Logger fishing

The logger fishery or " large herring fishery " was an offshore deep sea fishery for herring . It was operated from around 1860 to 1976 (FRG) or 1981 (GDR) and consisted on the one hand of the fishing vessels, the herring loggers , and on the other hand of the farms, the loggeries , in which the herring slaughtered and salted at sea was processed and ready for sale the loggers have been supplied and equipped.

History of logger fishing

The logger replaces the Buise

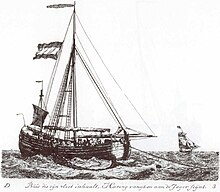

After the decline of the Baltic herring fishery at the end of the Middle Ages, the fishery and salted herring production relocated to the North Sea. On the one hand, the most profitable fisheries took place off Scotland , with fishing close to the coast and processing on land. Second, the developed Dutch a distant water with sea-going vessels, the Buisen , built in Kiel, about 23 m long and 5 m wide ships, with a square-rigged large boom and gaffelgetakelten smaller spanker (driver mast), as well as the front and a jib . The fishery was done with drift nets made of hemp , with 48 nets usually joined together, the so-called Fleet was about 1400 m long. The herring was slaughtered on board, salted and packed in barrels. The catch took place between May and October, usually 1 to 2 trips were made. They only returned home when the holds were full. Occasionally, however, the barrels were also reloaded at sea on so-called hunters, fast sailing cargo sailors, and thus freed up cargo space for further fishing.

The logger , a fast fishing ship used by the French canal fishermen , revolutionized and changed significantly the previous Dutch herring fishery with its comparatively clumsy and clumsy buisen from 1857. Due to their speed, four to five fishing trips could be carried out annually with the loggers. In addition, fishing was made much easier by replacing heavy hemp nets with cotton nets . The networks could be significantly enlarged, a logger led approx. 70 networks with a total length of the fleet of approx. 2000 m. The remuneration system for the crew contributed to the success of the fishery . The monthly wage was replaced by a system of shares in the catch. The wages of a sailor corresponded to that of a skilled worker , with a good catch also significantly more.

Forerunner of loggeries in Germany

Since the Middle Ages, German herring fishing has been mainly coastal fishing, for example in the Schlei , in the Elbe estuary and off Heligoland . The herrings were marketed fresh or smoked.

The first offshore fishing with buises was carried out around 1550 by Dutch people who had emigrated due to the war in Emden. Dutch fisheries were also active in the newly founded, at the time Danish and thus neutral Glückstadt . After the end of the Dutch War of Liberation in 1648, the operators returned to Holland with their ships.

A herring fishing company subsidized by the Danish state was founded in Altona , Denmark , in 1767 . In 1780 she owned 28 buises and 3 hunters. During the Napoleonic Wars, the English captured 18 Altona herring buises in the Heligoland harbor, which meant the end of the Altona herring fishing company.

After Emden became Prussian, an Emden herring company was founded in 1769 . The fleet soon grew to 55 Buisen. However, fishing also came to a standstill as a result of the Napoleonic wars and the continental blockade and barely recovered afterwards. The last Buisen from Emden were sold in 1858.

From the establishment of the first logging companies to the First World War

Following the example of the Dutch, the first German logger fishery was founded in Emden in 1872 (Emder Heringsfischerei Aktiengesellschaft). Initially, 6 sail loggers were bought in Holland, and by 1893 there were already 25 sail loggers in Emden. The Emden herring fishery soon threatened to go bankrupt, but was given massive support by the Prussian state with interest-free loans and direct subsidies. The logger fishery has depended on subsidies throughout its existence. The motivation for funding was different. On the one hand, the aim was to make salt herring available as a cheap food primarily for the poorer population. On the other hand, military purposes were also pursued. Highly qualified seafarers worked on the loggers, quickly available in the event of war, who were particularly useful in the navy, and the loggers were to be used as support ships in war.

After the successful start, and not least because of the state subsidies, a number of other herring fisheries were established at the end of the 19th century. In 1900 there were 7 herring fishing companies with a total of 118 loggers at the locations in Emden, Bremen-Vegesack ( Bremen-Vegesacker Fischerei-Gesellschaft ), Elsfleth, Geestemünde (today: Bremerhaven) and Glückstadt. By the outbreak of the First World War , the number of companies increased to 13. In 1911 the highest number of ships was reached with 284 loggers.

- Emder Heringsfischerei Aktiengesellschaft 1872

- Herring fishing cooperative North / East Frisia 1888

- Glückstadt Herring Fishery AG 1893

- Bremen-Vegesacker Fishery Society 1895

- Elsflether herring fishery 1896

- Dollart herring fishery , Emden 1899

- Great Elector Herring Fishery , Emden 1904

- Braker herring fishery 1904

- Empty herring fishery 1905

- Midgard Deutsche Seeverkehrs-AG , Nordenham 1905

- Visurgis Heringsfischerei AG , Nordenham 1907

- Norddeutsche Hochseefischerei AG , Bremerhaven 1907

- Brema Herring Fishery AG 1911

With the beginning of the First World War, logger fishing practically came to a standstill. The modern steam and motor loggers were now used as military auxiliary ships. 57 of them were lost in the war.

Between the world wars

After the war, logger fishing with the remaining approx. 200 vessels did not fully get going again until 1920 because of the danger of mines. However, in the following years the number of ships decreased by over 100, as the outdated sailing loggers were completely decommissioned by 1932.

Logger fishing has always been dependent on state subsidies, but these were frozen with the outbreak of the First World War and only resumed in 1925. The threatened end of logger fishing was averted with the resumption of subsidies. The state aid included protective tariffs on the salted herring, catch premiums, the deferral and granting of credits and building loans for the conversion and construction of loggers. In 1932 it was decided to build 30 motor loggers at state expense as a job creation measure and the ships were left to the herring fishing companies in return for a debt being entered. The Nazis continued the program in 1933 - because of their self-sufficiency and probably also for military reasons - and expanded it in 1934 to include the construction of a further 23 motor loggers. In 1935, the first combination logger that could fish with both the fleet and the bottom trawl was used.

In 1939, at the beginning of the Second World War , there were a total of 168 loggers at the four locations in Bremen-Vegesack, Leer, Emden and Glückstadt, including 110 motor loggers and 8 combination loggers. With the beginning of the war, the logger fishing came to a standstill, the more modern ships were drawn in by the navy and, after appropriate conversion, were used as outpost security and minesweeping boats.

After 1945 until the end of logger fishing in West Germany

45 ships were lost in the war, and 9 were decommissioned through sale and scrapping. The best and most modern part of the logger fleet was lost. Only a part of the remaining, mostly outdated ships could be used. By 1948, 76 loggers were operational at the following logger fishing companies:

- Emder Heringsfischerei Aktiengesellschaft

- Dollart herring fishery , Emden

- Great Elector Herring Fishery , Emden

- Empty herring fishery

- Glückstädter Heringsfischerei Aktiengesellschaft

- Bremen-Vegesacker Fishing Society

As in previous decades, the logger fishery was now dependent on state aid. From 1954 to 1957 a new logger building program was carried out with funds from the European reconstruction program, in which the herring companies only had to raise 20% of the construction costs - mostly financed by loans. Together with the scrapping bonuses introduced in 1961 for the decommissioning of obsolete loggers, this led to a modernization of the fleet through the construction of relatively well-equipped combination loggers which, in addition to salted herring, also landed fresh fish and thus enabled year-round operation. From 1963 4 modern stern loggers were put into service.

Despite the new construction program with combi and stern loggers and government subsidies, for example as catch premiums, there was an unstoppable decline in logger fishing in the 1960s for the following reasons:

- 1. Change in consumption habits. The supply of fresh fish - also inland - was constantly improved. Furthermore, the frozen fish production increased in importance and the processing into marinades and preserves led to the offer of a wide range of products. Salting lost its paramount importance as a preservation measure and salted herring was subject to other fish products in the product competition.

- 2. Competition with other fisheries. By modernizing the trawlers and introducing highly efficient fishing equipment such as the pelagic net or the purse seine, the fish could be produced much more cheaply than in traditional logger fishing.

- 3. Overfishing. By using these highly efficient fishing methods, it appears that more herring was caught than could be reproduced by the stocks, so that the North Sea stocks collapsed. There was a dramatic decline in catches in the logger herring fishery by the end of the 1960s.

- 4. Labor shortage. The remuneration consisted of a fixed wage and a share of the catch. As the catches fell, seafarers' incomes fell significantly. In addition, there were enough jobs on land, better paid, with regular working hours and free weekends, making it increasingly difficult to equip the loggers with the required qualified personnel.

In 1969 the logger fishing in Leer, Emden and Bremen-Vegesack was stopped. The Glückstadt herring fishery also went bankrupt, but was then partly continued by a building contractor for tax reasons. The last logger called at Glückstadt in 1975, and in 1976 the Glückstadt herring fishery was finally liquidated.

Logger fishing in the GDR

In the GDR, a large number of loggers were built in various shipyards from the 1950s to the early 1960s. As part of the reparation obligations to the Soviet Union, over 1000 loggers were delivered; only 35 loggers were used in the GDR's own fishery.

GDR deep-sea fishing began in 1950. At the suggestion of the Rostock City Council, the former site of the Ernst Heinkel Flugzeugwerke was made available. By 1956, the necessary infrastructure facilities for deep-sea long-distance fishing were created with docks, fish halls and repair shops and supply facilities. In 1950 the VEB Hochseefischerei Rostock was founded and the first 9 loggers were put into service in the same year. In 1952 the combine renamed VEB Fischkombinat Rostock already had the above mentioned. 35 loggers. The number of loggers changed little up to 1967, but then decreased from 1967, at the same time as the decline of the West German logger fishery, from 21 (1968) to 8 (1970). It remained with these 8 until 1978, in 1981 the last logger was decommissioned.

The loggers of the GDR fished with the bottom trawls, e.g. Sometimes also with the fleet. They could land both fresh fish and salted herring. As a special feature compared to the development in the FRG, the logger August Bebel was initially set up as a test logger for purse seine fishing ; After its successful trial fishing, a further 8 loggers were converted to purse seine loggers in 1967.

The last development of the FRG logger fishing, the use of stern loggers, was not followed in the GDR fishing. However, with the 16 North Sea- type frost trawlers built from 1965 to 1968, the Rostock fish combine had ships of the same size (49 m) and engine power (1000 hp) as the stern loggers.

Development of the ship type

Sailing logger

The sailing loggers introduced by the Dutch were 22.5 m long, 5.9 m wide, had a deck height of 2.85 m and a volume of 239 cubic meters. They were rigged as ketch with gaff sails. The main mast was foldable so that the loggers lay very quietly behind the canal when fishing. The loading capacity was about 400 kantjes (barrels for salted herring). They were usually manned by 14 men, a captain, a helmsman, two boys ( Avhauer and Reepschießer ), three ordinary sailors (including one youngest ) and seven sailors. One of the ordinary seamen was also the cook.

Around 1900 a wooden sailing logger in Germany with a capacity for 400 barrels of herrings (kantjes) without a steam winch and without net equipment cost 25,000 marks (adjusted for inflation, that would be 165,000 EUR today), the nets cost 10,000 to 15,000 marks (today 66,000 to 99,000 EUR, depending on their length ) ). The sailing logger was the standard ship of the German herring fishery until 1914, the most important technical innovation was the introduction of the steam capstan . Until then, the Reep had to be fetched by four men using the circulating capstan , but the steam cap made work much easier. However, the fleet was also considerably lengthened, so that now 100 nets were used for a total length of 3000 m.

Logger with auxiliary steam drive

In 1896, as part of a competition to design fishing vessels, the design of a herring logger with auxiliary machine was submitted by Walter Laas . With a length of 24.5 m, width of 6.4 m and a board height of 3.2 m, the ship was not significantly larger than a sailing logger. 450 kantjes and 25 barrels with supplies could be loaded. This so-called steam logger was made of steel and had an engine with 70 hp. To increase the loading capacity, the logger dimensions were soon extended to 28 m. When lying behind the canal, not only the main mast but also the chimney could be put down.

The first steam loggers at this time cost 56,000 marks (adjusted for inflation, that would be 365,000 euros today), of which the machine cost 15,000 marks (today 98,000 euros). In 1901 the first of these loggers was built with the “Welle”. It was built in 1901 as building number 448 at the Bremer Vulkan for the Bremen-Vegesack fishing company . The crew grew by another two men to 16 sailors. New additions were the machinist to look after the steam engine and a cook to take care of the team.

The steam loggers were actually classic sailing loggers with auxiliary machinery. At the same time, they meant a considerable increase in efficiency, since the fishing spots could now be reached quickly even in unfavorable winds and the extension and retrieval of the nets could be supported if necessary.

Motor and combination logger

In 1902 the first logger with a diesel engine was delivered. Problems with the propulsion system meant that more loggers with diesel propulsion were not built until 1911. The loggers built in 1933/34 as part of government job creation measures were 30 m long and their engine was 150 hp. They could load 1000 kantjes and were about 9 knots fast. They also had a ketch-like sails with about 210 m 2 of sail area, with a foresail, a mainsail and a mainsail as well as a mizzen and a mizzen top sail.

Since the loggers could only be used for a limited time from May to December, around 1900 the Geestemünde herring fishery used five fish steamers from January to May for catching fresh fish and from May to December for catching and processing salted herring. The other logger fisheries did not follow this example until 1936. This mode of operation was used as a basis in 1936 by the Emden shipyard Schulte & Bruns for the construction of combined loggers with a length of 34 meters. You could fish with both driftnets and herring bottom trawls. With a capacity of 1,200 to 1,400 kantjes, a 500 HP diesel engine, bow rudder, echo sounder, direction finder and radio system, they were fast (10 knots), versatile and modern fishing vessels. After the war, the loggers were once again significantly enlarged up to 42 m, got more powerful machines and Pleuger active rudders. They were equipped with large, isolated fresh fish rooms so that they could fish all year round. They still had a mizzen support sail for fleet fishing.

Rear logger

As the last type of ship, the new stern logger was put into service. The Netzfleet was no longer used on these ships. The trawls were launched and retrieved via the stern. Both bottom trawls and the comparatively large pelagic swim trawls could be used. The Bremen-Vegesack herring fishing company received three (Lesum, 1963, Hamme, 1965 and Wümme, 1965), the Glückstadt-based company received one stern logger (Milly Ekkenga, 1966). The ships were 49 m long and the engine made 1000 hp. Salted herring, fresh fish and frozen fish could be produced. The crew was 20 men.

Due to their larger radius of action, greater speed, stronger towing force and thus the use of larger bottom and pelagic swimming trawl nets, it was hoped for significantly better catches. However, these did not materialize due to the strongly declining herring stocks in the North Sea. The unfamiliar work (the catch was processed in the ship, standing on the assembly line) and the low wages due to low catches made it very difficult to staff the ships with qualified personnel.

In the case of an assessment by experts, it was recommended not to continue building this type of ship. For an economical annual operation, the ship would also have to fish in the more distant fishing areas outside of the classic logger fishing grounds in the North Atlantic. But its sea properties are not sufficient for this. Overall, it was not evident that these ships could ever break even.

Logger shipbuilding

The Bremen-Vegesacker Fischerei-Gesellschaft , together with the Bremer Vulkan in Germany, has done significant pioneering work in the development of logger drive machines, but also in the series production of loggers. There were only a few German shipyards that did not build loggers.

In the first 15 years of the Bremer Vulkan , 49 herring loggers were launched there , 41 of them for the neighboring Bremen-Vegesack fishing company , the rest was delivered to other German herring fishing companies. Other important shipyards for the construction of loggers were Abeking & Rasmussen , C. Lühring , the Unterweser shipyard , G. Seebeck , the Elsflether shipyard , Frerichs & Co. Nobiskrug , HC Stülcken Sohn , the Meyer shipyard and the Junge Werft .

On the one hand, a total of 390 riveted loggers were manufactured in the GDR. The three shipyards SAG Neptunwerft Rostock 179, VEB Elbewerft Boizenburg 161 and VEB Roßlauer Schiffswerft 50 loggers. On the other hand, 615 loggers were produced using welded technology, 588 of them in the VEB Volkswerft Stralsund alone. Through considerable innovations in welding technology and consistent application of the sectional construction, the transition to industrial series production was achieved with the so-called "flowing production in a cycle process"; in 1957 alone, over 100 loggers were produced.

Fishing technique

Fleet fishing

Originally the loggers operated a pure herring fishery with drift nets that were size-selective for the herring. While the nets used in business fisheries were still made from hemp, the much lighter and more manageable cotton was used in logger fishing. In order to make the nets more durable and bulky, they were "taant", that is, impregnated with linseed oil and the tanning agent catechu . The value of a network fleet composed of 70 networks was around 10,000 marks around 1890 (adjusted for inflation, 64,000 euros today).

With the advent of German deep-sea fishing, a number of net factories emerged at the end of the 19th century, the largest in Itzehoe. Although they made the cotton nets, they mostly did not impregnate them themselves, this was done in Holland. The re-impregnation of the used nets, on the other hand, took place in the logging companies' farms. It was not until the 1960s that the cotton nets used were replaced by plastic nets.

The single net was 30 m long and 15 m deep. At the upper edge there was a rope called a Sperreep with braided corks (flotjes), at the lower end leads so that the net stood like a wall in the water. With the first loggers, 70 nets were lined up to form a "fleet", with the advent of the steam cap up to 100 nets, with the motor loggers up to over 120 nets.

When the German Fleet was deployed, the nets were attached to a 5 cm thick, continuous hemp rope on the Fleetreep with so-called siskins and at the same time a buoyancy device, the Brails (later plastic air bubbles), was attached to each individual net on the Fleetreep. At the Scottish Fleet, the Fleetreep was under the nets. At certain intervals, the brails or bubbles were replaced by buoys with poles and pennants, the "Jonas", in order to make the course of the fleet more visible.

The herring makes daily migrations and rises to areas near the surface at night. Therefore, the canal fishing was a pure night fishing. The net was extended in the late afternoon while slowly reversing and retrieved shortly after midnight. When it was fetched, the Fleetreep was hoisted with the capstan, but the net itself was hauled in by the crew and the pegs knocked out. The catch was then slaughtered, salted, packed in barrels and stowed away.

Trawling

bottom trawl for logger fishing (combined logger) 1: Kurrleine 2: otter boards 3: Jager 4: Stick with stick-cock depots 5: Headline stand 6: Latch stand (middle) 7: Basic stand 8: Long antenna 9: Short antenna 10: 1st and 2nd height otter board 11: Headline with buoyancy balls 12: Ground rope, weighted down with chains 13: Square 14: Belly 15: Hundred mark piece and tunnel 16: Star 17: Cod line

Up to the end of the 19th century, the classic gear used in trawling was the tree trawl , in which the net is held open by a large rod, the tree. Shortly before the end of the century, the otter board was invented and revolutionized trawl fishing in a very short time. As a further improvement, around 1920 the development of special herring trawls with smaller mesh sizes and the additional height otter board was added. The latter enlarged the net opening so that fish standing higher above the bottom could also be captured. The height otter lines, the so-called antennas, had an additional scare effect, which led the fish down and into the net.

The example of the Geestemünder herring fishery of fishing herring with fish steamer and the bottom trawl and processing it into salted herring or landing it fresh as early as 1900 was followed by the other logging companies with the introduction of the combination logger from around 1936. These loggers were fitted with a rope winch in front of the bridge and on the starboard side in front and behind each a gallows. The net was deployed when drifting sideways over starboard, including the precharging, height and side shear boards and part of the hoist line. The ship then made a bow to get the fishing gear behind the ship. On the stern gallows, the two lifting lines were combined with a slip hook and the net was dragged in this way. The retrieval was carried out in reverse order, also via the starboard side. Large catches were divided, i.e. H. the cod-end is filled several times out of the tunnel, tied off and brought to deck and emptied.

Pelagic fishing

In logger fishing in the 1960s, pelagic swim trawls were used in addition to bottom trawls . Since the pulling power of the combi logger alone was not enough to haul these large nets, two ships were used in a team. The stern loggers, on the other hand, could also use the pelagic network alone. When fishing in a team, the necessary distance between the two combination loggers ensured the necessary lateral opening of the nets, the head rope was provided with numerous buoyancy balls and thus opened the net upwards, the ground rope weighted with chains or leads downwards. It was towed at 3 to 4 knots and took about 3 hours. In the case of the stern loggers, the pelagic otter boards provided for the side opening. The height of the net above ground could be controlled by the speed of travel and the length of the rope.

For the most effective catch possible, it was necessary to locate schools of fish as precisely as possible. The combination loggers only had an echo sounder and fish magnifier, but not the advance sonar used in the large pelagic fishing trawlers and the sonar on the head rope to monitor the altitude of the net and the catch recorded by the net.

Purse seine fishing

In the 1960s, purse seine fishing was the most effective fishery for schooling fish. Together with the pelagic fishery and the steadily improving fish sonars, this led to record catches, especially in the Scandinavian fisheries (mostly processed into fish meal ), but also to overuse of the fish stocks and ultimately to their collapse. Daily catches of 400 t and more of herring are reported; this roughly corresponds to the half-year catch of a traditional fleet logger.

The West German logger fishery has no longer followed this development. In 1967, 8 loggers were converted into purse seiners in the GDR. The last of them went out of service in 1981.

Fish processing at sea

The pegs were in the salt herring production immediately after being caught at sea slaughtered and salted. The slaughter or " throating " is done with a special "cake knife" with a short cutting edge; This involves piercing behind the gill covers with one movement and removing the gills , foregut and stomach as well as the heart so that the herring can bleed out . The gonads as well as the midgut gland and the rest of the intestine remain in the fish, the ferments of the midgut gland contribute significantly to the maturation of the salted herring. The salting took place in the warback, a crib open at one end . A basket of slaughtered herring was mixed with the necessary amount of salt in the warback and then packed and stowed in the barrels in layers . When salted herring, the ratio of fish to salt in the Hartsalzung 5: 1, the mildgesalzenen matjes 9: 1st

In the case of large catches, the entire crew including helmsmen , cook and machinists were involved in the slaughter. A skilled man could produce about 1 to 2 kantjes salted herring an hour.

Land operation

In the logger fisheries, there was about one employee on land operations for every two seamen. On the one hand, the landed sea-throated and sea-salted herring was processed further in the farms ready for sale. For this purpose, the pegs were sorted according to size and quality. The sorted herrings were then repackaged in layers in barrels and stored or handed over to the fishmongers. The herring lost some weight and volume as a result of the salting, so that the content of a kantjes filled at sea was around 0.8 land kantjes.

On the other hand, the loggers were serviced and equipped on the farms. There was also a locksmith's shop and a forge , and painters and electricians were also employed. The Bremen-Vegesacker Fischerei-Gesellschaft even had a floating dock for ship repairs . There was a cooperage for the manufacture and repair of the kantjes . Before the introduction of the plastic air bubbles for the Netzfleet, the coopers also made the net buoys, the Brails and Jonas. For the repair and maintenance of the used nets and the sails they had a netmaker , rigging and sailmaking shop and for re-impregnation of the drift nets a so-called taanerei. The nets were dried on large racks on drying areas the size of a hectare.

literature

- Anja Benscheidt, Alfred Kube: Deep sea fishing. Pictures from a bygone world of work (= history in pictures. Volume 1). Wirtschaftsverlag NW, Bremerhaven 1996, ISBN 3-89429-757-3 .

- Wilfried Brandes (Ed.): Logger-Jantjes. The Bremen-Vegesack fishing company and the herring catch. 2nd Edition. Edition Temmen, Bremen 1996, ISBN 3-86108-257-8 .

- Christian Grotewold: The German deep-sea fishing in the North Sea (= library of technology and industries. Volume 9, ZDB -ID 536295-7 ). EH Moritz, Stuttgart 1908.

- Gerhard Köhn: Sea thrown & sea salted. Logger fishing off the German North Sea coast. In memory of the Glückstadt herring fishery founded 100 years ago. Mocker & Jahn, Soest 1994, ISBN 3-87902-800-1 .

- Peter Kuckuk , Hartmut Roder , Günter Scharf: frames and sections. Shipyards and shipbuilding in Bremen and the Lower Weser region in the 20th century. Steintor, Bremen 1986, ISBN 3-926028-03-3 .

- Jens Rösemann: Kok-in-Ruum on the herring logger. A youth at sea or the pursuit of perfection. Johann Heinrich Döll, Bremen 1996, ISBN 3-88808-227-7 .

Web links

- History of German logger driftnet fishing, Federal Research Center for Fisheries ( Memento from February 21, 2013 in the web archive archive.today )

- Unsfisch Verlag, Kpt. Günther Kröger, with extensive material on GDR fishing, especially Rostock fishing

- Sail logger Vegesack BV2, built in 1895, technical data and travel offers

- Origin and social situation of the logger crews

Movie

- Herring fishing in old films. Jantjes and Kantjes. VHS, 45 min., Edition Temmen, Bremen, ISBN 978-3-86108-654-3 , historical recordings up to approx. 1935.

- Last exit logger. E. Ballhaus, Society for Cultural Studies Film, 2005/2006, 70 min. DVD.