Carrara marble

Carrara marble is one of the most famous marbles in the world. Carrara marble is the generic term for more than 50 different trade names, depending on the quarry , tradition, quality and convention, e.g. B. Carrara marble C , Ordinario , Venato and Calacatta can be named. Carrara is a city in the Italian province of Massa-Carrara and is located in the Tuscany region .

Carrara marble has been mined since the end of the Roman Republic . It was only the Renaissance sculptor Michelangelo that made this marble famous. Due to unfavorable economic and political conditions as well as the effects of the war, marble production in Carrara lagged behind its capabilities for centuries. The extraction of the heavy stone blocks was extremely laborious and expensive until the beginning of the 19th century, and only technical innovations, such as the stone processing machines powered by steam, diesel fuel and electrical energy, made the mining possible on a large scale. This made Carrara an international center for marble processing. At the beginning of the 1960s it was possible to bring production in line with demand when the quarries in exposed locations were opened up by a network of roads.

Carrara marble was created in the Tertiary 30 million years ago, because the continental plates of Africa and Europe moved towards each other and bulged towards the Apuan Alps . The calcite deposits from dead marine organisms were compressed under high pressure and very high temperatures and thus turned into marble.

In addition to being used for sculpting and monuments, Carrara marble is now mainly used as floor and stair coverings and window sills in interior fittings and as natural stone tiles in bathrooms. The stone sculptors use the legendary and expensive statuario as they did in the past . While 100,000 tons were extracted annually at the beginning of the 20th century, today it is approx. 5 million tons, which environmental activists strongly criticize.

geology

The Apuan Alps are geologically integrated into the Apennines . The outcrops for Carrara marble in the Apuan Alps cover about a quarter of this area. The Apuan Alps formed in the Paleozoic , about 240 million years ago, on the older subsoil of clay slates , sandstones and breccias . In the Upper Triassic , 200 million years ago, a shallow, warm sea developed in which fossil microorganisms, living organisms and biological deposits of lime settled on the sea floor. Since the sea was well ventilated, pure lime could form, from which the later Carrara marble emerged. Over time, the deposits formed thick sediments (deposits) that were solidified into limestone. Due to the continental drift, the limestone deposits and the various rocks were superimposed and shifted. Two plates of the cooled earth crust, Africa and Europe, moved towards each other, the sediment layers were pressed together at great depths under very high pressures and chemically changed, deformed and converted into marble at very high temperatures. The metamorphosis of the marble takes place at pressures of 10 3 bar and temperatures above 400 ° C.

In this process, a metamorphic rock , a marble , was created from the limestone deposits . These movements came to an end in the Upper Miocene , about 30 million years ago, when the marble mass was raised at different levels in different regions. The occurrence of the Carrara marble is a marble mountain up to a height of almost 1900 meters. Lenticular rock bodies with a length of up to 10 kilometers and a thickness of up to 400 meters were formed.

Stone sculptors and buildings

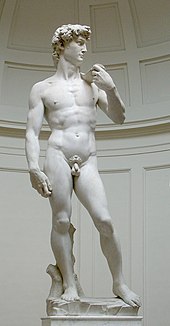

Michelangelo , Gian Lorenzo and Luigi Bernini , Pisano , Donatello , Canova and other well-known sculptors obtained their marble blocks from the quarries in the mountains of Carrara . Carrara marble was found in the Duomo of Florence , in the Campanile of Pisa , in St. Peter's Basilica in Rome, in the former World Trade Center in New York, in casinos in Las Vegas and as the exterior cladding of the Finlandia Hall in Helsinki and the Grande Arche de la Défense in Paris built.

history

Roman time

Carrara marble was used from around 50 BC. Broken by the Romans. According to Pliny the Elder , Mamurra , the praefectus fabrum of Caesar in the Gallic War, was the first to be killed in 48 BC. He had his house built entirely from marble and used it, besides Karystic, also Lunensian marble. The term Lunensian goes back to the Roman colony of Luna . Carrara marble was used from the last quarter of the 1st century BC. BC to the usual building material of prestige buildings in Rome. Before that, the Romans mainly imported Greek marble from Paros . Carrara marble was widely used in both architecture and sculpture during Roman times. Examples of architecture are the Dioskurentempel on the Roman Forum , the Augustusforum and the Trajan's Column on the Trajan's Forum , which consists of 18 marble blocks; From the field of sculpture, reference is made to the Laocoon group , whose famous Roman copy was made from Carrara marble.

Near what is now Carrara, the Romans founded the settlement of Luna and a port, the excavations of which can be visited. In Luna, the surfaces of the stone blocks were roughly worked by workers and slaves in order to prepare them for shipment. The Magra river silted up (the archaeological site of Luna is now about two kilometers from the sea) and hindered further marble trade. These troubles and raids by the Lombards in 640, Saracen and Norman pirates in the 9th and 10th centuries led to the decline of Luna. The Phocas column in the Forum Romanum from the year 608 was probably the last Roman work made of Lunensian marble. The place Luna was finally abandoned in the 13th century.

Middle Ages and Early Modern Times

Around 1000 farmers founded the hamlet of Cararia . The quarries for the construction of the parish of Carrara may have been reopened around 1250 , as marble was required for this. Commissions from Genoese merchants for columns, capitals and slabs gave an impetus to the resurgence of the marble trade. They operated with it a lively trade in the Mediterranean area. The deciding factor for restarting the marble quarries was primarily the orders from Niccolò Pisano for the construction of the cathedral in Pisa .

At the end of the Italian Romanesque period , it had become customary for sculptors to choose their rough blocks themselves in the mountains of Carrara. These raw blocks were transported to the installation site where they were processed. After they were brought to the valley with the lizzatura (see below), the raw blocks were transported with two-wheeled (so-called carrette) or four-wheeled (so-called "currus") carts with carts of oxen. It was calculated that each pair of oxen on the plain could pull around 800 kilograms. The number of pairs of oxen was used to calculate the transport and customs costs.

The Renaissance sculptor Michelangelo, who created the David , the Pietà , the Moses and other famous sculptures from the sculptural material Statuario, made this stone famous.

Art lovers from Europe traveled to the marble sculptures of the Renaissance and reported about them in their home countries. The Italian cities of Florence , Rome and Naples bought the marble, but sales in Italy remained low in relation to sales in England, France and Spain. Italy, like Germany, was split up into small states and the customs duties were immense. The transport was not only a technical problem because of the size of the stone blocks and the freight costs significantly exceeded the costs for the stones.

The owners of the quarries in Carrara received only a fraction of the proceeds that were achieved in the marble trade through the intermediary trade. The Genoese merchants, who dominated sales, coined the saying: "Marble is white gold ". The operation of the quarries had become financially unattractive and some were abandoned. Carrara tried in the 16th century to market the white marble directly with little success. As a result of this sales crisis, not only the income but also the self-confidence of the stonemasons and stone workers was impaired. Even the master stone carvers had no more masterful work. They had to work in groups in the workshops of the quarry owners and refined mortars and small pillars for balustrades, but also sarcophagi, vases and oil vessels. Another product that was made entirely by housework, including with the help of women and children, was marble floor tiles. These were taken over directly by Genoese merchants, who held the monopoly on sales.

In the Baroque period there was a reduced demand for white marbles, as colored and speckled limestones and marbles were preferred.

classicism

In the period of classicism , Europe returned to white marble. In 1769 the Accademia di Belle Arti di Carrara , a sculpture school, was founded. The expansion of the marble trade remained restricted by the armed conflicts in Europe. After the occupation of Carrara by the Napoleonic troops, who drove out the Austrian occupation, production came to a standstill in 1800. After the French left, marble production increased again and in 1857 there were 600 quarries. Not only Italians, but also French, Swiss and English were involved in building up the marble industry. Around 1815, an Italian worker, Giuseppe Perugi, invented the stone saw with several saw blades, the first frame saw for natural stone, which was driven by high- speed water wheels. The Swiss Carlo Müller improved this technology, and in 1831 the French Nerier constructed eight iron frames that made it possible to manufacture several large-format marble slabs one centimeter thick. This process was awarded a prize at the World Exhibition in Paris in 1867 . In 1870 there were 40 sawmills of this type in Carrara, 15 in Massa and 26 in Seravezza . In 1895, spiral wire powered by diesel engines was first used in Carrara for sawing stones. The steel cables were hundreds of meters long and were led through pulleys through the quarries to cool them down. Later the diesel engines were replaced by electric motors. With the so-called helicoid saws , the use of explosives could be minimized, which led to the huge rock rubble that can still be seen today as the snow of the Carrara mountains . The use of explosives largely ceased after World War II .

industrialization

In addition to the technical innovations in the course of industrialization, the trade in Carrara marble was made easier for the quarry owners by new financing concepts by the Englishman Thomas Robson. The ox teams were replaced by steam-powered tractors. The infrastructure was significantly improved through the construction of suspension cables and railways to transport stone into the valley and the construction of loading bridges in the port of Avenza. With the construction of the marble railway in the last decades of the 19th century, the transport costs could be reduced by ten percent because it established the connection between the quarries and the sawmills, the national railway network and the loading bridges of the ships. Between the end of the 19th century and the beginning of the 20th century, carts of oxen were replaced by heavy steam tractors in the mountains, where road transport had to continue.

In the unification efforts in Italy, the workers and the liberal citizenship of Carrara sided with the Republicans . After Italy was unified, marble production increased and the number of stone workers doubled to 10,000. However, trade was hampered by the American Civil War and high protective tariffs in Europe.

The workforce came not only from Carrara, but also from the surrounding villages. The way to the quarries in the mountains was long. During the week the quarry workers had to spend the night in the quarry huts, hard manual work was common and work safety was poor; there were frequent serious accidents. In addition to the poor working conditions, the working hours were unregulated and long. The pension scheme was also completely unclear. These factors led to violent labor disputes, which resulted in the construction of children's homes and poor houses, the establishment of public welfare institutions and the establishment of a vocational school in Carrara.

20th century to the present

The First World War brought marble production to a standstill and the Great Depression of 1929 reduced the slowly restarting production by half. The consequences of the war with Ethiopia and the resulting drop in sales of Carrara marble were attempted by the fascist government of Mussolini with monumental commissions with the 17.40 meter high Mussolini obelisk , 60 approximately 5.0 meter tall monumental statues and the spherical fountain with a diameter of 3 meters and to conceal 37 tons of weight for the Foro Italico . For example, the raw block of the Mussolini obelisk (19.00 × 2.35 × 2.35 m) weighing around 300 tons was moved into the valley with the so-called lizzatura (see below). 36 pairs of oxen pulled the monolith for shipping in the port of Massa . Such monumental commissions hardly changed the economic situation of Carrara.

The Second World War not only brought marble production to a standstill, but the German Wehrmacht also destroyed most of the facilities in the quarries in their fight against partisans in 1944/45. The defense line of the Wehrmacht, the so-called Gotenlinie , ran between Massa and Carrara and not far from Carrara the Waffen-SS carried out the massacre of the villagers of Sant'Anna di Stazzema and Fivizzano , each with around 400 murdered civilians. A large part of the population, especially the workers and women, participated in the bitter resistance against the German occupiers. In the women's uprising in Carrara in June 1944, women were able to use their resistance to prevent the evacuation order from being implemented for the entire civilian city population of Carrara.

As a result of the reconstruction after the end of the war and the European construction boom in the 1960s, the production volume rose to 500,000 tons. In the course of this development, the road network in the mountains was expanded. The raw blocks were transported from the Carrara mountains to the valleys in some cases until the 1960s using a special method, the so-called lizzatura. The huge blocks were attached to three ropes made of hemp (from 1920 with steel ropes) and by slackening the ropes, the sledge was transported to the valley on soaped wood; an extremely dangerous undertaking that killed numerous people. The transport of the stone blocks on sledges is said to have been used for the first time in ancient Egypt, ancient Greece and also in Roman times in Carrara. A traditional lizzatura is held every year in August. Today the huge raw blocks, some of which weigh more than 20 tons, are transported on trucks on the accident-prone, winding mountain roads into the valley.

Today Carrara has to assert itself as the stone center of Europe not only against the stone processing center around Verona in its own country, but also against stone processing centers in China, India and Brazil. Today the companies in Carrara not only process Carrara marble, but all the stones in the world.

Location of the quarries

The marble quarries around Carrara are located in the Apuan Alps, mainly in the so-called three basins called Bacino di Fantiscritti , Bacino di Torrano and Bacino di Colonnata . Most of the quarries are about 1000 meters above sea level. The historical breaks are Grand Canal , Colonnata , Fantiscritti , Polvaccio and Poggio Domizio . In some of these quarries there are traces of demolition methods from that time, the so-called Roman tagliate (cut), with which the stone blocks were cut free from the stone walls.

In the pre-industrial times there was a division of labor and the profession of stone cutter was divided into three activities. The Marmorarii broke the ingots from the stone walls, the Quadratarii brought the raw uncut blocks with the chisels in a rectangular shape and the Sectores serrarii split plates.

Marble track

Stone transport has always been a dangerous and difficult undertaking. Before the first steam-powered train was completed, the blocks had to be transported into the valley using the lizzatura method (see above) and then with ox carts. Even after the railway was built, the rough blocks were lowered above the tracks with the lizzatura. The marble railway, which connected the three basins by tunnels and bridges, was built by a Belgian and put into operation around 1876. The marble railway connected the places Carrara and Miseglia and led below the place Colonnata (Statione Tarone) via Fantiscritti to the Cava Polvaccio.

After the construction of the railway and with steam-powered tractors, the transport of oxen ended. The lizzatura continued to be practiced. It was not until the 1960s that the roads leading to the quarries were expanded and it was possible to transport the goods directly from the quarries by truck.

Fantiscritti basin

The valley basin of Fantiscritti, in which there are currently around 30 quarries, is located above Carrara, above the small town of Miseglia. In this area the marble types Ordinario (whitish), Venato (white and gray), Cremo (light gray) and earlier the zebrino (gray-green striped) are broken at Ponti di Vara . In addition to around 30 farmed quarries of various sizes, there are two bridges in this valley, over which the original marble path led. The five-arched bridge is now used as a road. The Galleria Ravaccione underground quarry , which can be visited, is located in the middle of Mount Torrione . The excellent quality of the marble was discovered in the center of the tunnel when it was cut into the mountain to connect the Fantiscritti and Torano valleys. Today this tunnel is only used as a single-lane tunnel to the Fantiscritti quarry. Above the tunnel is a high marble mountain and another open quarry. In front of the underground quarry Galeria Ravaccione is a private marble museum and a place where open-air concerts and theater performances take place.

Torano Basin

There are around 30 active quarries in the Torano Basin , in which the Statuario (white and yellow sculptural material), Statuario Venato (gray and white sculptural material), Calacatta , Cremo , Ordinario and Arabescato are quarried . In the Torano valley basin is the Polvaccio quarry, from which Michelangelo extracted some of his stone blocks and is now known as Cava-Michelangelo.

Colonnata Basin

In Colonnata is the biggest quarry of the Apuan mountains, Gioia -Steinbruch. There are also around 30 quarries in operation, in which the Ordinario (whitish), Venato (white), Arabescato and the Bardiglio (blue) are mined. Next to the Roman quarry Fossacava , which can only be reached on foot, is the oldest marble railway bridge from 1875. The small village of Colonnata is the most original place for the quarry workers with a remarkable cemetery for those who died at work and a memorial for the quarry workers.

More quarries

In addition to the open, surface quarries, there are other underground quarries, but most of them are operated in opencast mines.

The quarry that Michelangelo opened on behalf of Pope Leo X is high on a flank of the Monte Altissimo mountain near the village of Seravezza .

A remarkable technical achievement can be admired in the Cervaiole quarry on the more than 1859 meter high Monte Altissimo with a huge hollow of about 80 meters in length, a depth of 25 meters and a height of 40 meters. This quarry has been operated by the Henraux company from Carrara since the post-Napoleonic period.

Extraction

Today the Carrara marble is cut out in about 150 quarries above and below ground with wire saws and with cutters and is no longer removed from the quarry walls by hand.

Wire saws guide long steel cables densely covered with carbide beads through the marble layers in the quarry or through the raw blocks in the processing plants , as required . There are industrial diamonds in the hard metal beads. A constant stream of water cools the saw ropes. Schrämen use saw blades to cut loose joints up to a length of four to five meters at a working depth of around two to two and a half meters in the rock layers. The Schrämen are mobile oversized chainsaws that work without water cooling. The ingots are further shaped as required using pneumatic hammers and stone splitting tools . These devices bring the heavy ingots to the appropriate size for further processing. The raw blocks are brought into the valley on trucks on the dangerous, winding mountain roads. This often leads to accidents. The blocks are transported to the more than 250 stone processing plants in Carrara and Massa, where they are further processed into slabs, slabs, tiles and other stone products using gang saws, circular block saws or wire saws.

As in other marble quarrying areas, partial blocks of marble that are not economically recovered are ground in industrial stone mills into marble dust in the size of a thousandth of a millimeter, which is used in toothpaste , soap , abrasives and in glass and paper production.

Another economic use of Carrara marble is the supply of rounded pieces of marble that were originally taken from the streams in the Carrara area and are now also made by machine. They are mainly used in horticulture on flower beds.

Mineral inventory

Carrara marbles are metamorphic rocks that contain at least 50 percent by volume calcite . They consist of almost only one carbonate mineral , they are mono- mineral . Marbles have undergone a transformation under high pressure and high temperature, a metamorphosis . The crystal grains of the calcite in Carrara marble are mostly visible to the eye.

use

There are around 50 different types of marble in the Carrara area (e.g. Carrara marble C, Ordinario, Venato, Calacatta, Statuario, Bardiglio, Gioa , etc.). The most valuable is the so-called "Statuario", the marble for statues. Large statuario blocks have become rare and expensive today. The statuario is not entirely white, but partially striped yellow. Statuario is particularly fine-grained and enables filigree work by the stone sculptor.

Carrara marble is not exclusively white, but sometimes gray to blue, yellowish or reddish. The yellow color is caused by limonite , the blue and gray-blue color by graphite , carbonaceous substances or bitumen and the reddish color by hematite . But there are also extremely dark blue Carrara varieties. Chlorite and serpentine minerals turn green. Calacatta Vagli , the reddish-brown to reddish-gray arabesque on a white background , and Calacatta Rocchetta , the gray- greenish arabesques, have a color that is unique among Carrara marbles . These material admixtures in the original limestone lead to the decor typical of marbles, to marbling , which can show up in different shades of color.

The white Carrara varieties can contain finely divided pyrite mineral in individual cases and may turn yellow to brownish after installation. Pyrite can decompose to sulfuric acid under the action of water . Carrara marbles have a water absorption of less than 0.5 percent by volume and, due to this property, are among the frost-resistant rocks.

In addition to being used for sculpting and monuments, Carrara marble is used, for example, for floor and stair coverings, as well as for window sills in interior fittings and for natural stone tiles or basins in bathrooms. In the confectionery industry, worktables made of Carrara marble are often used because icing has to cool down quickly and marble surfaces are particularly suitable for this, and dough does not stick to marble surfaces.

As a rough block, one cubic meter of Carrara marble costs around 1,500 euros, whereby the highest quality types can achieve a price of 10,000 euros and more per cubic meter. 50 percent of today's funding goes to Arab countries, for example for the interior design of airports or mosques. A total of three quarters of total production goes abroad. Around 3,500 people work for marble mining companies in Italy, 1,000 of them in direct demolition. In 1999, one million tons was processed, resulting in around three million tons of unused material, i.e. stone debris. That was a mining of about 1.5 million cubic meters of rock. Some of the rubble is further processed into marble powder for industrial purposes, marble chippings and gravel for garden design.

A specialty shouldn't go unmentioned, which has become a specialty for gourmets: The Lardo di Colonnata (bacon from Colonnata) is a very fat bacon that is layered in specially made marble troughs with salt, spices and herbs and at least half a half Year has to mature. Only a specially selected large crystalline Carrara marble is suitable for the marble troughs. Lardo di Colonnata used to be the food of the stone workers who needed high calorie food for their hard work.

See also

literature

- Aldus Casa di Edizioni in Carrara (ed.): Carta Tematica delle Cave di Carrara, 1: 8000 . Italian, English, German, French, etc.

- Karlfried Fuchs: Natural stones from all over the world, discover, determine, use . Callwey, Munich 1997.

- Luciana and Tiziano Mannoni: marble, material and culture. Callwey, Munich 1980, ISBN 3-766-70505-9 .

- Mario Pinzari: Methods, techniques and technologies for quarrying ornamental stones. In: Marble in the world, ed. v. Società Editrice Apuana Srl, Carrara 1990.

- Dietmar Reinsch: Natural stone studies. An introduction for civil engineers, architects, preservationists and stonemasons . Enke, Stuttgart 1991, ISBN 3-432-99461-3 .

- The mirror. Issue 13 from March 26, 2012.

Web links

- Marmo Carrara (Italian, interesting subpages)

- Marble Museum in Carrara

- Structural anisotropy and weathering of Carrara marble (PDF, 4.44 MB)

Individual evidence

- ^ Karlfried Fuchs: Natural stones, page XII, see literature

- ↑ Luciana and Tiziano Mannoni: Marmor, page 52 ff., See literature.

- ↑ Pliny, naturalis historia 36.7; see also Luciana and Tiziano Mannoni: Marmor, page 185, see literature

- ↑ The consul M. Claudius Marcellus was able to finally defeat the Ligurian Apuans in 155 and establish security for the inhabitants of ancient Luna. As a thank you, they erected a monument made of Lunensian marble. Only a column capital on which his name is carved has been excavated from the monument. If it is a contemporary representation, it is the first Carrara marble workpiece to be used architecturally. See Luciana and Tiziano Mannioni, Marble, page 184, see Literature

- ↑ Luciana and Tiziano Mannoni: Marmor, page 185, see literature

- ↑ Luciana and Tiziano Mannoni: Marmor, page 188, see literature

- ↑ Luciana and Tiziano Mannoni: Marmor, page 191, see literature

- ↑ Luciana and Tiziano Mannoni: Marmor, page 102, see literature

- ↑ Luciana and Tiziano Mannoni: Marmor, page 203, see literature.

- ↑ Luciana and Tiziano Mannoni: Marmor, page 208, see literature

- ^ Marble saws in Carrara

- ↑ Luciana and Tiziano Mannoni: Marmor, page 212, see literature

- ↑ "The great massive blasting operation", perhaps the most spectacular ever, which occurred in a Torrione quarry (Carrara, Italy) in 1932. 200 quintals of blasting powder brought down approx. 700,000 tons of stone towards the valley. “ Mario Pinzari: Methods, page 165, see literature

- ↑ Illustration of a steam-powered tractor in the quarry

- ^ Illustration of the marble train in the mountains of Carrara

- ↑ Luciana and Tiziano Mannoni: Marmor, page 212, see Lit

- ↑ Illustration of the Mussolini obelisk in the quarry with a seated stone cutter

- ↑ Mario Pinzari: Methods, page 164, see Literature

- ↑ Illustration of the transport of the enclosed Mussolini obelisk pulled by 36 carts of oxen

- ↑ Massacre of Sant'Anna di Stazzema ( Memento of the original from July 16, 2009 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Resistenza von Carrara ( Memento of the original from August 3, 2007 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Luciana and Tiziano Mannoni: Marmor, page 216, see Lit

- ↑ Luciana and Tiziano Mannoni: Marmor, page 99, see literature

- ↑ Information on www.marmor.de , accessed on November 11, 2009

- ↑ Images of Carrara marble types ( Memento of October 9, 2007 in the Internet Archive )

- ^ Karlfried Fuchs: Natursteine, page 84, see literature

- ↑ Dietmar Reinsch: Natursteinkunde, page 179, see literature