Wendelstein 7-X

Wendelstein 7-X (W7-X) is an experimental facility for research into nuclear fusion technology , which is operated in Greifswald by the Max Planck Institute for Plasma Physics (IPP). The main component is a stellarator . With W7-X the physical and technical fundamentals are to be examined and the basic suitability for power plants of nuclear fusion reactors of the stellarator type demonstrated; this facility is not intended for a significant release of fusion energy . Other research facilities such as the ITER , which is currently under construction, work on the tokamak principle. It is not yet possible to predict which reactor concept will be chosen for a fusion power reactor that may be feasible in the future.

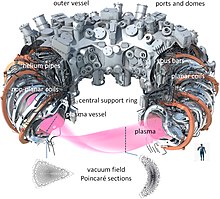

The centerpiece of the system is a circular magnetic field cage with a radius of 5.5 meters that encloses the 100 million degree hot plasma . This cage consists of a ring of 50 superconducting , approximately 3.5 meter high magnetic coils made of niobium - titanium . The mass of the enclosed plasma is only 5 to 30 milligrams, which are distributed over a volume of about 30 cubic meters. In addition to the Large Helical Device in Japan, the facility is the world's largest research facility of the stellarator type.

The plant produced the first helium plasma at the end of 2015 and the first hydrogen plasma at the beginning of 2016. In order to enable flexible experimentation, in contrast to ITER and the nuclear fusion reactors planned for the future, Wendelstein 7-X does not use a mixture of deuterium and radioactive tritium , but instead uses a plasma of pure ordinary hydrogen in the first phase of the experiment , so that no neutrons are released. Later a protium-deuterium mixture will be used; the fusion rate is very low at the planned temperatures and densities , so that only a few neutrons are released. The activation of the reactor materials is very low compared to future power reactors. The Wendelstein 7-X experiment is primarily intended to investigate the containment properties of an optimized stellarator and its long-term operability.

History and naming

The name Matterhorn was chosen for the early stellarator experiments at the Princeton Laboratory for Plasma Physics when it became clear that fusion research would be as arduous as climbing a mountain. The first German stellarators were in Garching near Munich, Bavaria . The name of the Wendelstein mountain in the Bavarian Alps was chosen in the late 1950s as an allusion to the Matterhorn experiments. The coiled, twisted shape of the magnetic field lines could also have played a role in the naming. The number 7 followed the stellarators of types 1 and 2 as well as the Wendelstein experiments 3–6 , which, however, were not stellarators. The first large stellarator at IPP was the W7-A in 1975. In 1988 W7-AS followed , the first stellarator with optimized, modular coils. Wendelstein 7-X is the direct successor experiment to W7-AS, with larger dimensions and numerous improvements.

Basics and goals of the project

Fusion research aims to explore the possibility of commercial generation of electrical energy from the fusion of atomic nuclei. The energy of the free neutrons generated in the nuclear fusion reactor would be converted into thermal energy and, like in other thermal power plants, used in a turbine with a generator to generate electricity.

Stellarators generate the toroidal magnetic field required to enclose the plasma and its necessary twisting exclusively by means of current-carrying coils arranged outside the plasma vessel. This means that stellarators are intrinsically suitable for continuous operation. The coils of the Wendelstein 7-X are cooled with liquid helium to temperatures close to absolute zero and are therefore superconducting . Once a current has been fed in, it can flow for any length of time without electrical resistance and the magnetic field is permanently maintained. Although Wendelstein 7-X is to investigate the properties of plasmas in continuous operation, the respective plasma duration is limited to a maximum of 30 minutes for practical reasons (size of the cooling system required, operating costs). This is sufficient for the experiments, since all relevant processes are in equilibrium before this period of time has elapsed.

The tokamak principle, an alternative to the stellarator, generates the twisting component of the magnetic field by a current flowing in the plasma itself, which has to be induced in the plasma ring (like in the secondary winding of a transformer ). As a result, tokamaks cannot initially work continuously, but only in pulse mode - the ITER experiment, which is currently under construction, aims for pulse durations of around 400 s. Whether and how a current in the plasma can be permanently maintained in tokamaks is the subject of current research.

Technology and data

Wendelstein 7-X is the largest of a new generation of so-called optimized stellarators . These use the design options of a system of modular, non-planar magnetic field coils. The system of 50 non-planar coils developed for Wendelstein 7-X uses five different coil types. The magnetic field which encloses the hot plasma can be optimized with regard to the criteria necessary for reactor operation:

- In particular, fast hot plasma particles tend to drift out of the three-dimensionally shaped stellarator magnetic field. Energy would then be lost to the plasma and it would cool down. This effect can be minimized in an optimized stellarator. In a strictly annular, i.e. H. Continuously rotationally symmetrical magnetic field as in the tokamak , this drifting of the particles is much less pronounced for fundamental reasons.

- These optimized properties must also be retained if the plasma begins to influence the magnetic field with increasing temperature and thus increasing pressure, i. H. to "dent". In particular, the outward displacement of the plasma ring caused by the pressure (this process is comparable to a bicycle tube, which becomes larger when inflated without a jacket) must be minimized. Instabilities in the plasma, which are driven by the high pressure differences between the inner and outer plasma, must also be minimized.

Wendelstein 7-X is based on an integrated optimization concept , the so-called HELIAS (HELIcally Advanced Stellarator), which is based on earlier Wendelstein experiments and was developed at the IPP Garching in the late 1980s. The selected so-called quasi-isodynamic magnetic field fulfills both of the above criteria at the same time and allows even further optimizations. These are used to minimize electrical currents in the plasma that are generated by the plasma itself, which leads to further stabilization.

The forerunner experiment Wendelstein 7-AS , which was carried out in Garching until 2002, had already shown, despite incomplete optimization, that the properties of the plasma can be influenced in the desired way. As part of the Wendelstein 7-X project, the correctness of this optimization concept is to be checked and, in addition, technical preconditions for the continuous operation of a hot fusion plasma are to be investigated:

- It must be shown that the three-dimensional magnetic field can be generated with sufficient accuracy and symmetry despite the size of the components and the high complexity of the system. Excessive deviations could on the one hand lead to local disturbances in the magnetic field (so-called magnetic "islands" ) or to an asymmetrical load on the heat exchanger elements of the first wall ( divertor ) and thus to their overheating. There atoms knocked out of the wall by the plasma by so-called sputtering would contaminate the plasma and allow it to cool down.

- All the components facing the plasma - graphite tiles in highly stressed areas , otherwise stainless steel structures - must be cooled as they would later in a commercial reactor. At the same time, a few centimeters behind it, the operation of the superconducting magnetic field coils at around −270 ° C must be ensured.

- Heating, diagnostics and their monitoring must be developed for continuous operation in a reactor.

| Mean large radius of the plasma | 5.5 m |

| Mean small radius of the plasma | 0.53 m |

| Volume of the plasma | ≈ 30 m³ |

| Mass of plasma | 5-30 mg |

| Expected density of the plasma | up to 1.5 · 10 20 particles / m 3 |

| Expected temperature of the electrons | up to 150 million K. |

| Expected temperature of the ions | up to 50 million K. |

| Desired inclusion duration (long-pulse operation) |

30 min |

| Volume of the plasma vessel | ≈ 50 m³ |

| Vacuum vessel | Diameter: 16 m; Height: 5 m |

| Magnetic field strength on the axis | 3 Tesla |

| Plasma heating (first operating phase ) |

Microwave heating : 8 MW Neutral particle injection : max. 10 MW |

| Plasma heating (long pulse operation) |

Microwave heating: 10 MW Neutral particle injection: max. 10 MW (10 s pulses) |

Components of the stellarator

Magnet system

The stellarator magnetic field has a five-fold symmetry at W7-X; Seen from above, the plasma is therefore not exactly circular, but tends towards a pentagon. This is based on the five identical modules that make up the W7-X. Each module contains ten non-planar superconducting coils and is again symmetrical in folding, so that each type of coil occurs twice in the module. The total of 50 non-planar coils are therefore composed of only five different types, which simplifies production and assembly. Although this magnetic field is sufficient to contain the plasma, the W7-X is equipped with additional coil systems in order to vary the magnetic field and, if necessary, optimize it for experiments:

- In each half of the module, two planar superconducting coils , which are inclined at opposite angles, allow both the toroidal component and thus the rotational transformation to be varied, as well as to generate an additional vertical field with which the plasma can be shifted radially.

- A fusion reactor requires a divertor , where particles that leave the inner confinement area of the magnetic field are specifically directed onto baffle plates provided for this purpose by means of a magnetic field structure. With the configuration chosen for the W7-X, such structures are created by themselves as magnetic islands on the edge of the plasma, without the need for separate divertor coils, as in tokamaks. In order to be able to vary the size of these magnetic islands and thus the distribution of the load on the baffle plates, normally conducting additional coils are installed in the plasma vessel just behind each of the ten divertors .

- Outside the vacuum vessel, five normally conducting trimming coils were installed, which would make it possible to compensate for any construction-related asymmetry of the magnetic field and thus prevent uneven loading of the divertors.

In the superconducting non-planar coils (weight about 6 t each, diameter about 3.5 m each), the current flows with typical currents around 20 kA in fibers made of a niobium - titanium alloy, which is superconducting at temperatures below 10 Kelvin; only above this critical temperature does it show an electrical resistance. The NbTi fibers are embedded in copper wires and twisted into an approximately 1 cm thick cable with 120 turns per coil in an aluminum sleeve. This cable is cooled to 4 K by liquid helium, which flows in the fine capillaries between the copper wires at normal pressure ( evaporative cooling ).

All superconducting coils were qualified before assembly under operating conditions with regard to temperature, superconductivity and magnetic field. Quench tests were also carried out. In the event of a quench, the superconductivity is lost as a result of local heating: the current then flows in the normally conducting copper wires of the coil, which must be dimensioned as a precaution for such cases. Because of the high currents and the resistance that is now present, high voltages occur there, which together with residual gas in the vacuum can lead to voltage flashovers and damage the insulation. In order to avoid this and overheating of the coil in the event of such a disturbance, the voltage on the coils is continuously measured and, if a critical value occurs, the current is directed into resistors outside of the experiment in order to release the energy there as heat.

Plasma vessel, divertor and first wall

The plasma vessel made of stainless steel is adapted to the three-dimensional shape of the plasma and separates the plasma from the insulating vacuum that surrounds the superconducting coils. 255 tunnel-like openings (ports) allow access from the outside through the insulating vacuum to the plasma.

On the plasma side , a water-cooled wall protection is pre-built: for highly stressed areas - especially on the inside of the torus - a heat shield reinforced with graphite tiles made of water-cooled CuCr1Zr plates (maximum local load 500 kW / m², average load 250 kW / m²), stainless steel panels with water flowing through it at less stressed areas (maximum local load 200 kW / m², average load 100 kW / m²).

Those particles (e.g. the inevitable impurities) that have to be removed from the confinement area of the magnetic field are directed onto the water-cooled baffle plates of the ten divertors - one at the top and one at the bottom per module. The baffle plates made of CFC ( Carbon Fiber Carbon Composite ) on water-cooled CuCr1Zr fingers are designed for a local heat load of 10 MW / m² in long-term operation, which corresponds to the limits of what is technically feasible. The geometry of the divertor and the magnetic field in front of it help to convert as much of the energy as possible into radiation and thereby distribute it more evenly. Pumps installed behind the divertor help to control the return flow of neutralized hydrogen atoms back into the plasma. Neutral hydrogen atoms, e.g. B. outgassed from the baffle plates are not influenced by the magnetic field and would otherwise cause the particle density in the central plasma to increase in an uncontrolled manner. At the same time, the penetration of impurities, which are knocked out of the baffle plates when the plasma particles hit, into the main plasma is made more difficult.

In the first phase of the experiment, the long-pulse divertor ( High Heatflux Divertor , HHF) , which is finally planned , will be replaced by a geometrically identical Test Divertor Unit (TDU) that is only cooled by thermal inertia to minimize development risks . Although this only allows test times of about 10 s, it is less sensitive to short-term local overheating and thus allows first to gain experience with divertor operation and, if necessary, to identify critical points with regard to overheating. For permanent cooling, the surfaces of the baffle plates must not be too far away from the cooling water - i.e. H. the baffle plates must not be too thick - so that the temperature differences to the cooling water are not too great and thus the maximum temperatures are not too high. A divertor for continuous operation is therefore surprisingly more sensitive to short-term overheating than an uncooled one, which has a slower temperature behavior due to its thicker wall.

Cryostat

The superconducting coils and the steel structures that support them must be thermally insulated from both the environment and the hot plasma. For this purpose, they are located in a so-called cryostat based on the principle of a thermos flask (however, here - in contrast to hot tea - the cold object is inside): The coils are located in a vacuum tank, which is passed through the plasma vessel on the one hand and the outer vessel of the system on the other is formed. Cryoshields surround the coils and - even when cooled - keep them away from residual thermal radiation. Access through this vacuum vessel and between the superconducting coils to the plasma - for heating, cooling lines or diagnostics, for example - is made possible by 255 approximately 1.8 m long likewise heat-insulated nozzles (so-called ports).

Support structures

All superconducting coils are attached to a central ring structure and must also be supported against each other, since they move against each other when they cool down to working temperature and when the magnetic fields are switched on. In some cases, very considerable forces occur, which limits the number of permissible operating cycles of the system. In order to avoid material fatigue, the number of configuration changes will therefore be limited as far as possible and the magnetic field generated with superconductivity will be left unchanged over a longer period of time (e.g. one week). The total mass of the stellarator is around 800 t, of which 425 t have to be run cold. A cooling process will likely take 1 to 2 weeks (1 to 2 K per hour).

Plasma heating

The most important heating method is electron cyclotron resonance heating (ECRH) with microwave beams . The electrons, which move on helical paths around the field lines due to the Lorentz force ("gyrate") in the magnetic field, are accelerated with precisely this gyration frequency. The magnetic fields used have a thickness of 2.5 t . For this purpose, the W7-X is equipped with ten gyrotron transmitters that each generate a microwave beam of around 1 MW at the required gyration frequency of 140 GHz. The rays are directed into the plasma via mirror optics. The transmitters developed for the W7-X, most of which are already operational, are the first series gyrotrons that can deliver this power for over half an hour. The ECRH system was financed by the Karlsruhe Institute of Technology (KIT) and set up and tested by KIT in cooperation with the IGVP (formerly IPF) of the University of Stuttgart and the ECRH team of the IPP Greifswald.

For shorter times (10 s each, every few minutes), four - in a later expansion stage eight - neutral particle injector sources (PINIs) are available from the start (divided into two injector boxes). These are particle accelerators for hydrogen ions with a downstream neutralizer, so that ultimately neutral hydrogen is injected into the plasma. The neutral atoms can penetrate the magnetic field (ions would be deflected by the magnetic field). Each source delivers about 1.5 MW into the plasma.

The heat output that can be achieved in the first phase of the operation is limited to a maximum of 13 MW by the number of initially five available high-voltage supplies. This power is taken from the grid via a substation.

Utilities

The helium cryogenic system, the systems for water cooling, the vacuum pumps and the systems for providing electrical energy are used to supply the stellarator .

During the experiments, despite the thermal insulation, 5 kW of heat must be dissipated in order to cool or keep the magnets and their supports (around 425 tons of material) at superconducting temperature . This permanent cooling is due to the residual thermal conductivity of the insulation materials used. At temperatures close to absolute zero , cooling can no longer be provided by a conventional refrigeration machine , but requires liquid helium , which boils at 4.22 K (−268.93 ° C). This cooling system must be gas-tight to a high degree so that no helium diffuses into the insulating vacuum of the stellarator and worsens the insulation there.

Project progress

The basics of a stellarator with optimization of the magnetic field according to the HELIAS concept developed in Garching using non-planar and superconducting coils were presented at the IAEA conference in Nice in 1988 and the largely elaborated application for support from the EU was submitted in August 1990. In the context of German reunification, the financing of such a project was initially open. An attempted Europeanization failed despite a positive international assessment and recommendation to the EU Commission in May 1994. The option of installing the project in the new federal states led to the establishment of a IPP sub-institute in Greifswald in 1996 both for national funding within the framework of an administrative agreement between the Federal Ministry of Research and the Ministries of Education in Mecklenburg-Western Pomerania and Bavaria and, after a second European assessment phase, for a funding commitment from the EU Commission.

The new building of the institute, begun in 1997, was occupied in April 2000. At the end of 2003, the first large components - a non-planar superconducting coil and the first sector of the plasma vessel - could be delivered. In 2005, the assembly of the first of the half-modules began. However, it became apparent that the transition from previous large-scale laboratory experiments to the complexity of a stellarator permanently operated with superconducting coils with the need to cool all components in the vessel could not be implemented in the structure of a W7-X assembly department with industrial support. The necessary restructuring and personnel reinforcement led to the company W7-X, founded in 2004, with a total of eight sub-areas and around 480 employees during the construction phase and a quality management system certified according to ISO 9001 and regularly monitored by TÜV-Nord CERT since 1/2010. This procedure, which is rather rare in a scientific experiment, was chosen to show how, despite the complexity of such a fusion system, the required technical properties can be achieved in accordance with the state of science and technology. The quality management concerns the implementation and documentation of all work and design processes, the specification of all components and their interfaces, the allocation and monitoring of the component production as well as the handling of quality deviations and the monitoring of all assembly steps.

In 2008 the last of the superconducting non-planar coils was successfully tested. Since September 2011, the torus in the experiment hall has been complete with the fifth module. The last welded connection of the modules was closed in May 2013. In the fall of 2012, the complex assembly of the components within the plasma vessel and the construction of the periphery in the experiment hall began. The assembly and piping of the stellarator itself was completed on schedule in May 2014, so that step-by-step commissioning could begin: the insulating vacuum in the cryostat has been in place since autumn 2014. The plasma vessel itself was closed in March 2015 after the internal fittings and diagnostic calibration work required for the first phase of the experiment had ended. In April 2015, after a three-week cooling phase, the working temperature of the superconducting coils of 3.8 K was reached, so that the tests of the superconducting coils could begin at the end of April. After the successful tests of the magnetic fields - also in continuous operation - a measurement of the magnetic field with electron beams ended the construction of the stellarator. Not only was the onion skin-like structure of the magnetic field detected in closed flux areas , but there was also a very small deviation from the calculated magnetic field structure; a confirmation of the high precision in setting up the experiment.

Assembly

The development and construction of the stellarator with its non-planar superconducting magnet coils must be viewed as part of the project.

For each of the five almost identical modules - consisting of the associated segment of the plasma vessel, surrounded on the outside by the cryoshield , magnetic coils and support structures - two half-modules were preassembled outside the torus hall and then combined to form a module and instrumented. The latter concerns the piping of the helium cooling lines, power supply lines and high-voltage cables as well as diagnostics for quench detection, sensors for the movement of the superconducting coils in their magnetic field or small coils for measuring the changes in the magnetic field resulting from currents flowing in the plasma and in the plasma vessel ( Rogowski coils ). Each module took a total of 28 weeks to build, and its weight was around 100 t.

For assembly, each module in the torus hall was first lifted into the lower half (lower shell) of the vacuum vessel / outer vessel, which was also provided with a cryoshield, and the instrumentation was completed there. This assembly was then brought to its final place on the machine foundation (see picture) in the experiment hall, where it first had to be held with additional auxiliary supports as long as the central support ring was not closed. The subsequent installation of the nozzle connected the plasma vessel and the outer vessel and was time-consuming, as the installation of the nozzles with their respective radiation shields and the necessary welded connections had to be carried out and qualified under comparatively tight conditions, since everything is then only accessible to a limited extent. Only then could the modules be connected to one another and, after the welding work was complete, the inside could be cleaned in order to start assembling the components in the plasma vessel.

In order to prevent asymmetrical loading of the divertors, the strength of interfering magnetic fields must not exceed 10 −4 the strength of the main field. This means that the superconducting cables may only be about 1 mm away from their design position after assembly. Symmetrical errors, such as are unavoidable when the coils are wound evenly, may, on the other hand, be significantly larger. The manufacturing process and assembly of each individual coil were therefore precisely monitored using metrological methods and any deviations found were taken into account in the next step.

Due to the required accuracy and poor accessibility in the event of a subsequent repair, the entire assembly was accompanied by extensive surveying work. The complex assembly also reflects the experimental character of the W7-X, whose optimization put experimental flexibility before technically easier feasibility.

In addition, the gas tightness of the experiment must be ensured. The leak test of the various components of the experiment is carried out with the test gas method of DIN EN 1779 with the noble gas helium and with a partial vacuum method developed at the institute, the so-called UST method.

business

The operating license was granted at the end of November 2015 and the first plasma was generated with helium on December 10, 2015. After further experiments with helium, the first hydrogen plasma was generated on February 3, 2016.

The focus of the first operational phase (operational phase OP1.1), which was carried out until around mid-March 2016, was initially technical investigations into plasma start, heating and diagnostics, and experiment control. 2200 tests were carried out on plasmas heated with microwaves. In September 2017, the installation of over 8000 wall tiles and 10 divertor modules was completed and the operation phase (OP1.2) had begun. The long-pulse capable high heat flux divertors (HHF) are still being replaced by the geometrically identical but more robust uncooled test divertor unit (TDU) and not all of the components in the plasma vessel are cooled. This allows operation for up to 10 s with 8 MW ECRH or NBI heating. The aim of OP1.2 is to experimentally check the correctness of the calculated optimization over the course of approximately one and a half years and then to develop an integrated high-density scenario as the basis for the high-performance long-pulse operation aimed at in the second operation phase (OP2). This requires control and understanding of the magnetic configuration, even with increasing plasma pressure, control of the radial profiles of electron or ion temperature and the particle density, as well as a sufficiently low concentration of impurities in the plasma center. One focus is on conditions at the plasma edge that are tailored to divertor operation, in particular with tolerable loads on the divertor plates (targets). Before the start of OP2, a conversion to a cooled, long-pulse capable divertor, which is expected to take 15 months, as well as additional cooling measures on other components and diagnostics in the plasma vessel are planned.

Radiation protection aspects

Wendelstein 7-X only examines plasmas made of hydrogen (H) or deuterium (D), so it does not use a mixture of deuterium and tritium, as is necessary for later fusion reactors. Dispensing with this reduces the release of neutrons and enables access to the system and the instruments surrounding it immediately after each test has been completed. This makes modifications for follow-up tests easier. During operation, however, access to the torus hall is generally not possible for safety reasons (risk of voltage flashovers, stored energy in the magnetic fields).

Hydrogen is intended as the working gas for normal operation. In addition, experiments with deuterium will be carried out in order to extrapolate the properties of a plasma mixture of deuterium and tritium. To a small extent, fusion reactions between deuterium nuclei can occur in which neutrons are released. In order to shield these, the torus hall is surrounded by an approximately 1.8 m thick wall made of borated concrete. Boron is a strong neutron absorber ; In addition to a Li-7 core and an alpha particle, the absorption reaction also produces a gamma quantum with an energy of 478 keV, which, however, is absorbed in the massive concrete shield. Thus there is no monitoring area in the sense of radiation protection directly outside the torus hall , i.e. That is, work can be carried out without having to wear a dosimeter for monitoring.

When operating with deuterium, very small quantities of neutrons in particular can activate steel components ( cobalt is important ) . In order to minimize this and not have to gradually restrict access to the system over the years, only selected types of steel are used for components within the concrete shell.

The movement of electrons and ions in the plasma also creates X-rays , which, however, are already shielded by the plasma vessel.

In accordance with the requirements of radiation protection and in preparation for the operating license for the research facility, the State Office for Health and Social Affairs (LAGUS) Mecklenburg-Western Pomerania, as the approval authority, commissioned TÜV Süd as an independent expert in February 2013 to carry out a radiation protection report.

The report was published in October 2013. It was found that the Wendelstein 7-X research facility “fully” meets the requirements of radiation protection. Corresponding tests were carried out by TÜV Rheinland in 2014 and 2015 . Jens-Uwe Schmollack, project manager at TÜV Rheinland, explained in February 2016: "We have completely redrafted the existing regulations, taking into account the current state of science and technology, for this special case under safety aspects."

criticism

In the summer of 2012, the Mecklenburg-Western Pomerania regional association of the Federal Environment and Nature Conservation Germany (BUND), which rejects nuclear fusion as a whole, criticized the construction process of the experimental facility. According to the environmental association, this contains serious shortcomings in the area of radiation safety. The BUND referred to a review of the files kept by the State Office for Health and Social Affairs (LAGUS) Mecklenburg-Western Pomerania as the approval authority. Fears were, among other things, an incorrect composition of the radiation protection concrete used to shield the system, cracks in the hall roof, inadequate shielding of neutrons at the hall gate, too high tritium values in the exhaust air, and the possible leakage of irradiated cooling water into the public sewage network in the event of a disaster (too technical Basics of these radiation protection aspects see above). In order to question the Max Planck Institute's statement on the concerns, the approval authority appointed TÜV Süd as an independent expert. The report states: "With the submitted documents and the extended investigations (core drilling, calculations for the shielding effect and variation of the concrete parameters [...]) it could be proven that the structure (toroidal hall and gates) built according to the requirements for the concrete parameters Radiation protection requirements with regard to the fulfillment of the protection goal are fully met through professional planning (materials, dimensioning) and high-quality shell construction. In particular, it guarantees reliable compliance with the limit values for the effective dose in the calendar year for staff, the population and the environment according to §§ 46 and 55 StrlSchV [...] could not bring about the necessary clarification of radiation safety. The then Minister for Labor, Equality and Social Affairs came to the following conclusion:

"The safety concerns about the shielding effect of the torus hall are completely invalidated by the report."

The operating license issued by the State Office for Health and Social Affairs on December 10, 2015 contains conditions that primarily relate to later operation with deuterium as the filling gas.

financing

The Wendelstein 7-X project is financed around 80% from national funds and around 20% from the European Union . The United States is contributing $ 7.5 million to the US Department of Energy's “Innovative Approaches to Fusion” program. National funding is provided in a ratio of 9: 1 by the federal government and the state of Mecklenburg-Western Pomerania . The investments for the stellarator experiment (totaled over the years 1997-2014) amount to 370 million euros. The total costs for the IPP Greifswald location , i.e. the investments plus operating costs (personnel and material resources), amount to 1.06 billion euros for this period of 18 years. Because of the long development phase (personnel costs), this is more than twice as much as originally estimated.

Cooperation partner

Germany

- Technical University Berlin

- University of Greifswald

- research center Julich

- Karlsruher Institute for Technology

- Institute for Interfacial Process Engineering and Plasma Technology at the University of Stuttgart

- Physikalisch-Technische Bundesanstalt

Europe

- Commissariat à l'énergie atomique et aux énergies alternatives (France)

- Centro de Investigaciones Energéticas, Medioambientales y Tecnológicas (Spain)

- INP Krakow and National Center for Nuclear Physics (Poland)

- Institute of Plasma Physics and Laser Microfusion, Warsaw (Poland)

- KFKI Research Institute for Particle and Nuclear Physics of the Hungarian Academy of Sciences (Hungary)

- Trilateral Euregio Cluster (Germany / Belgium / Netherlands)

United States

- Los Alamos National Laboratory

- Oak Ridge National Laboratory

- Princeton Plasma Physics Laboratory

- University of Wisconsin – Madison

Japan

Web links

- Wendelstein 7-X. Max Planck Society, Munich, accessed on October 14, 2016 .

- Interview with Thomas Klinger, the scientific director of the Wendelstein-7-X. Resonator Podcast of the Helmholtz Association, May 19, 2014, accessed on June 30, 2014 .

- Frank Rieger and Felix "Fefe" von Leitner: Extensive talk with Thomas Klinger and Adrian von Stechow at alternativlos.org. In: alternativlos.org. April 19, 2016. Retrieved April 19, 2016 .

- idw-ticker, December 2, 2009: All main components for Wendelstein 7-X completed (with pictures)

- idw-ticker, February 11, 2010: Cool underworld for Wendelstein 7-X completed

- Richard A. Fuchs: Generate energy like the sun. DW World, March 9, 2010, accessed June 30, 2014 .

- idw-ticker, July 7, 2011: USA participates in the Wendelstein 7-X merger project

- Günter Paul: America is heating up in the solar furnace. faz, August 6, 2011, archived from the original on August 11, 2011 ; accessed on June 30, 2014 .

- Nuclear fusion experiment "Wendelstein 7-X" before the start. heise.de, May 19, 2014, accessed June 30, 2014 .

- Holger Dambeck and Benjamin Braden: Wendelstein 7-X nuclear fusion plant: This artificial sun is supposed to solve all energy problems. In: Spiegel Online . December 10, 2015, accessed December 10, 2015 .

Videos

- Wendelstein 7-X - From the idea to the technical implementation on YouTube , November 20, 2013

- Wendelstein 7-X: The first helium plasma, Max Planck Institute for Plasma Physics, 2015 on YouTube

- Large-scale experiment "Wendelstein 7-X": Here comes the sun, DER SPIEGEL, 2015 on YouTube

- Stellarator Wendelstein 7-X - report, GolemDE, 2015 on YouTube

- Wendelstein 7-X - Ceremony for the first hydrogen plasma, Max Planck Institute for Plasma Physics, 2016 on YouTube

- Bernd Hopp: Interview with Adrian von Stechow from Wendelstein 7X - follow-up to the podcast without alternatives on YouTube , from October 2nd, 2017

- Fusion research: Stellarator Wendelstein 7-X in Greifswald, 2020 on YouTube

Individual evidence

- ↑ Introduction - the Wendelstein 7-X stellarator , Max Planck Institute for Plasma Physics . Retrieved January 8, 2016.

- ↑ First plasma: Wendelstein 7-X fusion system went into operation. In: ipp.mpg.de. December 10, 2015, accessed December 10, 2015 .

- ↑ http://www.ipp.mpg.de/de/aktuelles/presse/pi/2016/02_16

- ↑ Isabella Milch: Wendelstein 7-X in operation . In: Physics in Our Time . 50, No. 1, 2019, ISSN 0031-9252 , pp. 16-23. doi : 10.1002 / piuz.201901524 .

- ↑ WI-A, WI-B, WII-A, WII-B, W7-A, W7-AS: G. Grieger, H. Renner, H. Wobig: Wendelstein stellarators . In: Nuclear Fusion . tape 25 , no. 9 , September 1985, pp. 1231 , doi : 10.1088 / 0029-5515 / 25/9/040 .

- ↑ Max Planck Institute for Plasma Physics. 50 years of research for the energy of the future

- ↑ Resonator podcast of the Helmholtz Association : Der Wendelstein 7-X (episode 32, May 19, 2014)

- ↑ CuCr1Zr. Retrieved December 4, 2018 .

- ↑ Products - Ultra-high vacuum - Max Planck fusion reactor. (No longer available online.) In: www.kompaflex.ch. kompaflex AG, archived from the original on October 23, 2013 ; accessed on October 1, 2011 (W7-X-Stutzen).

- ↑ Presentation of the cryogenic system by Linde ( Memento from February 17, 2009 in the Internet Archive )

- ↑ B. Renard, G. Dispau et al. a .: Ten years of cryomagnetic W7-X test facility construction and operation. In: Cryogenics. 51, 2011, pp. 384-388, doi: 10.1016 / j.cryogenics.2011.03.005 .

- ↑ Wendelstein project Group, WENDELSTEIN 7X PHASE II, Application for Preferential Support, CCFP 62/61, IPP-EURATOM ass., June 1994

- ↑ G. Grieger, W. Lotz et al. a .: Physics optimization of stellarators. In: Physics of Fluids B: Plasma Physics. 4, 1992, p. 2081, doi: 10.1063 / 1.860481 .

- ↑ Wendelstein 7-X in time-lapse version 5 on YouTube , from November 15, 2012

- ↑ First measurement of the Wendelstein 7-X magnetic field - it fits! Max Planck Institute for Plasma Physics , July 16, 2015, accessed on January 1, 2016 .

- ↑ New standard for the selection of a suitable method for leak detection and tightness testing , January 7, 2013

- ↑ Spin-off: 1st prize for highly sensitive leak detection method of "Lambda Leak Testing." March 19, 2013.

- ↑ Ultra-sniffing test gas method based on the partial vacuum effect. January 7, 2013

- ↑ dpa , Axel Kannenberg (axk): "Wendelstein 7-X" nuclear fusion plant in Greifswald receives an operating license. In: Heise online . December 1, 2015, accessed December 1, 2015 .

- ↑ Operating license granted for nuclear fusion experiment. sueddeutsche.de / dpa, December 9, 2015, accessed on August 10, 2020 .

- ↑ Wendelstein 7-X fusion system: The solar machine is running . In: Spiegel Online . December 10, 2015 ( spiegel.de [accessed December 10, 2015]).

- ↑ heise online: Wendelstein 7-X fusion experiment generates the first hydrogen plasma. In: heise online. Retrieved February 3, 2016 .

- ↑ http://www.ipp.mpg.de/de/aktuelles/presse/pi/2016/07_16

- ↑ MPI / IPP: http://www.ipp.mpg.de/de/aktuelles/presse/pi/2017/08_17

- ↑ MPI / IPP: http://www.ipp.mpg.de/4095699/op1_1

- ↑ James E. Martin: Physics for Radiation Protection: A Handbook . 2008, ISBN 978-3-527-61880-4 , pp. 660-661 ( books.google.com ).

- ↑ a b Home - State Office for Health and Social Affairs Mecklenburg-Western Pomerania. In: lagus.mv-regierung.de. October 30, 2013, archived from the original on November 3, 2013 ; Retrieved December 10, 2015 .

- ↑ TÜV Rheinland: Safety-related support for the "Wendelstein 7-X" nuclear fusion facility (press release from February 3, 2016, accessed on August 14, 2016)

- ↑ Major safety concerns with the Wendelstein 7-X nuclear fusion experiment. (No longer available online.) In: bund-mecklenburg-vorpommern.de. July 25, 2012, archived from the original on December 11, 2015 ; Retrieved December 10, 2015 . Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Security issues. Accessed December 31, 2015 .

- ↑ Wendelstein 7-X nuclear fusion experiment: BUND Mecklenburg-Vorpommern sees incurable deficits in radiation protection. (No longer available online.) In: bund-mecklenburg-vorpommern.de. May 19, 2014, archived from the original on December 11, 2015 ; Retrieved December 10, 2015 . Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ http://www.lagus.mv-regierung.de/cms2/LAGuS_prod/LAGuS/index.jsp?&pid=60807 ( Memento from November 3, 2013 in the Internet Archive )

- ↑ FAZ: Start free for German solar furnace from December 10, 2015

Coordinates: 54 ° 4 ′ 22.9 ″ N , 13 ° 25 ′ 24.7 ″ E