Hydroelectric power plant

A hydropower plant or hydropower plant is a power plant that converts the potential energy of the water into mechanical energy or electrical energy . This makes hydropower usable for people. This can u. a. by turbines in rivers or reservoirs or by current and tidal power plants on the sea.

functionality

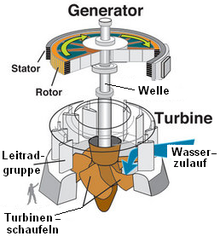

In most hydropower plants, water is retained in the reservoir at a higher level by a dam system (also known as a dam or dam ) . The kinetic energy of the effluent water is a water turbine or a water wheel transfer, which in turn directly or via a gear an electric generator drives the mechanical energy into electrical energy converted. Many hydropower plants also have a substation for feeding into a medium or high voltage network .

A basic distinction is made between run-of-river power plants and storage power plants.

Run-of-river power plants

Run-of-river power plants can have little or no influence on the volume of dammed water and therefore serve to cover the base load in a power grid . They usually consist of a through a weir formed barrage in a flowing body of water.

Storage power plants

Storage power plants have energy storage in the form of lakes or ponds, the level of which can be controlled by the power plant operator. Often these are reservoirs that have been artificially created by means of dams or walls for energy generation, but natural lakes are also used more rarely for this purpose. The output of the power plants can be adapted very well to the actual demand in the power grid; if there is no demand, the plant can also be temporarily shut down. Storage power plants therefore serve to cover the peak load in an electricity network. The output can be ramped up within minutes and, in large systems, can reach the output of a nuclear power plant .

Depending on the size of the memory, a distinction is made between short-term daily memory and weekly memory or long-term annual memory. Annual storage tanks are mostly used to collect water from the snowmelt , which is used over the winter months when the run-of-river power stations can produce less electricity due to the lower flow of water in the rivers.

In Switzerland, only power plants with annual storage that can cover at least a quarter of winter production count as storage power plants. The remaining storage power plants belong to the run-of-river power plants.

Pumped storage power plants use excess energy in the power grid during off-peak times to pump additional water into the storage basin. In the event of a peak load , it can be retrieved from the storage facility and used to generate electricity. In Switzerland, pumped storage plants, the majority of which use previously pumped water to generate electricity, are known as circulating plants . In these power plants, the upper reservoir has only a small natural inflow compared to the amount of water pumped up. The circulating plants include the Limmern headquarters of the Linth-Limmern power plant or the Nant de Drance power plant, which has not yet been commissioned . Both plants have the output of a medium-sized nuclear power plant.

power

The power P depends on the water flow Q (in m 3 / s), the height of fall h (in m), the acceleration due to gravity g (≈ 9.81 m / s²) and the density of water ρ (≈ 1000 kg / m 3 ) :

The total efficiency η results from the product of the individual efficiencies of the inlet, the water turbine, the gearbox, the electrical generator and the machine transformer .

For the rough calculation, the approximately constant factors such as the acceleration due to gravity g , the density ρ of water and the total efficiency are summarized in a constant . With an overall efficiency of η = 85% the following results:

With this constant, the approximate calculation of the power can be expressed as:

Example: 20 m 3 of water flows through the turbine of a run-of-river power plant with a storage height of 6 m . This results in a power of P = 20 m 3 / s · 6 m · 8.5 kN / m 3 = 1020 kW.

The maximum output of a hydropower plant is achieved when the expansion flow Q a is achieved with optimal efficiency.

The installed capacities of hydropower plants worldwide are between a few kW and 22.4 GW ( Three Gorges Dam in the People's Republic of China ). At the same time, they achieve a very high level of efficiency compared to other types of electricity generation. Your turbines and generators can convert up to 90% of the usable water power into electricity ( water to wire ).

Expansion capacity

The expansion capacity P a is the maximum electrical output of a power plant that results from the expansion inflow Q a . However, this inflow is not permanent due to natural fluctuations in the discharge. On average, the expansion inflow in Central Europe is reached or exceeded on around 30 to 60 days a year.

Degree of expansion

The degree of expansion is defined differently for run-of-river power plants and storage power plants.

Degree of expansion for run-of-river power plants

In run-of-river power plants, the degree of expansion f a is understood to be the ratio between the expansion flow Q a and the mean water discharge MQ.

- (without unit)

- f a degree of expansion (without unit)

- Q a expansion flow rate (in m 3 / s)

- MQ mean water discharge (in m 3 / s)

Degree of expansion for storage power plants

In contrast to the above-mentioned system type, the degree of expansion f a for storage power plants results from the ratio of storage volume V SP to the annual water load of the inflows V ZU .

- (without unit)

- V SP storage volume (in m 3 )

- V ZU annual water load of the tributaries (in m 3 )

The choice of the degree of expansion is based on the aspects of the discharge characteristics of the body of water (discharge evenly or strongly fluctuating), type of use of the hydropower plant (individual supply, ground, medium, peak load power plant), other requirements for water use (shipping, minimum water) and the cost-benefit -Factor. For base load power plants with a high level of delivery security and a relatively low investment, a low level of expansion is selected (Q a, I ). For peak load power plants, on the other hand, the choice of a high degree of expansion (Q a, II ) is advisable, as well as higher investment costs.

Benefit plan

The performance plan provides information about the average annual energy yield of a hydropower plant and is therefore of great importance for energy management considerations. To determine the annual production of a power plant, the mean excess duration curve of the inflow must be known. Furthermore, the duration curve of the underwater level and the upper water level, from which the head duration curve can be determined, is required. Usually, duration curves based on daily mean values are used. To secure the statement, however, several annual duration curves should be included in the evaluations and an average should be formed.

By multiplying the excess duration curve of the inflow and the fall height duration curve, the performance duration curve for one year results, and from its integration over time, the annual work of the system results.

Types of hydropower plants

Classification according to the useful gradient

The useful gradient or the height of fall is the difference in height between the water level above the turbine ( upper water ) and the water level behind the turbine (underwater).

Low pressure power plants

Hydropower plants with a drop height of around 15 m are referred to as low-pressure power plants. In contrast to medium-pressure or high-pressure power plants, these are located in the middle of a river and therefore have significantly higher discharges.

The number of installed machine sets is determined according to the flow rate, discharge characteristics, individual operation or flow storage in a power plant chain. Other usage goals besides the generation of electrical energy can be, for example, an improvement in flood protection or the containment of existing bed erosion.

In the case of low-pressure systems in particular, a suction pipe is often arranged in order to increase the efficiency.

- Key data

- Fall height: 15 m

- Use for: base load

- Turbine types : Kaplan turbine , bulb turbine , flow turbine , straflo turbine

- Types of construction: river power plants , diversion power plants , tidal power plants , wave power plants

Medium pressure power plants

Medium-pressure power plants are hydropower plants with a head between 25 m and 400 m, whereby the transition between low-pressure and medium-pressure systems as well as between medium-pressure and high-pressure systems can be described as flowing. This type of power plant is usually implemented in connection with low dams as storage power plants or in combination with higher weir systems on river power plants. It is characteristic of these two types of hydropower plants that the typical mean water throughput can only be achieved through storage management. Apart from the issues necessary for energy generation (compensation of different seasonal discharges, pumped storage, etc.), other goals (drinking water supply, flood protection, recreational effects, etc.) must also be taken into account.

- The following purposes can be distinguished

- Single-purpose systems

- Systems that cover a specified electricity demand

- Systems for equalizing the runoff of a flowing water

- Plants for peak power generation

- Multipurpose systems that primarily serve to generate energy, but also meet other requirements (e.g. flood protection, irrigation, drinking water supply).

- Multipurpose plants that are primarily used for purposes other than generating energy. In particular, this area includes systems for retaining navigable rivers.

- Characteristic of medium pressure systems in addition to the drop height threefold division of the nacelle

- Inlet with rake and turbine gate

- extended inlet hose or penstock

- Inlet spiral, water turbine, suction hose.

Dam power plants that are built in direct connection with earth dams or concrete dams are usually located close to the air side. The power house is located directly at the foot of the dam or wall and allows short and hydraulically favorable pressure pipelines. An arrangement further downstream, as well as in particularly cramped conditions in caverns (rather seldom in medium-pressure systems) is possible.

- Key data

- Fall height: 25–400 m

- Use for: base load, medium load

- Turbine types: Francis turbine , Kaplan turbine (rare)

- Types of construction: run-of- river power plants , storage power plants

High pressure power plants

High-pressure systems are used when the effective head is more than 250 m. In order to be able to realize such a large gradient, such systems are built in the middle and high mountains. To dam are dams , dams or a dam used so that large amounts of water can be stored for over a year, which are transported by means of pressure tunnel and pressure wells to the power plant, which is located mostly in the valley.

With this constantly available water volume, peak loads in electricity consumption can be balanced out and adapted to short-term, high demand. However, extremely large amounts of water then occur, which then have to be removed suddenly. From an ecological point of view, it is problematic to give them off easily to the underwater. This is why retention basins and intermediate storage tanks are used to delay and regulate the water discharge to the lower reaches.

Because of the high pressure, only Pelton and Francis turbines are used. The construction is very similar to the construction of a medium pressure system. The moated castle is an essential addition . It is used to reduce the pressure surge in the pipeline that occurs when the fittings in the pipeline are closed.

In contrast to low-pressure and medium-pressure power plants, the losses and fluctuations in head that occur in the supply lines and sockets due to the large total heads do not have any particular negative effects on the profitability of the system. In contrast, fluctuations in the relatively low flow rates cause problems. This fact can be countered by expanding the catchment area of the plant, for example by including neighboring reservoirs and by-pipes. As already mentioned above, a surge tank can be arranged to protect the sometimes very long pressure tunnels from the pressure surges that occur when the turbines are quickly closed.

Three types of systems can be distinguished according to their basic arrangement

- High-pressure systems with gravity sewer and inlet basin or gravity tunnel and pressure line

- In these systems, the weir systems are only low in height and are only used to collect water and not to increase pressure.

- High pressure systems with complete pressure line (tunnel or pipeline)

- This type of system is particularly suitable where a particularly large drop height can be achieved by shortening the flow path, for example by breaking through tunnels at river bends. In contrast to systems with gravity channels, the water level has a direct influence on energy generation due to the closed pressure connection (arrangement of a water lock necessary) to the storage tank. This context results in the need for the greatest possible storage height.

- Dam power plants

- Similar to the medium-pressure systems, the power house is built here in direct connection to the dam, but the heads are greater.

Key data

- Height of fall

- from 250 m

- Use for

- Peak load

- Turbine types

- Francis turbine , Pelton turbine

- Types

- Storage power plants , pumped storage power plants , underground power station

Examples:

- Naturns - maximum 180 MW, drop height over 1,150 meters. It is one of the power plants with the largest drop in the world.

- Campocologno power plant from 1907, at that time the world's highest head of 418 m, two Francis turbines

- Walchensee power plant from 1924. Four Francis turbines and two Pelton turbines produce a total of 124 MW.

- Fully power plant , commissioned in 1914 with a 1643 meter head, was the plant with the highest head in the world for 20 years

Further classification features

| Approach | Classification |

|---|---|

|

Utilization The amount of electricity generated ( normal energy capacity ) results in the utilization of a power plant in relation to the nominal output . |

Base load power plant : utilization:> 50% types: River power plant , tidal power station , power buoy , wave power plant medium load power plants : capacity: 30-50% types: River power plant threshold operation, storage power plant peak load power stations : capacity: <30% types: storage power station , pumped storage power station , hydroelectric power station |

| Installed capacity | Small hydropower plants (<1 MW) medium-sized hydropower plants (<100 MW) large hydropower plants (> 100 MW) |

| topography | Lower reaches (river power plant) low mountain range (run-of-river and storage power plant) high mountain range (storage power plant) |

| Operating mode | Island operation, interconnected operation |

Types of hydropower plants

- Run-of-river power plant

- In a run-of-river power plant , a river is dammed and electricity is generated with the water flowing away.

- Storage power plant

- In a storage power plant , the water is stored over a period of time (several hours to several months) in order to generate valuable peak energy when required.

- pumped storage power plant

- A pumped storage power plant is a storage power plant in which excess electricity is used to pump water from a low location into a reservoir at a higher level in order to generate peak electricity later when there is an increased demand for electricity. Pump storage power plants are currently the only energy systems that offer the possibility of storing electricity economically and to a significant extent with the help of potential energy (storage water).

- Cavern power plant

- A cavern power plant uses artificially created cavities as energy storage or as a location for power plant components, so it blends very inconspicuously into the landscape.

- Tidal power plant

- A tidal power plant uses the energy from the constant alternation of ebb and flow

- Wave power plant

- In wave power plants , in contrast to a tidal power plant, it is not the tidal range that is used, but the energy of the continuous ocean waves themselves.

- Flow power plant

- A flow power plant uses the kinetic energy of flowing waters without the need for a weir. Examples are power buoys and ship mills .

- Ocean current power plant

- An ocean current power plant uses the kinetic energy of ocean currents.

- Glacier power station

- A glacier power station uses the melt water from a glacial lake. It is piped to the power house for energy generation.

- Aqueduct power plant

- Special design of a run-of-river power plant to reduce pressure in main water pipes . One example is the Gaming water pipeline power plant as part of Vienna's second high spring water pipeline .

Economic importance

In 2016, hydropower plants with a cumulative capacity of around 1096 GW were installed worldwide, which produced around 4100 TWh of electrical energy. Thus, hydropower provided 16.6% of the world's electrical energy requirements and around 2/3 of the total electricity generated from renewable sources, which covered 24.5% of the world's electricity demand. Norway covers almost all of its electricity needs with hydropower, Brazil around 80%. In Austria , the hydropower quota is around 55% (36 TWh ) of total electricity production, in Switzerland it is around 60%. The share of gross electricity generation fluctuates between 3 and 4%, which means that hydropower has now dropped to fourth place behind wind energy, biomass and photovoltaics.

From the installed capacity of 4.7 GW in Germany and the energy generated annually in Germany (the standard energy capacity ) of 21,600 GWh, 4600 full load hours are calculated . Over the year there is a utilization rate of 52%.

The costs of investing in hydropower plants are very high and put a strain on the profitability of the plant. Therefore, the electricity produced in hydropower plants is initially more expensive than that in comparable steam power plants . The gratuitousness of nearly unlimited available water resources force makes itself felt only when the proceeds of the current sales have covered the construction costs. For this reason, hydropower plants are designed for a long service life in order to be able to use this effect for as long as possible.

Hydropower plants are preferably built in the middle and high mountains as well as on large rivers in order to increase profitability through large differences in altitude or through flow.

Ecological impact

The use of landscape when building hydropower plants, especially when building new reservoirs or barrages, can lead to conflicts in which the disadvantages and advantages, also in comparison to other solutions, have to be weighed up in each individual case.

advantages

The advantages of hydropower plants are direct and indirect:

- There are no CO 2 emissions from direct operation (compared to thermal power plants that use fossil fuels ); Hydropower is therefore one of the renewable forms of energy

- A hydropower plant can indirectly benefit from the dam and thus serve to protect against flooding , because the water can be retained and released in a targeted manner through targeted control of the dam

- the dam system has advantages for shipping in that a constant water depth can be achieved on sections of the river.

- The damming up of the water also offers advantages for agriculture , as this can prevent the areas from drying out.

- the energy yield is largely independent of weather and time. Compared to many other alternative forms of energy, the output fluctuates only very slowly over the course of a year

disadvantage

- Expropriations of the neighbors. In some cases even resettlement of the residents, for example through the construction of the “ Reschensee ” reservoir in South Tyrol or at the Drei-Schluchten-Damm

- ecological changes by reducing the amount of residual water , impairing nature and the landscape, destroying the natural river regime , fish deaths due to turbines , flotsam rakes and pumps

- Reservoir flushing and silting in the reservoir area of storage power plants and run-of-river power plants . With the regular implementation of this method an attempt is made to increase the volume of the storage space. There is also the production of climate-damaging digester gases in the storage space of storage power plants and run-of-river power plants through putrefaction of organic deposits as a result of silting and in the reservoir of storage power plants, provided that the affected area is not cleared before the damming (see Tucuruí reservoir )

- The surge operation in storage power stations can lead to a number of ecological effects in rivers. This is especially true in the mountains .

- Massive intervention in the groundwater balance through the construction of dams , sealing of the reservoir or through the construction of drains . This often leads to a rise in the groundwater level.

- Loss of habitat due to floating debris . The extraction of various materials, such as driftwood , by the computer systems of hydropower plants causes the loss of important underwater habitats . For many organisms such as fish , floating debris is an important habitat. This is lost when it is removed.

- Overflow and destruction of cultural assets such as the planned Ilısu dam in Turkey

history

5000 years ago there were water wheels in China and in the former Mesopotamia. At that time it was found out that the flow energy of water can be made useful to humans. Even later in ancient Rome and Greece, water wheels were used for grinding grain and for irrigation.

In 1767, the English civil engineer John Smeaton made the first cast iron waterwheel; this is considered to be the nucleus of today's energy generation using water. In 1878, the first hydroelectric power station was built in the north of England to power the electric lighting at the Cragside country estate . Around 1896, the world's first large power plant was built at Niagara Falls in the USA (details here ). In 1900 a hydroelectric power station was first mentioned in Seifersdorf near Dippoldiswalde, which the Johannes Konrad Theodor von Haßler company in Augsburg acquired. They converted an oil mill built in 1864 and the bone mill next to it.

At the beginning of the 20th century, interest in hydropower increased as there were more efficient and larger turbines and the demand for electricity grew steadily.

In 1911, a few kilometers west of Rjukan, Norsk Hydro built the Vemork hydroelectric power station ( 59 ° 52 ′ 16.1 ″ N , 8 ° 29 ′ 29 ″ E ) , at the time the largest in the world. In the following years further power plants (including the Såheim power plant) and industrial plants were built; In 1917 there were around 10,000 people in Rjukan and the surrounding area.

In 1941, the Grand Coulee Dam was completed in Washington State ; it has a nominal output of 6,495 MW.

After the construction of the Aswan Dam in Egypt (1960–1971) - it dammed the Nile - it became clear how much a dam can interfere with river ecology.

The Three Gorges Dam in China has a total of around 18,200 MW. Construction began in December 1993; all 26 turbines have been in operation since 2008.

See also list of the largest hydropower plants on earth ; by clicking on the triangle above the “Completion” column, the list is arranged chronologically.

There were many breaks in dams, e.g. B. earthquakes and / or construction defects (list here ). On May 17, 1943, Royal Air Force bombers dropped special bombs on the Möhne Reservoir (→ Möhne disaster ) and into the Edertalsperre . On August 8, 1975, a typhoon in China triggered a cascade rupture of 26 dams ( Banqiao Dam ).

The principle of a hydropower plant was and remains unchanged to this day: water is fed from a storage facility located higher up to the power plant via pressure pipes .

Remarkable

Occasionally one finds hydropower plants or elements of them as part of coats of arms.

- The coat of arms of North Korea contains a hydroelectric power station with an electricity pole .

- The Upper Austrian municipality of Roitham am Traunfall has a turbine with a step in its coat of arms as a symbol for the power plant and the Traunfall .

Hydropower plants with special characteristics

- Inga Dam - on the Congo, the Grand Inga expansion project, which was decided on in 2013 for 2015, is to become the largest power plant in the world with 40,000 MW

- Three Gorges Dam - on the Yangtze River in China, the world's largest power plant since 2008

- Itaipú - the second largest power plant in the world, on Parana between Paraguay and Brazil

- Goldisthal pumped storage plant - Germany's most powerful pumped storage power plant

- Lac des Dix - largest hydropower plant in Switzerland

- Malta power plants - the most powerful hydropower plant in Austria

- Roselend Dam - powerful hydropower plant in France

- Eisernes Tor 1 power plant - Europe 's largest hydropower plant

- Cahora Bassa - Africa 's largest power plant

- Grand-Coulee - largest power plant in the USA

- Hoover Dam - famous American power plant

- Walchensee power plant - classic storage power plant in Germany

- Bujagali - planned controversial power plant in Africa

- Southeast Anatolia Project - Turkey's largest regional development project , includes 22 dams and 19 hydropower plants and irrigation systems

literature

- Jürgen Giesecke, Stephan Heimerl, Emil Mosonyi, Hans-Joachim Gutt: Hydropower plants: planning, construction and operation. 5th, updated and expanded edition. Springer, Berlin 2009, ISBN 978-3-540-88988-5 .

- Christoph Jehle: Construction of hydropower plants: Practice-related planning principles. 5th, revised and expanded edition. VDE, Berlin / Offenbach 2011, ISBN 978-3-8007-3214-2 .

See also

- List of hydropower plants in Germany

- List of hydropower plants in Switzerland

- List of the largest hydroelectric plants in the world

- Federal Association of German Hydroelectric Power Plants (BDW)

- Hydropower screw

Web links

- Federal Association of German Hydropower Plants.

- Hydropower Switzerland. Swiss Water Management Association

- Hydropower. In: Student Lexicon. Learning aid

Individual evidence

- ↑ hydropower plants. Education Group

- ↑ a b Federal Office of Energy (Ed.): Statistics of the hydropower plants in Switzerland (WASTA) . Explanations of the central sheet. April 18, 2018, name and type of hydropower plant, p. 1-2 .

- ↑ Omar Ellabban, Haitham Abu-Rub, Frede Blaabjerg, Renewable energy resources: Current status, future prospects and their enabling technology. In: Renewable and Sustainable Energy Reviews . 39, 2014, 748-764, pp. 751f. doi: 10.1016 / j.rser.2014.07.113

- ↑ a b c d T. Strobl, F. Zunic: Wasserbau, Current Basics-New Developments . Springer-Verlag, Berlin / Heidelberg / New York 2006, ISBN 3-540-22300-2 .

- ↑ a b c d e f J. Giesecke, E. Mosonyi: Hydropower plants, planning, construction and operation . Springer-Verlag, Berlin / Heidelberg / New York 2005, ISBN 3-540-25505-2 .

- ↑ Global Status Report 2017 . REN21 website . Retrieved July 26, 2017.

- ↑ Time series on the development of renewable energies using data from the Renewable Energy Statistics working group (AGEE-Stat) in Germany. ( Memento of November 3, 2013 in the Internet Archive ) (PDF file; 0.813 MB). Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (BMU); Status: February 2013.

- ↑ Jeremy Black: The Making of Modern Britain: The Age of Empire to the New Millennium. The History Press, Chalford 2008, ISBN 978-0-7509-4755-8 , p. 76.

- ↑ The world's largest hydropower plant is to be built on the Congo. on: orf.at , May 19, 2013.