Sieve

The sieve (from Middle High German / Old High German sip / sib , as Strain dating back to Indo seip- * "pour, strain " or as a sieve to the Germanic root sib , "seven", in relation to the drying of the West Germans) is a tool for separating or separating solid materials ( bulk goods ) according to grain size. As a result, at least two fractions are obtained, which differ significantly from one another in terms of their minimum and maximum grain sizes. In mechanical process engineering that counts seven of the classification process .

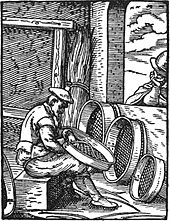

The feed material is mostly a solid mixture of different grain sizes (e.g. bulk material , heap ), but it can also be a solid mixture together with liquid. The separation takes place through the sieve bottom or sieve lining , a finer or coarser mesh , wire mesh, perforated plate or the like , depending on requirements . Braided screens made of z. B. wicker or horsehair have been known for a very long time, they were mainly used to select and clean grain , flour and the like.

Definition of terms

In the case of solid-liquid mixtures as the feed material, there are similarities between a sieve and a filter . If the aim is to separate solids (regardless of grain size) and liquids from one another, we speak of filtration. In the case of solid-liquid mixtures, however, a sieve is used to separate coarse material above a certain grain size.

Certain sieves with large openings that are used in the coarse grain area are also referred to as grates or, in some cases, as rakes.

In a figurative sense, the term sieve also describes logical processes that work with comparison operators, such as B. in mathematics the sieve of Eratosthenes for the determination of prime numbers .

In electrical engineering , sieving is the reduction of the alternating voltage component of a pulsating direct voltage . Here, low-pass filters are used, which in the simplest case consist of a capacitor . The term is often used for power supplies .

In a figurative sense, but with a derogatory meaning, one speaks of sieve processes when groups of people (e.g. schoolchildren, students, athletes, applicants) are classified in a selection process according to performance criteria .

Basic terms of screening technology

The sieve lining or sieve bottom as the actual separating medium contains a large number of openings of the same size. It consists either of metal ( perforated sheet metal , wire mesh , metal mesh or metal rods), plastic, rubber of various hardnesses or silk gauze. The size of the openings is called the mesh size and defines the screen section . In most countries the opening is defined in "mm" or "µm", in the USA however in "mesh" (number of meshes per inch , sometimes also number of openings per square inch ). The larger grain stays at the top (sieve overflow), the smaller grain falls down (sieve passage). A grain of roughly the same size is called a border grain. A sieve can consist of one or more sieve linings lying one above the other, whereby the sieve with the largest mesh size is on top of the sieve stack. The cleanliness of the screen lining is of great importance for the efficiency of a screen. In particular, the clogging of the sieve openings by boundary grain must be carried out by suitable measures (e.g. brushes, balls, chains, rubber cubes that “run” on or under the sieve or by increasing the diameter of the holes downwards, as in, for example, conical or double cylindrical holes) can be avoided.

In large-scale applications, screen linings are driven to make certain movements to improve the screening performance (screening machine). The movement of the screen lining serves to transport the feed material further in the longitudinal direction of the screen, to eject the boundary grain from the mesh openings and to ensure the sustainability of the separation ( screen efficiency ).

Applications

Sieves in steam power plants

In power plants , sieves are used to remove sponge rubber balls that are inserted into the cooling water flow of a condenser for pipe cleaning . The sieves required for this can have a nominal width of over 3000 millimeters within the pipeline and are considered fittings . They have no mesh, but longitudinal bars with a gap of five to ten millimeters. The sieve surfaces are movably mounted so that they can be rinsed from the back by turning them if they are dirty.

Papermaking

In the manufacture of paper , fibers are skimmed off from the pulp.

See also : ladle sieve , watermark , sieve cloth

laboratory

Sieves are used in laboratories to determine particle size distributions according to criteria that are as objective as possible. Such test or test sieves are in DIN set 3310 to 3310-3.

A sieve analysis is used to determine the distribution of grain sizes in a solid mixture. The result is shown graphically in a grading curve.

Sieving machines in raw material processing

Sieving machines are used to process bulk materials such as sand , gravel , coal , crushed stone , powders, color pigments , recycling materials , etc. They are predominantly excited by an oscillating movement , a distinction is made between the following types:

- Linear vibrating screening machines

- Circular vibrating screening machines

- Directly excited screening machines

- Flip shaft screening machines

- Plan vibrating screening machines

Drum screening machines and moving grids (e.g. roller grates) work according to different movement principles. A sensible technical design of a screening machine can only be made with detailed knowledge of the given conditions and the desired goals. Basically, the throughput increases with the width of the sieve and the quality of separation improves with the length of the sieve. The sieving performance is generally worsened with a high proportion of sieve passage, with a relatively low separating grain size, with higher moisture content of the feed material or with fibrous materials.

Sieving machines in the food sector

In a mill , with the help of stacks of sieves with different mesh sizes (from 125–1000 µ), the grain parts resulting from the grinding of grain are separated into intermediate ( meal ) and end products ( flour , semolina , haze and bran ). The machine used for this is called a sifter , usually a plansifter . The term plansifter is also used in the sugar industry, although it is actually a screening machine.

kitchen

In the kitchen, coarse and fine mesh screens (are straining ) for straining and strikeout (fachsprachlich both passing called) used d. H. For the rough separation of solid and liquid substances (pouring off food, pressing curd cheese , making quark ), for cleaning liquid ( broths , sauces , soups ), creamy ( purees , farces , flammeris ) or powdery substances ( flour , powdered sugar , Cocoa powder ) from foreign bodies or lumps as well as fruit that has been cooked to grind (e.g. applesauce ) and vegetables (e.g. mashed potatoes ). Sieves are also used for the preparation of certain pasta products ( spaetzle sieve , tarhonya ).

Both corrosion-free metals and plastics are used as materials. A distinction is made between the curved kitchen sieve ( Passoire ) and the pointed sieve ( Chinois ). Screens with very coarse perforation, which also often have handles and a stand or a floor plan are as a colander, strainer or with the old concept Strain referred; They are used to pour off the cooking water from pasta, potatoes, vegetables and the like. used. The strainer and hair strainer, which are mainly used for straining , are particularly fine-meshed sieves . Very small strainers are called tea strainers. A special, flat screen shape for the straining of cocktails , the bar sieve ( strainer ). Single-handed sieves are mechanical sieves for flour or powdered sugar .

The principle of the sieve is also used by some special kitchen appliances. The spice sachets or the spice ball, the tea infuser , the press ram jug ( cafetière ) and the sieve shaker (for powdered sugar or cocoa powder) should be mentioned here.

Related kitchen utensils are the straining cloth , the press sack and the filter bag , in a broader sense also various straining devices (" Flotte Lotte ", potato press ) as well as the spaetzle press and spaetzle slicer or the garlic press .

A flat Lay- splatter guard keeps liquid drops (fat splashes) back in the pan, but allows water vapor and oxygen from the air to pass.

See also

- Basic sieve : in surgery

- Molecular sieve : separation of gases, vapors or dissolved substances with certain molecular sizes.

- Stacking sieve : dividing the bulk material into several grain sizes in one operation

- Expanded metal : manufacture of screens

- Screen printing : fabric as a screen

- Plankton net : filtering small organisms out of water

- Eddy current sieve: drum sieves / sieve drums

Individual evidence

- ^ Friedrich Kluge , Alfred Götze : Etymological dictionary of the German language . 20th ed., Ed. by Walther Mitzka , De Gruyter, Berlin / New York 1967; Reprint (“21st unchanged edition”) ibid 1975, ISBN 3-11-005709-3 , p. 706 ( Sieb und sichten ²).

- ↑ Laser-drilled filter elements. on: chemietechnik.de

- ↑ Uta Löwenstein: Item ein Bettth ... Apartment and estate inventories as a source for housekeeping in the 16th century. In: Trude Ehlert (Ed.): Household and Family in the Middle Ages and Early Modern Times (Lectures at an interdisciplinary symposium from June 6th to 9th, 1990 at the Rheinische Friedrich-Wilhelms-Universität Bonn ). With a register by Ralf Nelles, Jan Thorbecke, Sigmaringen 1991, ISBN 379954156X , pp. 42–70; here: p. 58 f.

- ↑ See. In: Johann Georg Krünitz : Oekonomiſche Encyklopädie, or general system of the state = city = house = u. Agriculture