DR series 41

| DR series 41 | |

|---|---|

|

41 025 in RAW Frankfurt-Nied, 1939

|

|

| Numbering: | 41001-366 |

| Number: | 366 |

| Manufacturer: | various |

| Year of construction (s): | 1937-1941 |

| Retirement: | 1971 (DB) 1986 (DR) |

| Type : | 1'D1'-h2 |

| Genre : | G 46.18 / G 46.20 |

| Gauge : | 1435 mm ( standard gauge ) |

| Length over buffers: | 23,905 mm |

| Wheelbase with tender: | 20,175 mm |

| Smallest bef. Radius: | in a curve 140 m, downhill 300 m |

| Empty mass: | 92.6 t |

| Service mass: | 101.9 t |

| Service mass with tender: | 176.1 t (with full stocks) |

| Friction mass: | 70.0 t / 78 t |

| Wheel set mass : | 19.7 t |

| Top speed: | 90 km / h forwards 50/80 * km / h backwards (* special approval) |

| Indexed performance : | 1397 kW |

| Starting tractive effort: | ~ 191 kN |

| Coupling wheel diameter: | 1600 mm |

| Driving wheel diameter: | 1600 mm |

| Impeller diameter front: | 1000 mm |

| Rear wheel diameter: | 1250 mm |

| Control type : | Heusinger |

| Number of cylinders: | 2 |

| Cylinder diameter: | 520 mm |

| Piston stroke: | 720 mm |

| Boiler : | Old boiler |

| Boiler overpressure: | 20 bar |

| Number of heating pipes: | 85 |

| Number of smoke tubes: | 20th |

| Heating pipe length: | 6800 mm |

| Grate area: | 3.89 m² |

| Radiant heating surface: | 15.90 m² |

| Tubular heating surface: | 187.25 m² |

| Superheater area : | 72.22 m² |

| Evaporation heating surface: | 203.65 m² |

| Tender: | 2'2 'T 34 |

| Water supply: | 34.0 m³ |

| Fuel supply: | 10.0 tons of coal |

| Drive: | Two-cylinder superheated steam with internal inflow |

| Brake: | Knorr type |

| Train heating: | steam |

| Speedometer: | Deuta |

| Control: | 41 001 & 41 002 Heusinger, Kuhnsche Loop, from 41 003 hanging iron |

| Particularities: | Axle mass adjustable 18 t / 20 t |

The locomotives of the class 41 were freight train - einheitsdampflokomotive the Deutsche Reichsbahn .

history

When looking for a new, fast freight locomotive, the Deutsche Reichsbahn-Gesellschaft (DRG) favored the proposal of a 1'D1'-h2 locomotive ("Mikado") submitted by Berliner Maschinenbau AG (BMAG, formerly Louis Schwartzkopff ) in 1934 . The design, largely developed by Friedrich Wilhelm Eckhardt , deviated from the DRG's original requirement for a 1'D machine. On a 1'D1 'chassis, the required performance parameters with an axle mass of 18 tonnes could be accommodated better than on a 1'D machine. In the end, sticking to the given wheel arrangement would not have meant any real advantage over the Prussian freight locomotives to be replaced. The Reichsbahn-Zentralamt Maschinenbau (RZM) finally accepted the proposal of the BMAG and commissioned the company to thoroughly design the submitted draft and to produce two prototypes.

In January 1937 the DR received the prototype locomotives 41 001 and 41 002. Intensive testing immediately followed and finally the acceptance. The two models already impressed with their performance, smoothness and exceptional acceleration.

In the development of the 41 series, the principle of standard locomotives also demonstrated the financial advantages of standardization. The construction costs of the machine were less than 10,000 Reichsmarks due to the use of assemblies from the 03 , 06 and 45 series , which were developed at the same time .

The Deutsche Reichsbahn-Gesellschaft, which was converted into the state-owned Deutsche Reichsbahn (DR) in February 1937 , commissioned the first series 41 locomotives from October 1938. All well-known German locomotive manufacturers such as BMAG , Borsig , Maschinenfabrik Esslingen , Henschel & Sohn , Arnold Jung Lokomotivfabrik , Krauss-Maffei , Krupp , Orenstein & Koppel and Schichau were involved in the production of the locomotive .

In contrast to the prototype locomotives, the standard locomotives did not use the angle valve pressure equalizers and used Nicolai (later " Karl-Schultz-Schieber ") pressure equalizing piston valves for better idling . In terms of control , a normal hanging iron control replaced the more expensive Kuhn loop of the model.

Similar to the 03, 45 and 50 series, the 20-bar boilers made from the steel grade St 47 K , which is not sufficiently resistant to aging, caused considerable problems due to cracking after a short time. Interestingly, however, according to statistics from the DR from August 31, 1941, the damage in this series varied depending on the manufacturer. For example, 78% of the machines manufactured by Krauss-Maffei showed damage, whereas the slightly larger construction lots from Orenstein & Koppel and BMAG did not. Due to the formation of cracks and boiler bangs (e.g. at 50 185), the DR ordered the lowering of the permissible operating pressure of all boilers made of St 47 K to 16 bar on August 21, 1941 . This initially slowed down the boiler wear and tear. At the same time, the procurement of replacement boilers made of the material St 34 began. In order to enable a boiler pressure of 20 bar due to its different strength properties, the boiler plate thickness was increased from 20 to 22 millimeters. Despite the design for 20 bar, the replacement boilers, the order of which was discontinued in 1943 in view of new welding processes for repairs, were also only accepted for a pressure of 16 bar.

The axle drive mass of the locomotive could be changed between 18 tons and 20 tons by repositioning bolts in the compensating levers . This should make the locomotive more flexible. However, hardly any use was made of this option. The Deutsche Bundesbahn and also the Deutsche Reichsbahn in the GDR later had the bolts set at 18 tons.

With the exception of the prototype locomotives equipped with the 2'2'T32 tender, the locomotives were coupled with type 2'2'T34 tenders. However, machines are also known that were on the move with type 2'2T30 tenders because of the use of 20-meter turntables .

Due to the war, the acceptance of fast freight locomotives increasingly stagnated, until in January 1941 the orders that had already been placed were completely canceled. On June 2, 1941, the MF Esslingen, 41 352, delivered the last locomotive of this series to the DR. Thus, in a period of almost four years, 366 units of this locomotive series were produced.

A modern peculiarity is an increase in speed when reversing (tender ahead) of some operational museum locomotives by means of suitable technical upgrading and a resulting extended operating license from the Federal Railway Authority . This was necessary because suitable turning options (turntables or track triangles) on the modern railway due to closure of the plants are missing. Equipped with special approval and technical upgrade, these locomotives can now transport passenger trains at speeds of up to 80 km / h when reversing.

Whereabouts

After the Second World War, 216 machines remained with the Deutsche Bundesbahn and 122 with the Deutsche Reichsbahn . There is also evidence that 22 locomotives from the holdings of the former Reichsbahndirektion Wroclaw remained in Poland and were later operated by the Polish State Railways (PKP) as Ot 1-1 to Ot 1-19. 41 153 was listed on the Czechoslovak State Railways (ČSD) after 1945 . 41 034 and other locomotives (41 076, 41 082 and 41 312) from locomotive columns ( reparation payments ) that were later given to the PKP remained in the area of the Soviet State Railways ( SZD ) . The fate of other locomotives is not known.

The use of the two prototype locomotives in the Schneidemühl Pbf (today Piła) depot in front of fast-moving cattle trains to Berlin gave these machines the rather incongruous nickname ox locomotive .

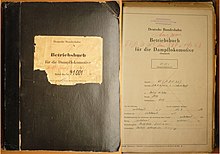

None of the locomotives with old boilers have been preserved for posterity. Small relics such as license plates or company books are therefore rare and are popular with enthusiasts.

Reconstruction of the DB

| DB class 41 | |

|---|---|

|

41 241 in Essen Central Station

|

|

| Number: | 107 |

| Year of construction (s): | 1957–1961 (conversion) |

| Retirement: | 1977 |

| Service mass: | 101.5 t |

| Service mass with tender: | 175.7 t (with full stocks) |

| Friction mass: | 74.5 t |

| Wheel set mass : | 20.2 t |

| Indexed performance : | 1,427 kW (coal) / 1,453 kW (oil) |

| Starting tractive effort: | ~ 153 kN |

| Boiler : | New boiler DB |

| Boiler overpressure: | 16 bar |

| Number of heating pipes: | 80 |

| Number of smoke tubes: | 42 |

| Heating pipe length: | 5200 mm |

| Grate area: | 3.87 m² |

| Radiant heating surface: | 21.22 m² |

| Tubular heating surface: | 156.32 m² |

| Superheater area : | 95.77 m² |

| Evaporation heating surface: | 177.54 m² |

| Fuel supply: | 12 m³ of oil |

| only data that differ from the standard locomotive | |

Since the boilers of the vehicles increasingly suffered from material fatigue, they began to be repaired in the 1950s. Between 1957 and 1961, 107 vehicles were fitted with completely welded combustion chamber boilers, as they were also installed in the 03.10 series . The new boiler produced 13.32 tonnes of steam per hour at nominal load, whereas the original boiler only produced 11.58 tonnes. In addition, the front area of the frame and the circulation were changed. 40 copies were also converted to main oil firing (fuel heavy oil ). As it turned out during the test drives that with the oil firing in view of the heat resistance of the superheated steam oils used to lubricate the steam cylinders of around 420 ° C harmful steam temperatures of up to 480 ° C were reached, the steam collecting box was equipped with a spraying device for hot water. This device, to be operated by the engine driver, made it possible to reduce the steam temperatures to a tolerable level by spraying water into the superheated steam.

The series 41 with oil firing was assigned to the Osnabrück Hbf and Kirchweyhe railway depots. They were used in freight, express, passenger and express train services, mainly on the Hamburg – Ruhr area. In 1968 they all came to the Rheine depot and from then on were run as the 042 series. The coal-fired locomotives that were still in existence were designated as the 041 series from 1968 onwards, but were no longer in operation until 1971.

They pulled the heavy freight and ore trains on the Emsland route until they were electrified. This made them one of the last scheduled steam locomotives of the DB. The last steam locomotive of the 042 series, the 042 113, was taken out of service in the Rheine depot in autumn 1977.

Whereabouts

- The former DB locomotives 41 105 and 41 241 have been retained as representatives of their series at Stoom Stichting Nederland in the Netherlands .

- The operational 41 018 of the Munich steam locomotive company is stationed in the Augsburg railway park .

- 41 096 is kept operational by the steam locomotive community of the same name in Klein Mahner in the condition at the time of delivery with a new boiler. * 41 113 is on display in the Technikmuseum Sinsheim .

- The Osnabrück steam locomotive friends receive 41 052, which was a technical monument in Osnabrück- Schinkel for a long time .

- 41 271 (042 271-7) belongs to the Rendsburger Eisenbahnfreunde e. V. and is based in the former Neumünster depot.

- The 41 360 was operated by the Oberhausen steam locomotive tradition .

- The 41 024 is being kept in the Darmstadt-Kranichstein Railway Museum as a rollable exhibit.

- 41 226 (DB-ÖL) is in a complete condition in the locomotive shed in Tuttlingen.

- 41 073 (DB-Öl) is located in the Heilbronn Railway Museum after moving from Haltingen.

Class 41 of the Deutsche Reichsbahn and Rekolok DR

| DR series 41 (Rekolok) | |

|---|---|

|

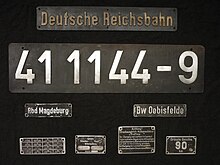

41 1144-9 of the IPI "Werrabahn Eisenach eV"

|

|

| Number: | 80 |

| Manufacturer: | Raw Zwickau Raw Karl-Marx-Stadt |

| Year of construction (s): | 1959–1960 (conversion) |

| Retirement: | 1988 |

| Empty mass: | 92.3 t |

| Service mass: | 101.5 t |

| Wheel set mass : | 18.2 t |

| Indexed performance : | 1,434 kW / 1950 PSi |

| Starting tractive effort: | ~ 153 kN |

| Boiler : | 39E |

| Boiler overpressure: | 16 bar |

| Number of heating pipes: | 112 |

| Number of smoke tubes: | 36 |

| Heating pipe length: | 5700 mm |

| Grate area: | 4.23 m² |

| Radiant heating surface: | 21.3 m² |

| Tubular heating surface: | 185.0 m² |

| Superheater area : | 83.80 m² |

| Evaporation heating surface: | 206.30 m² |

| Tender: | 2'2'T34 or 2'2'T32 |

| Service weight of the tender: | 178.6 t |

| only data that differ from the standard locomotive | |

The Deutsche Reichsbahn also had difficulties with the St 47 K boilers . The lowering of the boiler pressure from 20 to 16 bar had slowed down the susceptibility to damage, but could not stop it. Of the 112 locomotives listed in the DR's collection in 1955, only 12 were already equipped with a St-34 replacement boiler "Type 1943" and were therefore "harmless". The problems with the St-47-K boilers increased massively. Repair welds did not lead to the desired success, but rather embrittled the material even more, and the risk of cracking and boiler cracking was greater than ever.

In addition to the 41 series, the 03 , 03.10 and sometimes 50 series with boilers made of non-aging-resistant St 47 K were also susceptible to damage. Due to increasing difficulties, the DR had to park over 300 locomotives in 1956, which suddenly led to an enormous locomotive bottleneck. The suddenly existing need for action finally led to the development and subsequent ordering of a new boiler (later referred to as "39E"), which could also be used for the 03, 03.10 and 39 series with minor changes.

Because the delivery of the ordered new boilers was delayed again and again, by January 1959 21 class 41 locomotives had been equipped with replica boilers that were made according to the old drawing sets. Raw Meiningen also produced a complete replica boiler for 41 075. Other boilers susceptible to damage were completely repaired and largely replaced.

Regardless of this, the DR engineers worked on a “reconstruction program to restore the steam locomotive park”. This included the modernization of 102 class 41 locomotives. As a result of disputes over competence, disagreements about detailed questions of the reconstruction program and the still missing recoilers , the start of the work was delayed again and again. It was not until the St-47-K boiler crashed on 03 1046 (1958) in Wünsdorf , under pressure from the then Minister of Transport, Erwin Kramer (1902–1979), that the recoprogram finally began.

By 1959, 80 class 41 locomotives in the Reichsbahn repair works (Raw) in Zwickau and Karl-Marx-Stadt were to receive the new type 39E reco boiler. During the reconstruction, mixing preheaters of the IfS / DR type, Trofimoff pressure equalizing piston valves and new Stühren type ash boxes were installed. The wider rear boiler required new cab front walls, the front windows of which were equipped with transparent devices. A new bellhousing had to be designed and installed for the larger and heavier VMP 15-20 compound mixing pump. This and the new mixing preheater required a changed arrangement of the main air tanks. The cylinders originally designed for 20 bar boiler pressure with a diameter of only 520 mm were retained. As part of the work, the brake system of the front wheelset was also omitted.

The type 39E Reco boiler used is, like the DB new boiler, a combustion chamber boiler , but has a considerably higher steam output of 15 t / h due to the larger grate and heating surface with a favorable ratio of radiant to tubular heating surface. Equipped with this tank, the machines even exceeded the performance parameters that they originally had with 20-bar tanks, despite the small cylinders.

The machines converted in this way are considered to be Reko locomotives . In contrast to other series, the series 41 was not given a sub-series designation during the reconstruction in order to be able to differentiate between reconstructed and non-reconstructed machines. When switching to EDP numbers to identify the grate firing, the DR assigned all class 41 locomotives to a 1 in the thousands, so that, for example, B. 41 122 became 41 1122-5.

Class 41 Recolokomotives could be observed in scheduled train service until 1988. The 1979/80 oil crisis and its effects on the economy of the GDR brought a number of series 41 machines a brief return to service. Even some locomotives intended for dismantling were reconditioned and given a new general inspection . In total, the Meiningen raw material refurbished 23 locomotives of this series between 1980 and 1983. But at the end of September 1984, the Oebisfelde depot ended the 41 series and handed over its locomotives to the Güsten depot . During next the operation site Göschwitz of railway operations work Saalfeld the Series 41 sent in November 1986 to the siding, until early retired May 1988 41 1231-4 the work site Staßfurt (Bw Güsten) the last 41 in the regular service of the DR.

The class 41 was the most versatile steam locomotive in the rail vehicle fleet of the Deutsche Reichsbahn and, in addition to freight and passenger trains, also carried high-quality express and express trains.

The traditional locomotive of the Deutsche Reichsbahn was the 41 1185-2 (now DB Museum Halle (Saale) ).

Preserved copies

Currently are

- 41 1144-9, IGE “Werrabahn Eisenach” eV (Eisenach); operational in use,

- 41 1150-6, Bavarian Railway Museum (Nördlingen), operational (HU expired)

- 41 052, Osnabrücker Dampflokfreunde eV (Osnabrück); currently in processing,

- 41 096, steam locomotive community 41 096 ( Klein Mahner ); HU expired,

- 41 105, Stoom Stichting Nederland SSN (Rotterdam),

- 41 241, Veluwsche Stoomtrein Maatschappij VSM (Beekbergen),

- 41 271, Rendsburger Eisenbahnfreunde e. V. (Neumünster),

- 41 360, community of owners (Oberhausen); not accessible, HU expired, canceled due to bankruptcy,

- 41 1231-4, traditional depot Staßfurt ,

- 41 024, Railway Museum Darmstadt-Kranichstein ,

- 41 018, Dampflokgesellschaft München eV, location Bahnpark Augsburg (operational)

- 41 226 Tuttlingen Railway Museum

- 41 364 Owner BayernBahn GmbH , loan to the Bavarian Railway Museum (Nördlingen)

- 41 073 EBM Heilbronn

- 41 186 EBM Dieringhausen

- 41 113 Sinsheim Museum of Technology

Received worthy of exhibition. Three examples of this steam freight locomotive are currently operational. Another eight Recolokomotives are available in different states (list) .

Video

Web links

- Literature from and about DR series 41 in the catalog of the German National Library

- Information on the surviving class 41 locomotives on the "Railway Museum Vehicles" website

Individual evidence

- ^ Peter Konzelmann: The Class 41 (German Steam Locomotives, Volume 7). Eisenbahn-Kurier Verlag, Freiburg 1977, ISBN 3-88255-141-0 , p. 29 f.

- ^ Peter Konzelmann: The Class 41 (German Steam Locomotives, Volume 7). Eisenbahn-Kurier Verlag, Freiburg 1977, ISBN 3-88255-141-0 , p. 35.

- ^ Peter Konzelmann: The Class 41 (German Steam Locomotives, Volume 7). Eisenbahn-Kurier Verlag, Freiburg 1977, ISBN 3-88255-141-0 , p. 36.

- ↑ Kjell Sonnemann: 440 passengers take the steam locomotive through the region for the last time. in: Salzgitter-Zeitung, March 27, 2018