Weibull parameters of some machine elements". In this. (Ed.) Reliability in vehicle and mechanical engineering: determination of component and system reliability . Springer, Berlin / Heidelberg 2004, pp. 255-263. ISBN 978-3-540-34996-9 ; here chapter 7, doi : 10.1007 / 3-540-34996-0_7 .

- Elmar Böckenhoff: "Presentation OM 471: Innovation meets Production". PowerPoint presentation TTM Magazin NL , March 17, 2011, PDF file (accessed March 27, 2011).

- Daimler AG: "Blue Efficiency Power: The new heavy-duty engine generation from Mercedes-Benz". Media Daimler press release , March 18, 2011, HTML (accessed March 18, 2011).

- Daimler AG: "New Actros 2011: Record Run Consumption Drive". Media Daimler press release , April 30, 2011, HTML (accessed May 1, 2011).

- Daimler AG: "New Mercedes-Benz Actros". Vehicle brochure. Mercedes-Benz , July 1, 2011, page no longer available , search in web archives: PDF file (accessed on August 23, 2011).

- Daimler AG: "BlueEfficiency Power: Mercedes-Benz presents a new generation of commercial vehicle engines". Media Daimler press release , March 13, 2012, HTML (accessed March 14, 2012).

- Philipp Deppe: "Engine production OM 47x in the Mannheim plant". Mercedes-Benz Passion April 7, 2011, HTML (accessed April 9, 2011).

- Hermann Doppler: "Presentation OM 471: Innovation meets Production". PowerPoint presentation TTM Magazin NL , March 17, 2011, PDF file (accessed March 27, 2011).

- Gerald Ferreira: "The New Medium-Duty Engines from Mercedes-Benz". Car Show News March 14, 2012, HTML (accessed April 6, 2012).

- Andreas Fuchs: "New generation of heavy-duty engines from Mercedes-Benz". ATZ Online March 18, 2011, HTML (accessed March 18, 2011).

- Michael Kern et al .: "With a big chest - the Actros drives up". 24-page Actros special. lastauto omnibus 8/2011, pp. 22–45. See also the extensive Actros web special , June 21, 2011 and onwards.

- Florian Oertel: "Two new record holders". Actros Record Run. Mercedes-Benz Transport 4, pp. 12–17. Also available online. July 1, 2011, HTML (accessed July 2, 2011).

- Wolfgang Pester: "Beefy commercial vehicle engine as a clean man". VDI nachrichten , April 8, 2011, HTML (accessed March 31, 2012).

- Simon Seno: "Mercedes-Benz And The New OM 470: Available To Lease". OSV , March 15, 2012, HTML (accessed March 17, 2012).

- Tognum AG: "At Agritechnica, MTU is showing future engines for agricultural machinery". Press release (part 1). Tognum News , July 26, 2011, HTML (accessed July 26, 2011).

- Tognum AG: "At Agritechnica, MTU is showing future engines for agricultural machinery". Press release (part 2). Tognum News , November 11, 2011, HTML (accessed November 23, 2011).

- Wolfgang Tschakert: "Mercedes commercial vehicle engines: Downsizing across the board". Motorvision , March 14, 2012, HTML (accessed March 16, 2012).

- Georg Weiberg: "Presentation OM 471: Innovation on Production". Powerpoint presentation. TTM Magazin NL , March 17, 2011, PDF file (accessed March 27, 2011).

- "The big cut: New presentation of Euro 6 engines". KFZ-Anzeiger 30. Mar. HTML (accessed April 6, 2012).

- "Mercedes shows the first Euro 6 touring coach". Omnibus Revue Sept. 7 HTML (accessed September 12, 2011).

- "OM 471 engine generation in detail". Autosieger March 20, HTML (accessed March 20, 2011).

Individual evidence

- ↑ https://media.daimler.com/marsMediaSite/de/instance/ko/Das-Mercedes-Benz-Werk-Mannheim.xhtml?oid=15692840

- ↑ Further letters are placed after the series designation, for example OM 471 LA: L means charge air cooler , A stands for turbo-charging .

- ↑ The h after the series designation refers to the horizontal installation position of the engine, which is used to save space in public buses .

- ↑ a b See also Doppler, slides 2-4. As Head of Global Powertrain Operations Daimler Trucks, Doppler has been responsible for the production of the engine series since the project started in 2002.

- ↑ See also Daimler AG . 2010. "Mercedes-Benz delivers heavy truck engines to Japan". Press release. Media Daimler April 23, HTML ( Memento of the original from January 4, 2014 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (accessed on March 21, 2011).

- ↑ a b See also Pester, "Beefy commercial vehicle engine as a clean man".

- ↑ See Weiberg, slide 4.

- ↑ a b To measure the stability, the so-called B10 service life is given. If an engine meets these requirements, less than 10 percent of the continuously operated units have to be fundamentally overhauled after the specified mileage. See also Bertsche / Lechner, Reliability , Chap. 7th

- ↑ See "New distributor series: The Mercedes Antos enters the stage". EuroTransport May 10th. HTML (accessed May 11, 2012).

- ↑ See Unruh, Randolf. 2011. "Mercedes-Benz: Clear the stage for the Citaro". EuroTransport Aug. 9 HTML (accessed on August 14, 2011). Also “Mercedes-Benz Citaro: ESP for the first time in a city bus”. T-Online News Commercial Vehicles May 24th. HTML (accessed June 4, 2011).

- ↑ a b For the legal regulation and listing of the pollutant limit values see European Community . 2010. “Euro 5 and Euro 6 standards: reducing pollutant emissions from light vehicles”. Regulation (EC) No. 715/2007, summary of the legal provision. Europa EU Jan. 7 HTML (accessed March 26, 2011).

- ↑ Due to the current diversity of Citaro variants, the Citaro was initially launched with the tried and tested in-line six-cylinder OM 457 (h) LA. The new OM 470 will be submitted later.

- ↑ See also Daimler AG. 2012. "Start free for Euro VI: start of series production for the cleanest diesel-powered bus". Press release Media Daimler May 11th. HTML ( Memento of the original from February 21, 2014 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (accessed on May 11, 2012).

- ↑ See Daimler AG on this. 2012. "Forward-looking and dynamic - the new ComfortClass 500 sets standards". Press release Daimler Media May 18. HTML ( Memento of the original from May 25, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (accessed on May 19, 2012).

- ↑ See the information in the corresponding motor data sheets for the OM 501 V6 ( Memento of the original from February 22, 2014 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 365 kB), OM 502 V8 ( Memento of the original from September 2, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 295 kB), OM 457 (h) LA ( Memento of the original dated February 22, 2014 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 155 kB) and OM 460 (Detroit Diesel MBE4000) (PDF; 1.0 MB), there p. 65f. In addition: List of all OM 500 engines in the Actros (PDF; 779 kB).

- ↑ See lastauto omnibus 8/2011, p. 40.

-

↑ For the individual data, see the data sheets of the competitors:

Scania DC 13 ( Memento of the original dated November 1, 2006 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , MAN D26 CR ( Memento from November 1, 2006 in the Internet Archive ), DAF Paccar MX ( Memento from December 9, 2008 in the Internet Archive ) (PDF; 423 kB), Volvo D13C (PDF; 688 kB), Renault DXi 13 ( Memento of the original from November 2, 2012 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. and Iveco Cursor 13 (PDF; 560 kB). As a proportionate overall document: trucker 8/2011, comparative test tipper (PDF; 2.5 MB)

- ↑ With the introduction of the new Euro 6 engines, the previous 11.7-liter in-line six-cylinder will be omitted (similar in construction to the in-line five-cylinder DC 8). It is replaced in all versions by the DC-13 motor with a displacement of 12.7 liters, which, together with the in-line five-cylinder DC 9, makes use of a standardized modular system. See also Nordström, Per-Erik. 2011. "New global engine platform guarantees optimal performance for all areas of application". Press release P11X21DE, Scania Medien , 25 Oct. PDF file ( Memento of the original from 24 September 2015 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (accessed November 30, 2011)

- ↑ Volvo and Renault use identical engines for their vehicles. However, there are Volvo variants between 279 and 397 kW (380-540 hp) to choose from, while Renault only uses types between 324 and 382 kW (440-520 hp).

- ↑ The newly introduced Euro 6 version of the Cursor 13 has a common rail injection for the first time. See lastauto omnibus 8/2011, p. 6.

- ↑ Estimate based on lastauto omnibus 8/2011, p. 20: filled 1121 kg.

- ↑ See also Oertel, "Zwei neue Rekordhalter".

- ↑ On the US market, the largely identical Detroit Diesel DD13 is offered between 261 kW (350 hp) and 350 kW (470 hp). See the Detroit Diesel sales prospectus.

- ↑ See DetroitDiesel sales brochure ( PDF ( Memento of the original from April 20, 2013 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this note. ). The OM 472, initially planned for the European market, was ultimately rejected.

- ↑ The company HAF Marine Diesel in Buchholz marinates diesel engines from MAN, Mercedes-Benz and MTU for use in various types of ships.

- ↑ The DD15 Fuel System includes the Amplified Common Rail Fuel System (ACRS) ( English detroitdiesel.com). Archived from the original on June 21, 2011. Retrieved September 9, 2019.

- ↑ The MCM is a further development of the MR2 and has already been used for the OM 500 and OM 457 series.

- ↑ See Böckenhoff, slide 10.

- ↑ For the approximate conversion of the torque into mechanical power, see the corresponding article on power in physics .

- ↑ See lastauto omnibus 6/2012, p. 8.

- ↑ a b c See Ferreira, "The New Medium-Duty Engines from Mercedes-Benz".

- ↑ a b The engines used were originally developed by Deutz AG based in Cologne (model TCD 2013) and are offered in parallel as built-in engines for commercial vehicles .

- ↑ The engines used by DAF and Iveco are based on a common base engine (bore × stroke: 102 × 120 mm). This engine series was developed by Iveco in the early 1980s together with the US company Cummins (4BT and 6BT, later ISB 3.9 and ISB 5.9). After license disputes, a separate further development took place, which resulted in different values for cylinder bore and piston stroke . The new series is now being produced by Cummins as the ISB4.5E5 and ISB6.7E5 engine (with Euro 5 homologation) and used by DAF; At IVECO, the new series continues to roll off the production line as the Tector 4/6 with a larger displacement as well.

- ↑ Renault only uses engines with 270/300 HP (195/217 kW) and 1010 or 1070 Nm torque.

- ↑ a b See lastauto omnibus 6/2012, p. 38.

- ↑ See Millikin, Mike. 2012. “Mercedes-Benz introduces new engine generation for commercial vehicles; Euro VI compliant ". Green Car Congress March 13 HTML (accessed March 17, 2012).

- ↑ Mercedes-Benz Citaro NGT. Natural gas the economical alternative. In: Busmagazin.de. April 11, 2019. Retrieved May 29, 2019 .

- ↑ Engine Holding GmbH, a joint venture of Daimler AG and Rolls-Royce Group plc , has been the majority shareholder of Tognum AG (94% of the shares) since September 2011 . See also dpa. 2011. "Tognum purchase: Daimler and Rolls-Royce secure a solid majority". Handelsblatt June 24th HTML (accessed July 17, 2011).