Polypropylene

| Structural formula | |||||||

|---|---|---|---|---|---|---|---|

|

|||||||

| General | |||||||

| Surname | Polypropylene | ||||||

| other names |

|

||||||

| CAS number | 9003-07-0 | ||||||

| Monomer | Propene | ||||||

| Molecular formula of the repeating unit | C 3 H 6 | ||||||

| Molar mass of the repeating unit | 42.08 g mol −1 | ||||||

| Type of polymer | |||||||

| properties | |||||||

| Physical state |

firmly |

||||||

| density |

0.90 .. 0.915 g / cm³ |

||||||

| safety instructions | |||||||

|

|||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . | |||||||

Polypropylene ( abbreviation PP ) is a thermoplastic material produced by chain polymerisation of propene . It belongs to the group of polyolefins and is partially crystalline and non-polar . Its properties are similar to polyethylene , but it is a little harder and more heat-resistant. Polypropylene is the second most common standard plastic and is widely used for packaging . In 2016, 17.66 million tons were used for flexible packaging material and 23 million tons of molded plastic parts were produced worldwide.

history

The chemists J. Paul Hogan and Robert Banks first made polypropylene in 1951 for the Phillips Petroleum Company . Using the method developed by Karl Ziegler , a synthesis was achieved in 1953 at the Max Planck Institute for Coal Research in Mülheim, which promised more success for large-scale application. Polypropylene was synthesized in crystalline form by Karl Rehn in the Hoechst dye works and at the same time by Giulio Natta at the Milan Polytechnic .

With the patent applied for by Natta , production began in the Italian company Montecatini . Since Ziegler had also applied for a patent, a legal dispute over patent rights ensued .

The polyethylene produced according to the Ziegler process proved to be more resistant to pressure and higher temperatures. In 1955, 200 tons were initially produced, in 1958 17,000 tons and from 1962 more than 100,000 tons. In 2001, 30 million tons of polypropylene were produced worldwide. In 2007 the production volume was already 45.1 million tons with a value of approx. 65 billion US $ (47.4 billion €). Today, after polyethylene , polypropylene is the second most important ( standard ) plastic worldwide (in terms of sales) .

Manufacturing

PP by polymerization of propene produced. Around two thirds of the propene produced worldwide is used in the production of PP. According to Römpps Lexikon der Chemie , there are three industrial processes today:

- the suspension (slurry) process

- the mass (bulk) method

- the gas phase polymerization process

properties

Polypropylene resembles polyethylene in many properties , especially in its dissolving behavior and electrical properties. The additional methyl group improves the mechanical properties and the thermal resistance, while it decreases the chemical resistance . The properties of polypropylene depend on the molar mass and the molar mass distribution , the crystallinity, type and proportion of the comonomer (if used) and the tacticity .

Mechanical properties

The density of PP is between 0.895 and 0.92 g / cm³. This makes PP the standard plastic with the lowest density. With a lower density, molded parts with a lower weight and more parts can be produced from a certain mass of plastic. In contrast to polyethylene, crystalline and amorphous areas differ only slightly in their density. However, fillers can change the density of polyethylene significantly.

The modulus of elasticity of PP is between 1300 and 1800 N / mm².

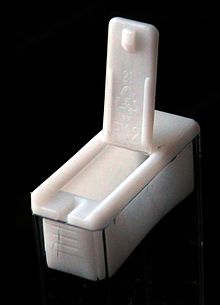

Polypropylene has excellent fatigue resistance. For this reason, hinges can also be made directly from PP ( e.g. glasses cases ).

Thermal properties

The melting and long-term use temperatures of polypropylene are higher than those of polyethylene, as are numerous mechanical properties ( rigidity , hardness and strength ). Polypropylene homopolymer can be used permanently between 0 and 100 ° C. Below 0 ° C it becomes brittle . This temperature range can be z. B. increase by copolymerization , so that items produced by die casting can be heated to 140 ° C after curing. The thermal expansion of polypropylene is very high at α = 100-200 10 −6 / K (but slightly less than that of polyethylene).

Chemical properties

Polypropylene is at room temperature against fats and almost all organic solvent -resistant , except for strong oxidizing agents . Non-oxidizing acids and bases can be stored in containers made of PP. At elevated temperatures, PP can be dissolved in solvents that are not very polar (e.g. xylene , tetralin and decalin ).

Due to the tertiary carbon atom, PP is less chemically resistant than PE (see Markovnikov's rule ).

PP is odorless and skin-friendly, it is suitable for applications in the food sector and pharmacy , it is physiologically harmless and biologically inert.

Others

The speed of sound in polypropylene is 2650–2740 m / s longitudinally and 1300 m / s transversely.

PP can be filled with mineral fillers such as B. talc , chalk or glass fibers can be filled. This significantly expands the range of mechanical properties (rigidity, usage temperatures, etc.).

Molecular structure

Tacticity

Polypropylene can be divided into atactic polypropylene, syndiotactic polypropylene, and isotactic polypropylene. With atactic polypropylene the methyl group is randomly aligned, with syndiotactic polypropylene alternating (alternating) and with isotactic polypropylene evenly. This affects the crystallinity ( amorphous or partially crystalline) and the thermal properties ( glass transition point T g and melting point T m ).

In polypropylene, tacticity describes the extent to which the methyl group is aligned (arranged) in the polymer chain. Commercial polypropylene is typically isotactic. This article therefore always refers to isotactic polypropylene, unless stated otherwise.

The tacticity is usually given in percent with the help of the isotaxy index (according to DIN 16774). The index is determined by determining the insoluble fraction in boiling heptane . Commercially available polypropylenes usually have an isotaxy index between 85 and 95%. The tacticity has an impact on the physical properties . The isotactic structure leads to a partially crystalline structure. The methyl group , which is always present on the same side, forces the macromolecule into a helix shape, such as B. also with strength . The higher the isotaxy (the isotaxy portion), the greater the crystallinity and thus also the softening point, rigidity, modulus of elasticity and hardness.

Atactic polypropylene, on the other hand, lacks any regularity, which means that it cannot crystallize and is amorphous .

Crystal structure of polypropylene

Isotactic polypropylene has a high degree of crystallinity ; in industrial products it is 30–60%. Syndiotactic polypropylene is a little less crystalline, atactic PP is amorphous (not crystalline).

Isotactic Polypropylene (iPP)

Isotactic polypropylene can exist in various crystalline modifications in which the molecular chains are arranged differently. Depending on the condition, the α, β and γ modification as well as mesomorphic ( smectic ) forms occur. The α-form is the predominant modification in iPP. The crystals are formed from lamellae in the form of folded chains. A special feature is that different lamellas are arranged in the so-called "cross-hatched" structure. The melting point of α-crystalline areas is given as 185 to 220 ° C, the density as 0.936 to 0.946 g · cm −3 . The β-modification is somewhat more disordered in comparison, as a result of which it forms more quickly and has a lower melting point of 170 to 200 ° C. The formation of the β-modification can be promoted by nucleating agents, suitable temperatures and shear stress. The γ-modification hardly occurs under industrial conditions and is little researched. The mesomorphic modification, on the other hand, often comes to light during industrial processing, since the plastic is usually cooled quickly. The degree of order of the mesomorphic phase lies between the crystalline and the amorphous, the density is comparatively low with 0.916 g · cm −3 . The mesomorphic phase is seen as the reason for transparency in rapidly cooled films (due to low order and small crystallites).

Syndiotactic Polypropylene (sPP)

Syndiotactic polypropylene is of much more recent origin than isotactic PP; it could only be produced with the help of metallocene catalysts . Syndiotactic PP melts more easily, depending on the degree of tacticity it is called 161 to 186 ° C.

Atactic polypropylene (aPP)

Atactic polypropylene is amorphous and therefore has no crystal structure. Due to its lack of crystallinity, it is easily soluble even at moderate temperatures, which means that it can be extracted from isotactic polypropylene as a by-product. The aPP separated in this way is not completely amorphous, but can contain up to 15% crystalline fractions. Atactic polypropylene has only been able to be produced in a targeted manner using metallocene catalysts for a few years now; this has a significantly higher molecular weight.

Atactic polypropylene has a lower density and strength as well as lower melting and softening temperatures than the crystalline types and is tacky and elastic at room temperature. It is a colorless, cloudy material and can be used between −15 and +120 ° C. Atactic polypropylene is used as a sealant, as an insulating material for cars and as an additive to bitumen .

processing

The world market price for unprocessed polypropylene in 2006 was just under € 1 / kg.

PP is suitable for injection molding , extrusion , blow molding , hot forming , welding , deep drawing and machining . It can also be used to make foam . Because of its low surface energy , polypropylene is difficult to glue or print on. Around 6.6 million t are drawn into fibers every year (as of 2014). Yarns, fleeces and fabrics are made from this.

Polypropylene foam (EPP)

Expanded polypropylene (EPP) was developed in the 1980s. It is a particle foam based on polypropylene. (Porous expanded polypropylene is abbreviated to PEPP.) Unlike EPS , EPP is delivered without a propellant, so that subsequent expansion based on propellant is not possible.

A distinction is made between two principle processes in EPP production: the autoclave technology (standard) and direct foam extrusion (rare).

Processing in the so-called molding process takes place in special molding machines. These differ from conventional EPS machines in their more stable design. The actual processing step consists in softening the foam particles using steam (steam temperature approx. 140 to 165 ° C - depending on the type of raw material) so that they sinter. Subsequent processing (e.g. deburring) is not common with EPP molded parts, unlike PUR foam parts.

Unstretched polypropylene film (CPP)

Cast polypropylene (dt. Unstretched polypropylene, abbreviation CPP ) is a versatile packaging material.

Like polypropylene (PP), CPP is a semi-crystalline thermoplastic and belongs to the group of polyolefins . Compared to conventional PE films , CPP is characterized by an extremely high level of transparency, rigidity and abrasion resistance. These properties make CPP, along with OPP (Oriented Polypropylene), the most widely used polymer in the packaging industry. The main areas of application are the packaging of food, textiles or medical articles and as a lamination layer in multilayer films.

Stretched polypropylene film (OPP and BOPP)

Polypropylene films can be made significantly more stable by stretching. For this purpose, the extruded film is passed over rollers that increase in speed in the machine direction. This leads to a stretching of the plastic in the longitudinal direction. In order to obtain a BOPP film, it is then also stretched in the transverse direction.

The advantages of this processing are, among other things, a reduced water vapor permeation . The mechanical strength increases, the foils stretch less, the optics ( transparency ) are improved. The tear strength also increases.

Disadvantages include decreasing sealability and printability. The light protection is lower and the oxygen barrier effect decreases.

OPP (oriented polypropylene)

The extruded PP granulate can also only be stretched lengthways to obtain OPP (oriented PP). It is used for the production of high-strength foils, packaging tapes, yarns or composite foils.

BOPP (biaxially oriented polypropylene)

This oriented PP is also stretched in the transverse direction in order to obtain the maximum strength of this type of plastic. This takes place in a stretching system (preheating - stretching - stabilizing - cooling). In order to minimize tension, the film is heat- set at the end of the manufacturing process by heating it up again .

This plastic film is mainly used in packaging on tubular bag machines (horizontal and vertical), as a mono film or a component of a composite film.

Types

Copolymers

In order to improve its properties, other copolymers (especially with ethene ) are offered in addition to regular polypropylene homopolymer (PP-H) . Depending on the structure, these are referred to as PP-B (block copolymer) or PP-R (random copolymer) according to ISO 1873 .

Application examples

The special properties of PP and EPP mentioned above allow this plastic to be used very widely . PP is increasingly replacing engineering thermoplastics (= more expensive plastics) such as ABS and PA .

- It is used in machine and vehicle construction for interior fittings for cars , dashboards and battery housings. Also crash absorber elements for vehicle construction, child seats , bicycle helmets .

- In electrical engineering it is used for transformer housings , wire and cable sheathing and insulating foils . BOPP has become particularly important as a dielectric for plastic film capacitors and power capacitors .

- In construction it is used for valves, fittings and pipelines ; in ventilation and air-conditioning technology in conditions that favor corrosion and when conveying corrosive gases, usually in the form of PP-S (S = flame-retardant).

- In concrete construction (reinforced / prestressed concrete), polypropylene fibers can be added to the concrete in order to meet fire protection requirements. The melted / burned fibers free pore space, which is used for the expansion of the water vapor or its escape.

- In the textile industry it is used as worsted yarn in polycolon . PP fibers are u. a. Further processed into home textiles, carpets, sports textiles, packaging materials, hygiene products, medical products, buoyant ropes , geotextiles .

- Many products are used in the food industry, in the household and in packaging technology: cups (for dairy products), bottle caps, interior parts for dishwashers, for heat-resistant films, reusable containers, thermal transport boxes or warming containers (EPP), packaging parts, drinking straws, adhesive film, ...

- In humid regions, PP is also used for plastic banknotes such as the Australian dollar and the New Zealand dollar .

- In model aircraft construction , EPP is used to manufacture very resistant, beginner-friendly model airplanes that can cope with a crash much better than classic balsa wood model airplanes.

- In general medical surgery , especially for elderly patients, more complicated fractures and recurrences (recurrence), polypropylene meshes are used for the closure of hernias , e.g. B. in hernias, used to strengthen the abdominal wall and prevent a recurrence of the hernia .

- When securing loads in freight containers, air-filled dunnage bags (GrizzlyBag ® ) with an outer shell made of PP are used.

- In advertising, twin-wall sheets made of PP (studded sheets and multi-skin sheets) are used in printed and glued (laminated) form for posters and displays.

recycling

Basically, polypropylene is good recyclable , but the recycling rate is currently pronounced still weak. In 2017 this was less than 1% worldwide, one of the lowest recycling values of all common consumer plastics today. The use for food packaging poses a particular challenge. In order to avoid contamination in the recycled material, special processes or closed recycling loops are required.

Web links

- Material archive: Polypropylene - extensive material information and images

- Polypropylene from wipo.krv.de, accessed on March 19, 2017.

Individual evidence

- ↑ J. Kahovec, RB Fox, K. Hatada: Nomenclature of regular single-strand organic polymers (IUPAC Recommendations 2002). In: Pure Appl. Chem. Vol. 74, no. 11.2, 2002, p. 1955. doi: 10.1351 / pac200274101921 ( abstract )

- ↑ a b Werner Martienssen , Hans Warlimont (Ed.): Springer Handbook of Condensed Matter and Materials Data . Springer Science & Business Media, Heidelberg / New York 2006, ISBN 3-540-30437-1 , pp. 488 (English, limited preview in Google Book search).

- ↑ This substance has either not yet been classified with regard to its hazardousness or a reliable and citable source has not yet been found.

- ↑ Plastics the Facts 2014/2015 on plasticseurope.org. (No longer available online.) Archived from the original on June 10, 2015 ; accessed on October 10, 2019 .

- ^ Polypropylene Market Report. Retrieved October 24, 2018 .

- ^ Stephen Stinson, Discoverers of Polypropylene Share Prize . In: Chemical & Engineering News . 65, No. 10, 1987, p. 30. doi : 10.1021 / cen-v065n010.p030 .

- ^ Günther Wilke: 50 Years of Ziegler Catalysts: Career and Consequences of an Invention. In: Angewandte Chemie. 115, 2003, pp. 5150-5159, doi : 10.1002 / anie.200330056 .

- ^ Peter J. Morris: Polymer Pioneers: A Popular History of the Science and Technology of Large Molecules . Chemical Heritage Foundation, 2005, ISBN 0-941901-03-3 , pp. 76 ( limited preview in Google Book search).

- ↑ Heinz Martin: Polymers, Patents, Profits: A Classic Case Study for Patent Infighting , 294 pages, Wiley-VCH Verlag GmbH & Co. KGaA (2007), ISBN 3-527-31809-7 .

- ↑ Polypropylene PP - Market Study: Analysis, Trends | Ceresana. Retrieved October 10, 2019 .

- ↑ Propylene Study: Market, Analysis, Trends | Ceresana. Retrieved October 10, 2019 .

- ^ A b Römpp Lexikon Chemie, 9th edition 1992, page 3566

- ↑ a b c d D. Tripathi: Practical Guide to Polypropylene . Smithers Rapra Press, Shawbury, UK 2002, ISBN 1-85957-282-0 , pp. 19–24 (English, limited preview in Google Book Search).

- ↑ Clive Maier, Teresa Calafut: Polypropylene: the definitive user's guide and databook . William Andrew, 1998, ISBN 1-884207-58-8 , pp. 14 ( limited preview in Google Book search).

- ^ A b c Wolfgang Kaiser : Synthetic chemistry for engineers: From synthesis to application . 2nd Edition. Carl Hanser, 2007, ISBN 978-3-446-41325-2 , pp. 228 ( limited preview in Google Book search).

- ↑ https://www.tmk-zerspanungstechnik.de/files/tmk/Pdfs/technischer_kunststoff_pp_polypropylen_hostalen_pp_novolen%20_v Various_farben_tmk_zerspanungstechnik.pdf

- ↑ a b S. Koltzenburg et al.: Polymers: Synthesis, Properties and Applications. 2014, ISBN 978-3-642-34772-6 , p. 407. ( limited preview in Google book search)

- ^ Rüdiger Kramme (ed.): Medical technology . Springer, Berlin / Heidelberg 2011, ISBN 978-3-642-16186-5 , pp. 902 .

- ↑ Ultrasonic or ultrasound sound velocity and impedance. Retrieved October 10, 2019 .

- ^ A b c Peter Elsner, Peter Eyerer: Domininghaus - Kunststoffe: Properties and applications . Ed .: Thomas Hirth. Springer, 2012, ISBN 978-3-642-16173-5 , pp. 251 ( limited preview in Google Book search).

- ^ A. Turner-Jones, JM Aizlewood, DR Becket: Crystalline forms of isotactic polypropylene . In: Macromol. Chem. Band 75 , no. 1 , 1964, pp. 134–158 , doi : 10.1002 / macp.1964.020750113 .

- ↑ G. Fischer: Deformation and failure mechanisms of isotactic polypropylene (i-PP) above the glass transition temperature. Dissertation . University of Stuttgart, 1988.

- ↑ a b c R. J. Samuels: Quantitative structural characterization of the melting behavior of isotactic polypropylene . In: J. Polym. Sci., Polym. Phys. Ed. tape 13 , no. 7 , 1975, p. 1417–1446 , doi : 10.1002 / pol . 1975.180130713 .

- ↑ YS Yadav, PC Jain: Melting behavior of isotactic polypropylene isothermally crystallized from the melt. In: polymer. 27 (5), 1986, pp. 721-727.

- ↑ WW Cox, AA Duswalt: Morphological transformations of polypropylene related to its melting and Recrystallization behavior. In: Polym. Closely. Sci. 7, 1967, pp. 309-316.

- ↑ DC Bassett, RH Olley: On the lamellar morphology of isotactic polypropylene spherulites . In: polymer . tape 25 , no. 7 , July 1984, p. 935-943 , doi : 10.1016 / 0032-3861 (84) 90076-4 .

- ↑ G. Natta, P. Corradini: General considerations on the structure of crystalline polyhydrocarbons . In: Il Nuovo Cimento . tape 15 , S1, February 1960, pp. 9-39 , doi : 10.1007 / BF02731858 .

- ↑ Physical Constants of Poly (propylene) . In: Wiley Database of Polymer Properties . 2003, doi : 10.1002 / 0471532053.bra025 .

- ↑ a b Guan-yi Shi, Xiao-dong Zhang, You-hong Cao, Jie Hong: Melting behavior and crystalline order of β-crystalline phase poly (propylene) . In: The Macromolecular Chemistry . tape 194 , no. 1 , January 1993, p. 269-277 , doi : 10.1002 / macp.1993.021940123 .

- ^ Mario Farina, Giuseppe Di Silvestro, Alberto Terragni: A stereochemical and statistical analysis of metallocene-promoted polymerization . In: Macromolecular Chemistry and Physics . tape 196 , no. 1 , January 1995, p. 353-367 , doi : 10.1002 / macp.1995.021960125 .

- ↑ a b J. Varga: Supermolecular structure of isotactic polypropylene . In: Journal of Materials Science . tape 27 , no. 10 , 1991, pp. 2557-2579 , doi : 10.1007 / BF00540671 .

- ↑ Andrew J. Lovinger, Jaime O. Chua, Carl C. Gryte: Studies on the α and β forms of isotactic polypropylene by crystallization in a temperature gradient . In: J. Polym. Sci. Polym. Phys. Ed. tape 15 , no. 4 , 1977, pp. 641–656 , doi : 10.1002 / pol . 1977.180150405 .

- ↑ WW Cox, AA Duswalt: Morphological transformations of polypropylene related to its melting and Recrystallization behavior . In: Polymer Engineering and Science . tape 7 , no. 4 , October 1967, p. 309-316 , doi : 10.1002 / pen.760070412 .

- ↑ FL Binsbergen, BGM de Lange: Morphology of polypropylene crystallized from the melt . In: polymer . tape January 9 , 1968, p. 23-40 , doi : 10.1016 / 0032-3861 (68) 90006-2 .

- ↑ C DEROSA, F AURIEMMA: Structure and physical properties of syndiotactic polypropylene: A highly crystalline thermoplastic elastomer . In: Progress in Polymer Science . tape 31 , no. 2 , p. 145–237 , doi : 10.1016 / j.progpolymsci.2005.11.002 ( elsevier.com [accessed February 1, 2018]).

- ^ A. Galambos et al .: Structure and Morphology of Highly Stereoregular Syndiotactic Polypropylene Produced by Homogeneous Catalysts . In: Edwin J. Vandenberg et al. (Ed.): Catalysis in Polymer Synthesis . 1991, ISBN 0-8412-2456-0 , pp. 104-120 , doi : 10.1021 / bk-1992-0496.ch008 .

- ↑ Jonahira Rodriguez-Arnold, Anqiu Zhang, Stephen Z. D Cheng: Crystallization, melting and morphology of syndiotactic polypropylene fractions: I. Thermodynamic properties, overall crystallization and melting . In: polymer . tape 35 , no. 9 , 1994, pp. 1884-1895 , doi : 10.1016 / 0032-3861 (94) 90978-4 .

- ↑ London Metal Exchange : LME Plastics Market Data: May 2005 - May 2007 ( Memento from January 15, 2010 in the Internet Archive ).

- ↑ Market Study: Polypropylene (3rd edition). Ceresana, accessed November 22, 2016 .

- ↑ werverpacktwas.de - Your search for packaging. Retrieved October 10, 2019 .

- ↑ Clive Maier, Teresa Calafut: Polypropylene: the definitive user's guide and databook . Plastics Design Library, Norwich, NY 1998, ISBN 1-884207-58-8 .

- ↑ Andrew J. Peacock, Allison Calhoun: Polymer chemistry: properties and applications . Hanser, Munich et al. 2006, ISBN 3-446-22283-9 .

- ↑ J. Glatzl, P. Nischer, J. Steigenberger, O. Wagner: PP fiber concrete for increased fire resistance . In: cement + concrete . No. 3 , 2004 ( zement.at [PDF]). PP fiber concrete for increased fire resistance ( Memento from February 21, 2014 in the Internet Archive )

- ↑ An overview of polypropylene recycling. Retrieved July 6, 2018 .