Lathe

A lathe is a machine tool that is primarily intended for the turning production process and is used to manufacture rotationally symmetrical workpieces ( turned parts ). All lathes can also be used for drilling , provided that the center of the hole coincides with the axis of rotation. Some lathes also have additional equipment for milling or shaping .

A wide variety of rotational bodies can be produced on the lathe ; In the simplest case, these are cylindrical turned parts, which can also have flat surfaces at right angles to the axis of rotation. More complex shapes are conical or spherical surfaces or free shapes, which can also deviate from rotational symmetry by means of additional devices. The workpiece performs the cutting movement through rotation. The tool, the lathe chisel , is firmly clamped on the tool slide, executes the feed movement with it and continuously removes a chip by moving the slide along or across the axis of rotation of the workpiece along the surface to be machined. However, there are also special designs with a stationary workpiece and a tool rotating around it. Lathes are available in numerous different designs and with every possible degree of automation . The main components are the frame with the guides for the slide and the tailstock, the slide, the drive and the control.

The predecessor of today's lathes is the lathe , which usually has no machine drive and never more than a tool slide. The change from the lathe to the lathe took place at the turn of the 18th century with the introduction of the tool slide, the use of tension and lead screw to generate the kinematics between the rotation of the workpiece and the feed of the tool, and the lathe made entirely of metal. The tool was positively driven with the lead screw, and the quality of the turned parts no longer depended so much on the skill of the lathe operator. Lathes made a decisive contribution to the industrial revolution , because many components for steam, spinning and weaving machines and many others could only be manufactured economically by turning. Typical components produced by turning are axles, shafts , screws, spindles or bolts. The term lathe did not become common practice until around 1950. It has now fully established itself in the specialist literature, but many professionals still use the term lathe orally.

Lathes in which the tool movements are controlled by a computer program are called CNC lathes .

history

The origin of the lathe can no longer be precisely dated today, but it represents a reversal of the kinematics of drilling. The earliest finds, which, due to their shape, suggest turning work, can date to the end of the 2nd millennium BC. BC and come from the Mycenaean area. However, the woods found are so weathered that the grooves typical of woodturning can no longer be seen and thus the final proof is missing. The first workpieces that were definitely identified as turning work were discovered in a grave near Corneto , the so-called Tomba del Guerriero (grave of the warrior), which dates back to the early 6th century BC. Is datable. The first representation describing the principle of the lathe was found in an Egyptian tomb, the tomb of Petosiris from 300 BC. One man propelled the workpiece with a cord while the other held the tool against the workpiece. According to tradition in Greek mythology, Daidalos invented the lathe with a pull cord.

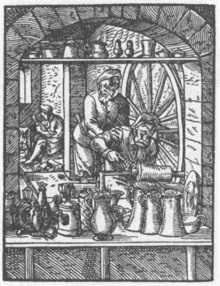

A drawing has survived from the 8th century AD showing the generation of the rotary movement with the aid of a fiddle-bow drive; the rotating part is rotated by a back and forth movement with a cord stretched in a bow. In the 13th century, the seesaw lathe appeared, in which the cord was attached to a running board at one end and to a spring, usually in the form of a lath attached to the ceiling, at the other end. With this construction, the lathe operator could drive the apparatus with his foot and had both hands free to guide the tool. The English name for Lathe, Lathe , descends from the used as a spring bar.

At the beginning of the 15th century, the hand crank was used as a drive. Also Leonardo da Vinci invented a lathe, has been driven in a flywheel on a footboard and enabled as a continuous rotational movement. However, this concept could not prevail. The first illustration of a lathe with support comes from 1480. The drawing describes a lathe with a wooden tool slide for delivering the turning tool and a turning part that can be moved in the longitudinal direction. Leonardo da Vinci was also using a tool holder as early as 1490.

In 1571 Jacques Besson designed a lathe with automatic mechanical feed via the lead screw . Two weights pulled the tool slide up over pulleys and thus pressed the tool against the workpiece. In precision mechanics, the lathes were already largely made of metal after 1650 and from 1750 had all the essential features of a modern lathe, such as lead screw, change gears and a cross support. Even a drawing of a copy lathe from 1741 is known. These early achievements were only possible because of their small size. The first support lathe suitable for mechanical engineering was probably made by the American Sylvanin Brown in 1791. Seven years later, David Wilkinson , also an American, patented a support lathe.

Henry Maudslay , one of the founding fathers of machine tool construction, finally succeeded in completely manufacturing a lead screw lathe for machine construction from metal. It had a cross support as well as a feed rate dependent on the rotation, which allowed the manufacture of identical, interchangeable parts. This method, known as interchangeable construction, was particularly suitable for screws, because before Maudslay's invention, all threads were individual and not interchangeable with one another. Shortly afterwards, the cross slide was constructed and also coupled with the lead screw. Maudslay, on the other hand, now also used change gears for the feed in order to be able to turn threads of different pitches with one and the same lead screw. The first lead screw lathe in Germany came from London in 1810 and was purchased by the Koenig & Bauer machine factory in Würzburg. The first vertical turning lathe was made in 1839 by the Swiss engineer Johann Georg Bodmer during his time at Whitworth in England.

In 1840 Joseph Whitworth expanded the well-known lathe to include other available tools and slides (multi-steel and multi-slide lathe). They were able to machine the workpieces with several tools at the same time and thus shorten the then very long machining times. In 1852 an attempt was made to use the crank pin lathe from the USA to generate the cutting movement with a rotating tool, but this method never achieved sufficient acceptance. 1852-1860, the American Stephen Fitch made the top slide as a turret head and thus invented the turret lathe . Just one year later, in 1861, the lathe was expanded to include additional work spindles. Ch. M. Spencer patented the first automatic lathe in 1873. The leading and pulling spindle lathe was developed in 1880 and was able to do almost all turning jobs at that time. In the years that followed, new versions of the lathe with more sophisticated technology came onto the market, such as the copy lathe , which made copies of stencils or patterns using a scanning device.

At the beginning of the 1950s, the first numerically controlled (NC) lathes were developed in the USA , in which the tool movements and speeds are implemented using control commands that are read into the control using punched tape. Up to the end of the 1970s, the punched tape was often processed record by record in the controls: a control information data record is processed in the machine, while the control reads the next data record and prepares it mathematically for the next movement. The progress in the field of data processing has since had a direct impact on the further development of the lathe.

Mechanically, the lathe was improved from 1945, especially in terms of accuracy and speed. The variety of designs also increased, as the mechanical transmission links were no longer required thanks to the CNC technology.

general structure

The lathe has been adapted to many special uses throughout its history. Today there is a wide selection of different models available, but they are basically similar in structure. The work spindle ( axis of rotation ) is usually arranged horizontally for small diameters of the workpiece, and more vertically for large diameters. The main components are the frame and the machine bed on which the other parts are attached, the headstock that contains the work spindle, the main drive for the spindle and the tool slide. There are also some additional facilities.

frame

The frame is either a welded steel construction or cast iron is manufactured as a composite structure with rarely polymer concrete . The frame bears the weight of all components, absorbs the forces from the machining process and must therefore be designed to be strong and torsion-resistant. In addition, it must have good damping so that vibrations within the machine can be reliably reduced. The frame and the machine bed listed below form a unit with regular sizes; only very small table lathes and watchmaker's lathes have a separation of the units “bed” (directly for the machining process) and frame (for lifting the machine to a comfortable working height).

Lathe bed

The horizontal machine bed rests on the frame at both ends and carries the tool slide, tailstock and steady rest . Since the cutting edge is constantly in contact with lathes , machine parts are excited to vibrate. This reduces the surface quality and the dimensional accuracy and increases tool wear , which is why the bed is cast from vibration-damping cast iron with lamellar graphite or reaction resin concrete and the cavities are filled with sand or synthetic resin-bonded granite (polymer concrete). On small machines, the bed and frame are one-piece, and all of the above share two guides . On larger machines, the tool slide moves on two separate guides. To improve work performance, the entire bed is often inclined (inclined bed ) or lies above the main spindle for better chip evacuation . Since the axis of rotation on vertical lathes is vertical, the slide guides are not referred to as a bed, but as a machine stand. On front lathes for flat rotating parts, on the other hand, the bed is perpendicular to the axis of rotation of the work spindle.

Headstock

The headstock is on the left side of almost every machine. The work spindle, which is often designed as a hollow shaft , is guided there in strong, pre-tensioned and adjustable precision roller bearings , as this only has a small effect on the dimensional stability and enables the chuck to be supplied with bar material. The work spindle is coupled to the motor via a belt drive and gearbox . CNC lathes and also hand-operated machines with infinitely variable motors often only have a two- to four-stage gear. As a result, a constant cutting speed with variable turning diameters, such as face turning , can also be guaranteed within the speed control range . In older models of hand-operated machines, the gearbox has 24 to 52 stages that can be switched with two or three levers. In addition, it includes a reversing gear on some machines to reverse the direction of rotation of the spindle. However, it is common practice to change the direction of rotation directly on the motor. Motor spindles are also used on numerically controlled multi-spindle automatic lathes . The spindle with workpiece holder is built directly into the motor, which saves installation space.

The torque is transmitted from the main spindle to the workpiece using various clamping devices such as chucks, collets , face plates and others.

Feed

Hand-operated universal lathes also have a feed gear that derives power from the work spindle and transmits it to the lead screw and pull spindle via change gears and feed gear. This z. B. set the gradients when threading through respective gear combinations. Numerically controlled machines, on the other hand, have their own drive for each machining axis. Backlash-free ball screw drives transfer the movement to the slide, whereby feed speeds of up to 60 m / min and accelerations of up to 8 m / s² are possible, but are usually significantly lower, especially during machining. Linear drives , which have become more and more widespread in recent years, are also suitable for the highest accelerations and travel speeds . The axes in the longitudinal and transverse directions (Z and X axes) are assigned to the tool slide. The travel distance is either read off on the scale rings on the handwheels or electronically recorded and displayed with distance measuring systems.

Special materials, such as free- cutting steels, are used in machining technology for high feed rates and cutting speeds . These are characterized by low machining forces, good surface quality that can be achieved and short-breaking chips that cannot get caught in the machines.

Tool slide

The tool slide, which is usually designed as a cross support , moves in the longitudinal direction on the bed , on which the cross slide moves across the axis of rotation. The tool carrier of the hand-operated master and tension spindle lathe is located on top of the top slide, which carries a tool holder (often designed as a quick-change holder for economical tool changes), and on CNC lathes often a tool turret for holding several tools. Various systems are available for guidance, whereby better damping guidance systems increase the surface quality and dimensional accuracy.

Nowadays, CNC lathes can be equipped with driven tools that are mechanically driven in order to drill or mill with them on all tool positions of the turret or on a part of it (often in every second position) . This is very often associated with a so-called spindle orientation, in which the turning spindle can be positioned at any exact angular value and then stopped. The turning spindle is then addressed by the control as a separate CNC axis and requires its own spindle encoder. This enables complex geometric motion sequences to be processed with one or more other axes using NC control (multi-axis interpolation). By using driven tools, the subsequent finishing on drilling machines and milling machines can be omitted, which is referred to as complete machining .

Tailstock and steady rest

The tailstock is used to support a long rotary members by means of a centering point , which in the end face is introduced into the workpiece centering engages. Conventional machines have a quill in the tailstock with a Morse taper holder for drill chucks or large drills , which can be turned out with a handwheel parallel to the bed to produce centric bores.

Long, thin turned parts can be supported at any point with the bezel . It prevents the workpiece from swinging and bending due to its own weight and the machining forces. The rotating part is supported in sufficiently wide places by means of sliding or roller bearings . A cutting force compensator can be used optionally or in addition.

Due to their design, front lathes and vertical lathes usually have neither a tailstock nor a steady rest.

Determination of work space

With the dimensions of the components specified above, some characteristic information can first be made about possible dimensions of workpieces that can be machined on the lathe.

A distinction is made between the following terms that must be taken into account when buying a lathe:

- Turning length between the tips, alternative information: tip width

- Circumferential diameter above the bed, alternative information: center height

- Circumferential diameter above the bed slide

The "turning length between centers " is often measured by dismantling the lathe chuck and installing a short face driver in the hollow work spindle from which the sharp-edged driver points only protrude slightly. On the right-hand side of the lathe, a short, non-bearing, rigid point is placed in the tailstock to enable the maximum turning length. In most cases, however, this equipment is not optimally suited for the purpose of turning, so that the real usable turning length decreases.

The "center height" indicates the radial distance from the tailstock center to the next guideway of the machine bed, runs at right angles to an edge of the bed, but usually not vertically; Doubling this dimension provides the swing diameter.

However, the swing diameter above the bed is by no means the same as the maximum workpiece diameter, since a workpiece usually has to be clamped outside by jaws on the chuck, and these jaws also have to rotate above the bed. The workpiece diameter can only be slightly smaller than the circumferential diameter above the bed for workpieces that can be clamped on the front or inside. In practice, it is often a matter of a few millimeters whether a workpiece can be machined on a particular machine or not. The swing diameter over the bed does not include the tool slide: it must remain to the right of the workpiece and, since the slide cannot pass under, machining must either take place on the front side or with long cantilevered and thus unstable tool holders on the circumferential side.

The swing diameter over the bed slide, in turn, is often considerably smaller than the diameter over the machine bed. With the vast majority of lathes, stable external machining is only possible if the slide moves under the turned part - and the workpiece diameter is therefore limited to that "above the bed slide". Since, in turn, the slide often does not remain “naked”, but also varies in size with clamping devices of different heights, revolvers or similar, only one consideration as a whole counts. In addition, care must be taken that any measuring equipment to be used can also be used. The question about sufficient working space of a machine is: Can the given workpiece with its raw dimensions (or preliminary dimensions) be clamped stably with the available clamping devices in such a way that with sufficiently stable tools (including their clamping devices) all of the turning surfaces to be machined specified in the drawing of the workpiece? can be achieved in order to carry out (not only an extremely scarce but also) economical processing?

As a rule, this question cannot be answered with simple statements such as “top height 400 times top width 1200”.

Types of lathes

The lathes can on the one hand be subdivided from the point of view of the application, i.e. according to their requirement profile, on the other hand the design and structure of the machine offer criteria for differentiation. In practice, both methods have their meaning from case to case and are used depending on the company structure of the manufacturer and customer. The Association of German Machine Tool Builders e. V. (VDW) as well as the specialist community for machine tools and manufacturing systems in the Association of German Machine and Plant Construction e. V. (VDMA) have been publishing a list of sources of supply for years, which divides machine tools according to various criteria. This differs slightly from the catalogs of the organizers of machine exhibitions that are oriented towards the international market, such as the European Machine Tool Exhibition ( EMO ). In this consideration the most important machines in the overview according to VDW and VDMA are to be dealt with, but other names such as the ultra-precision lathe are also used.

Center lathe and spindle lathe

The manually operated master and tension spindle lathe is the most widely used machine today with a share of more than 50% of all lathes sold and forms the basic form of the universal lathe. Almost all turning processes can be used on it and there are numerous extensions to choose from. It is always designed as a horizontal lathe with the mostly hollow main spindle and right-hand tailstock mounted in the headstock on the left. The tailstock is used as a counter bearing when machining longer workpieces. Other arrangements are not common. Their feeds can be operated both manually and mechanically using the tension and lead screw. Little planning effort, favorable prices and the versatile purpose enable an economical use in wide areas of single and small series production of turned parts.

Universal lathes

The universal lathe is no longer a specific type, but indicates an area of application. They are either mechanically automated machines such as master and tension spindle lathes with additional equipment or numerically controlled universal lathes.

If several tools are attached to a rotating device, the tool turret, on the slide, the machine is called a turret lathe. The turret tool slide consists of a bed slide, cross slide and turret head. With turret heads, depending on the orientation of the tool axis, a distinction is made between star or disk turrets with a vertical axis and drum turrets with a horizontal axis.

In series production, numerically controlled machines have replaced the manually operated lathes. In addition, mechanically program-controlled machines as single-spindle automatic lathes are still in operation in large-scale production.

In the post-forming lathe (or copy lathe ), a two- or three-dimensional contour is mechanically scanned and transferred to the feed movement of the tool. The contour is transmitted either directly mechanically on a prototype, via a guide curve or guide rail, or via force-amplifying systems, with the contour being scanned by a copy sensor and passed on to the tool hydraulically or electrically via a servo system. Since numerically controlled machines perform these tasks equally or better, this type of machine has largely disappeared.

The CNC lathe combines the advantages of all universal lathes . It often has an additional auxiliary axis, which is generally assigned as the axis of rotation of the work spindle. Each feed axis has its own motor and a position measuring system. The tool slide can accommodate a rotating tool turret and is guided separately from the steady rest and tailstock so that it can be moved independently of them. The machine bed is usually inclined to the side by approx. 30 ° in order to enable better chip removal. Only the effort involved in work preparation and the costs of custom-made simple parts are sometimes higher than with the mechanically controlled alternatives.

Vertical lathe

For particularly large workpieces, so-called vertical lathes are regularly used with a horizontal face plate as the work spindle. The workpiece is clamped centrally on the horizontally rotating face plate. A side tower or two towers and a crossbeam (also known as a crossbeam ) serve as a guide for one or more tool slides and booms, depending on the design (single column, double column or portal design ). With two-column or portal designs, up to three independent turning tools are used at the same time, which significantly shortens the considerable machining time that is typical for large workpieces. The length of the turned parts is relatively limited due to the design. Due to the possibility of a large-area mounting of the face plate, which is often designed as a hydrostatic sliding bearing in large machines , very heavy workpieces such as the pressure vessel of a nuclear or chemical reactor can also be processed.

Vertical lathe with self-loading spindle

Vertical lathes for small workpieces have a movable, vertical work spindle that usually takes a chuck . In most cases the spindle hangs on a horizontal guide and executes some or all of the feed movements. The work spindle ( pick-up spindle ) takes care of the supply of workpieces . With a controlled chuck, it sets down the finished workpiece, grabs a new blank and moves back to the working position. As with any modern machine, the turning tools are held in a turret head. For all-round machining, there are two-spindle vertical lathes with offset working spindles. Once the hanging spindle has completed its program, it automatically forwards the workpiece to the second stationary spindle, on which the back of the part is then machined. This is also generally referred to as the counter spindle and is also used on turning cells and automatic machines. (There with horizontal counter spindle). The tool slide of the second spindle moves on the same guides as the hanging spindle and executes all feed movements.

Automatic lathes

For the production of larger numbers of simple parts (e.g. screws , nuts, etc.), automatic lathes are used that have a slide equipped with several tools and controlled by a mechanical sequence drive in appropriate cycles (as well as clamping head and possibly also tailstock) to have. They are available in single and multi-spindle versions. The machines always have an automatic workpiece supply, occasionally also with tool changing devices. In single-spindle machines, the rod-shaped semi - finished product can usually simply be pushed mechanically through the hollow spindle. Multi-spindle machines require a bar loading magazine arranged behind the main spindles. The mechanical control of the machines is increasingly being replaced by numerical controls, whereby one control can also control several machines. In contrast to automatic lathes with a bar magazine, there are also so-called ring automatic lathes. With these, the workpiece does not rotate, but the turning tools. The raw material is wire wound in a ring, which is continuously fed to the machine, in some cases also dressed.

Furthermore, the short automatic lathes (short lathes) are worth mentioning, in which the workpiece cannot be moved in the axial direction with respect to the tools, and the long automatic lathes (long lathe). In the case of a long lathe, there is a relative movement between the workpiece and the tool. The workpiece is clamped in the spindle with the aid of a collet and guided in a guide bush (steady rest). The axial distance between the guide bush and the tools is constant. There are two systems: In the common "Schweizer" system (named after the inventor), the spindle can be moved axially in a longitudinal guide, while in the more exotic "Offenbacher" system, the rocker stand with the tools and the guide bushing inside is moved. The advantage of both systems lies in the constant distance between the machining point and the support point (steady rest ), even during longitudinal machining. This means that long workpieces can also be machined with small diameters. Long lathe lathes were therefore developed and used primarily in the watch industry for the production of drives such as those used in clockworks. The Swiss type automatic lathes are also used in the manufacture of medical instruments, e.g. B. bone screws made of titanium, as well as used and applied for dental medicine.

Flat bed lathes

Flat bed lathes (and facing lathes ) always have a horizontally arranged bed and a horizontal main spindle. Due to the rigid construction, heavy workpieces can be carried and high machining forces can be absorbed. It is used for workpieces with a swing diameter of more than 800 mm. They are usually designed as a center lathe similar to the master and tension spindle lathe, only that all components are much more powerful and the drives are operated automatically. In order to be able to respond to specific customer requests, the modular design is ideal for these expensive machines. The top width is usually several meters. If the bed is arranged transversely to the main spindle axis, it is usually referred to as the front lathe described below.

Front lathes

Short workpieces that do not require support from the tailstock are machined on front lathes , e.g. B. Brake drums . The lathe bed lies or stands transversely to the axis of rotation of the main spindle, which results in compact machine sizes and good accessibility is guaranteed. Front lathes for chuck processing are often equipped with two or more spindles and automatic workpiece change.

Ultra precision lathes

So-called ultra - precision machines are used particularly in the optical sector in the manufacture of mirrors, for mold inserts made of non-ferrous metals and for hard turning of hardened steels . Highly precise linear guides and spindles (sub- micrometer tolerances) as well as the use of single-grain diamonds as turning chisel edges are essential distinguishing features. Since the chip thicknesses are very small (a few micrometers), well preformed blanks are required. With extreme demands on the accuracy of the turning work, these machines are decoupled from the floor and operated in air-conditioned rooms. The guidance of the slide and the mounting of the spindle are mostly done with aerostatic bearings or hydrostatic bearings , since these have a much better damping and are less prone to vibrations. State-of-the-art hydrostatic threaded spindles also eliminate vibrations, but are only found sporadically due to the high costs. The development in the field of ultra-precision machines is currently aimed at using these machines for processing hardened steels in mass production as an alternative to grinding .

Rotary peeling machines

Rotary peeling machines occupy a special position among lathes, as the tool rotates here and the feed is usually carried out by the workpiece. They are used for peel turning of bar material (a variant of round turning) to a diameter that is the same over the entire length. To do this, the rod moves through a rotating ring equipped with several inwardly directed turning tools. This machine is mainly used to remove the rolling skin of long bars or to produce non-standardized bar diameters.

Special forms

Special lathes are not only profitable in mass production, machines can also be built for small series according to requirements with standard parts according to the modular principle. For example, there are special lathes for camshafts , turbine wheels , axles and crankshafts . Particularly in precision mechanics and precision engineering, there are highly specialized lathes. In watchmaking , this is the watchmaker's lathe or " decolletage machine ". In the watchmaking trade they are still mostly called lathe or swivel chair and not lathe.

Wheelsets of rail vehicles must correspond to a specified profile. These profiles are now turned automatically with CNC- controlled machines. New rail wheels, wheel disks, are turned over individually. The reprofiling of rail wheels is now often carried out without removing the wheel set from the vehicle in underfloor wheel set lathes.

There are horizontal lathes with swing diameters of more than eight meters and turning lengths of approx. 30 meters, which occupy a large machine hall alone (Siemens KWU in Mülheim an der Ruhr , for turning steam turbine rotors). With vertical lathes (so-called "vertical lathes"), workpiece diameter on the face plate of over 15 meters is achieved, with machining heights of up to ten meters (formerly large parts were manufactured at Five-Caille in Lille , northern France). A multi-story house could be turned on such a machine.

Another extreme are ultra-large vertical lathes in individual components. In the mineral industry (e.g. for ore extraction), turning machine components are used on site in the mine (apart from mechanical production facilities) that no longer have a common machine bed. One processing case is the turning of diameters of over 25 meters on race rings for rotary kilns and rotary converters. The processing takes place in such a way that a plan drive unit is concreted in the ground, on which a clamping cross carries the workpiece, the cast ring. 15 meters radially at a distance z. B. the tool slide unit is set in concrete. Measuring systems are placed that allow the dimension assignment between the drive unit (axis of rotation) and the processing unit to be recorded not only statically but also dynamically. While the work is in progress, a possible change in the distance between the tool unit and the drive unit that occurs during the machining process is measured in real time in several axes using laser interferometry and corrected accordingly in the CNC. Even such a machine still has a kind of “machine bed”: the floor and thus the soil into which the components are embedded. Vibrations and problems from the “softness” of this “machine bed” are compensated for in the control.

Since such machines are extremely expensive with high eight-digit replacement values (well over 20 million euros), machining on such machines is not only very expensive for every machining or machine hour; Since the manufacturers of such machines that have been in use for decades no longer exist, great care is taken to ensure that these machines do not suffer any defects, as replacement parts would be extremely difficult or impossible to manufacture.

Another special form is the hobby lathe, which is usually made in small dimensions so that it can be easily placed on a workbench. It is often equipped with a lead screw so that threads can also be produced. Their construction is of simple quality in line with the price, which also explains that the turning results rarely come close to those of professional machines. However, it is quite suitable for simple filming, as can be seen in the picture.

Lathes in series production

Until more powerful computers found their way into machine tool construction in the 1980s , cam-controlled lathes were one of the key factors in industrial production for over half a century. Functional principle: Instead of the lead and pull spindle, there is usually a control shaft in front of the machine, which executes a maximum of one revolution during the cycle time of a series part. Several exchangeable cam disks sit on this shaft, the shape of which defines the direction of movement of a tool slide. Drilling support, bar feed and clamping are also operated via cams or adjustable cam disks. Setup work is more time-consuming than with modern CNC machines, but in terms of durability, ease of repair and resource savings (no electronics), cam-controlled lathes are still unbeatable today. Simple workpieces in large numbers can still be produced very efficiently.

The short lifespan or small number of products makes it necessary to use flexible manufacturing equipment such as flexible manufacturing cells or flexible manufacturing systems . Existing CNC lathes are provided with various devices for this purpose in order to automate the work processes and at the same time to change the production goods quickly. The situation is different with rigid transfer lines, since the machines here only produce one workpiece for a long time. This means that high flexibility can be dispensed with in favor of throughput time.

Turning cells

Turning cells are suitable for small to large series production and consist of a CNC lathe together with a loading device for workpiece supply and disposal and possibly a transport system. In the simplest case, this is a bar feeder which, after machining a workpiece, releases a three-meter or six-meter bar of material and advances it by a defined amount as a blank for the next workpiece from the spindle bore. In mass production, the lathes often have several spindles and independently operating tool turrets. Tool changes and workpiece loading are always fully automatic. They can be linked to other cells to form production lines via a transport system.

Turning system

A turning system is used when, in addition to an automatic workpiece change system and the tool turrets , the tools themselves and possibly also the clamping devices or the measuring devices can be changed automatically. Such highly flexible machines can sometimes run unmanned without a machine operator.

literature

- Frank Arbeiter: Turning and milling: Basics and practical application including the “hot air motor” construction plan. 2nd Edition. Neckar, Villingen-Schwenningen 2004, ISBN 3-7883-0676-9 .

- Rainer Asch: Mathematics and geometry for CNC technology. 2nd Edition. Vogel, Würzburg 2008, ISBN 978-3-8343-3141-0 .

- Klaus-Jörg Conrad (Hrsg.): Pocket book of machine tools. Hanser, Hannover 2002, ISBN 3-446-21859-9 .

- Andreas Hirsch: Machine tools. Basics, design, examples. Vieweg & Teubner, Stuttgart 2012, ISBN 978-3-8348-0823-3 .

- Sven Jochmann: Investigations into process and tool design in high-precision hard turning. Shaker , 2001, ISBN 3-8265-9244-1 .

- Jürgen Eichardt: Turning for Model Builders Volume 1 and 2, 2nd edition. VTH, 2004, ISBN 3-88180-713-6 and ISBN 3-88180-714-4 .

- Jürgen Eichardt: Do-it-yourself small lathe. VTH, 2005, ISBN 3-88180-752-7 .

- Jürgen Eichardt: Milling with a lathe. 2nd Edition. VTH, 2000, ISBN 3-88180-099-9 .

- Kinseher Richard: The bow in culture, music and medicine, as a tool and weapon . (Chapter: Lathes with arc drive), BoD, 2005, ISBN 3-8311-4109-6 .

- Michael Stern, Hans Jendritzki: The watchmaker at the lathe. The watchmaker's lathe, its use and care. 3. Edition. 2006, ISBN 3-9809557-0-2 .

- Heinz Tschätsch: Practice of machining technology. 6th edition. Vieweg, Stuttgart 2002, ISBN 3-528-34986-7 .

Web links

swell

- ↑ Josef Auer: History of the Roman turnery. A Roman lathe. ( Memento of the original from October 6, 2007 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. Heimatverein Vetoniana Pfünz, January 6, 2004 (PDF file, 1 MB)

- ^ A b Günter Spur: On the change in the industrial world through machine tools, a cultural-historical consideration of manufacturing technology. Carl Hanser Verlag, Munich / Vienna 1991, ISBN 3-446-16242-9 .

- ^ Technical Museum Vienna

- ↑ [1]

- ↑ Walter Frick: Diversity of Variants. In: Machine Market. Vogel Industrie Medien GmbH & Co. KG, 2006 issue 8, p. 26.

- ↑ Multi-spindle machine. In: metra-mehrspindler.de. Retrieved January 19, 2019 .

- ↑ Hegenscheidt MFD vertical lathe

- ↑ Hegenscheidt underfloor wheel set lathe