Carbon nanotube

Carbon nanotubes , also CNT ( English carbon nanotubes ), are microscopic tubular structures ( molecular nanotubes ) made of carbon .

Their walls as those of the fullerenes or like the planes of graphite - a single layer of graphite is as graph denotes - only from carbon , wherein the carbon atoms occupy a honeycomb-like structure with hexagons and three binding partners (specified by the sp 2 - hybridization ) . The diameter of the tubes is usually in the range from 1 to 50 nm, but tubes with a diameter of only 0.4 nm have also been produced. Lengths of up to half a meter for individual tubes and up to 20 cm for tube bundles have already been achieved.

A distinction is made between single-walled and multi-walled tubes, between open or closed tubes (with a lid that has a section made of a fullerene structure) and between empty and filled tubes (for example with silver , liquid lead or noble gases ).

properties

Depending on the detail of the structure, the electrical conductivity within the tube is metallic or semiconducting ; carbon tubes are also known which are superconducting at low temperatures . Transistors and simple circuits have already been made with the semiconducting carbon nanotubes. Research is now looking for ways to specifically manufacture complex circuits from different carbon nanotubes.

The mechanical properties of carbon nanotubes are outstanding:

Single-walled CNTs (SWCNT) have a density of 1.3 to 1.4 g / cm³, multi-walled CNTs (MWCNT) of 1.8 g / cm 3 and a tensile strength of 30 GPa for single- walled versions and up to 63 GPa for multi-walled versions. Steel has a density of around 7.85 g / cm³ and a maximum tensile strength of 2 GPa. This results in a mathematical ratio of tensile strength to density ( tear length ) that is approx. 135 times as good for multi-walled CNTs as for steel. However, such calculation examples are only of a purely theoretical nature - for example for the space elevator . In practice, a comparison with carbon fiber or steel fiber would be more meaningful, since similar mechanisms (size effect, orientation) increase the tensile strength. The modulus of elasticity is up to 1 TPa . Steel has a modulus of elasticity of 210 GPa , so that of CNTs is about 5 times as high. However, this only applies to relatively small sections of carbon nanotubes (a few mm).

For the electronics industry, the current-carrying capacity and thermal conductivity are of particular interest: the former is estimated to be 1000 times the capacity of copper wires, the latter is more than 2.5 times as high as that of natural diamond at room temperature at 6000 W / (mK) with 2190 W / (m · K), the best naturally occurring heat conductor. Since CNTs can also be semiconductors, they can be used to manufacture transistors that can withstand higher voltages and temperatures than silicon transistors. The first experimental, functional transistors made from CNTs have already been manufactured.

Applications of the nanotubes

So far, apart from a few niches, there are no applications for nanotubes in industrial production or in products on the market. However, theoretical areas of application for so-called buckypaper are researched / conceivable. Various applications are developed in university and industrial research:

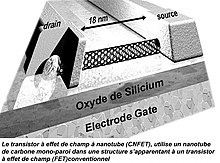

Transistors made from nanotubes

The semiconducting property of CNTs is used here. At each end of the tube there is an electrode (source / drain), the control electrode of the transistor is arranged around the tube . With basically the same functionality as a MOSFET, one hopes for better performance. Field effect transistors with nanotube technology are called carbon nanotube field effect transistors (CNTFET).

Nanotube storage

With the help of CNTs, non-volatile data memories can be implemented. The nanotubes are placed between two electrodes . An electric field between the two electrodes causes the nanotube to contract or stretch permanently. In the stretched state, it represents an electrical contact with a substrate electrode and thus enables a current to flow. Laboratory tests show switching times in the range of SRAM speeds.

Apart from these memories, in which the nanotube realizes the operating principle, research is also being carried out into realizing the capacitance in conventional DRAMs using CNTs.

Nanotubes for displays

Fields of nanotubes set up in parallel can be produced and the principle suitability as a component for flat and self-luminous field emission screens has already been demonstrated: The sharp tips of the nanotubes serve as a source for electrons through field emission (tiny electron gun, cold cathode even at relatively low voltages), which can be accelerated against a fluorescent screen like in a conventional television set .

Nanotubes for measurement technology

CNTs are also used as tips for high-performance scanning tunneling microscopes (STM), which are already commercially available and improve the resolution by a factor of 10 compared to conventional STMs.

Nanotubes to improve plastics

Nanotubes are mixed with conventional plastic , which improves the mechanical properties of the plastics. For example, tensile tests on a composite made of polyethylene and CNT with a CNT content of 1% showed a gain of 25% compared to the homopolymeric polyethylene. Völkl delivered an initial series of 60,000 tennis rackets .

It is also possible to manufacture electrically conductive plastics. Research at the Leibniz Institute for Polymer Research Dresden shows that adding just 0.04% CNT is sufficient to make a plastic electrically conductive. This means that CNTs are superior to conventional conductivity blacks in this respect.

In the manufacture of fiber composite materials, nanotubes are grown on the fibers in order to improve their connection to the surrounding resin, the matrix. This results in considerable improvements in the mechanical properties.

Nanotubes for aircraft

Lockheed Martin uses F-35 nanotubes in its stealth multi - role fighter to reduce weight. In order not to prolong the test phase for the machine too much, these were only used for parts that are not or only slightly stressed, since the approval of new technologies can be achieved more quickly here. From a purely technical point of view, however, according to Travis Earles, the company's head of the nanotechnology department, it is not a problem to use this even with components that are subject to higher loads.

Carbon nanotubes for mechanical applications

By enclosing paraffin in the individual carbon nanotubes (CNTs), a nanowarn made of carbon nanotubes can lift high weights: the filled nanotubes are wound into a straight yarn or a twisted yarn. They both have different uses; the drive is the same. The paraffin melts when heated and expands the CNT in its width. This increases the volume of the nanotube and shortens the CNT. The nanotube only needs 25 thousandths of a second (40 µs) for this reaction process. However, this only affects the CNT. Whether a melting / cooling cycle can be implemented at a corresponding speed needs to be investigated (especially with more extensive structures) (as of 2012). A rotating movement is made possible by the twisted spun yarn because the CNTs also shorten. Due to the rapid reaction of the paraffin and the stability of the incorporation into the carbon structure, the yarn is able to perform an average of 11,500 revolutions per minute. Cooling brings the nano yarn into the basic position.

Other potential uses

Whole bundles of nanotubes have already been processed into threads or mats that are to be used as material . Bundles of nanotubes that are electrically charged in an electrolyte can also act as actuators .

The Karlsruhe Institute of Technology (KIT) published in March 2011 that it had made significant progress in the creation of cycle-stable lithium batteries based on carbon nanotubes. Compared to conventional lithium batteries, the capacity has been doubled.

Production of extremely black surfaces: An American research group has succeeded in producing what is currently the darkest material with the help of nanotubes. It is a quarter as bright as the current black reference (0.16% reflection) made of a nickel-phosphorus mixture, whereby the body still has a special surface structure. The new material, a surface that is densely covered with nanotubes of different lengths, only reflects 0.045% of the incident light. Potential areas of application for the new material would be solar collectors and the shielding of radio waves in a very wide frequency range.

Chips and computers

In semiconductor technology , the use of nanotubes as a metallic compound, e.g. B. in the form of vertical contacts, researched in order to avoid electromigration problems. By combining two nanotubes of different diameters and with different electrical properties, diodes can be created. It is hoped that this will later be able to produce entire computer circuits from nanotubes.

Researchers at the Karlsruhe Institute of Technology, in collaboration with the DFG Center for Functional Nanostructures (CFN), have succeeded in using a nanotube as an electronic switch . The conductivity of a nanotube can be reduced locally to a thousandth by bombarding it with an electron beam . The reason for this are so-called quantum dots . The effect is reproducible and reversible. The high resistance can be reset by applying a high voltage . The nanotube is not damaged during this targeted switching on and off.

According to a report in the journal Nature , a research team at Stanford University , California, led by Max Shulaker, has succeeded in realizing a functioning computer based on carbon nanotubes consisting of 178 transistors. The calculator can perform some simple number operations and individual sets of instructions from the 1980s.

In 2014, Ken Takeuchi, professor at the Faculty of Science and Engineering at Chuo University in Tokyo, and the company Nantero demonstrated a 140 nm single-bit NRAM .

Structure of the nanotubes

Carbon nanotubes are derived from graphene (individual graphite layer ) that is rolled up into a tube: the carbon atoms form a honeycomb-like structure with hexagons and three bonding partners each. Tubes with an ideally hexagonal structure have a uniform thickness and are linear; However, kinked or narrowing tubes containing pentagonal carbon rings are also possible. Depending on how the honeycomb network of graphite is rolled into a tube (“straight” or “oblique”), helical (helically wound) and non-mirror-symmetrical, i.e. chiral structures are created. In the literature, the index pair (n, m) is used to differentiate and a distinction is made between three classes. These are called armchair (with (n, n) , achiral, helical), zig-zag ( (n, 0 ) , achiral, non-helical) and chiral ( (n, m) , chiral, helical). The first two names refer to the shape of the line that results from following the CC bonds along the perimeter.

The index pair can also be used to determine whether the tube is a semiconductor. If is an integer, the carbon nanotube is metallic, otherwise it is semiconducting. Thus, a third of all conceivable tubes are metallic, to which z. B. also count all armchairs .

Discovery and manufacture

Multi-walled carbon nanotubes (also MWNTs ) were accidentally discovered in 1991 by Sumio Iijima using an electron microscope . He had created an arc discharge between carbon electrodes. In 1987 Karsten Pietsch developed an arc process for metal coating; Only afterwards was it found that this coating consists of single-walled carbon nanotubes grown in parallel. The single-walled carbon nanotubes were only discovered in 1993, Morinobu Endo (* 1946) was already synthesizing carbon nanotubes in the 1970s, but could not observe them and did not name them, but made them usable as filters for medicine. They can also be produced in an electric arc if catalysts are added. The Nobel laureate Richard Smalley in 1996 published a laser process for the production of single-walled carbon nanotubes (SWNTs also, Eng. Single-walled nanotubes ). Here, graphite is removed ("evaporated") with a laser . In addition, nanotubes are created during the catalytic decomposition of hydrocarbons . With this CVD process , entire fields of largely parallel tubes can be grown on a substrate.

Each of the three processes (arc, laser, CVD) has meanwhile been developed to such an extent that larger quantities of more uniform CNTs (in terms of diameter, length, defects, multiple walls) can be produced with them. Today you can buy finished carbon nanotubes from various manufacturers in gram quantities.

Removal of catalysts

Nanoscale metal catalysts are important components of many efficient synthesis processes for CNTs, especially CVD synthesis. They also allow a certain degree of control over the structure and chirality of the CNTs formed. During the synthesis, catalysts can convert carbon-containing compounds into tubular carbon, but are usually themselves encapsulated by partially graphitic carbon layers. In this way they can become part of the resulting CNT product. However, such metallic impurities can be problematic for many applications of CNTs. Catalyst metals such as nickel , cobalt or yttrium can, for. B. raise toxicological concerns. While unencapsulated catalyst metals can be washed out relatively easily with mineral acids, catalyst particles encapsulated with carbon require an upstream oxidative process step to open their carbon shell. An effective removal of catalysts, especially encapsulated ones, while maintaining the CNT structure, therefore usually represents a procedural challenge. It has been investigated for many CNT qualities and individually optimized. A new approach to break such encapsulations and to evaporate metal-containing catalysts consists in the extremely rapid heating of CNTs and their impurities in a thermal plasma jet .

Health effects

So far, there has not been sufficient research into the health- impairing , so-called nanotoxic effects that have occurred in connection with carbon nanotubes. One argument points to the elongated spatial structure, which is similar to that of asbestos . Studies based on animal experiments show different results, for example with regard to inflammatory reactions in the lung tissue of mice . In more recent studies on the toxic effects of carbon nanotubes, the metallic residues ( cobalt , nickel , molybdenum and iron ) from the catalyst that remain during the synthesis are receiving increasing attention. It appears that the acutely toxic reactions were due to these contaminants. Purified preparations of CNTs show no acute toxic effects. By adding branched "antennas" with carboxyl (-COO-) groups on the fullerenes (of which carbon nanotubes belong to the subspecies), hydrophilic fullerenes are created that are even supposed to protect nerve cells . The condition for this is again the purity of the fullerene or the carbon nanotube (no metals , radicals , etc.). However, pathological changes, such as the formation of growths in the lungs, seem to be triggered by CNTs, which gives them a very harmful potential. Despite the ongoing controversy, which is beginning to reach the general public to a limited extent, large-scale industrial production of CNTs started in early 2004.

Industrial realization

At the end of January 2009, 80 partners from industry and research joined forces in Leverkusen to form the Inno.CNT innovation alliance . Immediately before its kick-off event, Bayer AG laid the foundation stone for the world's largest pilot production facility for carbon nanotubes, which has been in operation since January 2010 and cost 22 million euros. It has a production capacity of around 200 tons per year. In 2013 Bayer ceased operations because it did not fit in with the rest of the Group's portfolio.

See also

Web links

Individual evidence

- ↑ Ron Dagani: Nanotube Strands Are Centimeters Long . In: Chemical & Engineering News . tape 80 , no. 18 , 2002, p. 11 ( acs.org ).

- ↑ R. Zhang, Y. Zhang, Q. Zhang, H. Xie, W. Qian, F. Wei: Growth of Half-Meter Long Carbon Nanotubes Based on Schulz-Flory Distribution . In: American Chemical Society (Ed.): ACS Nano . tape 7 , no. 7 , 2013, p. 6156-6161 , doi : 10.1021 / nn401995z .

- ↑ SH Kim, GW Mulholland, MR Zachariah: Density measurement of size selected multiwalled carbon nanotubes by mobility-mass characterization . In: Carbon . tape 47 , no. 5 , 2009, p. 1297-1302 , doi : 10.1016 / j.carbon.2009.01.011 .

- ↑ Min-Feng Yu: Tensile Loading of Ropes of Single Wall Carbon Nanotubes and their Mechanical Properties . In: Physical Review Letters . tape 84 , no. 24 , 2000, pp. 5552-5555 , doi : 10.1103 / PhysRevLett.84.5552 .

- ↑ Min-Feng Yu, Oleg Lourie, Mark J. Dyer, Katerina Moloni, Thomas F. Kelly, Rodney S. Ruoff: Strength and Breaking Mechanism of Multiwalled Carbon Nanotubes Under Tensile Load . In: Science . tape 287 , no. 5453 , 2000, pp. 637-640 , doi : 10.1126 / science.287.5453.637 .

- ↑ TR Anthony: Thermal diffusivity of isotopically enriched . In: Physical Review B . tape 42 , no. 2 , 1990, p. 1104–1111 , doi : 10.1103 / PhysRevB.42.1104 .

- ↑ Fischer, Matthias: Analysis of the mechanical behavior of miniature test bodies made of polyethylene carbon nanotube composites under tensile load , Bachelor thesis, Martin Luther University Halle-Wittenberg, Institute for Physics, 2010, pp. 31–32.

- ↑ B. Krause, M. Ritschel, C. Täschner, S. Oswald, W. Gruner, A. Leonhardt, P. Pötschke: Comparison of nanotubes produced by fixed bed and aerosol-CVD methods and their electrical percolation behavior in melt mixed polyamide 6.6 composites . In: Composites Science and Technology . tape 70 , issue 1, 2010, p. 151–160 , doi : 10.1016 / j.compscitech.2009.09.018 (English).

- ↑ Lockheed Martin reveals F-35 to feature nanocomposite structures

- ↑ KIT: New battery material for electric vehicles

- ↑ Zu-Po Yang, Lijie Ci, James A. Bur, Shawn-Yu Lin, Pulickel M. Ajayan: Experimental Observation of an Extremely Dark Material Made By a Low-Density Nanotube Array . In: Nano Letters . tape 8 , no. 2 , 2008, p. 446-451 , doi : 10.1021 / nl072369t .

- ↑ KIT scientists discover unexpected electronic effect. Retrieved May 18, 2012 .

- ↑ Max M. Shulaker, Gage Hills, Nishant Patil, Hai Wei, Hong-Yu Chen, H.-S. Philip Wong, Subhasish Mitra: Carbon nanotube computer. In: 501. Nature, September 25, 2013, pp. 526-530 , accessed on September 26, 2013 (English).

- ↑ Nora Schlüter: First computer made of carbon. Wissenschaft.de, September 25, 2013, accessed on September 14, 2019 .

- ↑ Heinz Arnold: Nantero: New NRAMs go into series production: The holy grail of storage technology - finally found? www.elektroniknet.de, June 5, 2015, accessed June 6, 2015 .

- ↑ Yamada T, Namai T, Hata K, Futaba DN, Mizuno K, Fan J, et al .: Size-selective growth of double-walled carbon nanotube forests from engineered iron catalysts . In: Nature Nanotechnology . 1, 2006, pp. 131-136. doi : 10.1038 / nnano.2006.95 .

- ↑ MacKenzie KJ, Dunens OM, Harris AT: An updated review of synthesis parameters and growth mechanisms for carbon nanotubes in fluidized beds . In: Industrial & Engineering Chemical Research . 49, 2010, pp. 5323-5338. doi : 10.1021 / ie9019787 .

- ↑ Jakubek LM, Marangoudakis S, Raingo J, Liu X, Lipscombe D, Hurt RH: The inhibition of neuronal calcium ion channels by trace levels of yttrium released from carbon nanotubes . In: Biomaterials . 30, 2009, pp. 6351-6357. doi : 10.1016 / j.biomaterials.2009.08.009 .

- ↑ Hou PX, Liu C, Cheng HM: Purification of carbon nanotubes . In: Carbon . 46, 2008, pp. 2003-2025. doi : 10.1016 / j.carbon.2008.09.009 .

- ↑ Ebbesen TW, Ajayan PM, Hiura H, Tanigaki K: Purification of nanotubes . In: Nature . 367, 1994, p. 519. doi : 10.1038 / 367519a0 .

- ↑ Xu YQ, Peng H, Hauge RH, Smalley RE: Controlled multistep purification of single-walled carbon nanotubes . In: Nano Letters . 5, 2005, pp. 163-168. doi : 10.1021 / nl048300s .

- ↑ Meyer-Plath A, Orts-Gil G, Petrov S et al .: Plasma-thermal purification and annealing of carbon nanotubes . In: Carbon . 50, 2012, pp. 3934-3942. doi : 10.1016 / j.carbon.2012.04.049 .

- ↑ Katharine Sanderson: Carbon nanotubes: the new asbestos? In: Nature News . 2008, doi : 10.1038 / news.2008.845 .

- ↑ Study Says Carbon Nanotubes as Dangerous as Asbestos . In: Scientific American , February 15, 2008.

- ↑ Thorwald Ewe: A miracle substance and what became of it fullerenes and nanotubes. On: Wissenschaft.de from November 14, 2000.

- ↑ See Stefan Jorda: Small tubes really big. In: Physics Journal. 8, No. 3, 2009, p.11 ( online ).

- ↑ ( Page no longer available , search in web archives: Fachportal process.de article ) from February 11, 2010, accessed on February 19, 2010.

- ↑ Bayer ends research on carbon nanotubes. Retrieved September 11, 2019 .