Insulation material

An insulating material is a building material that is preferably used for heat and / or sound insulation . Thermal insulation materials are materials with low thermal conductivity and reduce heat or cold losses. Soundproofing materials have a low dynamic stiffness and serve to reduce airborne or impact sound . Thermal and sound insulation materials are used in the construction industry , in plant engineering , in the manufacture of refrigerators or freezers and the like. Ä. Used.

history

The climatic conditions in the northern and southern latitudes have always forced people to deal with the subject of thermal insulation . For millennia, humans have been using the principle of low thermal conductivity in static layers of air for thermal protection. As early as the Bronze Age, reed or thatched log houses were built in wooded areas, which had good thermal insulation. It is astonishing that even the walls were built with two shells in the Bronze Age. With two mud-covered wicker walls, the space between them was filled with dry grass, excellent insulation values were achieved, which were only achieved again with the 1995 thermal insulation ordinance. Up to today's building construction measures - such as double-shell masonry - the principle of still air layers has been taken up again and again.

The use of insulation materials came into focus at the beginning of the 20th century through cold stores , which became possible with the development of refrigeration technology. Cork , glass wool and vulcanized fiber were used as the first insulation materials . The structural thermal insulation gained in importance

- through the possibility of restricting ceilings, walls and the building envelope to the statically required amount

- due to the increasing demands on living comfort and moisture protection .

Was used mainly wood wool , cork, flax fiber , tree and sheep wool , lightweight building materials on the basis of pumice or slag (metallurgy) and mineral fibers . At the beginning of the 1940s, the first synthetic (resin) foams were produced industrially. Today, insulation materials are used for a variety of renovation measures, from high-tech materials to proven classics to numerous natural insulation materials. Each material has strengths in certain areas of application.

The "DIN 4106 - Guidelines for the wall thicknesses of residential buildings and structurally similar buildings", introduced in 1937, defined the basis for the requirements for wall thicknesses according to climate zones for the first time. The first minimum requirements for thermal insulation in building construction were created in 1952 with the "DIN 4108 - guidelines for thermal insulation in building construction". Further impetus for the development and use of insulation materials came as a result of the oil crisis through the 1st Thermal Insulation Ordinance in 1977. The Energy Saving Ordinance (EnEV) now applies .

Building physical properties

The most important physical properties of insulation materials are:

Thermal conductivity

The thermal conductivity indicates the heat flow that passes through a substance with a layer thickness of 1 m at a temperature difference of 1 K. The lower the value, the better the insulating effect of the material. Air is a poor conductor of heat, which is why it is the main component of most insulation materials. The more air pockets there are in a fabric and the smaller they are, the more restricted the movement of the air molecules and the better the insulation performance of the material. In the case of thermal insulation materials in construction , the thermal conductivity group (WLG) is sometimes specified in addition to the thermal conductivity .

Dynamic stiffness

The dynamic stiffness characterizes the resilience of an insulation material. The lower the value, the better the sound-absorbing effect. Light insulation materials with a high proportion of air have an advantage here. The dynamic stiffness depends on the thickness: the thicker the insulation material, the lower the dynamic stiffness.

Bulk density

The gross density and the insulation or conductivity value of an insulation material are closely related ; in general, the following applies: the lower the gross density of the insulation material, the higher its thermal insulation value. As a rule, the bulk density is not relevant for the choice of material. For static reasons, however, this can be important in individual cases. It is often the other way around for sound insulation ; A greater bulk density is also an advantage for summer heat protection .

Water vapor diffusion resistance

The water vapor diffusion resistance indicates the extent to which the insulation material can be penetrated by water vapor . This is (in addition to its ability to absorb or reject moisture) important for the location of the insulation material. Vapor-tight constructions are necessary in areas with high vapor pressure , e.g. B. necessary in bathrooms and in the ground, while diffusion-open insulation materials in the vicinity of organic materials can help protect them. In the case of diffusion-open roofs, for example, the penetrating moisture can be released again, while with vapor-tight roofs there is a risk that the moisture will accumulate in the wooden structure and thus contribute to its destruction in the long term.

Specific heat capacity

The higher the specific heat capacity of an insulation material, the better it is suitable for keeping the heating of the interior rooms due to the sun's rays low in the summer when converting the attic (so-called "summer heat protection"). Such insulation materials also reduce the soiling of facades with ETICS through algae growth, since they cool down less strongly at night, so that less condensation forms.

capillarity

Particularly in critical applications where condensation can be expected to form in the insulation material or in adjacent layers, the capillarity of the materials plays an important role in ensuring that moisture is transported to the surface of the components for evaporation.

Many cases of damage have shown that the formation of a permanently functional vapor barrier is often not reliably possible under normal construction site conditions. In the case of interior insulation without a vapor barrier , condensation can even be assumed as planned in the wall structure. Therefore, only insulation materials that are able to conduct moisture to the wall surface in a liquid state are suitable for this purpose.

Usual insulation materials made of polystyrene (Styrofoam) and mineral fibers are not suitable, as these do not have active capillaries.

In the case of insulating materials made from renewable raw materials, sufficient capillarity can generally be assumed, provided that there is not an excessively high proportion of synthetic resin that hinders capillary transport.

Mineral insulation materials have also been developed that are suitable for interior insulation. These are usually referred to as calcium silicate , mineral foam or mineral interior insulation panels. These insulation materials differ from mineral fiber insulation materials in that they have a pore structure.

In order to achieve continuous capillarity, it must be ensured that there are no capillary-breaking layers in the wall structure . Foils or materials with excessively high synthetic resin contents must not be used. Air layers naturally also prevent capillary transport. In order to compensate for existing unevenness largely without voids, the insulation materials are usually bonded to the wall surface with mineral lime or clay mortar.

When insulating uneven wall surfaces in historical buildings, care must be taken that capillarity is not interrupted by enclosed air spaces. Usually the wall surface is first finished with a wall plaster with high permeability, such as air- lime plaster and, in particular, clay plaster . A leveling layer of plaster can be dispensed with by

- Flexible insulation panels are covered with a panel material that can be screwed to the substrate. Wood fiber insulation boards have good capillarity. They are also offered as a ready-made combination of firm and soft fiber layers, which can be pressed onto the wall surface without voids by screwing them to the substrate.

- a cavity is created by a facing shell and filled with pourable cellulose or wood fiber flakes. However, if the fill is too loose, capillarity may be too low, so that an additional vapor barrier is required on the inside of the insulation.

- fibrous material such as cellulose flakes is moistened in a special machine and blown onto the wall surface. As with the application of shotcrete , a void-free, firmly adhering, but uneven layer is created on the wall before finishing.

Capillary building materials generally have the advantage that in the event of an unplanned, local entry of moisture, e.g. through broken pipes, clogged drains or leaks in the roof skin, the liquid is quickly distributed in walls and ceilings over a large area so that it can dry off quickly. The prerequisite is, of course, that the components do not contain any blocking layers such as foils or plastic foams. Even wood-based panels lead the moisture only very slowly.

Aspects of the choice of insulation

Different insulation materials are in competition with one another, with features such as:

- Heat transmission / thermal conductivity

- Dynamic stiffness

- raw materials

- Delivery form (loose or bound insulation materials)

- price

- Heat storage capacity

- Water absorption capacity

- Water vapor diffusion resistance

- Bulk density

- Availability

- Service life and durability (stress cracks, soaking, mold, etc.)

- Environmental compatibility:

- Energy consumption or CO 2 emissions during manufacture and during transport from production to the construction site

- Release of pollutants

- Problems with the disposal of leftovers or demolition materials

- Behavior in case of fire

- Flammability

- Emission of toxic substances in case of fire

- Disposal of waste

Insulation materials have been discussed for a long time, initially technically and economically and then, if necessary, biologically and ecologically. The building materials industry is often criticized because, in the opinion of critics, it uses arguments for its own purposes that support its own product or often ignore, reject or question it if they weakened its competitive position.

Thus, the studied biology the effect of insulating materials on the indoor climate and healthy living, eg., The lung deposition of fibrous particles.

Building ecology discusses the energy balance or the ecological balance of insulation materials, i.e. how long the insulation material must be used in order to save the energy that had to be used in its manufacture.

Areas of application according to DIN 4108-10

D oh, D corner

- DAD - A ußendämmung of roof or ceiling, protected from the weather, with D eckung

- DAA - A ußendämmung of roof or ceiling, protected from the weather, with A bdichtung

- DUK - outside insulation of a U m k ehrdaches, exposed to weathering

- DZ - Z wipe rafter insulation

- DI - lower-side I nnendämmung the ceiling or roof, ceiling tiles

- DEO - inside insulation under E stroked o teeth sound insulation requirements

- DES - internal insulation below E ran S challschutzanforderungen

W and

- WAB - A ußendämmung the wall behind B ekleidung

- WAA - A ußendämmung the wall behind A bdichtung

- WAP - A ußendämmung the wall under P utz

- WZ - insulation of such weischaligen walls

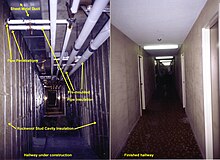

- WH - insulation of H olzrahmen- and H olztafelbauweise

- WI - I nnendämmung the wall

- WTH - insulation between H from t bulkheads

- WTR - insulation of R aum t bulkheads

P erimeter

- PW - External thermal insulation (perimeter insulation) of W alls against the ground (outside seal)

- PB - External thermal insulation under B odenplatten against the ground (outside seal)

Product property according to DIN 4108-10

D ruck load capacity

- dk - k a compressive strength, e.g. B. Between rafter insulation, cavity insulation

- dg - g eringe compressive strength, for. B. under screed in living and office areas

- dm - m edium pressure resistance, for. B. under screed, unused roof areas with waterproofing

- ie - h igh pressure resistance, for. B. Terraces, used roof areas

- ds - s ehr high compressive strength, eg. B. industrial floors, parking deck

- dx - e xtremely high pressure resistance, e.g. B. highly stressed industrial floors, parking deck

W ater absorption

- wk - k a requirement, e.g. B. Interior insulation

- wf - no deterioration in water absorption by f lüssiges water, eg. B. External insulation wall

- wd - no deterioration in water absorption by liquid water and / or D iffusion, z. B. Perimeter insulation, inverted roof

Z ugfestigkeit

- zk - k a requirement, e.g. B. cavity insulation

- zg - g eringe tensile strength, z. B. External insulation wall behind cladding

- zh - h igh tensile strength, z. B. External insulation wall under plaster

S challtechnische properties

- sk - k an acoustic requirements

- sh - h igh compressibility of z. B. 5 mm, e.g. B. House partition

- sm - m edium compressibility of z. B. 3 mm, e.g. B. Impact sound insulation under floating screed, house partition

- sg - g eringe compressibility of z. B. 2 mm, e.g. B. Impact sound insulation under floating screed, house partition

deformation

- tk - k a requirement, e.g. B. Interior insulation between stiffening profiles

- tf - dimensional stability under F euchte and temperature, eg. B. External insulation of the wall under plaster

- tl - dimensional stability under L ast and temperature, eg. B. Roof with waterproofing

Compressibility CP and dynamic stiffness SD

EN 13162 provides for four levels of compressibility from 2 to 5 mm, which are designated with CP (for compressibility ).

DIN 4108-10 assigns a payload of 5 kPa , CP3 4 kPa, CP4 3 kPa and CP5 2 kPa to level CP2 . However, the manufacturer's instructions apply if they differ from this.

For wood fiber insulation boards (WF) with the abbreviation sh un sg , DIN 4108-10 generally states a dynamic stiffness SD of 50 MN / m³.

For expanded perlite (EPB), the stiffness SD is specified as 30 MN / m³ for sm or CP3 and 50 MN / m³ for sg or CP2.

For expanded polystyrene (EPS), the abbreviations sh or CP5 as well as sm and CP3 indicate the stiffness SD as 30 MN / m³ and for sg and CP2 it is 50 MN / m³.

For mineral wool (MW) the stiffness SD is given as 25 MN / m³ for the abbreviation sh or CP5, 40 MN / m³ for sm or CP3 and 50 MN / m³ for sg or CP2.

For payloads (according to DIN 1055) over 5 kN / m², insulation materials of level CP2 are to be used, for which the creep behavior has also been tested. DIN 18560-2 makes the following specifications:

- Under floating screeds with traffic loads of 3 kN / m² surface load or 2 kN single load, insulation materials with a compressibility of 3 mm must be used,

- with heated screeds and when using artificial stone, natural stone or ceramic coverings, the compressibility of the insulation layer must not exceed 5 mm,

- In the case of mastic asphalt screed , the compressibility of the insulation layer must not exceed 3 mm,

- Even in the case of multilayer insulation layers, the overall compressibility must be within the stated values.

So far, the unit kPa has been used in DIN 18560 for payloads. The numerical value corresponds to the values specified in the unit kN, so that no conversion is required.

Common insulation materials

(Internationally used abbreviations in brackets)

- foamed plastics, mostly as rigid foam boards ; PUR and PIR also as in-situ foam

-

Polystyrene

- expanded (EPS) - polystyrene beads are mostly still recognizable; Colloquially known as Styrofoam

- extruded (XPS) - with a smooth, uniform surface; often light blue or pink; available with rebate

- Polyurethane (PUR)

- Polyisocyanurate (PIR)

- Phenolic resin (PF)

- Polyethylene

-

Polystyrene

- foamed elastomers based on neoprene rubber, EPDM or similar rubber-like base materials,

- mineral fibers such as mineral wool (MW), glass wool or high temperature wool ,

- mineral foams such as pumice , Thermosit (no longer on the market), expanded clay , expanded mica , bulking perlite (EPB), calcium silicate plates , foamed glass (see foam glass (CG), expanded glass ) or airgel plates and webs have,

- vegetable raw materials such as wood fiber (WF), wood wool (WW cement or magnesitgebunden, eg. Heraklith ,) coconut fiber , hemp fiber , flax fiber , kapok , expanded cork (ICB), cattail , reed (mats), sea or meadow grass ,

- animal fibers such as sheep's wool ,

- Recycled material such as cellulose (from waste paper ).

Depending on the material properties, these insulation materials are commercially available as panels - sometimes with tongue and groove or stepped seams - in rolled form, as sheets or mats, rigid or semi-rigid, and often also as nonwovens .

Loose insulation materials are applied loosely as bulk insulation materials, introduced into existing or specially constructed cavities as blow- in insulation materials , or sprayed onto vertical walls or ceilings when wet. Organic materials such as are commonly used styrofoam beads , cellulose and wood fiber flocks, Ceralith from rye , cork, flax or hemp shives and mineral materials, such as expanded glass , expanded clay , perlite or rock wool flakes.

Another form of application are insulation materials that are only foamed when they are applied at the construction site, such as polyurethane foam ( PU foam ). This is used on the one hand as assembly foam to fill cavities and gaps - for example when installing windows - and on the other hand as a wall insulation material in buildings and vehicles.

Vacuum insulation panels consist of insulation materials packaged in foil, which are evacuated after filling. This allows the thickness to be reduced to 10 to 20% with the same thermal resistance .

Thermal insulation materials in comparison

| Insulation material |

Gross density [kg / m³] |

Heat transfer capability λ R * [W / (m · K)] |

Price range [€ / m²] |

Emission of pollutants when in use |

Emission of pollutants along the product lifeline |

Primary energy content |

Fire behavior ** Building material class according to DIN 4102-1 |

Fire behavior ** Euroclass according to EN 13501-1 |

Temperature resistance ° C |

|---|---|---|---|---|---|---|---|---|---|

| Airgel mat 10 | 150 | 0.015-0.017 | No | No | low | A1, A2 or B | E. | ||

| Expanded glass bulk | 270-1100 | 0.040-0.060 | No | No | high | A1 | |||

| Expanded mica fill ( vermiculite ) | 70-150 | 0.070 | No | No | medium | A. | |||

| Expanded perlite fill | 90 | 0.039-0.050 | No | No | medium | A. | |||

| Expanded clay fill | 300 | 0.160 | No | No | medium | A. | |||

| Calcium silicate plate | 300 | 0.065 | No | No | ? | A1 | |||

| Flax fiber | ? | 0.040 | 34.50 15 | No | No | low | B2 | ||

| Glass foam granulate | 130-170 | 0.070-0.090 | No | ? | ? | A1 | |||

| Hemp fiber insulation board 12 | 28-100 | 0.040 | 30.00 15 | No | No | low | B2 | ||

| Wood fiber insulation board | 130-270 | 0.037-0.050 | soft 29.50 15 firm 41.00 |

No | no 1 | low? | B. | ||

| Wood wool lightweight panel | 360 | 0.090 | No | No | low | B. | |||

| Isocyanate spray foam 13 | 6.57 | 0.037 | ? | ? | ? | ? | E. | ||

| Coconut fiber mat or plate | 75-125 | 0.045 | No | No | low | B. | |||

| Cork board and granules | 120-200 | 0.045 | Granules 45.50 15 | no 3 | no 3 | low | B. | ||

| Magnesium oxide cement - in- situ foam 11 | 33 | 0.037 | No | No | ? | A1 | |||

| Mineral foam insulation board | 350 | 0.045 | No | No | medium | A1 | |||

| Mineral wool panel (glass, rock wool) | 20-200 | 0.032-0.040 | Glass wool 16.50 15 | possible 2 | yes 1 2 | medium | A. | ||

| Polyester fiber fleece | 15-30 | 0.035-0.040 | No | ? | ? | B1 | |||

| Polyisocyanurate (PIR) 17 | 40-330 | 0.023-0.026 | B2 | B-s2 d0, C-s2 d0, C-s3 d0 | -200 to 120 or 200 | ||||

| Polystyrene sheet | 15-30 | 0.030 | EPS 12.50 15 | yes 4 | yes 4 | high | B1 | ||

| Polyurethane board (PUR) 18 | 30th | 0.024-0.025 | possible 5 | yes 5 | high | B2 | B-s2 d0, C-s2 d0 | -180 to 100 | |

| Aerated concrete | 200-700 | 0.080-0.210 | No | No | ? | A1 | |||

| Resol rigid foam 9 | > 35 | 0.020-0.025 | ? | ? | ? | B1, B2 | B-s1 d0, C-s2 d0 | ||

| Cattail plate 14 | 220-320 | 0.048-0.060 | No | No | low | B. | |||

| Sheep wool felt | 20-120 | 0.040 | no 7 | no 7 | low | B. | |||

| Foam glass plate and granules | 100-165 | 0.040-0.052 | no 6 | No | medium | A1 | |||

| Reed plate | 190-225 | 0.060 | No | No | low | B. | |||

| Straw plate | 500 | 0.110 | No | No | low | B. | |||

| Straw bale 8 | 100 | 0.045 | No | No | low | B2 | |||

| Vacuum insulation board 16 | 180-210 | 0.003-0.008 | No | No | low? | B2 | E. | ||

| Pulp insulation | 35-60 | 0.040 | No | No | low | B2 | |||

| Cellulose composite element ( corrugated cardboard ) | 195 | 0.040 | No | No | low | B2 | |||

| Cellulose flakes (recycling) | 35-70 | 0.040 | Filling 10.50 Injection 17.50 15 |

No | no 1 | very low | B. | ||

| Insulation material | Gross density [kg / m³] |

Heat transfer capability λ R * [W / (m · K)] |

Price range [€ / m²] |

Emission of pollutants when in use |

Emission of pollutants along the product lifeline |

Primary energy content |

Fire behavior ** Building material class according to DIN 4102-1 |

Fire behavior ** Euroclass according to EN 13501-1 |

Temperature resistance ° C |

When comparing the costs, it should be noted that the prices of many renewable insulation materials are still falling, as this market is still developing and the supply is growing. The 2013 prices listed in the table are already significantly undercut by some providers.

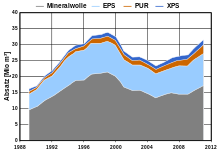

In 2016, mineral fiber insulating materials cost an average of 30% and wood fiber insulating materials 70% more than those made from polystyrene (Styrofoam). The higher material costs are clearly put into perspective when one takes into account that the costs for installing the insulation are generally a multiple of the pure material costs and that building structures are normally very durable.

The behavior in the event of fire is particularly important if flammable insulation materials are not protected from ignition by fire-resistant cladding. For example, special precautions must be taken above facade openings to prevent flames emanating from the polystyrene insulation panels of an ETICS facade catching fire. Closed roof boxes, for example, should also prevent insulating strips made of wood fibers from being ignited by a fireworks rocket.

quality

In Germany , insulation materials used to have to be manufactured in accordance with valid standards (e.g. DIN ) or in accordance with approved manufacturer regulations. Compliance with these standards or regulations and the material quality ( e.g. bulk density ) were monitored by the Federal Institute for Materials Testing or a test center commissioned by it ( quality monitoring ). Insulation materials therefore had to have a certification mark on the packaging or material ( Ü mark ).

This has changed today in the course of European harmonization and deregulation .

Some of the manufacturers have stayed with the old monitoring and now call it quality assurance ; In some cases, manufacturers' associations have published their own quality or quality criteria. Therefore, when buying insulation materials, attention should be paid to the evidence of promised properties.

Thermal and impact sound insulation under the screed

Insulation materials with the designation DEO "without noise protection requirement " and DES "with noise protection requirement " are used , alternatively also flat roof insulation panels DAA or perimeter insulation PB.

DIN 4108-10 provides insulation materials made of mineral wool (MW), expanded polystyrene hard foam (EPS), expanded perlite (EPB) and wood fibers (WF) for impact sound insulation.

When specifying the thickness of polystyrene insulation boards, manufacturers often add the degree of compressibility with a hyphen. In the group with the abbreviation sm , for example, the thicknesses 15-2, 20-2 and 25-2 (with 3 kPa payload) are available.

Insulation boards under the screed without noise protection requirements (DEO)

Example of labeling - EPS 035 DEO dh, CS (10) 150 DLT (2) 5 (former designation: PS 20 SE, WLG 035 ...)

Expanded polystyrene thermal insulation board (EPS) of the thermal conductivity group (WLG) 035 (calculated value λ = 0.035 W / (mK) with a compressive stress at 10% compression of 150 kPa and a deformation under defined pressure and temperature stress (40 kPa, 70 ° C) of 5%.

Compressive stresses at 10% compression are mostly in the range of 100 to 200 kPa. The previously used abbreviations for the density PS 20 and PS 30 corresponded to a compressive stress of 150 and 200 kPa, respectively.

Insulation boards under the screed with noise protection requirements (DES)

Example of marking - EPS 035 DES sh, SD30 CP5 (former designation: PS 20 SE, WLG 035 ...)

Expanded polystyrene thermal insulation board (EPS) of the thermal conductivity group (WLG) 035 (calculated value λ = 0.035 W / (m · K) with a dynamic stiffness of 30 MN / m³ and a compressibility of 5 mm.

The dynamic stiffness (usually 9–70 MN / m³) is decisive for determining the level of impact sound improvement in the floor structure. The lower the dynamic stiffness of the insulation layer, the better the impact sound insulation of the floating screed. Calculated values for impact sound insulation materials made of polystyrene and mineral fibers are given in supplement 1 of DIN 4109. In the case of other insulation materials, the degree of impact sound improvement must be determined by the product manufacturer by means of a suitability test or within the framework of a general building authority approval (abZ). With increased requirements (noise protection levels (SSt) II and III of VDI 4100), insulation materials with a dynamic stiffness s' of 10 MN / m³ should be used.

Industrial use

Many industrial processes take place at temperatures of up to 1800 ° C. Part of an efficient control of these energy-intensive processes is a combination of refractory products for direct contact and insulation materials for the thermal encapsulation. In addition to traditional, refractory bricks and masses ( refractory material ), a number of heat-insulating products such as lightweight refractory bricks and high-temperature wool have been developed over the last few decades .

Norms

- DIN 4108-10 Thermal insulation and energy saving in buildings - Part 10: Application-related requirements for thermal insulation materials - Factory-made thermal insulation materials .

- EN 13162 Thermal insulation products for buildings - Factory made mineral wool (MW) products - Specification .

- EN 13163 Thermal insulation products for buildings - Factory made expanded polystyrene (EPS) products - Specification .

- EN 13164 Thermal insulation products for buildings - Factory made extruded polystyrene foam (XPS) products - Specification .

- EN 13165 Thermal insulation products for buildings - Factory made rigid polyurethane foam (PU) products - Specification .

- EN 13166 Thermal insulation products for buildings - Factory made phenolic foam (PF) products - Specification .

- EN 13167 Thermal insulation products for buildings - Factory made foam glass (CG) products - Specification .

- EN 13168 Thermal insulation products for buildings - Factory made wood wool (WW) products - Specification .

- EN 13169 Thermal insulation products for buildings - Factory made expanded perlite (EPB) products - Specification .

- EN 13170 Thermal insulation products for buildings - Factory made expanded cork (ICB) products - Specification .

- EN 13171 Thermal insulation products for buildings - Factory made wood fiber (WF) products - Specification .

- EN 14064-1 Thermal insulation materials for buildings - Mineral wool (MW) thermal insulation produced at the point of use - Part 1: Specification for bulk insulation materials prior to installation .

- EN 14064-2 Thermal insulation products for buildings - Mineral wool (MW) thermal insulation produced at the point of use - Part 2: Specification for the installed products .

- ÖNORM B 6000 Factory-made insulation materials for thermal and / or sound insulation in building construction - product types, performance requirements and usage regulations .

- ÖNORM B 6001 Insulation materials produced at the point of use for thermal and / or sound insulation in building construction - product types, performance requirements and usage regulations .

See also

Web links

- Comprehensive insulation material overview from the English Wikipedia

- The coefficient of thermal conductivity λ , ChemgaPedia

- Brochure insulation materials made from renewable raw materials , Federal Ministry of Food, Agriculture and Consumer Protection and Agency for Renewable Raw Materials e. V., pdf file, accessed February 2016

- Guide to ecological insulation materials (PDF; 863 kB), NABU

- Brochure insulation materials at a glance , sanier.de

- Calculate the U-value

- Brochure Expanding and Designing with Renewable Raw Materials , Federal Ministry of Food, Agriculture and Consumer Protection and the Agency for Renewable Raw Materials e. V., PDF file, 2016

Individual evidence

- ↑ Michael Stahr, Jürgen Weber, Friedhelm Hensen, Hilmar Kolbmüller, Uwe Wild: Building renovation . Ed .: Michael Stahr. Vieweg + Teubner Verlag, Wiesbaden 2011, ISBN 978-3-8348-8144-1 , p. 629 ( limited preview in Google Book Search [accessed January 3, 2017]).

- ↑ baunetzwissen.de ( Memento of the original dated November 7, 2010 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ A. Drewer, H. Paschko, K. Paschko, M. Patschke: Thermal insulation materials: Compass for selection and application. Verlagsgesellschaft Müller, 2013, ISBN 978-3-481-03094-0 , pp. 120, 136.

- ↑ A. Drewer, H. Paschko, K. Paschko, M. Patschke: Thermal insulation materials: Compass for selection and application. Verlagsgesellschaft Müller, 2013, ISBN 978-3-481-03094-0 , p. 120.

- ↑ Brochure insulation materials made from renewable raw materials , Umweltzentrum Tübingen, undated, accessed on June 29, 2019.

- ↑ On impact sound insulation panels made of mineral fibers, it can be observed, for example, that sprayed water can be recognized as a damp stain over a longer period of time without the moisture being distributed in the material or evaporating.

- ↑ Wood fiber insulation system to level uneven surfaces , Unger-Diffutherm; accessed in November 2019.

- ↑ Article half-timbered walls with interior insulation on Heiz-Tipp.de; accessed in September 2016.

- ↑ EU Köhnke, ö.buv expert for timber house construction: The fault is always the other person - How does moisture get into a floor separating ceiling? In: The new Quadriga. 4/2012, p. 44 ff

- ↑ Matthias G. Bumann: Sorption ( Memento of the original from December 19, 2013 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. - A consideration on the subject of “moisture in the external wall component” (PDF; 965 kB). This treatise is to be read critically. Not all statements seem to be conclusively proven.

- ↑ a b Script classification and properties of insulation materials , Waermedaemstoffe.com, accessed on June 29, 2019.

- ^ Egbert Müller, Insulation layers under screeds (thermal and sound insulation) , technical information from the Federal Association of Screeds and Flooring eV, January 2011; accessed in October 2016.

- ↑ Mineral wool insulation materials - Technical Info No. 2/2004 for architects, planners and builders , Quo Vadis Fußboden eV; accessed in October 2016.

- ↑ a b Price groups on the U-Wert.net page, accessed on June 29, 2019.

- ↑ http://aerodaemmtechnik.eu/produkte/aero-ball/. Retrieved April 24, 2018 .

- ↑ Table comparison of the most important insulation materials on Waermedaemmstoffe.com, accessed on June 29, 2019.

- ↑ Pentane in expanded styrene XPS , biomess engineering office, accessed on December 31, 2017.

- ↑ Price comparison in the brochure Insulating materials made from renewable raw materials from the Fachagentur Nachwachsende Rohstoffe eV (FNR), as of 2013, accessed on June 29, 2019.

- ↑ Information in the radio program "Marketplace - thermal insulation, climate and wallet protection" from Deutschlandfunk on May 19, 2016.

- ↑ Label search. The VERBRAUCHER INITIATIVE e. V. (Federal Association), accessed on March 16, 2019 .

- ↑ a b Brochure ISOVER EPS - Standardization and labeling for insulation materials made of EPS rigid foam ( Memento of the original from March 19, 2015 in the Internet Archive ) Info: The archive link has been inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. , Saint-Gobain Rigips GmbH; accessed in October 2016.

- ↑ EPS insulation materials - Technical Info No. 1/2003 for architects, planners and builders , Quo Vadis Fußboden eV; accessed in October 2016.