vacuum cleaner

A vacuum cleaner (formerly also a vacuum cleaner ) is a cleaning device that is equipped with a fan that creates a negative pressure . There is a suction opening on the suction side of the vacuum cleaner. This is guided by the user specifically over the surfaces to be cleaned. The sucked in air flows through several filters or a cyclone ; these filter dust (mostly house dust ) and smaller dirt particles out of the air flow. The air leaves the vacuum cleaner much cleaner than it came into it. Brush fires in the electric motor can generate ozone . If the exhaust air is passed over the motor to cool the motor, this can result in a “fresher” smell when vacuuming, the effect is used in some models with an ozone generator .

Technical characteristics

The vacuum cleaner replaced the broom in many areas and the carpet beater almost everywhere . Vacuum cleaners can pick up dust or dry dirt from smooth and rough surfaces. Only special vacuum cleaners are suitable for vacuuming up wet dirt (mud, etc.). Vacuuming saves you having to sweep it up with a hand brush and go to the ash bucket; With modern filters, significantly less dust is thrown up than when sweeping. Tapping suction devices save tapping the carpet; This means that carpets no longer have to be taken out of the house to be cleaned and tapped. It was the vacuum cleaner that created the basis for the current spread of carpets.

Carpets - both loosely laid and firmly laid - can also be cleaned with foam cleaner.

history

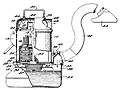

The vacuum cleaner was invented in the USA between 1860 and 1876 . The first devices are said to have been developed by Daniel Hess in the state of Iowa and Ives W. McGaffey, an inventor in Chicago . McGaffey received a patent in 1869 for a hand-operated vacuum cleaner with an external filter bag. On September 19, 1876, Melville Bissell received a US patent for the first functioning vacuum cleaner for carpets ("Carpet Sweeper"). Many sources unanimously report that Anna and Melville Bissell allegedly owned a device that was mounted on a horse-drawn cart. From there the house was then cleaned with a hose. The air pump on these teats was still operated by hand. Around 1901, Hubert Cecil Booth was surprised that a device was used on trains to blow dirt and dust off the seats. He considered that it would make more sense to use a handy device that sucks in the dust. Booth patented his invention in England but never succeeded with his idea. In 1905 the first portable vacuum cleaner was presented by Walter Griffiths. It combined the advantages of simple handling with electrical suction technology.

The other inventor was the American James Murray Spangler , a caretaker from Canton, Ohio . In 1906 he made a vacuum cleaner out of a fan , a box and a pillow. In addition to the suction, his device also used a rotating brush to loosen the dirt. Spangler patented his device in 1908 and soon sold the idea to his cousin's company, the "Hoover Harness and Leather Goods Factory". Even today, Hoover is one of the leading manufacturers of vacuum cleaners. In Great Britain the name Hoover even became a synonym for vacuum cleaner or vacuuming itself ( doing the hoovering ).

In 1910 Eberhard Seger patented the vacuum cleaner in Sweden and began manufacturing a variant of the American model of the Santo brand. It was called Salus L 3.585 and was manufactured in Sweden in 1913 by Lux AB , which became Electrolux in 1919 .

From 1910 Gustav Robert Paalen and Axel Wenner-Gren developed a light version of the Santo vacuum cleaner for household use, which Paalen had sold on the international market since 1907. In 1912, the two entrepreneurs became competitors, Paalen with a forerunner of the Santo broom (produced by AEG from 1922, Vampyr from 1928 ) and Wenner-Gren with the Lux I model , whose patent he sold in 1919 from his company Elektromekaniska AB and Lux AB forged the Electrolux company .

Until the First World War , vacuum cleaners were a luxury. Only rich people could afford such a device, and even they preferred to hire maids to clean the dust. As a rule, permanently installed house vacuum cleaners were used. These were central devices with a pipe system branching out throughout the house , to which the hand devices were connected via a hose line . In Berlin there were also red “vacuum cleaners” as vehicles, awkward boxes on wheels in which an engine hummed. Long hoses ran up to the windows, sucking dust from carpets and furniture. The developments by Paalen and Wenner-Gren revolutionized the market and brought both entrepreneurs to enormous wealth. In the 1920s and 1950s, portable devices spread and gradually became more affordable. At the same time, carpets became a common floor covering . In the 1980s, small, battery-powered handheld vacuum cleaners came onto the market, but they were poor in suction and, with their rigid, slit-shaped suction opening, could not reach corners that were difficult to access.

Working principle

In general, the functional principle is the same for all common vacuum cleaners. The device consists of the device body. This houses a motor (usually a series motor or an all-current motor , sometimes also a shaded pole motor ) for the fan to generate the negative pressure. The fan consists of a one- or two-stage centrifugal compressor .

The negative pressure generated by the fan causes the ambient air, which is exposed to normal air pressure, to flow powerfully into the vacuum cleaner in order to compensate for the negative pressure. In the process, dust and dirt are carried away and enter the interior of the housing via the suction pipe. The air enriched with dirt is cleaned there. It then flows through the motor to cool it - this is the only way to keep it so small that transportable devices are possible. Since the negative pressure is maintained by immediately blowing the incoming air out again, a continuous flow of air is created. It becomes clear that the term "vacuum cleaner" is actually out of place. The English appropriately call it "vacuum cleaner". There is no suction at any point. The fan pushes the air out of the device, thus creating a negative pressure and the usual air pressure pushes ambient air into the device. Where there is no air pressure, e.g. B. on the moon, no "vacuum cleaner" can work. The fan blades would turn with no effect whatsoever.

In series with the motor there is usually a triac controller ( phase control ), on which the suction power can be set with a variable resistor via the current flow angle . The controller is also used to limit the inrush current .

A distinction can be made between bag vacuum cleaners and bagless vacuum cleaners. Bagless vacuum cleaners include cyclone vacuum cleaners and vacuum cleaners with separators.

Bag vacuum cleaner

The air flow is directed directly into the air-permeable bag. This filters the air and collects the dust at the same time. Bags made of multi-layer paper filters (2–5 layers of different grain size) or non-woven bags are common.

After the bag, the air usually flows through another filter that separates finer dust. There is also a coarse filter in front of the motor, which protects the motor and fan if the bag tears when sharp objects are sucked in. In the exhaust air area there is usually a microfilter that also captures the fine carbon abrasion from the motor's carbon brushes . According to industry estimates, around 220 million euros per year are spent on vacuum cleaner bags in Germany. The production costs are around 10 to 20 cents. In Germany there are over 1,200 different types of bags, in Spain there are only about five.

Bagless vacuum cleaners

Bagless vacuum cleaners generate a vortex in the incoming air flow, whereby the dust particles are pressed outwards and separated due to the centrifugal force ( centrifugal separator ). Since the typical smell of a vacuum cleaner comes primarily from the contents of the vacuum cleaner bag, bagless vacuum cleaners are usually odorless, provided they are cleaned after each use. If the rotation speed of the vortex is correspondingly high, there is no need for an additional filter behind the vortex, which could also generate odor. In contrast to bag vacuum cleaners, the centrifugal separators do not become clogged with dust, so that - if no additional filter is installed - there is no loss of suction power over time.

Single cyclone vacuum cleaner

In cyclone vacuum cleaners, the air vortex is generated by blowing the air into a conical container from the side. The centrifugal force pushes the dust outwards, it moves down along the cone and falls into a collecting container, while the clean air in the center of the vortex is sucked upwards. As a rule, the dust is collected in a dry container, but there are also containers with water, which means that it does not generate dust when emptying. Single cyclones work quite well, at least with larger debris, while fine dust still has to be caught by a central paper filter. This central filter clogs up relatively frequently, which then greatly reduces the suction power, and must therefore be cleaned correspondingly frequently - usually under running water. The filter then has to dry completely before the paper, which has been swollen by the moisture, releases its pores and thus regains its permeability. A so-called HEPA filter is often used as the filter insert .

Multi-cyclone vacuum cleaner

As with the single cyclone vacuum cleaner, the incoming air flow is initially set in rotation in order to separate the larger dirt particles. The air is then passed through a second "cleaning stage" with several smaller cyclones instead of a central filter. Due to the smaller diameter of these smaller cyclones, the air is set at a much higher rotation speed, which means that finer dirt particles can also be separated out. As the number of cyclones increases, the size of the separated dust particles decreases, so that the central filter can also be omitted with many cyclones. This also eliminates the need to clean the central filter and its loss of suction power. The first relatively expensive vacuum cleaners with multi-cyclone technology were brought onto the market by the Dyson company in the 1980s . Meanwhile there are also much cheaper models with multi-cyclone technology from various brands and a few no-name companies. While most multi-cyclone vacuum cleaners are satisfied with two cyclone levels, Dyson now offers vacuum cleaners with three cyclone levels, which should improve the separation efficiency even further. However, a particulate filter is also required for these models to separate fine dust .

In 1985, the British engineer James Dyson further developed these vacuum cleaners, which work according to the cyclone principle, to a more manageable design. The devices were first offered in Japan and were very expensive. Since 1995 they have also been offered in Europe at moderate prices. In addition to Dyson, other suppliers are now also producing such small vacuum cleaners. The air in cyclone vacuum cleaners is moved around a container in tapering circles at high speed. The centrifugal force causes the dirt particles to migrate to the walls of the container. The pre-cleaned air is then led outside through a fine dust filter. In the case of bagless vacuum cleaners with filters, the filters must be regularly cleaned of the dust that is sucked in. A new filter purchase is usually required once a year in order to maintain the function.

Vacuum cleaner with a water filter

These vacuum cleaners use different techniques to bind dirt to the water. They have the advantage over dry vacuum cleaners that they can also pick up wet dirt. In addition, there is no loss of suction power due to the dust picked up if no additional filter is installed. However, they must be emptied after each use, otherwise there is a risk of mold growth.

With separator

This type of vacuum cleaner has a so-called separator - a rapidly rotating rotor that actively rotates the air. The first vacuum cleaner with a separator was developed by JW Newcombe in 1922. The dust was collected in a dry container. Due to the movement of air, the dust did not settle as well. For this reason, CA Brock added a water bath to the vacuum cleaner in 1937. The dust is now quickly bound in the water and can no longer stir up. To this day, most water vacuum cleaners are made according to this pattern. When the air flows into the vacuum cleaner, an air channel forms in the water at the intake opening to the water bath. The air flows through this, causing coarse dirt to get stuck in the water. Fine dust is then separated by the separator. While the air is sucked into the separator, the latter sets the air in rapid rotation. As a result, large centrifugal forces act on the dust particles, which is why they do not flow into the separator, but are thrown into the water bath and are bound there. Some water vacuum cleaners do without an additional filter, as this could lead to a loss of suction power or even germs over time. The dirty water is disposed of in the toilet after each vacuum without causing the dust to be raised again. Water vacuums with separators are usually significantly more expensive than multi-cyclone vacuums.

Without separator

Water vacuums without a separator are cheaper because the motors are smaller. The air flows through water and filters. Either a dry filter is installed after the water bath or a wet filter inside the water bath. If the dry filter is placed after the water bath, the dry filter collects the fine dust while the coarse dirt ends up in the water beforehand. Some vacuum cleaners circulate the air in the water so that the dust is better bound in the water. Due to the high volume flow, however, it is not possible to separate the fine dust in the water simply by swirling it. The fine dust is then collected in the dry filter. Alternatively, filters are also used under water. To prevent contamination, these filters must be washed after each vacuum. This is time-consuming, but has the advantage that it prevents odor formation.

General types

Three construction variants have become established for portable vacuum cleaners for home and workshop use:

- The cylinder vacuum cleaner consists of a unit mounted on castors or wheels, in which the motor, fan, filter and bag are located. The suction tube with brush head is connected to the device unit via a hose. Wet, dry and industrial vacuum cleaners also have this basic structure ( see next section).

- The hand or trunk vacuum cleaner is composed of an apparatus body, in the motor, blower, filter and bag are housed and to which the suction pipe is mounted directly below, at which the brush head is located. On the upper side there is the handle at the end of a tube leading out of the device.

- The hand-held or wand vacuum cleaner consists of an elongated housing, housing the motor, blower, filter and bags, and passes directly into a wide, slit-shaped suction port. As a rule, it has no suction pipe and no hose. There is a handle on the top.

The effectiveness of the devices can be increased by brush heads, which support the removal of dirt from carpets by built-in rotating brushes; these are driven by the air flow or an additional electric motor (electric brush). With some devices, the brush heads are supplied or are permanently installed, some devices can be retrofitted.

Additional nozzle accessories enable dust and dirt to be removed even in hard-to-reach places.

Historically and regionally, different vacuum cleaner designs are preferred in the household: In Germany today, cylinder vacuum cleaners are predominantly in use, while earlier, more hand-held vacuum cleaners were in use due to smaller apartments. Upright vacuum cleaners are often used in England, and hand vacuum cleaners are more common in Italy.

Special designs

Industrial vacuum cleaner

At the end of the 1950s, thanks to advances in industrial production, there was an increasing desire to dispose of dust and similar waste products inexpensively and hygienically. For this purpose, the boiler principle was further developed. A Danish company was the pioneer in this sector and initially built rather misshapen industrial vacuum cleaners that looked like an overturned barrel and were driven by one or more household vacuum motors (1-phase). The shape and size gradually adapted to market requirements. The boiler principle in industrial vacuum cleaners is still evident today.

The area of application of these devices has expanded significantly over time. In the beginning an industrial vacuum cleaner was mainly used for cleaning rooms, buildings or workshops, later production systems, grinding machines, punching machines, handling devices etc. were added, some of which are in use around the clock. In today's industrial vacuum cleaners mostly three-phase motors are installed.

In the meantime, industrial vacuum cleaners, some in large-scale design as a special vehicle, are also used to remove leaves during street cleaning or during earthworks in road construction, where the excavation is no longer heaved onto a dump truck by excavator and shovel, but is vacuumed directly. Something similar happens with demolition work on buildings.

The test procedure for industrial vacuum cleaners and dust-removing machines (SBM) according to the EN 60335-2-69 standard has changed in the course of technical progress. Accordingly, devices have been evaluated over time using different test methods and it is often not clear which use category of a device corresponds to a certain dust class. An overview developed by the Institute for Occupational Safety and Health of the German Social Accident Insurance therefore shows the classification according to the various test principles based on the intended suitability of the devices.

Boiler vacuum

With boiler suckers , also purpose vacuum cleaner or N ASA / t rock sucker called, in addition to dry dirt and liquids are absorbed. The filling volume depends on the boiler size. The container is usually around 20 to 30 liters. Containers with a volume of 40 liters or more are mainly used commercially. No dust bags are used in wet operation, only cylindrical filter cartridges. If these vacuum cleaners are to be used exclusively for dry work, a relatively large dust bag can be used in addition to the filter cartridge on many models, which on the one hand greatly simplifies emptying and makes it much more hygienic, on the other hand, due to the additional filter effect in combination with the filter cartridge that is already present, it also has an exhaust air side allows more hygienic operation.

In the case of boiler vacuums, the dirt and water separation is supported by a centrifugal separator (pot with helical air movement). Kettle vacs were also available for domestic use as early as the 1930s (Siemens-Schuckert-Werke).

Mud sucker

A variant of the tank vacuums are sludge vacuums with which bottom sludge and sludge are sucked out of swimming ponds and ornamental ponds. More powerful models work on a different principle with impeller pumps and flow.

Leaf vacuum and table vacuum

For outdoor use in the garden, there are leaf vacuums , which are often powered by a small combustion engine. For foliage and other purposes there are devices that are carried on the back.

Smaller, battery-operated devices are used as table vacuum cleaners . These are also known as cordless vacuum cleaners. They offer increased flexibility due to the lack of a cable, but are nowhere near as powerful as the larger models.

Street vacuum

For outdoor use on streets and sidewalks, there are mobile suction devices with which the operator can remove contamination. The devices roll on small tubular tires and are soundproofed.

In some countries, motorbike-mounted vacuum cleaners are also used to vacuum up dog poo.

Vacuum cleaner robots

Since the 2000s there have been various vacuum cleaner robots that remove dust automatically. Discus-shaped machines (approx. 35 cm in diameter and 12 cm in height) move autonomously through living rooms, the geometries of which they measure themselves with the help of sensors, and suck up the dust from the floor. It is powered by accumulators which are recharged at a charging station after the work phase. Advanced systems drive these charging stations automatically after their work is done. Depending on the model, time programming is also possible.

Other models also carry out wet floor mopping. In the simplest, early developed case, a ball rolls with an internal center of gravity shifting drive and takes a light, rotationally symmetrical cap with it, the central hat-shaped cage of which is carried along by the ball, so that a disposable fleece that is attached to the underside of the wide brim resting on the floor, slides across the floor and picks up dust.

Central vacuum cleaner

Centrally installed systems ( central vacuum cleaner , vacuum cleaner system , built-in vacuum cleaner or house vacuum system ) consist of the central suction unit, which is stationary (usually in the basement, an adjoining room or in the garage). From there, a pipe system is laid throughout the house, to which the suction pipe with the brush head is connected via a hose line . Dust can be removed directly using dust cans instead of a dustpan . After it has been conveyed to the device via the vacuum tubes in the walls, the suction air is cleaned in a cyclone filter or lamellar filter and directed outside via tubes. The odor like conventional vacuum cleaners through the turbulence of the air in the room is omitted, which is especially for fine dust - Allergy is an advantage. The noise from such a device is correspondingly low and the overall energy balance is also slightly better than with handheld vacuum cleaners. This design has been around since the beginning of the 20th century, but was only able to establish itself in certain regions, e.g. B. in the Scandinavian countries and North America. Central vacuum cleaners usually last longer than hand-held vacuum cleaners, so it is important to ensure that the system is installed and maintained carefully. When planning a house suction system, a suitable combination with a possibly existing ventilation system must be ensured.

Technical specifications

The performance of a vacuum cleaner, if stated at all, is characterized by various parameters:

- Maximum pressure difference , measured in meters of water column , millibars or pascals [Pa]

- Air speed , measured in meters per second [m / s]

- Volume flow , measured in cubic meters per second [m³ / s] or liters per second

The suction force is the maximum pressure difference to the surrounding air pressure that the vacuum cleaner fan can generate. A good device can generate a pressure differential of around 25 kPa. This corresponds to about 25% of the normal air pressure of 100 kPa. However, this information alone is not sufficient for characterization, as it is only achieved when the air flow is prevented. Good suction properties can only be achieved if sufficient negative pressure is still generated at a certain volume flow. The maximum volume flow of an industrial vacuum cleaner is, for example, about 60 l / s, which results in a flow rate of about 48 m / s with a suction tube diameter of 40 mm. If the volume flow and the pressure difference are halved, the kinetics of the air volume flow in this vacuum cleaner are around 440 watts.

Usually the manufacturer only specifies the electrical power consumption of the vacuum cleaner in watts . However, this information does not allow any conclusions to be drawn about how effectively the vacuum cleaner works. It only provides an indication of the suction power, because this depends largely on the aerodynamic design of the fan, the e-motor efficiency, the air duct and the suction attachment (the nozzle). The suction power also decreases quickly, especially with small filter bags and a lot of dust.

If the suction power is too high, the nozzle can get stuck on the floor or on curtains. Therefore, most vacuum cleaners are provided with an additional adjustable air opening (secondary air) or better with a triac actuator for electronic control of the motor power.

Further quality criteria of a vacuum cleaner are its dust emission, sound power level and the reliably functioning filter and dust bag change. Some vacuum cleaners are mechanically locked to prevent accidental operation without a dust bag.

EU regulations

Limitation of power consumption

Beginning in July 2013 put the European Commission with Regulation (EU) no. 666/2013 a regulation under the Ecodesign Directive of vacuum cleaners before. Accordingly, from September 1, 2014, only vacuum cleaners with a maximum power consumption of 1600 watts may be sold; on September 1, 2017, the limit was reduced to 900 watts. At the same time, limit values for dust and noise emissions as well as minimum values for dust absorption and durability are specified.

The Stiftung Warentest assesses the limit values as uncritical. In a test in January 2014, 7 out of 15 vacuum cleaners had a “good” suction power of less than 1600 watts. The test winner only needed 870 watts and thus already met the stricter limits that will apply from 2017. According to the industry, the industry is calm about the introduction of the power limitation for vacuum cleaners. In addition, some types of vacuum cleaners have been exempted from the regulation, for example vacuum robots, cordless vacuum cleaners, wet vacuums, central vacuum cleaners, industrial vacuum cleaners and floor polishing machines.

Limitation of noise emissions

The limit value for noise emissions set by the European Commission at the beginning of July 2013 with Regulation (EU) No. 666/2013 as part of the Ecodesign Directive for vacuum cleaners is 80 dB (A).

Energy label

The new energy label for vacuum cleaners has brought six new pieces of information since September 1, 2014:

- Energy efficiency class A to G : The most important starting point for achieving a good energy efficiency rating is to reduce the input power.

- Annual electricity consumption in kWh : calculated for an average household with 87 m² of living space and 50 cleaning processes per year.

- Sound power level : indicates the noise level of a vacuum cleaner in dB (A).

- Dust emission class A to G : is an indicator for clean exhaust air.

- Carpet cleaning classes A to G : describes the dust absorption of a standardized test carpet.

-

Hard floor cleaning classes A to G : describes the dust pick-up from a crack filled with dust on a wooden plate.

Since January 19, 2019, vacuum cleaners can again be sold without an energy label.

equipment

Most vacuum cleaners today have three additional attachments as standard accessories. Some models have a flap behind which these three can be kept within easy reach.

- A crevice attachment (crevice nozzle; a long, narrow "trunk" with which you can vacuum in narrow gaps (e.g. cracks in the couch)).

- A furniture brush (round suction opening; hair / bristles forward to avoid scratches on sensitive surfaces).

- An upholstery nozzle (for upholstered furniture, car seats, car carpets, etc.)

Major manufacturers and brands (selection)

- sorted alphabetically by manufacturer -

|

|

|

literature

- Christoph Glauser: Simply squeaky clean: The story of the vacuum cleaner Orell Füssli Verlag, 2001.

References

See also

Web links

- Swiss collection of vacuum cleaners from various manufacturers , hangar.ch, accessed on April 24, 2015

Individual evidence

- ↑ Lueger, Otto; Lexicon of all technology and its auxiliary sciences , Volume 8; Stuttgart, Leipzig 1910, p. 273 u. 743

- ↑ Patent US29077 : Carpet Sweeper. Published July 10, 1860 , inventor: Daniel Hess.

- ↑ MH Herlt: Household vacuum cleaner . In: dust . Volume 44, 1956, pp. 208-214.

- ^ University of Houston's College of Engineering : Melville and Anna Bissell (English), accessed on November 6, 2011

- ↑ U.S. Patent Number 182,346, September 19, 1876, accessed November 6, 2011

- ↑ Development of the first portable vacuum cleaner. Retrieved May 7, 2019 .

- ^ Swedish Innovations. Retrieved November 15, 2019 .

- ↑ History Lux Germany , lux-deutschland.de, accessed on January 3, 2015

- ↑ Absurd diversity - The eternal trouble with the vacuum cleaner bag , welt.de, November 20, 2013

- ^ Institute for Occupational Safety and Health of the German Social Accident Insurance (IFA): Dust classes for industrial vacuum cleaners, dust extractors and vacuum sweepers. Retrieved May 4, 2020 .

- ↑ Regulation (EU) No. 666/2013 (PDF) of the Commission of July 8, 2013

- ↑ Vacuum cleaner test by Stiftung Warentest , test.de, magazine test 2/2014, pp. 70-75 and test.de from January 30, 2014. Press release , test.de, accessed on January 3, 2015

- ↑ a b Energy label for vacuum cleaners , accessed on March 9, 2017

- ↑ FAZ.net January 22, 2019: Vacuum cleaners can be sold again even without an energy label