Cylinder bank

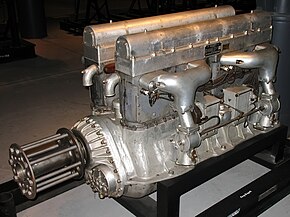

The cylinder bank is part of a reciprocating - engine . It consists of two or more cylinders (with cooling fins or water jacket ), the cylinder head and, in the case of four-stroke engines , parts of the valve control . With the exception of H and U engines , the pistons and connecting rods of all cylinder banks act on a common crankshaft .

No cylinder banks have single-cylinder engines , further star and multiple radial engines in which the cylinders are individually around the crankshaft circular, and in particular V- and boxer engines with only two cylinders.

Cylinder banks in various designs of engines

The number of cylinder banks and their position relative to one another determine the design of a reciprocating internal combustion engine.

In-line engine

The in- line engines common today have only one cylinder bank. In automobiles and motorcycles , a maximum of six cylinders are combined in a cylinder bank. Eight- cylinder in-line engines were still used in passenger cars until the 1950s ; however, they are very long and the crankshaft tends to develop undesirable twisting and vibrations with increasing speeds . In the case of slower-running marine diesel engines , in-line engines with up to 14 cylinders have been implemented in one bank (for example the Wärtsilä RT-flex96C ).

A special feature are in-line engines with several cylinder banks coupled in series. They were used in the early days of motorization and later in motorsport . Two examples with central output, i.e. a power output in the middle between two banks coupled in a row, are the racing cars Mercedes-Benz W 196 (1954 / '55) and Bugatti Type 251 (1955).

Boxer and V-engine

Engines with more than one cylinder bank are available in different designs and are also frequently found in vehicle construction . If two banks are arranged at an angle to each other, it is a V-engine .

A distinction must be made between engines with two cylinder banks, a bank angle of 180 ° and a central crankshaft: A (real) boxer engine is only involved if the connecting rods of two opposing cylinders act on two crankpins offset by 180 ° . The two pistons move in opposite directions and are always in the same position, mirror-inverted, for example both in top dead center .

In the case of a 180 ° V-engine, however, two connecting rods engage the same crank pin and move synchronously. So there is always one piston in the “upward movement” (e.g. in the compression stroke ), the other in the “downward movement” (e.g. in the working cycle ). Since the inertial forces ( inertia forces) of the individual cylinder pair, in contrast to the boxer engine, do not balance each other out, this type of construction only makes sense with several cylinder pairs.

Underground engine

The U-engines are rare special forms with two cylinder banks (double in-line engines with two banks positioned next to each other and two crankshafts). Similar to engines coupled in series, they were also occasionally in use in the early days of motorization and later in motorsport. Examples of automobiles with two cylinder banks in a U-formation are the British Duplex 10 hp from 1919 / '20 and the Bugatti models Type 45 and 47 from the late 1920s.

W, X, Y, H as well as series star and series delta motors

A wide variety of internal combustion engines can be put together with three or more cylinder banks, but these are rare in vehicle construction today; Reciprocating piston engines with up to 56 cylinders were realized.

With three banks of cylinders, W , Y , 120 ° in-line star (star in-line engines) and in-line delta engines (three-shaft opposed piston engines) such as the Napier Deltic are possible. Examples of automobile engines with three cylinder banks, the concept study of the street sports car Audi Avus quattro from 1991 and the Formula 1 - racing cars of Life Racing in the 1990 season , and also that of Guy Nègre 1989 converted for test drives Formula 1 racing cars AGS JH22 , each with independent 60 ° -W-engines and 12-cylinders.

With four cylinder banks along a central crankshaft, W (as double V) , X and 90 ° in-line radial engines as well as H-engines with two crankshafts are possible, but these are very rare in today's practice. Examples of this are the Clerget X-16 aircraft engine from the French company Clerget-Blin , a 90 ° in-line radial engine with 16 cylinders from 1911, the Bugatti Veyron 16.4 with a 16-cylinder W engine (more precisely: a V-VR engine) 2005 as well as the BRM P83 Formula 1 racing car with 16-cylinder H engine from 1966.

Occasionally in the history of engine construction, especially for ships and tanks , in-line radial engines with five or more cylinder banks were also realized. The M4A4 Sherman tank, for example, had a 30-cylinder “multibank” engine from Chrysler . The design with a displacement of 20.6 liters and an output of 425 hp consisted of five banks of six cylinders each. The most extreme example is the Zvezda M520 marine diesel engine , an in-line star engine with 56 cylinders, which are divided into seven cylinder banks of eight cylinders around a crankshaft.

The cylinder bank / cylinder block ratio

Common case: a bank, a block

In terms of manufacturing technology , a cylinder bank often, but not necessarily, corresponds to a one-piece cylinder block, which is also called a cylinder housing, (cylinder) crankcase (ZKG) or engine block . In the older literature, the terms block engine or monobloc (k) are often found for engines in which two or more cylinders are cast together in one block . From around 1910 onwards, people knew how to cast the cylinders together as a cylinder bank.

Other forms

With modern production techniques and casting materials , it is possible and sometimes advantageous for reasons of stability, weight and sealing, to cast the complex shape of a V-engine with its two cylinder banks in just one part. In this case, the two cylinder banks are connected to one another by the (upper) crankcase to form a unit. In the case of VR engines with their small cylinder bank angles, the connection of two cylinder banks to form a cylinder block and the use of a common cylinder head are typical design features .

Conversely, a cylinder bank, especially when using cylinder liners, can be manufactured from multi-part cylinder housings.

In the early days of engine construction, before the block engine prevailed, it was common, and later for air-cooled engines, to place the cylinders individually on the crankcase. Lined up one behind the other, they resulted in a cylinder bank with several cylinders. In an intermediate phase at the beginning of the 20th century, it was common practice to manufacture cylinders in pairs and join them together to form a longer cylinder bank with four or six cylinders.

The differentiation and designation of several cylinder banks

In the case of reciprocating internal combustion engines with two or more cylinder banks, it is necessary to differentiate between the cylinder banks during development, possibly also during production and finally during control and maintenance . However, no uniform designation has become established. In many cases, the banks are numbered in ascending order from 1 or with Latin capital letters in sequence, starting with A. Sometimes a distinction is only made between the right and left bank, and possibly also the middle or upper and lower bank.

The bank in which cylinder 1 is located is regularly referred to as cylinder bank 1 or A of an engine. Which cylinder receives the number 1, however, is again not uniformly defined. For the motor vehicle sector , German manufacturers regularly use DIN 73021 as a guide. According to this, the cylinder is given the number 1, which is at the front left from the viewer; The view must be from the end of the engine that is not (!) where the power output / flywheel is. Engine manufacturers from other countries as well as German companies that produce engines for general use or as a marine engine , however, often orientate themselves on ISO 1204, 1205. This leads to the opposite results: the cylinder again receives the number 1, the one from the front is on the left; here, however, the view is from the end of the motor where the power is delivered.

According to both standards, the cylinders behind them in the same bank receive the following digits. The process continues - again starting from the front of the viewer - with the cylinders of the bank that follows clockwise around the crankshaft. The only exceptions are the VR engines, which are treated like an in-line engine in the cylinder sequence despite two cylinder banks, and the V-VR engines with four cylinder banks, the cylinders of which are counted with two banks like a conventional V engine. These exceptions are justified by the fact that in the VR cylinder block, due to the inherently small cylinder bank angle, the connecting rods of each cylinder are articulated on their own crank pin in the interest of a round engine - as in an in-line engine - and there is only one common cylinder head for both cylinder banks. The two cylinder banks of a VR engine are therefore occasionally referred to as a single (VR) cylinder bank.

The question of how the cylinder banks are designated depends on the individual case, in particular on whether the manufacturer adheres to the DIN recommendation or, conversely, to the ISO recommendation. On the other hand, the common view that the designation is based on the direction of travel or from the driver's seat is incorrect.

Sometimes specialist books use different specifications in detail. The choice of the left bank is sometimes justified by the fact that it is "usually" (due to the cylinder bank offset) "offset towards the viewer".

The importance of the cylinder bank in the design, development, construction, control and maintenance of an engine

The cylinder bank as a structural basis

In many cases, reciprocating internal combustion engines have been and are modularly designed, developed and built as engine families . The cylinder bank of an in-line engine can be combined on a new crankcase with a second cylinder bank of the same type to form a V engine, and with a third cylinder bank of the same type to form a W engine. In terms of design, there is the option of aligning the further cylinder bank (and the pistons) in the same direction (so-called installation on "envelope") or rotated 180 ° around the cylinder's longitudinal axis. The shared parts principle implemented in this way saves time and money in many ways. The M 120 V12 cylinder engine from Mercedes-Benz from 1991 is a derivative of the M 104 six-cylinder in-line engine from 1989.

The situation is similar when, for example, the cylinder bank of a four-cylinder in-line engine is lengthened to an in-line five or six-cylinder or, conversely, shortened to an in-line three or two-cylinder. It is also common to derive V-engines with four, six, eight, ten or twelve cylinders from one another.

The cylinder bank as a functional unit

When it comes to the supply of engine oil as lubricant, as well as water, oil or the air flow for engine cooling, the cylinder bank is regularly viewed as a unit. In OHC and DOHC engines, each cylinder bank regularly has one or two overhead camshafts . Motors controlled in this way, but often also those with OHV or SV valve control , have one cylinder head per bank.

In the past, with several banks of cylinders, one carburettor per bank was responsible for the mixture formation , for example in the Lagonda V12 from 1939 and the early Porsche 356 (one single carburetor each up to 1957). The ignition was often carried out by an ignition distributor with an ignition coil or an ignition magnet per bank, as in the early Ferrari sports and racing cars. Even simple injection systems in the form of so-called single-point injection controlled and regulated the mixture formation and ignition, often bank by bank. In modern injection systems with common rail technology for direct injection of the fuel , a separate rail is usually used for each cylinder bank. Furthermore, each cylinder bank usually has its own knock sensor .

The M 120 V12 cylinder engine from Mercedes-Benz from 1991, for example, uses a Bosch LH-Motronic per cylinder bank, i.e. two fully electronic injection systems with hot-wire air mass meters that are connected to one another via a common data channel ( CAN bus ). At the beginning of the 1990s, the BMW twelve-cylinder models 750i and 850Ci also used an L-Jetronic with digital engine electronics (DME) per cylinder bank, which are networked with other control units via a CAN bus.

With supercharged engines , each cylinder bank often has its own compressor or its own (smaller) turbocharger , which is only supplied with the exhaust gas from this bank , sometimes in the special form of register charging . Important pioneers in the use of such bi-turbo engines with one turbocharger per cylinder bank were the manufacturers Renault and BMW . The former established the technology with the 1.5 V6T engine in the racing / gasoline sector in the Formula 1 racing cars Renault RS10 to RS14 in the 1979 Formula 1 season ; The latter resulted from the end of 1998, the bi-turbo charging with the engine type M67 in diesel engines , a, a V8 direct injection engine in the model 740d Series E38 .

On the exhaust side, each bank regularly has its own manifold and, in the case of so-called complete double / multi-flow exhaust systems, its own front and rear silencer with a separate tailpipe . Alternatively, the exhaust lines from two banks are brought together in a Y-shape by means of a Y-shaped pipe to form a single-flow exhaust system. In modern engines, each cylinder bank usually has its own close-coupled (pre-) catalytic converters and, in the case of completely twin / multi-flow exhaust systems, its own lambda probe and its own underfloor / main catalytic converter , sometimes a secondary air fan for each bank for exhaust gas treatment in the warm-up phase.

Practical implications

The number of cylinders in a cylinder bank and the question of how several cylinder banks of a reciprocating internal combustion engine are arranged in relation to one another have a direct influence on the design of the crankshaft, the camshafts and the firing order . In addition, they determine the extent to which the inertial forces and moments of the first and second order are balanced , and thus the running comfort of the engine, as well as its sound.

The shape and arrangement of the cylinder banks also have a direct influence on the length, width and height of the engine as well as the positioning of auxiliary units such as carburetors, components of the injection system, alternators , pumps , filters , fans , air conditioning compressors , turbochargers and compressors (so-called package or installation space Management).

Cylinder bank deactivation

The cylinder bank deactivation is a technical means of reducing fuel consumption and a special form of cylinder deactivation in relatively powerful engines with two (or more) cylinder banks. With them, a complete cylinder bank is switched off in the partial load range . In conventional designs with a common crankshaft for several banks, the pistons of the switched-off bank continue to move; however, they no longer perform any work because the combustion chambers of this bank are no longer supplied with fuel or the valves in this bank remain closed. Modern engines use control electronics and a hydraulic system in the area of the valves. A V8 or V12 engine then works practically like an inline four or six cylinder.

One of the first automobiles with cylinder bank deactivation was the American Enger Twin-Six from the Enger Motor Car Company with 12 cylinders from 1916 / '17. One of the first automobile engines in which a cylinder bank deactivation ex works was offered at least for a surcharge was the V12 cylinder engine type M 137 from Mercedes-Benz from 1999. The bank deactivation was available in the luxury class models S 600 L and CL 600 . Even before the automotive sector, cylinder bank shutdowns were common in ship engines.

For cylinder bank deactivation, engines with six-cylinder banks and other V and W engines with specific cylinder bank angles are generally suitable. Even after the work of a complete cylinder bank has ceased, the crankshafts used here, with their typical cranks, enable sufficient rotational uniformity and sufficient running comfort for the engine. In the case of the M 137 V12 cylinder engine in the partial load range, for example, Mercedes-Benz decided to switch off a complete cylinder bank, but for the technically closely related M 113 V8 cylinder engine, due to the unfavorable bank angle, it decided to switch off two cylinders in each bank. The latter therefore continues to work with both cylinder banks in the partial load range like a V4 engine.

Cylinder bank angle

With two cylinder banks and a common crankshaft, the cylinder bank angle, also simply bank or V-angle, sometimes also called fork angle, is the angle at which the two surfaces are to each other, which are each determined by the longitudinal axes of the cylinders belonging to a bank. Such a system exists in particular in V engines, with three or more cylinder banks also in W, X, Y, double V and in-line engines. With boxer engines it is by definition 180 °. For "real" in-line radial engines with the specification of uniform angles, it results from the formula 360 ° divided by the number of cylinder banks.

Typical cylinder bank angles, depending on the number of cylinders per bank, are 90 °, 60 °, 45 ° or 72 ° for V2 ( Buell , Voxan ) and V10 engines. Its multiple results in a full circle of 360 ° or a complete cycle of all four cycles of a four-stroke engine with a crank angle of 720 ° and thus enables simple crankshaft shapes, uniform ignition intervals and good mass balance. In VR engines, the cylinder bank angle is usually only between 10 ° and 15 °.

With the exception of VR engines, the engine components required for mixture formation and intake can often be accommodated in the space between the cylinder banks to save space. However, for some engines a cylinder bank angle of 60 ° (and less) is too narrow to be able to accommodate sufficiently long intake manifolds in the cylinder V, as is desirable for displacement and powerful engines. Modern designs with variable intake manifold lengths that enable an optimized torque curve are also made more difficult.

With the 6.0-liter V12 cylinder engine type M 120 from Mercedes-Benz from 1991, the intake manifolds could not be accommodated between the cylinder banks because of the narrow cylinder bank angle of 60 °. The header pipes are therefore crossed with respect to the associated cylinder banks.

The term cylinder angle, which is largely used synonymously or as a generic term, is more common. This also fits for those reciprocating internal combustion engines that are designed without cylinder banks, in which the cylinders are thus arranged individually around the crankshaft, such as V2 engines, two-cylinder boxers and star and multiple star engines.

The cylinder (bank) angle must be distinguished from other angles that play an important role in the design and installation of engines, such as the valve angle and the angle of inclination. The former is the angle at which the intake and exhaust valves are positioned to one another, which influences the shape of the combustion chamber. The latter is the angle at which a cylinder bank is installed in a vehicle inclined around the longitudinal axis of the crankshaft from the vertical in order to lower the overall height or the vehicle's center of gravity.

Cylinder bank offset

The cylinder bank offset, also simply called bank offset, is a special design feature in reciprocating internal combustion engines with several cylinder banks along a crankshaft and describes the length by which two cylinder banks are shifted against each other on the longitudinal axis along the crankshaft for structural reasons.

In conventional, typical V-engines, in which the two connecting rods of a V-cylinder pair are each articulated to the same crank pin, the cylinder bank offset generally corresponds at least to the connecting rod width. For correspondingly designed W, X, Y, double V and inline star engines, the offset of the additional cylinder banks increases with each additional connecting rod on the same crank pin by at least one more connecting rod width.

If, on the other hand, the connecting rods of a V-engine are distributed over different crankpins - comparable to an in-line engine (atypical V-engines, often with unusual, especially small cylinder bank angles), the cylinder bank offset is regularly increased by at least the length of the crankshaft spacer between these two connecting rods lies. The same applies to boxer engines in which the connecting rods of an opposing pair of cylinders are, by definition, hinged to different crank pins.

In VR engines with their inherently small cylinder bank angles, the connecting rods of each cylinder are regularly articulated on their own crank pin in the interests of smooth engine running. A cylinder offset by just one connecting rod width and the length of the crankshaft intermediate cheek is often not sufficient for them, because the cylinders of both banks could nevertheless intersect in the lower area due to the small cylinder bank angle.

Possible solutions are individually or in combination:

- an increase in the bank offset, whereby the length advantage of the VR engine compared to a conventional in-line engine is partially lost again,

- the extension of the connecting rod and thus the increase in the deck height, which makes the VR engine even heavier, or

- an offset of the cylinder banks. The two cylinder banks in the lower area are offset slightly outwards. As a result, the two surfaces that are formed by the cylinder longitudinal axes of the respective bank do not intersect in the crankshaft longitudinal axis, as is usual, but below, which increases the material load.

The cylinder bank offset in engines for automobiles and motorcycles is typically in the small centimeter range. With the 6.0-liter V12 cylinder engine type M 120 from Mercedes-Benz from 1991, it is only 20 millimeters. The cylinder bank offset has a direct influence on the overall length of the engine and must therefore be taken into account when dimensioning the engine compartment, for transverse installation in the engine compartment width. Furthermore, the cylinder bank offset can affect the camshaft (s) and their drive as well as the positioning of ancillary units.

In order to prevent cylinder bank misalignment, various structural means can be used as an alternative:

- Connecting rods (the second connecting rod of the V-cylinder pair or the other connecting rods of a W, X, Y, double V or inline star engine are not hinged to the crank pin, but to the first connecting rod, which is often the case with complex inline star engines),

- Fork connecting rod with a fork to the longitudinal axis of the crankshaft (the second connecting rod of the V-cylinder pair has two parallel connecting rod feet that are hinged in front of and behind the first connecting rod, for example on older Harley-Davidson engines),

- Forked connecting rod with a fork perpendicular to the longitudinal axis of the crankshaft (the connecting rod branches above the connecting rod foot in a Y-shape into both cylinder banks) or

- Connecting rod with a set connecting rod (in which the upper and lower connecting rod eyes are offset by a special design of the connecting rod shaft). However, each of these approaches increases the design effort and the stress on the material.

In addition to the term cylinder bank offset, the term cylinder offset used largely synonymously or as a generic term is also common. This also fits those engines that are designed without cylinder banks, in which the cylinders are thus arranged individually around the crankshaft, such as V2 and two-cylinder boxer as well as star and multiple star engines.

literature

- Hans-Hermann Braess: Vieweg handbook automotive technology . Ed .: Ulrich Seiffert. 6th edition. Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden 2011, ISBN 978-3-8348-1011-3 , p. 162 ff., 175 ff. and 181 .

- Richard van Basshuysen: Handbook Internal Combustion Engine: Fundamentals, Components, Systems, Perspectives . Ed .: Fred Schäfer. 7th edition. Springer Vieweg, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden 2015, ISBN 978-3-658-04677-4 , p. 10 ff., 163 ff., 414 ff., 503 ff. and 753 f .

- Eduard Köhler, Rudolf Flierl: Combustion engines: engine mechanics, calculation and design of the reciprocating engine . 6th edition. Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Business + Science Media, Wiesbaden 2011, ISBN 978-3-8348-1486-9 , p. 30, 85 f., 164, 433 f. and 444 .

- Konrad Reif (Hrsg.): Otto engine management: control, regulation and monitoring . 4th edition. Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden 2014, ISBN 978-3-8348-1416-6 , p. 93 and 186 .

- Konrad Reif, Karl-Heinz Dietsche: Kraftfahrtechnisches Taschenbuch . Ed .: Robert Bosch GmbH. 27th edition. Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden 2011, ISBN 978-3-8348-1440-1 , p. 412, 481 and 588 .

Individual evidence

- ↑ Braess / Seiffert, Vieweg Handbook Automotive Technology Edition 6; Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden, 2011, ISBN = 978-3-8348-1011-3, pp. 162-164.

- ↑ Basshuysen / Schäfer: Handbook Combustion Engine: Fundamentals, Components, Systems, Perspectives, Edition 7., Springer Vieweg, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden, 2015, ISBN = 978-3-658-04677-4, Pp. 10-12.

- ↑ a b Köhler / Flierl: Combustion Engines: Engine Mechanics, Calculation and Design of the Reciprocating Engine, Edition 6, Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Business + Science Media, Wiesbaden, 2011, ISBN = 978-3-8348-1486- 9, p. 444.

- ↑ Braess / Seiffert, Vieweg Handbook Automotive Technology Edition 6; Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden, 2011, ISBN = 978-3-8348-1011-3, p. 181.

- ↑ a b Daniel Ghebru: Modeling and analysis of the transient thermal response of the internal combustion engine and the overall vehicle . Logos Verlag Berlin GmbH, Berlin, 2013, ISBN 978-3-8325-3432-5 , p. 60.

- ↑ Köhler / Flierl: Combustion Engines: Engine Mechanics, Calculation and Design of the Reciprocating Engine, Edition 6, Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Business + Science Media, Wiesbaden, 2011, ISBN = 978-3-8348-1486-9, P. 433 f.

- ↑ a b c d e f g h i j Braess / Seiffert, Vieweg Handbook Automotive Technology Edition 6; Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden, 2011, ISBN = 978-3-8348-1011-3, p. 162.

- ↑ Helmut Pucher, Karl Zinner: Supercharging of internal combustion engines: Fundamentals, calculations, explanations. Springer-Verlag, Springer Science + Business Media, Berlin / Heidelberg, 4th edition, 2012, ISBN 978-3-642-28989-7 , p. 332.

- ↑ a b c d e f Köhler / Flierl: Combustion Engines: Engine Mechanics, Calculation and Design of the Reciprocating Engine, Edition 6, Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Business + Science Media, Wiesbaden, 2011, ISBN = 978-3- 8348-1486-9, p. 30.

- ^ A b Günter Engelen: Mercedes-Benz SL 280 - SL 600: From Myth to Revelation. Motorbuch Verlag, Stuttgart, 1994, ISBN 978-3-613-01547-0 , p. 191.

- ↑ Braess / Seiffert, Vieweg Handbook Automotive Technology Edition 6; Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden, 2011, ISBN = 978-3-8348-1011-3, p. 164.

- ↑ Braess / Seiffert, Vieweg Handbook Automotive Technology Edition 6; Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden, 2011, ISBN = 978-3-8348-1011-3, pp. 178-183.

- ↑ Tobias Aichele: Porsche 911: forever young. Motorbuch Verlag, Stuttgart, 2004, ISBN 978-3-613-02353-6 , p. 104.

- ↑ Reif / Dietsche: Kraftfahrtechnisches Taschenbuch, edition 27, Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden, 2011, ISBN = 978-3-8348-1440-1, p. 412.

- ↑ Günter P. Merker, Rüdiger Teichmann (Ed.): Fundamentals of internal combustion engines: functionality, simulation, measurement technology. Springer Vieweg, Springer Science + Business Media, Wiesbaden, 7th edition, 2014, ISBN 978-3-658-03194-7 , p. 368.

- ↑ Basshuysen / Schäfer: Handbook Combustion Engine: Fundamentals, Components, Systems, Perspectives, Edition 7., Springer Vieweg, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden, 2015, ISBN = 978-3-658-04677-4, P. 754.

- ↑ Günter Engelen: Mercedes-Benz SL 280 - SL 600: From Myth to Revelation. Motorbuch Verlag, Stuttgart, 1994, ISBN 978-3-613-01547-0 , p. 221.

- ↑ Horst Ahlers (Ed.): Multisensorikpraxis . Springer-Verlag, Springer Science + Business Media, Berlin / Heidelberg, 2013, ISBN 978-3-642-64365-1 , p. 155.

- ↑ Reif: Otto Engine Management: Control, Regulation and Monitoring, Edition 4, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden, 2014, ISBN = 978-3-8348-1416-6, p. 61 f. (On the air side, the outputs of both compressors are brought together in front of the suction pipe.).

- ↑ Comprehensive information on charging in automobile and ship engines: Helmut Pucher, Karl Zinner: Supercharging internal combustion engines: Fundamentals, calculations, explanations . Springer-Verlag, Springer Science + Business Media, Berlin / Heidelberg, 4th edition, 2012, ISBN 978-3-642-28989-7 , in particular pp. 155, 182 f., 332, 345 and 352.

- ↑ Hermann Hiereth, Peter Prenninger: Charging the internal combustion engine - the vehicle drive . Springer-Verlag Wien GmbH, Vienna / New York, 2013, ISBN 978-3-7091-7219-3 , pp. 230 and 241.

- ↑ Reif / Dietsche: Kraftfahrtechnisches Taschenbuch, edition 27, Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden, 2011, ISBN = 978-3-8348-1440-1, p. 481.

- ↑ Reif: Otto Engine Management: Control, Regulation and Monitoring, Edition 4, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden, 2014, ISBN = 978-3-8348-1416-6, p. 123 f.

- ↑ Reif / Dietsche: Kraftfahrtechnisches Taschenbuch, edition 27, Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden, 2011, ISBN = 978-3-8348-1440-1, pp. 481 and 588.

- ↑ Braess / Seiffert: Vieweg Handbook Motor Vehicle Technology, Edition 6, Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden, 2011, ISBN = 978-3-8348-1011-3, pp. 183-185.

- ^ A b Klaus-Dieter Pannes: Analysis and classification of unsuccessful product innovations using the example of the automotive industry . Diplomica Verlag GmbH, Hamburg, 2003, ISBN 978-3-8324-6686-2 , p. 56 f.

- ↑ Hansa: Central organ for shipping, shipbuilding, harbor (magazine), 1991, volume 128, p. 271 for the D 28 V ship engine series from MAN , which was designed primarily for fast yachts , customs and police boats: cylinder bank deactivation when idling by making changes to the injection pump.

- ↑ a b c Basshuysen / Schäfer: Handbook Internal Combustion Engine: Fundamentals, Components, Systems, Perspectives, Edition 7th, Springer Vieweg, Springer Fachmedien Wiesbaden GmbH, Springer Science + Business Media, Wiesbaden, 2015, ISBN = 978-3-658-04677 -4, p. 11.

- ↑ Günter Engelen: Mercedes-Benz SL 280 - SL 600: From Myth to Revelation. Motorbuch Verlag, Stuttgart, 1994, ISBN 978-3-613-01547-0 , p. 193.

- ↑ Jürgen Stoffregen: Motorcycle technology: Basics and concepts of engine, drive and chassis. Vieweg + Teubner Verlag, Springer Science & Business Media, Wiesbaden, 8th edition, 2012, ISBN 978-3-8348-1716-7 , p. 165.

- ↑ a b Köhler / Flierl: Combustion Engines: Engine Mechanics, Calculation and Design of the Reciprocating Engine, Edition 6, Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Business + Science Media, Wiesbaden, 2011, ISBN = 978-3-8348-1486- 9, p. 164.

- ↑ Köhler / Flierl: Combustion Engines: Engine Mechanics, Calculation and Design of the Reciprocating Engine, Edition 6, Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Business + Science Media, Wiesbaden, 2011, ISBN = 978-3-8348-1486-9, P. 86.

Remarks

- ↑ Köhler / Flierl: Combustion Engines: Engine Mechanics, Calculation and Design of the Reciprocating Engine, Edition 6, Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Business + Science Media, Wiesbaden, 2011, ISBN = 978-3-8348-1486-9, On page 30, instead of DIN or ISO, more generally refer to a " convention to designate the foremost cylinder of the cylinder bank on the left as seen from the front ( control side ) as cylinder no. 1", also page 433. This formulation appears in any case for those, predominantly older ones Reciprocating internal combustion engines unclear in which the camshaft (s) are not controlled from one of the two end faces, but from the side ( OHC / DOHC engines with lateral drive of the overhead camshaft (s) via vertical shaft as well as OHV and SV engines), or which do not require camshafts ( two-stroke engines , four-stroke cycle - valve engines ).

-

↑ Köhler / Flierl: Combustion Engines: Engine Mechanics, Calculation and Design of the Reciprocating Engine, Edition 6, Vieweg + Teubner Verlag, Springer Fachmedien Wiesbaden GmbH, Springer Business + Science Media, Wiesbaden, 2011, ISBN = 978-3-8348-1486-9, However, p. 84 ff. Refer to the difficulties encountered in the development of modern V-engines and their pistons:

- Typically, for a number of reasons, the designers of V-engines have long combined the components required for mixture formation and the intake in a space-saving manner between the cylinder banks in the area of the cylinder V. In contrast, the components required for the exhaust, in particular the exhaust manifold, which is subject to high thermal loads, are regularly located on the outside of the engine. In one bank, the inlet is on the so-called “pressure side” (the side of the cylinder bore on which the piston is supported during the downward movement during the working cycle), and in the other bank on the so-called “counter pressure side”. In order to be able to implement the principle of identical parts, the piston, connecting rod and cylinder wall must be designed for this.

- Valve lift and arrangement, coupled with the desire for large valves on top of the pistons, increasingly require so-called valve pockets. In an effort to optimize the combustion, so-called combustion bowls are also increasingly provided on the top of the pistons. In order to be able to install the same pistons on the "envelope", these valve pockets and combustion bowls on the top of the pistons, if one does not want to do without them, must produce a symmetrical "bottom appearance".

- After all, the designers of modern engines like to use the means of offsetting the pistons. A misalignment towards the pressure side, a so-called "noise misalignment", reduces or avoids the so-called "cold slap", a typical noise that occurs primarily with cold play when the piston skirt hits the pressure-side cylinder wall on the pressure side after exceeding top dead center instead of rolling at certain points. Conversely, in the case of diesel engines, dislocation on the counterpressure side reduces or avoids sealing problems between the piston and cylinder as well as the deposition of oil carbon (so-called “thermal dislocation”). If the same cylinder banks and pistons are to be used for the right and left side of a V-engine, these offset options are not applicable, depending on the structure.