compact disc

| Storage medium Compact Disc (CD)

|

|

|

|

| General | |

|---|---|

| Type | Optical storage medium |

| capacity | 74 min audio or 650 MB data (standardized) up to 100 min audio or 900 MB data (non- standardized ) |

| size | ⌀ 12 cm or 8 cm |

| Reading speed |

176 kB / s (CD-DA) 150 kB / s (1 ×) 10800 kB / s (72 ×) |

| Writing speed |

150 kB / s (1 ×) 8400 kB / s (56 ×) |

| use | Data storage ( CD-ROM ), audio CD , video CD |

| origin | |

| idea | 1981 (radio exhibition in Berlin ) |

| Launch | 1982 |

| predecessor | Floppy disk , vinyl record , compact cassette |

| successor | DVD , SA-CD |

The Compact Disc (short CD , English for compact disc ) is an optical storage , the beginning of the 1980s to the digital storage of music from Philips / Polygram and Sony was introduced and the record was intended to replace. From the late 1990s to the early 2010s, the compact disc was one of the most widely used audio carriers. Later, however, it was increasingly replaced by music streaming services . Initially, the compact disc was only used for digital audio data. This is why it is often referred to as a synonym for Compact Disc Digital Audio (CD-DA). Later, however, other uses were added, such as for storing data as CD-ROM , for videos as VCD or for interactive data as CD-i . As a recordable CD-R , it replaced the compact cassette as the preferred audio recording medium in the private sector at the end of the 1990s , but was largely supplanted by MP3 technology in the 2000s .

When CD-ROM was introduced in the early 1990s, “CD” still stood for audio CD and “CD-ROM” for data CD, but a decade later at the latest, “compact disc” alias “CD” can be used as a synonym for all types understood by CDs - the distinction is made by the exact designation of the medium (CD-ROM, CD-R, CD-RW) and the data contained on it (audio, data, video, interactive).

history

Manufacturing

CDs are made of polycarbonate and a thin metal layer (e.g. aluminum vapor deposition) with protective varnish and printing inks. In contrast to records, they are not pressed, but rather molded onto the father die in injection molding machines. The systems for the production of optical data carriers are still called press shops .

functionality

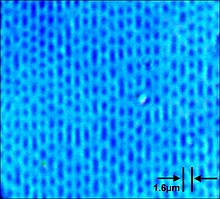

The information on the CD, the so-called "program", is arranged on a spiral track that runs outwards; they occupy a maximum of 85% of the total CD area. The program area reflects light with clear color phenomena due to its microstructure, the pits. The length and spacing of these small depressions form a serial digital code that represents the stored information. A maximum of 99 music tracks can be stored on an audio CD; each disc has a table of contents (TOC) and a time code stored in the information. Text overlays and further information can optionally be applied. The CD is scanned contactlessly from the reflective underside using a laser interference detector that tracks the track. The speed at which the data is read in depends on the speed of the CD; this is traditionally regulated so that a specified data rate is adhered to. The data track has a constant web speed (engl. Constant linear velocity, CLV ). This results in a throttling of the speed when the scanning system moves outwards. In the case of processes similar to the analog record, however, one speaks of constant angular velocity (CAV).

| Technical specifications | Cross section of a compact disc with a laser beam path |

|---|---|

|

Wavelength : 780 nm (vacuum) 503 nm (in the CD with refractive index 1.55) Numerical aperture : 0.45 Diameter of the laser spot: 2.1 μm Track spacing: 1.6 μm |

|

Structure of a CD

| feature | CD: punched | hole | "CD without a hole" |

|---|---|---|---|

| radius | 60 mm | 7.5 mm | like CD, perforated |

| diameter | 120 mm | 15 mm | |

| scope | 377 mm | 47.12 mm | |

| Edge height | 1.2 mm | 1.2 mm | |

| surface | 111.33 cm² | 1.77 cm² | 113.10 cm² |

| volume | 13.360 cc | 0.212 cc | 13.572 cc |

| Dimensions | 15.9 g | - | 16.2 g |

In the case of a CD, data is stored with the help of a spiral track running from the inside to the outside (i.e. the opposite of that on a vinyl record). The spiral track consists of pits (pits) and lands (surfaces) that are applied to the polycarbonate . The pits have a length of 0.833 to 3.054 µm and a width of 0.5 µm. The spiral track is about six kilometers long . The pits are created depending on how the CD is created. In industrial production, a glass master is first produced photochemically and then one or more stampers (negative) are produced using galvanic means. A polycarbonate pane is then embossed in a press shop using a spraying process and the reflective and protective layer is added.

A CD is therefore largely made of polycarbonate. The reflective layer above it consists of an aluminum layer vapor-deposited in a vacuum.

Between the imprint (graphics and text) and the aluminum layer (thickness of the reflective layer: 50 to 100 nm ) there is a protective lacquer layer to protect the aluminum from external influences. The finish is the imprint, which is applied using the screen printing process (up to six colors). Alternatively, the offset printing process can also be used here.

Data rate of a CD

| Speed factor | Data rate | Speed factor | Data rate | |

|---|---|---|---|---|

| CD digital audio | 176 kB / s | |||

| 1-way | 154 kB / s | 16-fold | 2.46 MB / s | |

| 2-way | 307 kB / s | 24-fold | 3.69 MB / s | |

| 4-way | 614 kB / s | 32-fold | 4.92 MB / s | |

| 8-fold | 1.23 MB / s | 52 times | 7.99 MB / s |

When decoded, the data stream of an audio CD has a data transfer rate of 176.4 kB / s. With conventional data CDs, the block size is smaller than with audio CDs (2048 instead of 2352 bytes) due to a further error correction level ; This results in a data transfer rate of 153.6 kB / s with the same block rate (75 per second). This data transfer rate is known as simple speed . The speed specifications for CD-ROM drives are multiples of this data transfer rate; See also the table on the right: Data transfer rates for CD drives.

Due to the additional error correction level, data CDs can be read at higher data transfer rates depending on the drive used, so that many drives only achieve their specified speed with data CDs, whereas audio CDs work more slowly.

CD-RW (Compact disc rewritable)

In principle, a CD-RW medium has the same layers as a CD-R medium. However, the reflective layer is a silver-indium-antimony-tellurium alloy, which in its original state has a polycrystalline structure and reflective properties. When writing, the writing beam uses its maximum power and heats the material selectively to 500 to 700 ° C. This leads to a liquefaction of the material. In this state, the alloy loses its polycrystalline structure, becomes amorphous, and loses its reflectivity. The polycrystalline state of the data carrier forms the trenches, the amorphous state the bumps. The scanning signal during reading is not created by extinction or amplification of the laser light by superimposing the reflected light with the emitted light, as is the case with pressed CDs ( interference ), but, as with recordable CDs, by given or not given (or weaker) reflection of the laser beam. To erase the data carrier, the write beam heats the - only metastable - amorphous areas with low power to around 200 ° C. The alloy is not liquefied, but returns to the polycrystalline state and thus becomes reflective again.

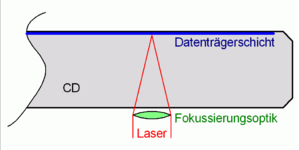

Reading process

A CD is scanned using a laser diode (wavelength 780 nm), with the CD being read from below. The laser beam is reflected on the CD and bundled with a semitransparent mirror in an arrangement of several photodiodes . The photodiodes register fluctuations in brightness. The fluctuations in brightness are partly due to destructive interference between the laser beam and itself: the focus of the laser beam is around two to three times the width of a pit. If a pit is being read out, the laser beam is partly reflected from the pit and partly from the surrounding land . Then two partial waves come back that have a slightly different route. The difference in height between pit and land is chosen so that the transit time difference is about half a wavelength (see also section " Functionality "), so that the intensity of the reflected light decreases due to destructive interference. In addition, at the will pit some of the light scattered off at the edges. The photodiodes thus register a reduced brightness on the pits . Since the CDs are pressed from the top, the pits (depressions) can be seen as hills from the bottom.

By means of a special light guidance on the photodiodes, for example through an astigmat on a square arrangement of four photodiodes, in addition to the useful signal (sum of all signals), manipulated variables for the track guidance and the focus (correct distance between CD and reading optics ) be determined.

The optics with the laser move from the inside to the outside when playing from the first to the last track - in contrast to the record . In addition, the CD does not have a fixed angular velocity (number of revolutions); this is adapted to the current position of the read head so that the path speed (CLV) and not, as with the record, the angular speed (CAV) is constant. If the reading head reads further out on the CD, the CD will rotate more slowly. In this way, you can work with full recording density anywhere on the CD, and a constant data stream is guaranteed, as is required for audio CDs. In the Red Book two different speeds are set, 1.2 m / s and 1.4 m / s. This means that playing times of 74:41 minutes or 64:01 minutes, with maximum utilization of all tolerances, 80:29 minutes are possible. This corresponds to a speed of rotation of over 500 min −1 at the beginning of the CD (inner tracks at 1.4 m / s) to less than 200 min −1 at the outer edge of the CD at 1.2 m / s. The speed of rotation is regulated by a control circuit based on the fill level of a FIFO buffer . Therefore, there is no need to switch (neither manually nor automatically) depending on the linear speed used. Thanks to the buffer mentioned, fluctuations in the speed do not affect the playback speed.

On the other hand, many modern CD-ROM drives with a read speed of around 32x or more read data CDs at a constant rotational speed in order to avoid the time-consuming acceleration and deceleration of the CD when jumping back and forth in the reading position (due to the necessary random access ). As a result, the data rate on data CDs depends on the position of the read head, i.e. ultimately the position on the CD. The speed indicated on the packaging is usually the maximum, not the average.

Due to the mechanical strength of the CD, there are limits to increasing the reading speed by increasing the speed of rotation. So-called "52-fold" drives rotate the CD with up to 10,000 min -1 . At these speeds, even the smallest imbalances in the CD lead to strong vibrations, which on the one hand are clearly audible and on the other hand can damage both the drive and the medium in the long run.

Data encoding

In order to record the user data on the CD, they must be encoded with a suitable channel coding (more precisely: line coding ), which must take into account the characteristics of the storage medium (in this case the optical scanning and the shape and size of the pits). With the CD this is the so-called eight-to-fourteen modulation (EFM). If the CD rotates at the correct speed, the data come from the optical scanner with a data rate of a good 4.3 Mbit / s, corresponding to a bit duration of approx. 231 ns. The EFM ensures that the polarity of the read out signal changes every three to eleven bit durations, i.e. two to ten 0s follow after a 1. This happens when the laser passes a transition from a recess (pit) to a section without a recess (land) or vice versa. The background to this is as follows: The sections with pits or without pits must be long enough for the laser to recognize the change. If a bit pattern were to be written directly to the data carrier, incorrect values would be read out with an alternating signal (1010101010101010 ...), as the laser could not reliably read the transition from 1 to 0 or from 0 to 1 or not even in the the necessary fineness could be 'pressed' into plastic. The EFM thus enables the high data rate. That sounds contradicting at first, as it expands the signal from eight to 14 bits, i.e. increases the amount of data mathematically. In addition, there are three more filler bits that are selected so that the above-mentioned requirement that the polarity changes every three to eleven bit durations is also met between the 14-bit symbols. But through this modulation, the data rate can be selected so high that unmodulated data can no longer be resolved into pits and land ; A pit cannot be shorter than its width (600 nm), but the length can still vary in fractions of its own width (approx. 278 nm at 1.2 m / s) - this fact is exploited by the coding. It is therefore a design decision that is responsible (among other things) for the playing time. The coding also ensures that the signal from the photodiodes does not contain any direct component ; this significantly simplifies signal processing.

Error correction and error concealment

So that scratches and production errors do not have a negative effect on the readability of the data, the data is secured using Reed-Solomon error correction so that bit errors can be recognized and corrected. Furthermore, successive data bytes are distributed over a greater length by interleaving . The Cross Interleaved Reed-Solomon Code (CIRC) is able to correct errors of up to 3500 bits (this corresponds to a track length of about 2.4 mm) and errors of up to 12000 bits (about 8.5 mm track length) on the audio CD . In the case of masking, the error is not corrected, but an attempt is made to make it inaudible, for example by means of interpolation . If the underside of the data carrier is very badly scratched, it can only be read to a limited extent or no longer.

A distinction is made between C1 and C2 errors. C1 errors indicate singular individual errors (e.g. small scratches), C2 larger block errors which could no longer be corrected by the first correction stage. Type C1 errors can only be reported by a few drives, for example those based on Plextor or Lite-On with special software ( Cdrtools , Plextools, k-probe, Nero DiscSpeed and QPxTool ). C2 errors can be determined by most drives, and there is software for so-called C2 scans, for example readcd , Nero CD-Speed or CD-Doctor .

Information that can be derived from C1 or C2 errors provides information about the condition of the optical data carrier (influenced by aging, scratches, etc.), about the basic reading or burning quality of an optical drive as a function of the speed (e.g. about C2 statistics of many media) and about the quality of freshly burned media for long-term data storage (large C1 / C2 values after burning indicate only limited long-term data security). One problem is that the causes of the error are difficult or impossible to separate. For example, a blank type that achieves poor results with a specific burner can still achieve good results with another burner type. In addition, the C2 information can be used to infer the quality with which audio data was read from CD when transferring audio material to a computer . This means that critical points can be read again if necessary or, conversely, reading can be restricted to the critical points.

When interpreting for media, new CDs should have a maximum of 250 C1 errors per second and no C2 errors. A frequent occurrence of C2 errors can be an indicator of a progressive aging of the medium. We recommend copying to a new medium for data backup. Such a data backup should also be carried out immediately after the purchase of media that are equipped with a 'copy protection' mechanism (“ Un-CDs ”), as these are usually intentionally produced with well over 250 C1 errors per second and therefore already one a small amount of otherwise harmless scratches can make such media illegible. A repair spray or grinding and polishing equipment can also be used to rescue a damaged CD or DVD . However, satisfactory results cannot be guaranteed in every case.

CD formats

Physical formats

CDs come in two different sizes, the most common is the version with a diameter of 120 mm and a weight of 15 grams, less often the mini CD with a diameter of 80 mm and 30% of the storage capacity with a weight of 6.7 grams.

There are also CDs that have a shape other than a round disc. However, due to playback problems (imbalance, no entry in slot drives), these so-called shape CDs were only rarely used.

Usual sizes

| Type / designation | Throughput diameter in cm |

Number of sectors |

Storage capacity | ||||

|---|---|---|---|---|---|---|---|

| Data 2048 bytes / sector |

Audio 2352 bytes / sector |

||||||

| in MB | in MiB | in MB | in MiB | in min | |||

| Business card CD | ? | ? | ≈ 20-110 | ≈ 19-105 | ? | ? | 5 |

| Mini CD | 8th | 94,500 | ≈ 194 | ≈ 185 | ≈ 222 | ≈ 212 | 23 |

| "540 MB" | 12 | 283,500 | ≈ 581 | ≈ 554 | ≈ 667 | ≈ 636 | 63 |

| normal CDs / "650 MB" | 12 | 333,000 | ≈ 682 | ≈ 650 | ≈ 783 | ≈ 747 | 74 |

| "700 MB" | 12 | 360,000 | ≈ 737 | ≈ 703 | ≈ 847 | ≈ 807 | 80 |

| "800 MB" | 12 | 405,000 | ≈ 829 | ≈ 791 | ≈ 953 | ≈ 908 | 90 |

| "900 MB" | 12 | 445,500 | ≈ 912 | ≈ 870 | ≈ 1,048 | ≈ 999 | 99 |

The format specifications of the audio CD ( CD-DA for short ), known as the “ Red Book ” standard, were designed by the Dutch electronics company Philips . Philips also has the right to license the “Compact Disc Digital Audio” logo. The music information is stored in 16- bit - Stereo ( quantization with 2 16 = 65,536 steps) and a sampling rate of 44.1 kHz is stored.

The specifications of the CD-ROM are laid down in the “ Yellow Book ” standard. A cross-platform file system for the CD-ROM was laid down by the ISO in the ISO 9660 standard . Its successor is UDF .

There are several ways to combine audio CD content and CD-ROM content on one disc. The simplest option is to put a data track with the CD-ROM content as the first track on the CD ( Mixed Mode CD , also called Enhanced CD by some manufacturers ). The now practically insignificant advantage that the CD-ROM part can also be read in CD-ROM drives that are only capable of single sessions is offset by the comparatively great disadvantage of the visibility of this data track for normal audio CD players, especially there some older CD players incorrectly interpret the CD-ROM data as audio data. The unintentional playback of the non-audio data leads, depending on the volume, to a deafening noise that can endanger the loudspeakers.

As a further development, the data track was given an index position of 0, which means that the CD player does not go to it without further ado ( i-Trax ). As with simple audio CDs, the audio material begins at index position 1 of track 1. (A problem for playback compatibility could be the fact that the mode changes from CD-ROM mode 1 to audio within the track .)

In the meantime, multisession CDs are practically exclusively used for this purpose - the audio data is in the first session , while the CD-ROM data is in a second session that is not read by audio CD players ( CD-Extra , CD-Plus ). A multisession-capable CD-ROM drive is of course required for the CD-ROM part.

A hybrid form is the CD + G (CD + Graphics). This CD shows graphic data, such as the lyrics, on a screen at the same time as the music. The most common application of this format is karaoke . In a normal CD player, the CD + G can be played as a normal audio CD . On special devices (more recently also on some DVD players ) the graphics can also be seen on the screen along with the music. The additional data is stored in the subcode of the CD, i. That is, in contrast to the content of data tracks, they are not readily visible to an operating system.

On the other hand, CDs with CD-Text are much more common . Additional information is stored in the subcode of the CD (usually in the lead-in ), for example title and artist. This information is then displayed by suitable devices while the CD is being played.

Other CD formats are:

There are also so-called HDCD CDs. These are encoded with real 20-bit music information (instead of 16) and should sound better in connection with the corresponding CD players. HDCD-CDs are fully compatible with "normal" CD players.

Further developments of the CD are the DVD-Audio and the Super Audio Compact Disc (SACD). DVD media offer much larger storage capacities from 4.7 (one layer) to 8.5 gigabytes (two layers). The main advantage is not a longer playing time, but that the audio data is available in 5.1 sound format. While the Super-Audio CD and DVD-Audio are used exclusively for audio data, various types of data are possible with the DVD (DVD Data, DVD-Video, DVD-Audio, DVD-ROM, DVD +/- R (W)). However, DVD has not caught on in the audio sector.

A variant of the CD further developed by Sony was the Double Density Compact Disc (DDCD). The storage capacity is twice the storage capacity of the 640 MB CD. It was available in two versions (a writable DDCD-R and a rewritable DDCD-RW), but could not prevail against the DVD.

Another variant developed by Sony is the Blu-spec CD , which was launched on the market in 2008.

The CD video format is (in contrast to video CD ) not a compact disc, but an LV / LD ( optical disc ) with analog video data and digital audio data.

copy protection

The CD standards do not provide for copy protection , because at the time of their definition in the early 1980s it was not foreseeable that writable digital storage media with the necessary data capacity would be affordable for the end user in the near future - copying was simply prevented by there was nothing where the data could realistically be copied. All that remained was the poor quality and not indefinitely repeatable analogue copy on audio cassettes, which was accepted just as with records. The advent of CD burners, high-capacity hard drives, compression methods such as MP3 and Internet file sharing networks in the 1990s changed this situation significantly.

Since 2001, media have also been sold in Germany that contain copy protection, which is intended to prevent the digital readout of the audio data (and thus the copying of the data). Some of them were also referred to as audio CDs , but they do not meet the requirements of the Red Book and are therefore not real audio CDs in this sense. These CDs are therefore also known as “Un-CDs” (non-CDs) .

Copy protection is implemented by introducing errors or a second faulty session . Deviations from the Red Book standard are also possible, but rarely. The "playback protection" arises from the fact that the errors are intended to prevent the discs from playing in the CD drive of a PC. This is to prevent copying. However, some CD drives and most DVD drives cannot be influenced by this and can still read the data, which ultimately makes this “copy protection” idea useless.

Instead, the errors on the "copy-protected" CD cause problems on numerous normal audio CD players and many car radios with an integrated CD unit. These media either cannot play these media at all or can only play them partially, and in some cases serious hardware defects occur, for example if the firmware of the CD player crashes and the medium can no longer be ejected. In addition, the sound quality and the service life of the playback device often suffer from copy protection.

Since November 1, 2003, manufacturers in Germany have been legally obliged by Section 95d UrhG to mark copy-protected media as such. However, it is hardly possible to infer from such markings which problems can arise in individual cases with car radios, MP3-CD players, DVD players and other devices.

Since the copy protection is hardly effective in practice, repeatedly leads to problems with playback and has also resulted in a partial reluctance to buy, more and more labels have given up the concept of “copy-protected CD” since around 2009. Ordinary, unprotected CDs are increasingly being published again according to the Red Book, especially as this also saves license fees for copy protection.

Manufacturer information and production facilities

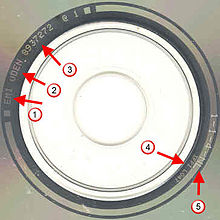

1 = label (here EMI )

2 = CD pressing plant (here Uden )

3 = catalog no. (here 8937272)

4 = IFPI identification (here L047)

5 = country code (here NL for the Netherlands )

Most CDs are on the inner ring of the scanning side with information about the manufacturer , the country of production (for example, Made in Germany by EDC , Made in France by PDO or Mastered by DADC Austria ) and other identifiers (eg Cat. , IFPI -Kennung , Source Identification Code (SID) ). These identifiers are i. d. Usually on a 5 mm wide circle (the mirror) and are difficult to see with the naked eye.

Such information is sometimes very important, especially for collectors of CDs, as they can be used to distinguish a legally produced CD from a black copy and to recognize “special pressings”. Often, CDs by one artist with the same content are produced in different countries. The editions can be of different sizes and accordingly valuable for collectors and fans .

Writable CDs

Writable CDs are available in a one-time writable variant ( CD-R : CD recordable) and in a multiple-rewritable variant ( CD-RW : CD rewritable). While the reflection properties of a CD-R are almost the same as those of a normal CD and should therefore also be readable in older CD drives, the read head output signal of a CD-RW is much weaker, so that these media can only be used by appropriately equipped (newer) ones. Drives or players can be read.

An ordinary CD player cannot be used to write to a CD . A so-called ' CD burner ' (or CD recorder ) is required. CD burners can not only write CDs but also read them. As a result, pure CD-ROM readers for computers have practically disappeared from the market.

The ISO-9660 file format of a CD-ROM does not permit subsequent changes. In addition, in contrast to hard disks, writable CDs cannot be written to in blocks. Therefore, a memory image must first be created that contains an exact copy of the data to be burned onto the CD. This image can then be "burned" (as a track) onto the CD in one go. Special CD burning programs are required for this. Current burning programs are able to create the image "on-the-fly", that is, the ISO image is created while writing.

However, as long as the CD has not been finalized, you can create a new file system with a further write process in a further track (that is usually in a further session) on the CD. The directories of this new file system can also reference files in the older tracks. Since the file system of the last track is always used during normal operation, it is possible to add, rename, “delete” and “overwrite” files. Of course, the occupied space cannot be used again. With special software (for example IsoBuster under Windows or ISO Master under Linux) it is also possible to access the older file systems, which means that the "deleted" files or the older versions of 'overwritten' files can still be accessed (multisession CD) .

Alternatively, the file systems in the tracks of a CD (analogous to partitions on a hard disk) can be viewed as different virtual drives (multivolume CD). This method was used, for example, in the classic Mac OS versions 8 and 9, but is otherwise rarely used.

CD-RWs can theoretically be written to in blocks. This must also be supported by the CD burner. Since the ISO-9660 file format used on CD-ROMs does not support subsequent changes to files, a separate file system called UDF was introduced, which is also used on DVDs . This format allows files to be stored directly on the CD , as is the case with a floppy disk , for example .

Label print

For the label imprint on the CD, as with the DVD, various printing techniques are available:

- Screen printing : In screen printing, up to six label colors are possible, spot colors ( HKS or Pantone ) can be selected. Screen printing is currently the most common way of printing CDs or DVDs, but it is being replaced more and more by offset printing. Screen printing is suitable for pressed CDs and DVDs, and blank printing is also possible. With screen printing, the colors are very brilliant.

- Dry offset printing : In dry offset are four label colors are possible ( CMYK ) combined with screen printing up to six (CMYK offset, additional white solid area and a spot color screen printing). Due to the higher resolution compared to screen printing, offset printing is ideal for photo-realistic presentations. Since the beginning of 2004, offset printing has not only been possible for pressed CDs and DVDs, but also for blank CDs and DVDs.

- Thermal transfer printing : In this printing process, a special printer is used to transfer color from a special ink ribbon to the CD or DVD by means of selective heating with a print head. For technical reasons, this printing process is more suitable for fonts and logos. In practice it is used for small editions (CDs and DVDs you have burned yourself).

- Thermal re transfer printing : The Thermoretransferdruck is the further development of thermal transfer printing. The label motif is printed on a transfer ribbon using the thermal transfer printing process, and a film of this is then applied to the CD. This technique enables better resolution. In this way, a photo-realistic print can be achieved even with short runs.

- Inkjet printing : Some manufacturers offer blanks with a paper-like coated surface. Such blanks, which are usually referred to as “printable” or the like, can be printed in full color in suitable inkjet printers with very attractive results. Photo-realistic image reproduction is the rule.

- LightScribe process: In this process, the laser of a LightScribe-capable CD burner burns any gray-scale graphic onto the front of the corresponding blank, which is designed using the appropriate software and transferred to the burner. The burning process takes about 15 minutes. Colored blanks have also recently become available.

- Labelflash : Alternative DVD labeling method

- DiscT @ 2 : CD-R labeling method

environmental Protection

The compact disc consists mainly of the valuable plastic polycarbonate . Pure recycling is not worthwhile for the production of new compact discs, but the very high quality raw material can be used in medicine, the PC and the automotive industry. Various companies offer collection systems. Collection containers are provided free of charge. Collection points (e.g. companies or municipalities) therefore do not have any risk, but only have to reserve an appropriate area for the collection container. Deutsche Telekom takes back its own CDs in its shops, AOL CDs can be sent to AOL freight collect.

Destruction of the data

Since a CD can also contain confidential data , secure procedures must be in place to make this data illegible before disposal, be it because the data is no longer needed or because it has to be deleted.

Ineffective procedures

- Painting is practically ineffective, even with waterproof felt-tip pens such as a Edding , as the ruts are retained during painting and are only slightly damaged. The paint layer can be removed with special cleaning agents, which only slightly damages the ruts. Firmly pressing on with a crayon, pencil or ballpoint pen can partially damage the data layer.

- Scratching the underside is almost ineffective if the scratches are not very deep. Even with many and deep scratches, considerable parts of the data can often be restored with special programs and tools. Scratching on the upper side helps, but even there parts that have not been scratched can still be read with special methods.

- Cutting up is also quite ineffective, since the large pieces can be evaluated quite well, but this becomes more difficult the smaller the pieces are.

Effective procedures

- CD burner - For some time now, various manufacturers of CD burners have also been offering additional functions ( Smart Erase ) in the drives with which a CD-R medium that has already been written on can be "overburned" again in order to finally end the data stored on it destroy. This does not work with pressed CDs.

- Breaking it (possibly with a hammer) is a relatively safe method, but the smaller the parts, the greater the safety. However, there is a risk of injury to hands and eyes from sharp-edged polycarbonate splinters flying around, which is why you should wear protective goggles and put the CD in an envelope or bag.

- Shredding - For extremely sensitive data, there are special CD shredders that shred CDs and other optical data carriers into pieces that are so small that the data carriers can be regarded as reliably destroyed, whereby the recyclability of the data carrier is retained. Some conventional paper shredders can also shred CDs. The suitability of a particular model for this purpose can be found in the instructions for use.

- Rubbing - You rub the label side of the CD on a rough surface (e.g. a rasp , a brick , etc.) until the CD is completely transparent and therefore unusable.

- Microwave oven or burning - works with both pressed and self- burned CDs. The metal layer is destroyed due to the heat generated by the electromagnetic waves or the fire. This process is basically very effective and perfectly suitable in an emergency, but it does produce harmful vapors. There is also a risk of fire.

- Etching - This involves placing the CD in a strong acid or base . The advantage is that the data layer becomes practically unreadable, and restoring the CD is extremely time-consuming and would only be possible in fragments. However, the material (acid / base and special vessel and tool) and the process are costly and require safety precautions such as eye protection and a trigger .

See also

- Optical Disc Comparison - Comparison of CD, DVD, HD-DVD and Blu-Ray Disc

- List of audio terms

literature

- Hartmut Gieselmann: Against forgetting. US researchers examine the lifespan of [writable] CDs and DVDs. In: c't , 1/2005, Heise-Verlag, p. 44

- Jürgen Karl Lang: The Compact Disc Digital Audio System: an example of the development of high-tech consumer electronics . University library of the Rheinisch-Westfälische Technische Hochschule Aachen 2012, ISBN 3-00-001052-1 DNB 1020294728 (Dissertation RWTH Aachen , Chair for the History of Technology, 1996, 306 pages online PDF, free of charge, 153 (double) pages, 20,600 kB).

- Rolf Müller: Music and Technology. The guitar and the silver disk. nova giulianiad, 1/83, ISSN 0254-9565 , p. 54 ff.

- Ken C. Pohlmann: Compact Disc Handbook: Basics of digital audio, technical structure of CD players, CD-Rom, CD-I, Photo-CD (original title: The Compact Disc Handbook , translated by Martin Schaefer) IWT, Vaterstetten 1994, ISBN 3-88322-500-2 .

- Kees A. Schouhamer Immink : The Compact Disc Story. Journal of the Audio Engineering Society , 46 (5), pp. 458-465, May 1998

Web links

- Structure and fundamentals, error correction, cleaning, repair

- For data destruction

- Collection points for Blueboxx GmbH

- Analysis, data recovery and archiving of CDs at channel code level

- The history of the CD

- When was the CD really born? A long story.

Individual evidence

- ↑ Definition of: CD. In: PC Magazine or PCMag.com Encyclopedia. Ziff Davis , accessed on December 13, 2017 : "(A Note on Terminology) In the early 1990s when CD-ROMs first became popular," CD "meant music, and" CD-ROM "meant data. Today, "CD" refers to both audio CDs and data CD-ROMs, which also include CD-R and CD-RW media. "

- ^ John A Cope: The physics of the compact disc. (PDF) In: Phys. Educ. 28. 1993, p. 16 , accessed on November 16, 2017 (English).

- ^ Samuel M. Goldwasser: Notes on the Troubleshooting and Repair of Compact Disc Players and CDROM Drives (Version 4.13). The CD player 'eye' pattern. April 15, 2014, accessed November 20, 2017 .

- ↑ http://www.muenster.de/~asshoff/physik/cd/cdplayer.htm

- ↑ Testing C2 information. In: cdrinfo.com. January 13, 2003, accessed January 21, 2018 .

- ↑ Nero DiscSpeed manual (German)

- ↑ QpxTool - Frequently Asked Questions

- ↑ Erik Bärwaldt: Check optical drives and media for errors with Qpxtool. In: LinuxCommunity. October 2014, accessed on August 6, 2020 (German).

- ↑ What does C1 / C2 use to perform error scans? (No longer available online.) In: Gleitz Forum. February 9, 2005, formerly in the original ; accessed on January 21, 2018 . ( Page no longer available , search in web archives )

- ↑ What is k-probe? In: k-probe.com. 2007, accessed on January 21, 2018 .

- ↑ decimal prefix (1 kB = 1,000 bytes)

- ↑ Dual prefix (1 KiB = 1,024 bytes)

- ↑ first commercially available (normal) size for the end customer or consumer (in Germany)

- ↑ second commercially available (normal) size (second generation), almost with the first excess length

- ↑ Third commercially available (normal) size (third generation), with a second or double extra length

- ↑ Sven Hansen: Un-CD-Tändiger - eliminate playback problems with unCDcopy c't 08/04

- ↑ Mike Lehmann, Kannste abhaken , CD single, catalog no. 7243 8 93727 2 4, LC 3098 , (P) 1996 Turbo Beat Music GmbH, © 1996 Virgin Schallplatten GmbH

- ^ Website of the Remedia company

- ↑ the company Blueboxx site

- ↑ Information from the Federal Environment Agency about CD / DVD recycling (with addresses) ( Memento from July 16, 2006 in the Internet Archive )

- ↑ Description of the recycling process for CD shredded material from Remedia. ( Memento of December 27, 2008 in the Internet Archive )

- ↑ Website of the ZENDAS (Central Data Protection Office of the Baden-Württemberg Universities) on methods that are not recommended for destroying data on CDs and DVDs

- ↑ The Compact Disc Story (PDF; 160 KiB)