Langenbrahm colliery

| Langenbrahm colliery | |||

|---|---|---|---|

| General information about the mine | |||

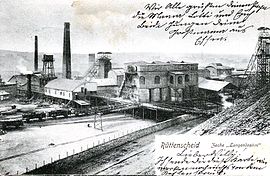

| historical postcard view from 1905 | |||

| other names | Langenbrahms Bank colliery | ||

| Funding / year | Max. 836,651 t | ||

| Information about the mining company | |||

| Employees | up to 2844 | ||

| Start of operation | 1800 | ||

| End of operation | 1966 | ||

| Funded raw materials | |||

| Degradation of | Hard coal | ||

| Geographical location | |||

| Coordinates | 51 ° 25 ′ 18 " N , 7 ° 0 ′ 20" E | ||

|

|||

| Location | Langenbrahm | ||

| local community | eat | ||

| Independent city ( NUTS3 ) | eat | ||

| country | State of North Rhine-Westphalia | ||

| Country | Germany | ||

| District | Ruhr area | ||

The Langenbrahm colliery is a former hard coal mine in Essen in the Rüttenscheid and Rellinghausen districts . The mine is one of the oldest collieries in the Ruhr area with one of the longest uninterrupted production times. The Langenbrahm colliery was one of the founding members of the Association for Mining Interests. The mine was also known as the Zeche Langenbrahms Bank at the beginning of the 19th century . The name of the mine is derived from the names of the flora in the Essen city forest. The gorse growing there was called " bram ", " brem " or " broom ". Langenbrahm was a forest slope by the cave on which this gorse grew.

history

The beginnings

As early as 1772 , the abbot Anselmus von Werden gave permission to mine a coal bank near Kluse. The company itself dated the founding of the Langenbrahm union in 1772. Mining began that same year . However, the hard coal Werck Langenbrahm was first mentioned by the mining authorities in 1796 . The Neuwieserbank field was also of major importance for the mine. In 1796 the Bosselbank seam was awarded. In the same year, when the Neuwieserbank field was awarded, a deep hereditary tunnel was created. The tunnel mouth hole was located about 450 meters west of today's Baldeney house and north of today's Freiherr vom Stein-Straße. The tunnel was north to Long Brahmer saddle ascended . He was later called Böllings Erbstolln .

The first years of operation

At the beginning of the new century the first coal was already being mined. The mining was initially carried out exclusively in the tunnel . In 1802 the mine was closed during harvest time . For promoting one was seigerer shaft with a depth of eight Lach Tern available. The shaft had a clearance of 8 × 4 feet and was equipped with a reel . In 1803, in addition to the Langenbrahm colliery, the Bosselbänkchen colliery was also in operation on the Langenbrahmer Sattel. At Langenbrahm, the two reel shafts 4 and 5 were in production. Both shafts had a deeper depth of 13 laughs. In addition to the normal dismantling, dismantling was also carried out in the substation . In the following year, the Langenbrahm colliery was named the Langenbrahm colliery union . In the same year, the mining authority recognized the merger of the two unions of Bosselbänkchen and Langenbrahm. As a result, the Bosselbänkchen colliery now belonged to the Langenbrahm colliery, based on a settlement concluded in 1788 between the Bosselbank and Neuwieserbank. In the same year Neuwieser tunnel was in the mouth hole section to rupture . In the years that followed, Langenbrahm's trades, Heinrich Bremer senior and Heinrich Bremer junior, made several suggestions about different seams.

In 1805, the deepest tunnel was started at a depth of +51 m above sea level . The tunnel mouth hole of this new tunnel was set about 50 meters south of the old tunnel between today's Freiherr vom Stein-Straße and the railway line. The new tunnel resulted in a depth gain of 10 1/2 laughs. The tunnel was first driven in a north-northwest direction. In the period from August 4th to September 17th of the same year, operations were stopped. The following year, a breakthrough was made between the new and the old tunnel. After the breakthrough had been made with a driveway length of 30 puddles, the new tunnel was driven further north. The tunnel was excavated with a height of 1 1/8 laughers and a width of 3/4 pools. In 1807 a track conveyor was built underground. The railway track was made of wood slats track on which Holzwagen promoted were. The track conveyance existed between the two reel shafts 4 and 5. In 1810, together with the Bosselbank colliery, a 600 Lachter-long sliding path to the coal storage facility on the Ruhr was created and put into operation. In the same year, the reel shafts 6, 7, 8 and 10 were put into operation. In 1812 a weather furnace was put into operation. In 1813 the deepest tunnel reached the first seam with a driveway length of 214 Lachtern with seam Bosselbänkchen . In 1815 the right to inherit the deepest gallery was now assumed as the Langenbrahmer Erbstolln. In the same year the last conveying reel shaft 4 was shut down. As a result, the transport to the coal storage facility on the Ruhr was also stopped. From now on, the production was carried out through the deepest tunnel using push carts to the Ruhr.

The other years of operation

In 1822, which was Berechtsame the disused colliery Bosselbank acquired. In addition, the Fendel-Stolln field was acquired. Overholding was planned in the Morgenstern seam (Geitling seam). In addition, a small seigerer day shaft was set up about 200 meters north of the Kluse this year. The first brake mountain was put into operation and mining began in Flöz Morgenstern. However, since the authorization relationships for this operation were unclear, the mining authority stipulated that this operation should be classified as a separate operation. In order to be able to weather the operation accordingly , the weather was removed from this area by means of a weather oven in the period from October to November . In 1823, at a depth of 12 3/4 puddles, a breakthrough was created between the small day shaft and a weather storm. Due to an order from the mining authorities, all operating points in the Morgenstern seam had to be combined to form the Morgenstern colliery . In 1825, the Wilhelm shaft , which took several tons, was put into operation. At that time, land sales were also promoted for a short time. In 1827 conveyor rails were laid in the tunnel for the first time. The rail track, which was constructed on a trial basis, had a length of 20 laughs, and rails made of cast iron were used. After the test went well, the following year the wooden rails were replaced with cast iron rails along the entire railway line. The track was extended until the coal defeat. In the same year the new railroad was put into operation and the 600 Lachter long sliding route to the Ruhr was shut down. The deepest Langenbrahmer tunnel was driven further north. In addition, the Morgenstern colliery was taken over this year. However, both authorized persons remained separate. The coal mined in the Morgenstern operating area was conveyed through the Tiefsten Langenbrahmer tunnel. In 1829 the right to inherit the deepest Langenbrahmer gallery was granted under the name of Böllings Erbstolln . It was planned to drive the Böllings Erbstolln into the Wilhelminus wing in Rüttenscheid.

The transition to civil engineering

In order to be able to develop deeper tunnel floors, the transition to civil engineering began in 1835 . First of all, the sinking work for a deep excavation shaft began this year. The shaft was named Friedrich Wilhelm, it was set up in Pierensiepen about 100 meters west of today's Klusenkapelle. In addition, a cut was planned in the Morgenstern seam at a depth of 53 meters above sea level (bottom of the Erbstollen). This year the Längenfelder Bosselbank, Hitzberg, Despite I, Mentor and Langenbrahm were awarded. In the following year, after cutting off, the first level was set at a depth of 42 pools and the second level at a depth of 70 pools. A steam engine was installed for the extraction . In addition, two tracks were laid in Böllings Erbstolln between the Friedrich Wilhelm shaft and the coal defeat on the Ruhr. The Friedrich Wilhelm shaft reached a total depth of 21 pools this year. In the following year, the cutting was widened and a dewatering tower was created. In the same year a steam engine was installed to keep the water flowing. After the Wilhelm shaft had reached the bottom of the Erbstollen, the sinking work was stopped. However, the shaft was not put into operation. The seams in the Langenbrahmer Sattel above the bottom of the Erbstollen had meanwhile been dismantled. Funding now took place in civil engineering. From 1840, the United Hermann field was resolved by the Bölling Erbstolln . From 1841 the Amsel & Schnepfe field and from the following year the Bredeneyer Crone field and the Wilhelmus wing were separated by the Bölling Erbstolln. In 1847 the Längenfeld Böllings Erbstolln Beilehn, consisting of parts of the Langenbrahm and Bosselbänkchen seams, was awarded. Due to the co-ownership law, a mining committee was formed for the Langenbrahm trade union for the first time in 1851 . In 1856 the preparatory work for the creation of the third level was carried out. At that time the mine was part of the Essen Mining Authority.

In 1860 a contract was signed between the Wilheminus, Bredeneyer Crone and Langenbrahm unions. On the basis of this contract, Langenbrahm acquired the right to sink a ton-long shaft and to carry out alignment work in Rüttenscheid, in the Wilhelminus wing above the bottom of the Erbstollen to Bredeneyer Crone and below Wilhelminus in the Mausegatt seam . This contract made it possible for the Langenbrahm colliery to switch to civil engineering. In return, the two neighboring mines were given the right to use the new Langenbrahm mine workings. In the same year, the barrel-length shaft above the bottom of the Erbstollen was initially set up and driven as a test cutting. During the excavation, old mine workings were cut through. In 1861 the trial cutting reached the bottom of the Erbstollen. In the same year, the trial cutting was carried out down to a shallow depth of 59 pools below the bottom of the tunnel. It was now intended to align the Langenbrahmsattel at this depth via a cross passage. A horse-drawn tram to the Essen train station of the Witten-Oberhausen Railway was to be built from the start. At that time the mine was part of the Kettwig mining district . In 1862 the trial cutting reached a shallow depth of 340 meters. The first level was set at a shallow depth of 212 meters and the second level was set at a shallow depth of 271 meters. In the deepest part of the test shaft (test cutting), a 20-puddle-long swamp was created. In the same year, the sinking work for a second shaft, which was required as a drainage shaft, began. This shaft was set up seven pools to the west parallel to the test shaft. The Böllings Erbstollen was used to drain the pit water . In 1864, work began on sinking another shaft. The shaft was set up 10 1/2 piles east parallel to the test shaft and sunk in tons. In 1865, the test shaft (test cutting) was prepared as a production shaft. In 1866 the first underground level was set at a shallower depth of 214 meters (−91 meters above sea level). In the same year the two quarter fields Johann Friedrich and Robert were awarded. The inflow of water increased with civil engineering. In 1867, 18 cubic feet of pit water were pumped to the bottom of the pit every minute using a high-pressure steam engine with an output of 24 hp . The mine was now part of the Werden mining district.

Further expansion and operation

From 1868 onwards, regular ropes were approved for the miners leaving . In 1869, consolidated the fields Bosselbänkchen, Morgenstern, despite I, II Despite, Böllings Erbstolln Beilehn, Robert, Langenbrahm, mentor and Johann Friedrich to Langenbrahm. In the same year a connection railway was built. In addition, preparations were made to begin work on the further sinking of the underground construction shaft below the second building level. In 1870, the sinking work on shaft 1 continued and the shaft was sunk deeper. At that time, the Langenbrahm colliery had become the most important colliery in the Werden mining area. In 1871, the third underground level was set in the Morgenstern seam via a tonnage blind shaft at a shallow depth of 191 meters (−68 m above sea level) . In 1872, the union began with the purchase of mining shares the mark distinctive Berechtsamen. In the same year, the colliery connection line to shaft 1 was put into operation. In the following year, the first coal washing machine was built at shaft 1. That same year, the promotion was in tonnlägigen blind shaft in seam Morgenstern followed by promotion set by the Böllings Erbstolln. From now on, all coal production was concentrated at shaft 1. In 1875, a cut was made in the Defens 1 field from the first excavation level. In the following year, the second excavation level was set at a shallow depth of 418 meters. In 1878, the coal washing plant at shaft 1 was put into operation.

In 1883 the Wilhelminus colliery was acquired. In the same year, the sinking work on shaft 1 was resumed and the shaft was sunk deeper from the first underground level. In 1884, shaft 1 was penetrated to the second underground level. In the following year, the production in shaft 1 started operating from the second underground level. In addition, the closed Fortuna colliery was acquired this year . However, since the field was separated from Langenbrahm by the authorized Bredeneyer Crone , no further exploration work could initially be carried out here. With the purchase of the Wilhelminus colliery, Langenbrahm was now able to sink another weather shaft in the Wilhelminus wing. The shaft was also intended for the extraction of mountains . In 1887 another Seigerer shaft called Wilhelmus was set up in the pit field . The following year, the Wilhelminus shaft went into operation up to the first level. In the same year, the sinking work for a tonnel-length blind shaft began with the second underground excavation level. At the tunnel mouth hole of the Bölling Erbstolln a cow was built. In addition, the Geitling colliery on the Wittenberge was acquired. In 1889 a weather chimney was built at the Wilhelminus weather shaft. In the following year, work began on aligning the third underground excavation level (−232 m above sea level) via the barrel-length blind shaft at a shallower depth of 355 meters. At that time, the authorized person consisted of eleven length fields and two square fields. In 1891, mining began from the third excavation level. In 1896 the Kuxen majority of the authorized persons Schnabel in the West I, Schnabel in the West II and Schnabel in the East were acquired. This year there were now six shafts in operation.

The other years

In 1897 the Langenbrahm colliery was part of the southern Essen mining area. This year all seams from Mausegatt to Tutenbänksgen were approached on the third excavation level with a saddle crosscut. About Days central condensation was built and the construction of a new this year processing plant started. On June 15, 1898, the private briquette factory in Dahlhausen went into operation in Bochum-Dahlhausen . In the same year, the rightful Fortuna was transferred to Langenbrahm, and the Bredeneyer Crone field was also acquired. As a result, there were no longer any obstacles in the way of developing the Fortuna field. In the mine at that time were a total of five seams in Verhieb , of whom two seams with mountains means , the other three coal seams were made of pure carbon. The thickness of the seams was between 0.7 and 1.2 meters, for the seams with rock material the thickness of the rock mass was between 0.15 and 0.3 meters. In 1899 a pit ventilator was put into operation at the Wilhelminus shaft, after which the old weather stove including the chimney was shut down. A contract was signed, on the basis of which the Langenbrahm colliery in the Geviertfeld of Vereinigte Hermann and in the Längenfeld Geitling Oberstolln was allowed to dismantle alternately with the Ludwig colliery . In the same year, the Schnabel nach Osten trade union began digging a civil engineering shaft. The shaft was set up at Rellinghausen station. In 1900, the Lackenbach & Lackenbänksken and Bredeneyer Crone in Werdenschen were acquired. In addition, two weather shafts were dropped this year . In the following year, entry and exit via the Böllings Erbstolln was discontinued, and from then on the tunnel was only used in emergencies. The Längenfelder Wiedergeburt and Glückstern and the Geviertfelder Omar and Johannes I were acquired. In 1902, the underground engineering shaft from Schnabel to the east went into operation. In the same year a breakthrough was made between the third underground level and the first level from Schnabel to the east. In 1903, work began on sinking another shaft. The shaft was placed next to shaft 1. In the same year, the Böllings Erbstolln was expanded for weather management. In addition, the Albert and Albertine mines were purchased. The quarter fields Albert and Albertine were awarded in the same year.

After the union had joined the Rhenish-Westphalian coal syndicate, it took care of solutions to problems with briquetting. In 1904, shaft 3 was penetrated with the first underground excavation level. In the same year the Längenfelder Vereinigte Dreifußbank & Erbenkampsbank were acquired. In addition, the Langenbrahm union from Geviertfeld Johannes Erbstollen acquired around half of the Kuxe. In addition, half of the Kuxe of the Längenfeld Johannes Erbstollen. The authorized person now consisted of eleven length fields and ten square fields. In 1905, shaft 3 went into production from the third underground level. The ton-long blind shaft in the Mausegatt seam was dropped in the same year in the area between the second and third underground level. In 1906, shaft 1 became a reserve weather shaft, and the Böllings Erbstolln became the main weather route. In 1907 the quarrying took place in the fields of rebirth and lucky star. In 1908, Schnabel's fourth excavation level was oriented towards the east. A total of eight shafts were in operation this year. The following year, the Langenbrahm union and a group of Berlin banks formed the Diamant-Brikettwerke GmbH Berlin. The purpose of this new company was the exploitation of patents for the production of briquettes. In the same year Langenbrahm acquired the remaining Kuxe from Schnabel to the east. In 1910, the Schnabel colliery to the east was also taken over by Langenbrahm. The Schnabel shaft to the east was henceforth called Langenbrahm shaft 2 . The seigere shaft next to shaft 1 was named Langenbrahm shaft 3 . In autumn of the same year, the first diamond briquette factory was put into operation on Langenbrahm. In addition, a uniform sole name was introduced on Langenbrahm this year. In addition, sinking work for a blind shaft was started from the 4th level. The Langenbrahm 1 shaft was taken out of production in 1911 and from then on served only as a weather shaft. In the same year, the fifth level was set in the blind shaft at a depth of 520 meters (−442 m above sea level ). At that time, the mine had two extraction shafts and three weather shafts. This year, for the first time, vibrating chutes were used for conveying purposes. In 1912 the remaining Kuxe were acquired from the southern field of Johannes Erbstollen. On June 24th of the same year the Fritz field was awarded. From 1913, a separate briquette factory was operated on shaft 2 . On the operation part 1/3 in shaft 1 the rope travel was stopped. In the same year the quarter field Paris was acquired.

The time of the two world wars

In 1914 the Langenbrahm coal trading company was founded. In the same year, the weathering over the Böllings Erbstolln was stopped and shaft 1 was put into operation as a weather shaft. From 1915 until 1922, the coal mine of the United Violence & God Trust was bought up. This year ten Kuxe were initially acquired. The following year the briquette factory on Langenbrahm was shut down. In 1917 the newly formed Geviertfeld Langenbrahm was acquired on the basis of a contract. The square had previously been formed from Schnabel to the east and other authorized persons and had an area of 0.8 km 2 . In 1920 the United Hitzberg colliery was taken over on the basis of a contract and exploration work was carried out in the field. In the following year, another 164 Kuxe of the United Force & God Trust colliery were bought. In the same year the Emil Geviertfeld was acquired. In addition, the briquette factory was rebuilt this year in order to be able to produce briquettes with the addition of coal tar pitch . In 1922, a blind shaft was started in construction site 2 from the 5th level. In addition, the Längenfeld Oebels was acquired that year. In 1923 the briquette factory on the Langenbrahm 2 part of the business was put back into operation. At that time, the rights holders covered an area of over 19 km 2 . In 1925, Stephan Benedict and field parts of the Kämpgesbank and lamp collieries were acquired. These fields were located west of the Langenbrahm mine field and were opened up from construction field 1/3 from 1927. Mining in the new western field began the following year . At that time, the Finefrau seam in the Langenbrahm 2 construction site was being mined.

In 1929 the development of the Stephan Benedict field began. In 1931, sinking work for a die began in construction site 2. The die was needed for the substation construction. In 1932 there were 36 party shifts at the mine . In the same year 480 of its own Kuxe were bought back by the King Ludwig union. As part of the economic upswing of the 1930s, the development of the southern field, which reached into the area of the Schellenberg Forest, began. In 1935 work began here on the Langenbrahm 4 shaft . The facility was given the name Langenbrahm 2/4. In 1937 a chew building was built in the lamp field at the Stollenmundloch. In the same year, shaft 4 went into operation as a weather shaft. On January 1, 1938, the rights to the already closed Eintracht Tiefbau colliery were acquired by the United Constantin the Great . However, there was no more mining in this part of the field. At that time, the rights holders covered an area of 26.7 km 2 . On April 22, 1940, three miners were killed by dull weather . In 1943, an underground connection was started between the pit buildings of 1/3 and 2/4. In 1945, the blind shaft from level 4 to level 5 was completed in construction site 1/3. At that time, the rights holders covered an area of 27.1 km 2 .

The years after the Second World War

In the first year after the end of the Second World War, construction site 1/3 and construction site 2/4 became penetrable. For this purpose, a connecting blind shaft from the 3rd level of construction site 1/3 to the 5th level of construction site 2/4 was put into operation in 1946. After the connection between the two construction sites was established, the 1/3 part of the operation was shut down. The coal mined in construction site 1/3 was conveyed underground via the connecting blind shaft to operating part 2/4 and conveyed there above ground. Shafts 1 and 3 initially remained in operation for ventilation. The 5th level was used as the main delivery level. The ton-length shaft 1 was no longer required and could be dropped and filled. In 1948 the shaft was filled . Shaft 2 was still used for ventilation. In 1949, the mine field was enlarged to the north by leasing the Ludwig colliery from the Gutehoffnungshütte in Bergerhausen . The entire right now covered an area of 30.8 km 2 . From then on, both shafts of the colliery were run as the pit department of the Langenbrahm colliery and were responsible for cable travel , extraction and weather management .

In 1950 the promotion to Ludwig was stopped. In the same year, the sinking work was resumed in shaft 2 and the shaft was sunk deeper. In 1951, the 6th level was set at a depth of 650 meters (−572 meters above sea level). In the same year the Langenbrahm coal trading company was dissolved. At that time, the rights holders covered an area of 31.5 km 2 . In the following year, the trade interests of the Langenbrahm union were integrated into the coal export company. In 1954 the Ludwig mine was finally taken over by Langenbrahm. In addition, the authorized united hall was acquired. In addition, over 105 Kuxe from the Lehmkuhle Union and 361 Kuxe from the Union of United Violence and God Trust were acquired. At the trade union meeting on December 15 of the same year it was decided to convert the Langenbrahm coal mine into the Langenbrahm Steinkohlenbergbau Aktiengesellschaft. This resolution came into effect retrospectively as of October 1st of the same year. The coal export company in Essen and the union united violence and god trust remained unaffected by this conversion.

The last few years until the shutdown

In 1956, a penetration was made on the 6th floor with the 6th floor by Ludwig. In the Ludwig construction site, the tracks were given the same gauge as the Langenbrahm tracks (645 mm). In 1957, the opening of the violence & God trust field began, after which the field was also mined. In 1960 the 6th level became the main extraction level. In the same year a field swap was made. A part of the field called Katharina, acquired from the Johann Deimelsberg colliery , was exchanged for a part of the field from Eintracht Tiefbau. After the exchange, the exploration of the part of the field began, and later mining was also carried out in the part of the field. In 1962, the sinking work for a blind shaft began on the 6th level. At that time, the rights holders covered an area of 30.5 km 2 . The following year, the 7th level was set in the blind shaft at a depth of 770 meters (−692 meters above sea level). In the same year, the 8th level was set at a depth of 888 meters (−810 meters above sea level). In 1964, mining began on the 7th level. On March 31, 1966, the Langenbrahm colliery was shut down after almost 200 years. The shafts at Langenbrahm and Ludwig were filled, with the exception of shaft Ludwig 2, and the daytime facilities were demolished.

Promotion and workforce

Lumpy lean coal of good quality was extracted from the mine . The coals were also used to make bricks. The first production figures come from 1800, in that year 1500 tons of hard coal were produced . The first workforce dates from 1802, when three miners were employed at the mine. In 1806, 2535 tons of hard coal were mined, the workforce was 21 employees. In 1810 the production rose to 4645 tons of hard coal, this production was provided with 27 employees. In 1815 the production sank to 2929 tons, the workforce was 23 employees. In 1820 around 5600 tons of hard coal were mined with 42 employees. In 1830, 21,568 tons of hard coal were extracted and the workforce was 81. In 1840, with 88 employees, 76,916 Prussian tons of hard coal were mined. In 1850 19,611 tons of hard coal were mined with 105 employees. In 1866, 153 employees produced 126,333 Prussian tons of hard coal. In 1875 the workforce was 298, the production was 85,298 tons of hard coal. In 1885 the production rose to around 151,000 tons of hard coal, this production was provided with 568 employees.

In 1890 the workforce was 848, the production amounted to 237,196 tons of hard coal. In 1900, 1031 employees produced 279,248 tonnes of hard coal. In 1910, production rose above the 500,000 ton mark for the first time. This year, around 637,000 tonnes of hard coal were extracted, and the workforce this year was 2,200. In 1915 the production sank to 490,169 tons, the workforce was 1642 employees. In 1920, 603,861 tonnes of hard coal were extracted and the workforce was 2,779. In 1925 the production rose to 654,533 tons of hard coal, this production was carried out with 2,844 employees. In 1930 around 759,000 tons of hard coal were mined with 2,720 employees. In 1935 the production rose to 726,426 tons of hard coal, this production was provided with 2,694 employees. The maximum production of the mine was achieved in 1939. With 2,722 employees, 836,651 tons of hard coal were mined. In 1950, 2260 employees produced 417,786 tonnes of hard coal. In 1960, 342,447 tons of hard coal were mined, the workforce was 1899 employees. In 1965, more than 400,000 tons of hard coal were extracted. The workforce was 1371. These are the last sponsorship and workforce figures.

Current condition

The Langenbrahm site 1/3 south of the Alfried Krupp Hospital is now cut up by the A 52 . The remaining area was partly renatured, partly the Langenbrahm industrial park and a new residential area are located there today . The Langenbrahm 2 site on St. Annenhöhe north of Frankenstrasse was built over by the Schnabelstrasse industrial estate . The area of shaft 4 has been renatured.

Individual evidence

- ↑ a b c d e f g h i j k l m n o p q r s t u v w x y z aa ab ac ad ae af ag ah ai aj ak al am an ao ap aq ar as at au av aw ax ay az ba bb bc bd be bf bg bh bi bj bk bl bm bn bo bp bq br bs bt bu Joachim Huske : The coal mines in the Ruhr area. Data and facts from the beginning to 2005 (= publications from the German Mining Museum Bochum 144) 3rd revised and expanded edition. Self-published by the German Mining Museum, Bochum 2006, ISBN 3-937203-24-9 .

- ↑ a b c d e f g h i j k l m n o p q r Wilhelm Hermann, Gertrude Hermann: The old collieries on the Ruhr. 4th edition. Publishing house Karl Robert Langewiesche, successor Hans Köster, Königstein i. Taunus 1994, ISBN 3-7845-6992-7 .

- ↑ a b c d e f g h i j k l m n o p q r s t u v w x y z aa ab ac ad ae af ag ah ai aj ak Gerhard Gebhardt: Ruhrbergbau. History, structure and interdependence of its societies and organizations. Verlag Glückauf GmbH, Essen 1957

- ↑ Historical Society for city and pin meal (ed.): History of city and pin meal . Twenty-seventh issue, GD Baedeker publishing house, Essen 1905, p. 53.

- ↑ a b c d e f g Manfred Rasch , Gerald D. Feldman (eds.): August Thyssen and Hugo Stinnes. An exchange of letters 1898-1922, Verlag CH Beck oHG, Munich 2003, ISBN 3-406-49637-7 .

- ↑ a b c d e f g h i j k l m n o p q Günter Streich, Corneel Voigt: Zechen Dominanten im Revier. 2nd expanded and revised edition, Verlag Beleke KG, Nobel-Verlag GmbH, Essen 1999, ISBN 3-922785-58-1 .

- ↑ R. v. Carnall (Hrsg.): Journal for the mountain, hut and saltworks in the Prussian state. Fifth volume, published by Wilhelm Hertz , Berlin 1858.

- ↑ Ministry of Commerce and Industry (ed.): Journal for the mountain, huts and saltworks in the Prussian state. Tenth volume, published by the royal and secret Ober-Hofdruckerei (R. Decker), Berlin 1862

- ↑ Ministry of Commerce and Industry (ed.): Journal for the mountain, huts and saltworks in the Prussian state. Eleventh volume, published by the royal and secret Ober-Hofdruckerei (R. Decker), Berlin 1863

- ↑ Ministry of Commerce and Industry (ed.): Journal for the mountain, huts and saltworks in the Prussian state. Sixteenth volume, published by Ernst & Korn, Berlin 1868

- ↑ Ministry of Commerce and Industry (ed.): Journal for the mountain, huts and saltworks in the Prussian state. Eighteenth volume, published by Ernst & Korn, Berlin 1870

- ↑ Ministry of Commerce and Industry (ed.): Journal for the mountain, huts and saltworks in the Prussian state. Volume nineteenth, published by Ernst & Korn, Berlin 1871

- ↑ Ministry of Commerce and Industry (ed.): Journal for the mountain, huts and saltworks in the Prussian state. Volume forty-sixth, published by Wilhelm Ernst & Sohn, Berlin 1898

- ^ Association for Mining Interests in the Upper Mining District Dortmund: The development of the Lower Rhine-Westphalian hard coal mining in the second half of the 19th century. Julius Springer's publishing bookstore, Berlin 1902, p. 340

- ↑ G. Keller: Paleographical investigation of the Finefrau horizon . In: Glückauf, Berg- und Hüttenmännische magazine. Association for Mining Interests in the Upper Mining District Dortmund (Ed.), No. 45, 65th year, November 9, 1929, pp. 1541–1548

- ↑ The coal of the Ruhr area . Compilation of the most important mines in the Ruhr coal mining area, specifying the quality of the coal mined, the rail connections, as well as the mining and freight rates. Second completely revised and completed edition, publishing bookstore of the M. DuMont-Schauberg'schen Buchhandlung, Cologne 1874

- ^ Royal Statistical Bureau in Berlin (ed.): Prussian Statistics XIII . Comparative overview of the course of industry, trade and traffic in the Prussian state 1866. Verlag Ernst Kuehn's statistical Separat-Conto, Berlin 1868.

Web links

- Early mining on the Ruhr: Langenbrahm colliery (accessed on July 21, 2014)

- Langenbrahm coal mining (accessed on July 21, 2014)

- Albert Grieseler: Langenbrahm colliery (accessed on July 21, 2014)

- Early documents and newspaper articles on the Langenbrahm colliery in the 20th century press kit of the ZBW - Leibniz Information Center for Economics .

Remarks

- ↑ The term coal bank is the name for the coal-bearing part of a coal seam . (Source: Carl Friedrich Alexander Hartmann: Vademecum for the practical miner. )

- ↑ A weather overburden is a mine that is built in the seam from bottom to top and is used for ventilation . (Source: Tilo Cramm, Joachim Huske: Bergman language in the Ruhr area. )