Turbine jet engine

A turbine jet engine (also Turbo-jet engine , turbo-jet engine , turbine jet engine , gas turbine aircraft engine , generally language and jet engine , jet engine , or simply nozzle ) is an aircraft engine , the central component of a gas turbine is and on the rebound effect of the air generated and exhaust gas flow ( recoil drive ). The word component "turbo" or "turbine" refers to the rotating internal parts of the engine (cf. Latin turbo , vortex, gyroscope ), d. H. on the turbine driven by the exiting exhaust gas jet ( gas expansion turbine ), which drives the turbo compressor to suck in and compress the combustion air.

Turbine jet engines are characterized by high performance and thrust, with comparatively small masses and sizes. They have been the most widely used engines since the middle of the 20th century. However, their advantages only have an effect above about 100 kilowatts of power; smaller aircraft therefore use piston or electric motors . The aircraft equipped with turbine jet engines are known as jet aircraft or jet aircraft.

Demarcation

The turbine jet engines belong together with the rocket engines , the ramjet engines and the pulse jet engines to the group of jet engines . With the exception of the rocket engine, they breathe air: they suck in air at the front, use the air inside them to burn fuel and emit the exhaust gases at the rear (through-flow engines). Missiles, on the other hand, are purely exhaust gas engines; Ramjet and pulse engines are not based on the gas turbine.

Overview of construction methods and types

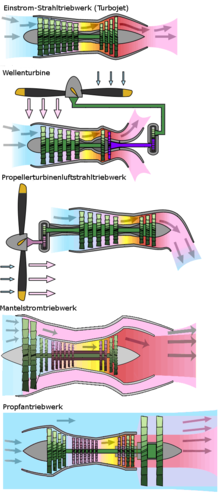

The gas turbine consists of a compressor that sucks in and compresses the air, a combustion chamber to burn the fuel and a subsequent turbine that uses part of the energy of the exhaust gases to drive the compressor. A turbo air jet engine also consists of at least one aerodynamic inlet in front of the gas turbine and a pressure-regulating nozzle behind it . This design is known as the turbojet engine and is the simplest and oldest design. The energy of the gases remaining after the turbine is converted into thrust. With further turbine stages, a further proportion of the gas energy can be converted into rotational power of the shaft in order to drive a (mostly upstream) fan, the diameter of which is usually significantly larger than that of the core engine. This accelerates an additional air flow around the core engine. This design is the most common and is known as a turbofan or turbofan. If so many turbine stages are installed that practically the entire energy of the combustion gases is converted into rotational energy, and so that no fan is driven, then one generally obtains a shaft power engine . A propeller can be attached to it ( turboprop engine ). In principle, you can also connect other machines or "consumers" to it, e.g. B. the rotor of a helicopter . A shaft power engine can also be used to drive ships (with a connected propeller ) or to drive a generator, for example in a gas power plant (stationary gas turbine). In fact, there are some gas turbines outside of aviation that were created as an adaptive design of an aircraft engine, these are known as aero-derivative .

Fighter jets often have an afterburner that injects and burns more fuel after the turbine to generate even more thrust.

functionality

Working principle

A jet engine in its current form is almost always a turbine air jet engine (in contrast to the ramjet engine or the deflagration jet engine, which is no longer in use today ). The turbine air jet engine sucks in the ambient air and compresses it in a compressor to increase the pressure . In the subsequent combustion chamber , the fuel (usually kerosene ) is injected and this mixture is then burned. The combustion increases the temperature and the flow rate, with the static pressure of the gas dropping slightly. The flow energy supplied to the gas is then partially converted into a rotary motion in the turbine following behind it , with the gas expanding even further (the turbine thus extracts energy). The turbine drives the compressor, the fan and other units such as generators or fuel and hydraulic pumps . The gas expands into the nozzle located behind the turbine and behind it to almost ambient pressure, whereby the flow speed increases further. Many jet engines working in the military and supersonic range have an afterburner behind the turbine to increase performance .

This process can be compared to that in a piston engine , but all four cycles - intake, compression, combustion and exhaust - take place simultaneously and continuously. The resulting force according to Newton's principle of action is the thrust (and possibly wave power). The advantage of jet propulsion over piston engine propulsion lies in its efficiency at high speeds (especially at supersonic speeds ) at great heights and in its high power density (both volume and mass power density), i.e. H. the engine is small and light in terms of the power it develops. Turboprops are more efficient at slower speeds .

A jet engine accelerates a relatively small mass of air very strongly, whereas a propeller accelerates a large air mass much less.

Depending on the type of engine, the turbine extracts more or less power from the gas energy (in the case of a shaft power engine, for example, almost completely, in contrast to the turbojet, only little gas energy is extracted). Many engines have a fan that transfers additional drive energy to the bypass flow .

Turbine air jet engines are more sensitive to foreign bodies than piston engine / propeller combinations (see also bird strikes ). Even an increased dust load can drastically shorten the maintenance intervals. On the other hand, sucking in water droplets is not a problem even in heavy rain.

The engine is started by bringing the compressor to a minimum speed. This can be done by blowing in air, electrically, by means of a separate turbine with a reduction gear ( air starter / cartridge starter ) or by a small combustion engine . In general, an electric starter is used for smaller engines today, all commercial engines on Airbus or Boeing aircraft have air starters. With the Boeing 787 , however, Boeing is using an electric starter for large engines ( GE Nx ). This is a further step towards the new “Electric Engine” concept.

After reaching the minimum speed, fuel is injected into the combustion chamber and ignited by one or more spark plugs . After the fuel has ignited and the engine speed continues to increase, the ignition is switched off; the combustion continues continuously. The speed control range between idling and full load is up to 95%, but usually only about 40%. As with all turbo machines, the power curve runs roughly logarithmically, at about 90% speed approx. 50% of the power is provided, at 100% speed 100% power is provided.

So-called bleed air is taken from the compressor and supplied to the pressure cabin .

Physical basics

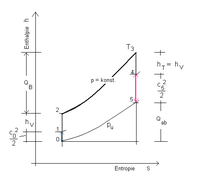

The (clockwise) thermodynamic cycle according to James Prescott Joule is best suited for the efficiency calculation of a jet engine . The decisive parameters in the Joule cycle are the pressure and temperature differences. Ideally, compression is therefore high, the turbine inlet temperature T 3 selected is as high as possible and the working gas is then expanded to the lowest possible temperature via the largest possible nozzle.

Thrust formula and propulsion efficiency

The thrust generated by the engines corresponds, in the case of a constant airspeed and a constant altitude, to the air resistance of the aircraft; the thrust must be greater than the drag if the airplane is to accelerate or climb.

The following simplified thrust formula applies under neglected fuel quantity and the assumption that the outlet pressure of the combustion gases corresponds to the ambient pressure:

- .

- Thrust in N

- Air mass flow in kg / s

- Gas exit speed in m / s

- Airspeed in m / s

However, the following applies to the propulsion efficiency

- .

For this reason, bypass engines with a high bypass flow ratio are used in civil aviation today, in which a large air mass flow leaves the engine relatively slowly, which results in better efficiency and, last but not least, a reduction in noise.

Engine types

Single-flow jet engine (turbojet)

The turbojet is the simplest form of a turbo jet engine. It consists of a gas turbine in which only the exhaust gas jet is used as a drive. The engine usually has only one shaft through which the turbine and compressor are connected. Due to the high exit speed of the drive medium, at lower speeds of the vehicle to be driven (mostly aircraft), it has a low level of efficiency by today's standards and generates a high noise level. The specific fuel consumption is particularly high at subsonic speeds, so that these engines are generally no longer used for economic and ecological reasons. In supersonic aircraft, turbojets usually also have an afterburner . These engines are quite compact and relatively easy to maintain. It was mainly used in the years after the Second World War until the mid- 1960s , in both civil and military aviation, whereby the turbojet was able to last longer in military use and is still used today in various types of aircraft ( e.g .: McDonnell F-4 Phantom , MiG-21)

Twin-flow jet engine (turbofan, bypass, bypass engine)

This type of engine is the predominant form of jet engine. Practically all jet aircraft today are equipped with turbofans.

Turbofan engines ( . English turbofan) have a (much) larger first blade stage (the so-called. Fan , English for blower.), Driven mostly by its own turbine stage - Fan and last turbine stage sitting on an inner, long low-pressure shaft , the remaining gas turbine on an outer, short high pressure wave . Alternatively, the slowly rotating fan can be coupled to the rapidly rotating high pressure shaft via a gear unit ("gear fan" design). Behind the fan, the air flow is divided into an inner air flow, which enters the actual gas turbine, and an outer air flow, which is drawn outside the core engine (the gas turbine). The ratio between these two air flows is called the bypass ratio .

The additional second shaft is necessary in order to be able to operate the fan at a significantly lower speed than the core engine. The fan has a significantly larger cross-section, its blades would develop too high centrifugal forces at high speeds; sometimes it should be avoided that the blade tips get into (local) supersonic speed. Sometimes the second shaft can be omitted if, instead, a reduction gear reduces the high speed of the high pressure shaft to a lower speed for the fan.

A turbofan offers several advantages over a turbojet:

- Better efficiency of the engine due to the lower average speed of the drive air jet and thus lower fuel consumption.

- Reduction of the noise level by dampening the hot, fast and therefore loud turbine gases by the surrounding cool and quieter gas flow of the first stage.

Today's fighters use turbofan engines with a relatively low bypass ratio of usually less than 1.5: 1. This causes only a relatively small reduction in noise compared to turbojet engines. In the civil sector and in transport machines, engines with a bypass ratio of up to about 9: 1 are used.

With conventional turbofan engines for commercial aircraft, the fan generates the majority of the propulsive force (often over 80%), the core engine and its exhaust jet significantly less.

Propeller turbine (turboprop)

A special form is the drive of an air screw (propeller) by a turbine. This type of propulsion is known as a turboprop. For this purpose, the gas turbine has two shafts and / or the propeller is driven by a reduction gear of the drive turbine. The first turboprop engines were built on the basis of turbojet engines in the late 1940s . Turboprop propulsion is the most economical aircraft propulsion system, particularly in short-haul traffic and at medium altitudes. The sound emission is dominated by the propeller and is low in propellers with low blade tip Mach numbers. The noise emission from the free jet is relatively low, since the speed of the exhaust gas jet is greatly reduced by the drive turbine. The exhaust gas flow contributes only to a relatively small extent to the propulsion, but is still included in the performance calculation for the shaft comparison performance . Compared to piston engines, the propeller turbine is characterized by high power density and long maintenance intervals . A comparable type of turbine is also used in helicopters .

To reduce the fuel consumption of aircraft, the use of propeller turbines is also being discussed at higher speeds. In order to limit the loss caused by the swirl generated by a propeller, only counter-rotating propellers are possible in this case, which are driven either via a planetary gear or by two counter-rotating low-pressure turbines. The noise emission of this type of propulsion is the subject of research and will be decisive for the commercial success of propeller drive at high flight Mach numbers .

Components

Divided according to functional assemblies, a turbo air jet engine consists of an inlet, compressor, combustion chamber, turbine and nozzle. The compressor and the turbine are usually mechanically connected to one another via one or more shafts. In free-wheeling turbines, some of which are used in turboprops, the turbine stages that drive the propeller are mechanically separated from the other components.

The core element of all turbojet engines is the gas turbine, also known as the gas generator or hot part. For use as an engine, an aerodynamic inlet, a nozzle and occasionally an afterburner are added. For stationary use of the gas turbines, for example in gas-fired power plants, a diffuser and another inlet are often attached instead of the nozzle - instead of thrust, shaft power should usually be provided, and the inlet must suck in instead of receiving "airstream".

If (for example, in the case of a shaft power engine) the turbine stages that generate the useful power output can be clearly demarcated from the upstream, remaining (core) engine (especially if the remaining engine (s) has (its) its own shaft (s)), then this becomes the same core engine Also known as a “hot gas generator” - from the point of view of the useful power turbine stages, its only function is to deliver a gas stream that flows quickly, is under high pressure and has a high temperature.

Air inlet

The air inlet ( inlet ) is usually open to the front. This supports its task as a diffuser, converting the kinetic energy of the flow into an increase in pressure and temperature, see enthalpy of stagnation . In addition, the speed of sound increases with temperature. Both together prevent the rapidly rotating compressor blades from being flowed through at supersonic speed (“ transonic ”).

At airspeeds in the subsonic range, the flow threads already deviate in the area in front of the opening, which is supported by the barrel-shaped curvature of the engine cowling - similar in cross section to the nose of a wing profile . Inside the air inlet, the cross-sectional area increases up to the compressor.

This is not the case with engines designed for this purpose in supersonic flight: There, the air in the narrowing inlet is compressed and slowed down by a series of oblique compression shocks (with regard to its speed relative to the engine). Engines for a wide range of supersonic speeds usually have an adjustable inlet geometry, see ramjet .

The air inlet is generally not supplied by the engine manufacturer, but is manufactured by the aircraft manufacturer as part of the " airframe " according to their specifications .

fan

Most modern civil jet engines are turbofan engines, also known as bypass engines or twin-flow turbine air jet engines (ZTL). In them there before the first compressor stage of the core engine ( core stream ) a fan (one as a blower designated blower ) - a stage engine with very large blades. The fan primarily generates the bypass flow , an air flow that is routed between the actual gas turbine and the outer engine cowling and blown out to the rear.

The fan has a significantly larger cross-section than the core engine, especially with a high bypass ratio of the engine; if the speed is too high, its blades would develop high centrifugal forces , which generates high mechanical loads. The inflowing air would also reach supersonic speed at the blade tips , which would reduce the efficiency.

This is why the fan is now usually on its own shaft, which is driven by the low-pressure turbine and runs at a significantly lower speed than the core engine. It is therefore also referred to as a two-shaft engine. A reduction gear can be arranged between the fan and the shaft driving it; then, however, the shaft is more likely to be assigned to the core engine and mostly also drives (low-pressure) compressor stages there.

Rolls-Royce RB211 and Trent even have three shafts. This more complex and expensive concept pays off, especially in the high thrust classes, as it offers the possibility of better adapting the speeds of the various components to their optimal operating condition and the engine can therefore run more smoothly over a larger thrust range.

The fan blades run in their optimal speed range, which improves the efficiency of the engine. This not only reduces consumption, but also noise emissions. The lower speed reduces the centrifugal forces and the blades of the fan can be dimensioned more easily.

Depending on whether the inner fan area (air flow into the core engine compressor) already makes a contribution to the compression, it is either regarded as a separate assembly (no contribution) or (partially) as the first compressor stage (of the core engine). The outer fan area (bypass), however, always causes the jacket flow to accelerate rather than compress it.

Compressor / Compressor

The foremost component of the core engine is the turbo compressor ("compressor"). It has the task of supplying kinetic energy to the inflowing air mass and converting it into pressure energy.

In early engines ( Heinkel HeS 3 , General Electric J33 , Rolls-Royce Derwent ) single-stage centrifugal compressors were used, which are now only used in smaller jet engines and shaft turbines. They are advantageous for small mass flows. Modern axial compressors have several compressor stages, each of which can consist of several impellers with rotor stages. The rotor stages are arranged one behind the other on a common drum, with modern engines also on up to three drums. The stator stages are permanently installed on the inside of the compressor housing. Since there are hardly any fixed structures apart from the stators in the area of the compressor (as well as in the turbine), the stator blades sometimes also serve as connecting struts to hold the shaft bearings and to (via the bearings) propulsion force from the shaft to the aircraft transferred to.

Older designs ( using the General Electric J79 as an example ) with many successive compressor stages achieved only moderate compression ratios. B. 17 stages with total compression of 12.5: 1 (pressure at the end of the compressor: ambient pressure), while newer developments achieve significantly higher compression with fewer stages (43.9: 1 with 14 stages in the GP 7000 for the Airbus A380 ). This is possible through improved profiles of the compressor blades, which offer very good flow properties even at supersonic speeds (resulting from the peripheral speed of the blades and the inflow speed). However, the pure flow velocity must not exceed the local speed of sound, as otherwise the effect of the diffuser-shaped channels would be reversed. It should be noted here that the local speed of sound also increases due to the increasing temperature in the compressor (see above up to 600 ° C).

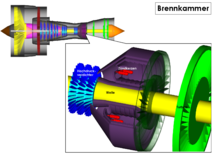

Combustion chamber

The high compression of the air causes a sharp rise in temperature (" compression heat "). The air heated in this way then flows into the combustion chamber, where it is supplied with fuel. This is ignited by spark plugs when the engine is started. The combustion then takes place continuously. The exothermic reaction of the oxygen - hydrocarbon mixture leads to a renewed increase in temperature and an expansion of the gas. This section of the engine is heavily loaded by temperatures of up to 2500 K (approx. 2200 ° C). Without cooling, even the high-quality materials (often nickel-based alloys ) would not be able to withstand these temperatures, as their strength is already greatly reduced from approx. 1100 ° C. Therefore, direct contact between the flame and the jacket is prevented. This happens through the so-called "secondary air", which does not get directly into the combustion area, but is led around the combustion chamber and only then, through holes in the sheet metal joints of the scale-like combustion chamber, gets into it and forms a film between the combustion gases and the combustion chamber wall lays. This is called film cooling.

Around 70 to 80% of the total air mass from the compressor is used as secondary air for cooling, only the rest is used in the combustion chamber as primary air for combustion. The mean axial flow speed of an engine is around 150 m / s. However, since the flame speed of the fuel used is relatively low (approx. 5 to 10 m / s), the flame stability must be ensured by a recirculation area in the flow of the primary zone. Today this is typically achieved by swirling the primary air when it enters the combustion chamber. As a result, hot combustion gases are repeatedly conveyed back to the fuel nozzle and thus ensure that the combustion continues. Furthermore, the air flow rate is reduced in the immediate vicinity (approx. 25 to 30 m / s) in order to prevent the flame from going out ( flame out) and to achieve optimal combustion. The design of the combustion chamber determines the pollutant content in the exhaust gas. A distinction is made between tubular combustion chambers, ring-tube combustion chambers and annular combustion chambers. The latter are the ones in use today.

turbine

The gases escaping to the rear then hit a turbine that drives the compressor via a shaft (possibly with an intermediate gear). Most single-flow engines use most of the kinetic energy for recoil. This means that only as much energy is transferred to the turbine as is needed to operate the compressor. Today two or three-stage turbines are mostly used.

Today's civil turbofan engines have several turbine stages (one stage, like the compressor, consists of a guide vane ring ( stator ) and an impeller ( rotor )) and is divided into high pressure turbine and low pressure turbine. Since the speeds of the fan and compressor usually differ significantly, these two systems run on two different shafts. The high-pressure turbine, which usually follows the combustion chamber , drives the compressor , while the low-pressure turbine, which is located after the high-pressure turbine, drives the fan; Occasionally, three-shaft concepts are also used. The sheath flow generates the main part of the thrust, so that the portion from the combustion recoil is negligible - the turbine uses the combustion energy, which it extracts from the gases coming from the combustion chamber, as completely as possible to drive the fan and compressor efficiently.

The blades of the turbine are usually cooled in a complex process (internal and / or film cooling) and consist of resistant superalloys based on titanium , nickel or tungsten-molybdenum . In addition, these substances are solidified in a preferred direction, so they are given a defined direction in their crystal lattice and thus allow the optimal material properties to become effective along the maximum load. The first stage of the high pressure turbine consists increasingly of single crystal blades. The part of the blades in the gas flow is protected against high temperatures and erosion with ceramic coatings. Because of the high load at speeds of over 10,000 / min. However, a breakage due to mechanical or thermal damage cannot always be ruled out. Therefore, the housings of turbines are designed accordingly.

jet

A nozzle is installed behind the turbine , which primarily regulates the pressure conditions in the turbine. The nozzle represents a resistance for propulsion, as does the turbine, for example. The common term “thrust nozzle” is therefore misleading.

Nevertheless, the exhaust gas flow accelerates due to the pressure gradient present at the turbine outlet (turbine outlet pressure - ambient pressure) when flowing through the nozzle; the pressure is finally completely converted into speed. As long as the pressure ratio of the turbine outlet pressure to the ambient pressure is less than a so-called critical value of approximately two, the pressure at the nozzle end is equal to the pressure in the surroundings. A convergent nozzle is then sufficient. But if the pressure ratio is greater than the critical ratio, then the jet accelerates to supersonic speed . Convergent- divergent nozzles, ie nozzles with a narrow throat, are then advantageous because the thrust then increases and the jet emerges with weaker compression shocks and is therefore significantly quieter.

Engines with an afterburner add more fuel to the gas flow before the nozzle, the combustion of which reduces the gas density due to the resulting increased temperature. The exit speed of the free jet is then greater with the same nozzle pressure ratio and thus also the thrust. Engines with an afterburner require an adjustable nozzle, as the narrowest nozzle cross-section has to be enlarged when the afterburner is in operation.

casing

Compressor and turbine require a solid housing, which on the one hand forms the outer contour of the flow channel and therefore has to withstand the pressures and temperatures occurring in these assemblies, and on the other hand withstands the centrifugal force of the torn off part in the event of a break in the blades , so that this does not Damage to airframe or injure people nearby. In order to prevent penetration of the engine housing, it is usually covered with mats made of, for. B. Aramid reinforced, which are also used for bullet-resistant vests , protective helmets or vehicle armor. The high temperatures in the turbine area prevent the use of aramid there.

The housing of the core engine also forms the inner contour of the bypass flow. A second housing around the fan and sheath flow forms the outer contour of the sheath flow and must, if necessary, shield the tear off of a fan blade.

Wave system

The turbine drives the fan and the compressor via one or more shafts. In addition, the waves transfer a large part of the propulsive power of the engine to the aircraft.

Since the compressor and turbine stages “close to the combustion chamber” tend to work well at high speeds, but “more distant” stages work better at slower speeds, mostly only simple or shaft power engines are so-called “single-shafts”; sometimes there is a reduction gear between the shaft and the very slow running fan.

“Two-shafts” often only drive the fan via the slow, inner shaft, or a few additional front compressor stages. The two waves run coaxially: the fast, short “high pressure wave” is hollow with a larger diameter, the slow, long “low pressure wave” connects the rearmost turbine stage with the fan located at the very front and runs through the inside of the high pressure wave.

In the area of the combustion chamber, the shafts are tube-like with a relatively small diameter; Between the rotor disks of the compressor or the turbine, the shaft usually consists of individual pieces (rings), which connect the rotor disks with a large diameter (“drum area”) and possibly at the same time form the inner contour of the core flow channel in their section.

With three waves, the innermost, longest, slowest wave only drives the fan. In order to avoid the third wave, the engine can instead be designed as a two-shaft shaft with a gearbox between the now faster low-pressure shaft and the now slower fan. (Faster low-pressure turbine = higher efficiency, slower fan = higher efficiency)

Outer engine cowling

The outer engine cowling is i. a. not assigned to the actual engine, but belongs to the airframe (earlier often referred to as the airframe). It does not have to transfer any drive forces from the engine to the airframe and is only used for aerodynamic air guidance or fairing.

parameter

A turbine jet engine has a variety of properties. Here is a list of the most important technical parameters in order to be able to make a quick comparison of different jet engines:

- thrust

- Specific fuel consumption (kg / (kNh); usual information in kg / kNh)

- Air flow (kg / s)

- Dimensions and dry weight

- Type of compressor and turbine (radial / axial / mixed form / special)

- Compression ratio of the compressor

- Type of combustion chambers

- for turbofan engines: number of fan stages and bypass ratio

- Number of low and high pressure compressor stages

- Number of low and high pressure turbine stages

- Number of waves

history

Beginnings

The propeller aircraft reached maximum speeds of around 700 km / h, which could be increased slightly by using adjustable propellers and various techniques to increase the performance of the engines. However, the goal of building aircraft that could fly faster than 800 km / h could not be achieved without developing new propulsion technology. Recoil drives , recognized early on as the best solution , could only be implemented when sufficient knowledge in the areas of aerodynamics , thermodynamics and metallurgy was available.

The first independently running gas turbine was developed by the Norwegian Aegidius Elling as early as 1903. Victor de Karavodine then developed the basics of the detonation jet engine in 1906. Georges Marconnet proposed this type of engine as a jet engine for aviation applications in 1909. In spite of everything, the turbine jet engine was the first design that, in addition to rockets, propelled an airplane.

A branch line to making a jet engine were hybrid designs where compression was done by an external energy source. In such a system as in Thermojet of Secondo Campini - an engine air jet engine - was the air by a blower through a conventional gasoline - aircraft engine was driven, mixed with the fuel and burned for generating thrust. There were three copies of this type, namely the Coanda-1910 by Henri Marie Coandă that much later developed Campini Caproni CC.2 and Japanese Tsu-11 engines, which are for the Ohka kamikaze airplanes by the end of the Second World War was planned . None of these drives was successful, the Campini-Caproni CC.2 turned out - although it already had an afterburner - to be slower in normal operation than a conventional aircraft with the same aircraft engine.

Engine development by Frank Whittle (radial engine)

The Englishman Frank Whittle submitted various proposals for the construction of jet engines as early as 1928, but could not win any partners.

The key to a usable jet propulsion system was the gas turbine , in which the energy to drive the compressor came from the turbine itself. Work on such an integrated design began in England in 1930. Whittle submitted corresponding patents for such a drive, which were recognized in 1932. Its engine had a single turbine stage that drove a centrifugal compressor .

In 1935 Rolf Dudley Williams founded Power Jets Ltd. and put Whittle as head of development. Whittle designed an engine, the Type U, the first test run of which took place on April 12, 1937 and showed good results. The Ministry for Coordination of Defense then provided money and the development of the aviation- grade W.1 began . The Gloster Aircraft company was commissioned to manufacture a suitable aircraft. This is how the Gloster E.28 / 39 test aircraft, flown for the first time on May 15, 1941, was created .

Engine development by Hans von Ohain (axial drive)

Independently of Whittle's work, Hans von Ohain began work on a similar engine in Germany in 1935 . Ohain turned to Ernst Heinkel , who immediately recognized the advantages of the new drive concept. Ohain and his master mechanic Max Hahn formed a new department within the Heinkel company.

The first drive - Heinkel HeS 1 - was already running in 1937. Unlike Whittle, Ohain initially used hydrogen as a fuel, to which he attributed his rapid successes. The following designs culminated in the Heinkel HeS 3 with 5.4 kN, which was built into the specially designed Heinkel He 178 . After an impressively short development period, this prototype flew in Rostock on August 27, 1939 as the world's first jet aircraft . As the first jet engine in series, the Jumo 004 was later produced from 1942, which was used in the twin- engine Messerschmitt Me 262 , among other things .

In the aviation industry, the axial drive finally prevailed.

Military development during the Second World War

The German turbojet engines were all equipped with an axial compressor and thus had a smaller diameter than the English types with a radial compressor. The main lines of development were the Junkers Jumo 004 , which was used with approx. 4750 units in the Messerschmitt Me 262 and the Arado Ar 234 . The later series production and only 750 pieces BMW 003 was used in the Heinkel He 162 and Arado Ar 234.

The priority of the German line of development was to increase speed; Fuel economy , weight and stability should be improved in the course of development. After 1941, it was necessary to achieve a new performance level of 800 kp (7.85 kN). Soon they no longer used regular gasoline , but instead diesel fuel , which was easier to obtain and has a higher boiling point . However, what was needed now was a modified ignition system.

By the end of the war, around 6,700 BMW-003 and Jumo 004 engines were produced, which continued to achieve improvements in performance, which later came to around 900 kp (8.83 kN). The Heinkel HeS 011 engine ran at 1300 kp (12.75 kN) at the end of the war and was the most powerful turbojet engine in the world. The first propeller turbines were also being developed at BMW and Heinkel.

The Rolls-Royce Welland engine was developed in Great Britain on the basis of the W.1 and delivered around 7.56 kN of thrust. This engine was initially used in the Gloster Meteor . A further performance-enhanced variant was the Rolls-Royce Derwent , which was also used in the Meteor. These two engines were used on the British side for combat aircraft in World War II. The entire development line of the British jet engine technology, which was successful in the post-war period, was based on this concept - centrifugal compressor, tubular combustion chamber and axial turbine - until 1950, the Rolls-Royce Avon with axial compressor was ready for series production.

The first operational American jet engine was the General Electric J31, also developed from the British W.1, with a radial compressor and an axial turbine, which was used in the Bell P-59 . The much more powerful Allison J33 was based on the de Havilland Goblin . It was used in the Lockheed P-80 and was de facto too late for use in World War II.

There were 13 jet engine projects in the Soviet Union before World War II. During the Second World War there were no significant developments in jet engines. Two of the 13 projects were completed shortly after the war, namely the first Soviet turbojet engine from Archip Mikhailovich Lyulka , and the first Soviet turbo-prop engine from Vladimir Uvarow .

Military advancement

The acquired knowledge formed the basis for further developments in the military alliances of the Warsaw Pact and in NATO . The aim of the developments was initially to increase performance without having to change the size. This quickly led to the development of the afterburner engines , which brought a significant increase in performance with a low additional weight. However, this has been achieved at the expense of fuel consumption. Typical representatives in the 1950s were the General Electric J79 in the west and the Tumanski R-11 in the east . Both engines enabled the advance into speed ranges up to Mach 2. The technical problems were largely solved. It was not until the advance towards Mach 3 in the mid-1960s that further development was required. The Tumanski R-31 was developed in the Soviet Union and the Pratt & Whitney J58 in the USA , which was operated with a special fuel (JP-7) due to the thermal load at these speeds.

With the end of the race for ever higher speeds and altitudes, the demands on the engines also changed. A high power density with low consumption, good acceleration and supersonic capability were now required. This led to the introduction of turbo fans in the military sector, such as the Pratt & Whitney F100 or the Tumanski R-33 . In order to be able to cover the broad speed range, sometimes very complex air inlets were also used in simple machines. Overall, the engines became more and more powerful in order to give the fighter pilots a good chance in dogfights without the possibility of using rocket armament.

Civil advancement

The first civil aircraft with jet propulsion was a Vickers Viking , which had been converted from propeller to jet propulsion on a trial basis with two Rolls-Royce-Nene engines. It completed its maiden flight on April 6, 1948 and proved that this type of propulsion system can also be used in civil aviation.

Initially, types used in the military were adapted and used in civil aviation. The first jet-powered commercial aircraft, the De Havilland “Comet” , was equipped with de Havilland Ghost engines, which were also used in the de Havilland DH.112 “Venom” fighter . The Comet was initially very well received by passengers due to its fast and vibration-free flight. Due to a puzzling series of accidents with Comet aircraft (which, however, had nothing to do with the new engines), there was considerable skepticism among passengers and airlines about jet aircraft in the mid- 1950s and a stagnation in the development of civil jet engines. Turboprop engines were preferred, and so this type of engine made good progress in its development. It was also almost completely problem-free. Engines in this development phase, such as the Rolls-Royce Dart , were largely derived from the first-generation turbojet engines.

The Soviet Union worked on both types of engines in parallel. The most powerful turbo-prop engine to date , the Kuznetsov NK-12 , actually developed for the Tupolev Tu-95 , was used shortly afterwards in the civilian Tupolev Tu-114 and proved that the power ranges of turbojet and turbo-prop engines were not far apart Advantages in speed with the turbojet and advantages in consumption with the turboprop.

The Mikulin AM-3 of the Tupolev Tu-104 presented in 1955 was also a derivative of a military engine like the Pratt & Whitney JT3 , which is actually a military Pratt & Whitney J57. In 1954 the first turbofan was presented, the Rolls-Royce Conway , which, like the Pratt & Whitney JT3D, was derived from a turbojet engine and only had a relatively low bypass ratio. The first jet engine specially developed for the civilian market was the Soviet Solovyov D-20 , presented in 1960 , which at the same time also opened up this type of propulsion for short distances, as it had acceptable consumption compared to the turbojets even at low speeds.

The turbofan quickly caught on. In the mid-1960s, practically no turbojets used for commercial purposes were sold any more. Smaller jet engines such as the General Electric CJ-610 for business jets , such as the Learjet , were in demand and brought onto the market in the early 1960s, as were the new turbofans with a high bypass ratio for the wide-body machines, such as the McDonnell Douglas DC- 10 or the Boeing 747 . Typical representatives of this time were the Rolls-Royce RB211 , the General Electric CF6 or the Pratt & Whitney JT9D . At this point in time, the Soviet Union had lost touch with turbo fans. The further development seemed to point towards supersonic traffic in the civil market as well, and so the Rolls-Royce Olympus 593, a civilian version of the military afterburner engine , was developed for the Concorde , and the Soviet Kuznetsov NK-144 , which was developed in Europe based on the military Kuznetsov NK-22 , for the Tupolev Tu-144 .

The first oil crisis and the associated explosive rise in energy costs forced a rethink. Since then, engine efficiency has been the focus of new developments. The CFM 56 is a representative of this time. With this engine, conversion programs for turbojet-powered aircraft such as the Douglas DC-8 or the Boeing 707 were offered and thus allowed the continued use of these sometimes quite young machines. At the same time, aircraft noise became a central issue. Here too, however, the modern engine developments helped.

Current civil development

The trend towards more economical, more efficient and more environmentally friendly engines continues. In general, the development of civil jet propulsion is aimed at higher compression, a higher combustion chamber temperature, a higher bypass ratio, higher reliability and longer service life of the engines.

Current engine types (such as the General Electric GE90 , the Pratt & Whitney PW4000 or the Rolls-Royce Trent 800 ) have a 45% lower specific fuel consumption than first-generation turbojets. The engine diameter of these units reaches up to 3.5 m with a thrust of over 500 kN (GE90-115B).

The current development is also in the direction that the next generation of jet engines could get a reduction gear for the fan ( geared turbofan ). The advantage is that the low-pressure turbine can be operated at a higher speed, which promises better efficiency. It is also possible to adjust the fan blades depending on the load and speed. Overall, the fan is approaching an encapsulated air screw ( Ducted Fan ). CRISP (counter-rotating integrated shrouded propfan) technology goes one step further, with two adjustable propellers rotating in opposite directions in a fan housing. These engines, such as the Kuznetsov NK-93 , already achieve a bypass ratio of 16.6 with acceptable external dimensions.

Multi-stage combustion chambers show more favorable behavior with NO x (up to 40% less nitrogen oxides), but are at the upper limit for the CO values and show increased consumption, especially when idling. The multi-stage combustion reduces the maximum temperature in the combustion chamber, which is mainly responsible for the formation of NO x .

Another way to improve efficiency is to use an exhaust gas heat exchanger with an intercooler. The exhaust gas temperature (e.g. through a lancet cooler in the exhaust gas jet) and the temperature of the air in front of the high-pressure compressor (through the intercooler) are reduced and the air in front of the combustion chamber is heated. Engines with this technology are also called recuperative engines .

In addition, blisk components are increasingly being used in compressors , in which the compressor or turbine blades and turbine disk are manufactured from one piece or, after individual production, are joined together using a friction welding process. This also results in advantages in terms of efficiency, since the components can be subjected to higher loads and have a lower rotating mass.

New technological approaches are partly countered by concerns of the operators, i.e. the airlines: They only want fully developed technologies and engines with e.g. B. use a small number of parts.

There is a constant conflict of goals between:

- Number of parts in an engine,

- Efficiency,

- Fuel consumption,

- Exhaust emissions,

- Noise emissions,

- Weight and

- Serviceability

With a development time of five to eight years, however, it is difficult to predict market requirements.

At the moment fuel costs are valued a little higher again. Different approaches are being pursued in the search for alternative fuels: One of the four engines on an Airbus A380 operated by Qatar Airways was converted to run on GTL fuels for test purposes . Boeing, in cooperation with Virgin Atlantic, also tested the use of coconut and babassu oil as biofuel on an engine of a 747-400 . For the use of renewable energies, engines with hydrogen as fuel are also being investigated. In terms of turbine technology, this appears to be problem-free, the weight of hydrogen is even lower than that of kerosene with the same energy content, but the hydrogen has to be carried at low temperature (−253 ° C) and requires a large volume because of its low density, even when liquefied. However, all of these investigations are still at a stage where the use of alternative fuels in regular everyday flight operations cannot be expected in the next few years.

In the short-haul range, however, slower and fuel-efficient aircraft with propeller turbines are still used, as they are cheaper under these operating conditions. The problem of high noise emissions is increasingly being reduced considerably by using propellers with more blades.

In the meantime, the first gliders are being equipped with a small fold-out jet engine in order to serve as a so-called " homecoming aid " when the thermals decline .

Engine market

The three most important manufacturers are GE Aviation ( General Electric ), Rolls-Royce , Pratt & Whitney ( United Technologies Corporation ), followed by Safran Aircraft Engines and MTU Aero Engines .

Overall, the supplier market is concentrated and global alliances are formed in the engine market. An example of this is the merger of General Electric and Pratt & Whitney to form a joint venture called the Engine Alliance for the development and construction of the GP7200 engine. In the military field, cooperation due to multinational projects is often forced by the associated national work share. For example, Industria de Turbo Propulsores (Spanish), MTU Aero Engines (German), Rolls-Royce (British) and Safran Aircraft Engines (French) founded EPI Europrop International GmbH specifically for the development of the A400M engine .

Accident risks

On aircraft carriers, catapults are used on a short runway; the landing gear is coupled to the catapult by one person just before take-off, while the engines are already being started up. At the air inlet, air is sucked in at such a high volume rate that a safety distance of 6 m is recommended all around. Repeatedly, people were sucked in who, contrary to regulations and good practice, were in front of an entrance. In particular, small aircraft, such as military fighters, have low-lying inlets. If a person comes too close here, they run the risk of being sucked into the engine by the air flow and killed by the rotating blades.

The exhaust jet behind an aircraft can be so strong and fast that a person can be knocked over and blown away, and on aircraft carriers it can also be blown overboard. The Princess Juliana International Airport on the Caribbean island of Saint Martin is known worldwide for the fact that landing, large aircraft only have to fly 10-20 m over the heads of onlookers on a beach, and they can be very close behind aircraft taking off. There were repeated serious injuries and also one death (2017).

literature

- The Jet engine Rolls-Royce, Derby 1969, 1971, 1973, 1986. ISBN 0-902121-04-9 (very well illustrated).

- The Jet engine Rolls-Royce, 65 Buckingham Gate, London SW1E 6AT, England, ISBN 0-902121-23-5 (very good and up-to-date illustrated).

- Klaus Hünecke: Aero engines. Your technology and function. Motorbuchverlag, Stuttgart 1978, ISBN 3-87943-407-7 .

- Willy JG Bräunling: aircraft engines. Basics, aero-thermodynamics, ideal and real cycle processes, thermal turbo machines, components, emissions and systems, 4th edition, Springer Vieweg Berlin Heidelberg 2015, ISBN 978-3-642-34538-8 , volumes I + II.

- Hans Rick: Gas turbines and aircraft propulsion. Basics, operating behavior and simulation. Publisher Springer Vieweg Heidelberg London New York 2013, ISBN 978-3-540-79445-5 .

- Reinhard Müller: Air jet engines, basics, characteristics, working behavior. Vieweg publishing house, Braunschweig 1997, ISBN 3-528-06648-2 .

- Ernst Götsch: Aircraft technology. Motorbuchverlag, Stuttgart 2003, ISBN 3-613-02006-8 .

- Klaus L. Schulte: Small gas turbines and their applications. KLS Publishing, Cologne 2012, 2nd edition, ISBN 978-3-942095-42-6 .

- Kral Schesky: aircraft engines. Rhombos Verlag, Berlin 2003, ISBN 3-930894-95-5 .

- Andreas Fecker: Jet engines: development - use - future. Motorbuch Verlag, Stuttgart 2013, ISBN 978-3-613-03516-4 .

- Hubert Grieb: Project planning for turbo jet engines. Book series technology of turbo aircraft engines. Birkhäuser Verlag, Basel, Boston, Berlin 2004.

- Alfred Urlaub: Aircraft engines - basics, systems, components. Springer, Berlin, 2nd edition, 1995.

Web links

- Top secret: Me 262 performance increase (historical document from 1945)

- Lecture at MIT by Professor ZS Spakovszky on thermodynamics and drive technology (English)

- Certification tests and conditions (PDF) European Aviation Safety Agency , March 12, 2015 (English).

- Rolls Royce - How To Build A Jumbo Jet Engine , in: DocumentaryTube.com, accessed on March 26, 2017 (video, 58:31 min., English, building a Rolls-Royce engine ).

Individual evidence

- ↑ Hans Rick: Gas turbines and aircraft propulsion. Basics, operating behavior and simulation . Springer Vieweg, Heidelberg / London / New York 2013, p. 3.

- ^ Alfred Urlaub: Aeroengines - Basics, Systems, Components. Springer, Berlin, 2nd edition, 1995, p. 52.

- ↑ Reinhard Müller: Air jet engines - basics, characteristics, working behavior. Vieweg, 1997, p. 19 f.

- ↑ Willy JG Bräunling: Aircraft Engines - Fundamentals, Aero-Thermodynamics, Circular Processes, Thermal Turbomachines, Component and Design Calculation. Springer, Berlin 2001, p. 117.

- ↑ Reinhard Müller: Air jet engines - basics, characteristics, working behavior. Vieweg, 1997, p. 1.

- ↑ Willy JG Bräunling: Aircraft Engines - Fundamentals, Aero-Thermodynamics, Circular Processes, Thermal Turbomachines, Component and Design Calculation. Springer, Berlin, 2001, pp. 22-30.

- ↑ Reinhard Müller: Air jet engines - basics, characteristics, working behavior. Vieweg, 1997, pp. 10 f., 295-297.

- ↑ Willy JG Bräunling: Aircraft Engines - Fundamentals, Aero-Thermodynamics, Circular Processes, Thermal Turbomachines, Component and Design Calculation. Springer, Berlin, 2001, p. 32 f., 36 f.

- ↑ Reinhard Müller: Air jet engines - basics, characteristics, working behavior. Vieweg, 1997, p. 11.

- ↑ Willy JG Bräunling: Aircraft Engines - Fundamentals, Aero-Thermodynamics, Circular Processes, Thermal Turbomachines, Component and Design Calculation. Springer, Berlin, 2001, pp. 41-46.

- ↑ Reinhard Müller: Air jet engines - basics, characteristics, working behavior. Vieweg, 1997, p. 73.

- ↑ Explanation of the compressors at NASA Glenn Research Center ( Memento from July 9, 2000 in the Internet Archive ) (English)

- ↑ Willy JG Bräunling: Aircraft Engines - Fundamentals, Aero-Thermodynamics, Circular Processes, Thermal Turbomachines, Component and Design Calculation. Springer, Berlin 2001, pp. 49-57.

- ↑ Reinhard Müller: Air jet engines - basics, characteristics, working behavior. Vieweg, 1997, pp. 101-103.

- ↑ Willy JG Bräunling: Aircraft Engines - Fundamentals, Aero-Thermodynamics, Circular Processes, Thermal Turbomachines, Component and Design Calculation. Springer, Berlin 2001, pp. 61-64.

- ↑ Reinhard Müller: Air jet engines - basics, characteristics, working behavior. Vieweg, 1997, pp. 133-136.

- ↑ Engmann, Klaus: Technology of the aircraft . 6th edition. Vogel, Würzburg 2013, ISBN 978-3-8343-3304-9 , pp. 606 ff .

- ↑ Willy JG Bräunling: Aircraft Engines - Fundamentals, Aero-Thermodynamics, Circular Processes, Thermal Turbomachines, Component and Design Calculation. Springer, Berlin 2001, pp. 69-73.

- ↑ Reinhard Müller: Air jet engines - basics, characteristics, working behavior. Vieweg, 1997, pp. 155-157.

- ↑ Willy JG Bräunling: Aircraft Engines - Fundamentals, Aero-Thermodynamics, Circular Processes, Thermal Turbomachines, Component and Design Calculation. Springer, Berlin 2001, pp. 82-87.

- ↑ Reinhard Müller: Air jet engines - basics, characteristics, working behavior. Vieweg, 1997, pp. 179-186.

- ↑ Willy JG Bräunling: Aircraft Engines - Fundamentals, Aero-Thermodynamics, Circular Processes, Thermal Turbomachines, Component and Design Calculation. Springer, Berlin 2001, pp. 80-82.

- ↑ Reinhard Müller: Air jet engines - basics, characteristics, working behavior. Vieweg, 1997, pp. 145 f.

- ↑ Reinhard Müller: Air jet engines - basics, characteristics, working behavior. Vieweg, 1997, p. 5 f.

- ↑ Reinhard Müller: Air jet engines - basics, characteristics, working behavior. Vieweg, 1997, p. 6 f.

- ↑ Willy JG Bräunling: Aircraft Engines - Fundamentals, Aero-Thermodynamics, Circular Processes, Thermal Turbomachines, Component and Design Calculation. Springer, Berlin 2001, p. 4 f.

- ↑ Reinhard Müller: Air jet engines - basics, characteristics, working behavior. Vieweg, 1997, p. 7 f.

- ↑ Willy JG Bräunling: Aircraft Engines - Fundamentals, Aero-Thermodynamics, Circular Processes, Thermal Turbomachines, Component and Design Calculation. Springer, Berlin 2001, p. 5 f.

- ↑ Reinhard Müller: Air jet engines - basics, characteristics, working behavior. Vieweg, 1997, p. 7 f.

- ^ Mark Harrison: Guns and Rubles: The Defense Industry in the Stalinist State . London 2008. p. 216.

- ↑ Willy JG Bräunling: Aircraft Engines - Fundamentals, Aero-Thermodynamics, Circular Processes, Thermal Turbomachines, Component and Design Calculation. Springer, Berlin 2001, p. 5 f.

- ↑ Harrison, Guns and Rubles, S. 216th

- ↑ CFM'S Advanced Double Annular Combustor Technology ( Memento April 26, 2009 in the Internet Archive ), cfm56.com, September 8, 2009

- ↑ Airbus tests first jet with alternative fuel , Spiegel online, September 9, 2009

- ^ Branson flies on biofuel , Spiegel online, September 9, 2009

- ^ About Engine Alliance ( Memento of August 3, 2004 in the Internet Archive ), Engine Alliance, September 10, 2009

- ↑ EPI Shareholders ( Memento of September 14, 2009 in the Internet Archive ), EPI Europrop International, September 10, 2009

-

↑ Danger of being sucked in: In a rare case, which is documented by a deck surveillance camera, a soldier who instructed an operator on a night mission on February 20, 1991 and therefore checked the coupling to the catapult, while the engine was at a standstill, approached with his head first of all largely sucked into the inlet panel and survived seriously injured - with a broken collarbone and torn eardrum. With a protective reflex he raised an arm while his helmet and life jacket were pulled or torn off by the airflow. While it wedged itself in the inlet for a split second, the two pieces of equipment that had been sucked in destroyed the blades and thus the engine, whose fuel supply then switched off.

YouTube: Sucked into the Intruder engine on the Theodor Roosevelt , Roy Hahmann, February 22, 2011, video (7:26) - incident from 1991.