CAD

CAD (from English computer-aided design [ kɔmˈpjuːtɐ ˈeɪdɪd dɪˈzaɪn ], in German computer-aided design ) denotes the support of constructive tasks by means of EDP for the manufacture of a product (e.g. car, airplane, building, clothing).

Which activities fall under the term CAD is treated differently in the literature. In a narrower sense, CAD is the computer-aided creation and modification of the geometric model. In a broader sense, it is understood to mean all computer-aided activities in a construction process, including geometric modeling, calculation, simulation and other information acquisition and information provision, from concept development to handover to manufacture or production ( work preparation ).

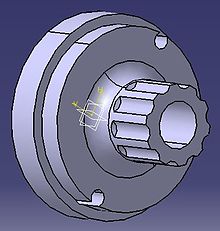

While CAD applications were initially used primarily for the production of manufacturing or manufacturing documents (marketing term: CAD as computer aided drafting / drafting ), with increasing computer power, CAD systems with complex expert systems and integrated FEM solutions for design and construction became more technical Solutions available, whereby the objects are treated as three-dimensional bodies from the start (three-dimensional CAD). Any technical drawings that may be required can be automatically produced from the virtual models of three-dimensional objects. A particular advantage of the 3D-CAD is the possibility of generating an image of the objects from any direction. The 3D printer enables the transition from the virtual model to the real object, which is also used in the hobby area. Together with the detectable material properties, extended CAD models are created to describe the physical properties (e.g. strength, elasticity) of the objects.

CAD is part of the so-called CAx technologies, which also include computer-aided manufacturing (CAM) or computer-aided quality assurance ( computer-aided quality , CAQ). CAD is used in almost all branches of technology: architecture , civil engineering , mechanical engineering , electrical engineering and all their disciplines and mutual combinations up to dental technology .

Use of CAD

CAD is used to generate digital construction models of various types, which provide the information from which the desired product can be manufactured (via technical drawing, NC transfer, etc.). The advantage of the computer-internal representation of the model consists in the rationalization of the construction process. The functionalities of the CAD aim, for example, at taking routine activities from the designer (for example through diverse use of the 3D or feature model or through the automatic hatching or dimensioning of technical drawings) or repetitive work processes, even in advanced phases of the design process and to be able to change it quickly (e.g. using parametrics) or to prevent information loss and errors. The generated CAD models can be used in other applications in a variety of ways (e.g. in simulation or calculation processes or as a digital mock-up ), and the results from these applications in turn change the CAD model, whereby the design is continuously optimized (and thus the product quality is increased) until the product is ready for production.

In the area of virtual product development , CAD supports as part of the CAx technologies. From a more technical point of view, especially the construction of process chains (CAD-CAM), the integrated modeling (e.g. using features ), the continuous flow of information based on a uniform database (digital master), the modeling of complete product models (virtual product) and from a more organizational point of view the faster provision of information ( e.g. via parametrics and 3D modeling), especially in the early phases of the development process (frontloading) through distributed and parallel working methods (simultaneous / concurrent engineering)

Another area of application is the modeling of manufacturing processes with CAD software. This enables an inexpensive and comparatively quick insight without the consumption of semi-finished products and machine occupancy for the manufacturing process used.

CAD modeling tools

CAD makes use of various tools that originate in different areas, such as in particular geometric modeling (which in turn relies on, for example, differential geometry , set theory , matrix algebra , graph theory ) or theoretical and applied computer science (e.g. software engineering , data structures ) . These tools can be combined and have different degrees of development depending on the CAD system and industry. In some cases, they are not an integral part of a CAD system, but can be installed as an (industry-specific) extension ( add-on, plug-in ) , whereby the database for the model remains the same.

The CAD systems are vector-oriented (opposite: grid orientation ), since all geometric objects can be traced back to lines and points and fully characterized.

2D modeling

In 2D modeling, geometric elements are drawn in one plane , mainly in the form of sections and views of components. The working method is similar to that of a manual drawing. You select the desired command (for example “draw line”), select the points required to model the object in the model environment and the program creates the desired object. In particular, lines ( straight lines , segments ), free-form curves (splines) , circles / arcs and points are used, to which further attributes can be assigned, such as line thickness, line type (for example dashed, dash-dotted, dotted) or color.

Furthermore, different transformations ( translation , scaling, rotation , mirroring, shearing, etc.) can be applied to these geometric objects or equidistants (offset curve) can be derived from them. They can also be trimmed or chamfered as closed lines ("polylines"), rounded off or filled with a color or a pattern. Texts, symbols or external image files (for example, scanned hand sketches that serve as templates) can also be inserted into the model environment.

2D modeling is mainly used to generate volumes that have been created from two-dimensional geometric elements through certain operations in the 3D area ( extrusion , sweeping , rotation, etc.). Furthermore, 2D modeling is used in those areas where a 2D model is sufficient to represent and explain a component, or where 3D modeling would be too expensive in relation to its usefulness or as a supplement to technical drawings that are based on a 3D -Model were generated. It is also used for drawing graphics of technical details of a component or for merely schematic representations of constructions (e.g. to explain concepts, considerations, instructions to production).

3D modeling

In 3D modeling, geometric objects are built up and stored in a three-dimensional form. On the one hand, they allow a realistic representation and better spatial representation of the body during and after the modeling; Spare parts catalogs, assembly and operating instructions) and technical-visual representations (collision analysis, exploded views, assembly, installation and assembly studies) from the system (partially) automate. Furthermore, the 3D description of an object is a prerequisite for many other applications in and outside the CAD system ( DMU , MKS , CFD , FEM , NC processing, virtual reality , rendering , 3D printing, etc.) and thus supports the construction of Process chains (especially CAD-CAM process chain) in virtual product development. However, this advantage of the wider range of applications of 3D models is offset by a higher construction effort, a correspondingly extensive knowledge and practice with the modeling tools.

As in the 2D area, the 3D models can be transformed (translation, scaling, rotation, etc.) or deformed (tapering, twisting, shearing, bulging) using various spatial operations.

In particular, the following computer-internal representation types occur in CAD:

- Edge models

- With the edge model (also wire -frame model ), an object is only represented by its edges, without volume or area information. This means that no geometric operations are possible that require a surface or a volume as a prerequisite (for example, penetrations need a volume for the automatic creation of the penetration edges). Therefore, pure edge models are only used in very specific cases, for example as a basis for generating surfaces or volumes or as auxiliary geometry. If you still want to have a 3D model as an edge model for display reasons, you can model a surface or volume model and just change the (graphic) display type.

- Surface models

- Surface models (surface models) are described by their surfaces, as a "shell" of a body (without information whether a point is inside or outside is located), and will always used where surfaces of a product, a complex formed shape (such as automobile bodies, aircraft fuselages , Consumer goods) which cannot be achieved by means of mere volume modeling and an intuitive modification of the surface is desired. In this case come analytically recordable ( Translation surfaces , control surfaces ) and analytically non-recordable areas (for example, B-spline, NURBS surfaces) is used, whereby as good as any shape in high geometric quality (class A surface) with respect to surface transition ( continuity ) , Area degree, number of area segments can be generated. A wide variety of generation options exist here. For example, surfaces can be created from edge curves, via a “movement” (for example lofting , sweeping ) from several levels or spatial curves or lines or by a network of curves (skinning) or arise as a “blending surface” of two surfaces. If necessary, the free-form surface can then be deformed by manipulating the support points using a "control network" stretched over it, which results from the degree of the surface and the number of support points. Analysis tools such as the colored representation of the Gaussian surface curvature , the display of combs of curvature or the representation by means of isophots help to check the continuity and smoothness of the surface . Afterwards there is the possibility to convert closed polysurfaces to a solid. In addition, surface models are used to match a polygon network (mesh) , which comes from a point cloud that a 3D measuring instrument (e.g. a tactile or optical system or CT method ) has created from a real object (in the course of reverse engineering )

- Solid models

-

In solid modeling , geometric objects are stored as solids (and not just as a shell, as in surface modeling) . It describes the geometry and, if a material density is specified, the mass of a body ("body model") clearly and completely, which is why the objects can be interpreted automatically by the system and the geometric consistency is ensured when the object is manipulated. Because of this, it has the highest degree of automation, which is why various operations, such as the determination of certain properties of the body such as moments of inertia , center of gravity , weight can be carried out automatically by the system. Volume modelers can use an extensive pool of modeling techniques. So can

- Volumes can be generated via 2D drawings using various transformations (e.g. extrusion, rotation).

- Volumes can be changed or globally deformed by means of Boolean operations or by cutting off using planes (“trimming”).

- Primitives (e.g. cuboids, spheres) can be manipulated using subdivision surface techniques.

- closed polysurfaces are converted to solids.

- Solid from system-internal (e.g. cuboid, sphere, cone), company-specific or standardized ( e.g. standard parts ) templates.

- In CAD there are mainly 2 ways in which solid bodies can be represented within the system:

- Constructive Solid Geometry

- In CSG modeling , a model is built from primitives (e.g. cuboids, cylinders) using set- theoretical operations and stored internally as a path and not as an end product. The advantage of the CSG modeling lies in the always consistent description, since the basic elements are already consistent and the history of development can be recognized. On the other hand, there is the disadvantage that elements such as edges and surfaces cannot be addressed directly and therefore cannot be manipulated.

- Boundary representation

- In the case of the B-rep , the volumes are determined hierarchically downwards from the boundary surfaces via the boundary edges, whereby the determination of the consistency (using Euler operators) must always be checked. The advantage of this volume presentation is that edges and surfaces can be addressed directly and thus manipulated. There is no history of origin.

- Since the advantages and disadvantages of the types of representation can be balanced against each other, “hybrid modelers” are predominantly used in CAD.

Direct modeling

With direct modeling (explicit modeling ), the geometric elements are changed directly using certain functions (scaling, moving, stretching, etc.). The geometric elements only contain fixed values (and no variables), which can only be changed by using functions. Here one selects the geometric element and the corresponding function which is to cause the desired change and changes the object either interactively with the mouse or by entering coordinates using the keyboard. Only the selected geometric elements are changed. In contrast to parametric modeling, there are no permanent dependencies between the geometric elements, which means that the geometry can be changed very intuitively and freely.

Due to this very free modeling option, direct modeling is used primarily in the early concept phase, where a quick and uncomplicated change of the geometry (without understanding the "genesis" of the parametric model or searching for the "correct" parameter that causes the desired change) is desirable. Furthermore, direct modeling can be helpful when importing (“foreign”), parameterized CAD models are changed, for example due to unclear or incomprehensible chronology or file format transfer errors. The model is adapted by marking and then dragging, pushing or similar of the desired surfaces or edges and the change is planted in the chronology tree (for example synchronous technology with NX or Live Shape with CATIA).

Parametric modeling

Parametric modeling means controlling the model using parameters . This means that - in contrast to direct modeling - the model is not addressed directly via its geometry, but via its parameters, which can change the model at any time. Depending on the application, the types of parameters differ roughly in geometry parameters (e.g. geometric dimensions, positions), physical parameters (e.g. materials, loads), topology parameters, process parameters (e.g. tolerances, data for heat treatments or NC travel paths). Because these parameters are stored internally in the system, relationships and dependencies can be established between them. This is restriction or constraints (constraints) implemented. The values entered or automatically linked from an external program (for example, a spreadsheet program) are "held" so that their dependencies and relationships can be calculated (using mathematical calculation methods) (constraint-based design) . These restrictions can be, for example, dimensions, algebraic relationships (length = 2 × width), logical operations (if length> 5 cm, then width = 8 cm, otherwise 12 cm) ("explicit restrictions") or horizontality, parallelism or Define congruence ("implicit restrictions") of geometric elements. This makes it possible to build an intelligent model that can be controlled with “ knowledge ” in the form of construction rules and only a few relevant values (“knowledge-based parametrics”).

In the two-dimensional area, parametric modeling is carried out using dimensions and restriction displays, which represent the parameters and are associated with the geometry (dimension-driven geometry) . The user first begins to roughly draw the geometry. The system tries (by means of rule-based procedures ) to recognize the design intent by applying implicit restrictions, which are indicated by a restriction display in the form of a pictogram . The user can then individually attach dimensions (with the values) to the geometry until the geometry is completely defined by parameters. The geometry can now only be changed via the parameters.

With parametric modeling, standard parts or even entire assemblies can be inserted from a library into the model environment, whereby the changeability of the underlying parameters is retained.

Due to the diverse relationships and dependencies in parametric modeling, a design methodology has been developed in which the user or designer must ensure that the parameters are clean and error-free and that the CAD models are structured logically in their geometric design.

Chronology-based modeling

This is where data structures are used that record the generation process of the model. This is shown to the user in a chronology tree (history tree) , which is continuously updated during the modeling and in which the individual modeling steps and the structure of the model can be viewed and changed if necessary in every phase of the construction process.

Certain dependencies (“parent-child relationships”) are shown in the chronology, which allow conclusions to be drawn about the way in which the model was created, such as the 2D drawing (“sketch”) on which an extrusion is based or the solid body on which a penetration is based. The respective elements are associated with one another, i.e. if the underlying element changes (e.g. the 2D drawing), the element based on it (e.g. the solid created from the extrusion) changes automatically.

Assembly modeling

In assembly modeling, separately saved CAD models (“individual parts”) are assembled into a holistic model (“assembly”) by referencing, whereby the file created in this way only contains references to the models and no geometry. Here, the individual parts can be related to each other (for example by means of distance information to areas or points). An assembly structure tree facilitates the overview.

The advantage of the assembly modeling is in particular the overall representation of the product with its individual parts and serves to check collisions and the assembly (packaging) or also visual inspections (e.g. "fly-through analysis") or kinematic analyzes.

Feature-based modeling

Feature-based modeling is the use of features for design purposes in the model environment. In CAD, features represent tools with which constructive aspects can be implemented as a unit in the model and manipulated (using parametrics). They have a higher information content that goes beyond the pure geometry (for example on technological, production-related or quality-related aspects) that other applications (for example CAM, FEM, CAPP) can access, which leads to a higher degree of automation of the processes and features to "information and integration objects ”throughout the product development process.

The features can be geometrical (form features) as well as / or semantic in nature, can combine a large number of product information and therefore show considerable flexibility and variety in the type and scope of their representation, which is why they are also used in all industries can. Examples of this are holes with additional tolerance information in mechanical engineering or multi-layer wall structures with all material parameters in architecture. However, this high flexibility also has the disadvantage of difficult transfer or conversion of features from one program to another. The categorization of features (feature taxonomy) , the transfer of individual features using certain "mapping techniques" (feature mapping) or the storage of the features from different constructional or production-related perspectives as an integrated model (multiple-view feature modeling) can help , but are currently still the subject of research.

Features can be created in 3 different ways. Due to the connection between features and parametrics, all features can be changed retrospectively via their parameters.

- Interactive feature recognition (Interactive feature recognition) : In this method, a feature model is generated by the user sequentially selects the feature to be defined as respective geometric elements interactively from a geometry model. He is either completely free to choose the geometric elements or is supported by the CAD system with a feature library with predefined features. The system then generates the desired feature and shows it in the chronology tree.

- Automatic feature recognition : In this process, a geometry model is translated into a feature model in that the CAD system automatically derives the corresponding features from the respective geometry using algorithms.

- Designing with features (Design by features) : This method features are generated from generic templates from a (native or company-specific) feature library. The user simply selects the desired feature, enters the parameter values and inserts it into the model environment. The created feature can then be combined with other features (for example, rounding) or changed using parameters. With this type of generation, the user is bound to the predefined, generic features so that it is possible to generate user-defined features in the CAD programs. The advantage of this method is that the designer can insert information right from the start that can be used for downstream processes, so that you can work with a continuously high level of information in the product development process. The disadvantage is a relatively large feature library with predefined features.

Macro technique

Macro technology is used in CAD to generate frequently used geometry or features with just a few inputs, the macro being resolved after the objects have been created. So it can no longer be determined afterwards whether an object was created via a macro. A distinction is made between two types:

- Shape macros : Gestalt macros are pre-defined stored (ie without stored variables) Primitives (For example, sinks, chairs in architecture or bolts in mechanical engineering) which are selected from a macro library and inserted as a whole in the model environment. If necessary, the geometric element generated in this way can then be broken down into its individual components again (using commands such as "explosion") and processed using direct or parametric modeling (using "post-parameterization").

- Command macros : Command macros are commands that are stored together and that are executed one after the other with just one command input and that generate the corresponding geometry in the model environment. They can either be entered individually by the user or the CAD system records the individual construction steps in the form of command sequences in a file ("log file", "program file"), which the user can access and change and optimize according to his wishes . The transition to variant programming is fluid.

Variant programming

With variant programming, the model is generated using native or higher programming languages such as C ++ , Python , Fortran or script languages such as Visual Basic for Applications or AutoLISP . The user writes (optionally with the support of utility programs ) in a text editor the desired modeling steps for generating the model. The CAD system reads and executes the procedures and creates the result in the model environment. If you want to change the model, the corresponding changes are made in the text (and not in the model environment) and the model is then recalculated and changed by the system. The model can, however, also be planted in the model environment as a discrete model (that is, equipped with fixed values) and modified by means of direct modeling or parametric modeling (by "post-parameterization"). Some systems also offer “ visual programming languages ” (for example Rhino 3D in combination with Grasshopper), with which geometric models, algorithmic and parameterized, can be created without programming knowledge.

General resources

CAD systems also have other capabilities that aid the user in modeling. An essential element of CAD systems is the viewport (viewport) , in which the model is depicted. It is thus possible to view, pan (pan) or rotate the model under different types of projection (for example axonometric, perspective) and from different distances (zoom) . The user can work in just one viewport or in several viewports at the same time. The object can be modeled in each of the individual viewing windows, but these can be controlled separately from one another with regard to the type of projection or graphic representation (for example a shaded representation in one and a wire-frame representation in another). It is also possible to display 3D sectional representations of the geometry or model details in a viewing frame while suppressing the geometry outside the viewing frame ( clipping ).

In order to be able to move and position geometric objects more easily in space, various aids are used, such as coordinate systems (for example Cartesian or polar coordinate systems on the one hand and world and working coordinate systems on the other), object snaps (with which, for example, end points, circle centers or tangent points of existing ones Geometries can be recognized, which can be locked), alignment with temporary “track lines” at certain angular distances or with a predefined grid.

There are also a few techniques for organizing the model. One of them is the layer technique ("layer technique"). Different objects, such as dimensions, constructive objects, texts, etc., can be categorized in order to keep the model clear on the one hand and to be able to show / hide the objects later if necessary (for example because they were only auxiliary geometries) or to give them the same attributes (such as the same line type or color) or to lock / unlock them so that they cannot be changed or selected during the modeling process, for example. Another type of organization is the grouping of objects in order to be able to carry out the same operations such as transformations for all objects in the group.

Use of the CAD model

Creation of manufacturing / manufacturing documents

An essential function of CAD is the creation of documents for the manufacture / manufacture of the product (for example technical drawings , parts lists , assembly plans ) and for documentation and archiving. For this purpose, the desired model views or sections (including projection and display type, scale, etc.) are positioned on the drawing sheet in a separate drawing sheet environment using view frames (which establish the connection to the model area).

In the case of parametric models, the derived 2D representation generated in the drawing area is unidirectionally or bidirectionally associatively linked to the underlying model, which means that, for example, changes in the model area automatically take effect in the drawing area. In addition, the system can automatically generate line widths, hatching and dimensions for parametric models. As a rule, however, even with these representations derived from 3D models, certain two-dimensional reworking is required in order to create a technical drawing that conforms to standards, such as a symbolic or abstract representation of certain parts that would or would overload the drawing under certain scales which did not necessarily have to be modeled three-dimensionally.

In the case of direct modeling, the drawing is already "drawn" in the model area (including the attributes). Dimensions, title blocks, texts and the like can be inserted either in the model space or in the drawing sheet environment.

The drawing produced in the computer can then be printed (up to paper format A3) or plotted (from paper format A2) or saved (e.g. as a PDF ).

Template for generative manufacturing processes

By means of certain procedures can be in the computer designed models directly from 3D CAD data produced in layers (without scheduling) as a whole and in one process step as a real (physical) objects to them eg. As a functional model, viewing model , prototype or even a primitive form to use. The surface of the 3D CAD model is converted into triangular surfaces ("triangulation") and saved as an STL file. After defining the layer thickness (slicing) according to which the physical model is built, it is produced and then, if necessary, subjected to post-processing or cleaning.

Visualizations

By means of certain visualizations, a better representation and idea of the product can be reproduced, they can be used for presentation or advertising purposes, or they can help avoid problems of understanding. For this purpose, in addition to visualization using concept graphics, a certain view of the 3D model can be displayed photo-realistically ( rendering ) . For this purpose, certain light (e.g. diffuse surface, point or directional light) and projection settings (e.g. projection type, distance from the object) are made or, if not already done in the model environment, material of the object (including texture, light permeability, mapping type) etc.) assigned. Using global lighting models that calculate the light with all these settings ( e.g. ray tracing ), depending on the hardware strength and resolution, a scene is gradually "rendered" at different speeds, which can then be saved as a raster graphic in a graphic format (e.g. BMP or JPG ).

Export to a different file format

Data formats

Due to the system, not all information can be transferred during data exchange. While pure drawing elements are no longer a problem today, the exchange of fonts, dimensions, hatching and complex structures is problematic because there are no standards for it. Even at the national level, there are very different specifications in different branches of industry, which makes standardization even more difficult.

Most programs use their own file format . This makes it difficult to exchange data between different CAD programs, which is why there are approaches to standardization . The DXF format from the world market leader Autodesk is usually used today as the data exchange format for drawings and for archiving documents.

A distinction must be made between CAD system-neutral and CAD system-specific data formats. Essential CAD system-neutral data formats are VDA-FS , IGES , SAT, IFC and STEP as well as the STL interface for special applications . The data formats in detail:

- The DXF format has largely established itself as the data exchange format for drawings; it is the only format supported by all CAD systems and has become the industry standard. Some of the CAD systems can only read and write DXF files as 2D data, and CAD system-specific features such as dimensions, hatching etc. are often lost or cannot be represented in the target system in an equivalent manner.

- The DWF (Design Web Format) was originally designed by Autodesk for data exchange over the Internet, supports all elements of DXF and is highly compressed. However, it could not prevail. DWF files could be displayed with plugins in browsers.

- VDA-FS - data exchange format for surfaces, developed by the Association of German Automobile Manufacturers (VDA), in the past a quasi-standard for this area;

- IGES - data exchange format for 2D drawings and 3D data (surfaces), common and possible in many CAD applications as an exchange format. Is replacing VDAFS more and more due to its better applicability, can be used more extensively and system-independent than DXF, but not as widespread and with the same weaknesses.

- STEP - a standardized file exchange format that is being developed internationally. STEP is considered to be the best interface for geometry data, whereby information such as colors, assembly structures, views, foils and model attributes can also be transferred. Can also be used to transfer drawing data (but not as powerful there as in the 3D area). STEP is not supported by all CAD systems.

- VRML 97- ISO / IEC 14772 - was originally developed as a 3D standard for the Internet . Most 3D modeling tools allow the import and export of VRML files, which is why the file format has also established itself as an exchange format for 3D models. For use as a CAD-CAD exchange format, it is rather unsuitable, but for transferring to animation and rendering software, for example.

- STL - models made up of triangular surfaces. Is mainly used for handover to rapid prototyping systems.

- IFC - an open standard developed for building technology. No drawings, but technical data and geometries are transferred. It was developed by buildingSMART eV (Industry Alliance for Interoperability eV until April 2010). It is a model-based approach for the optimization of planning, execution and management processes in the construction industry. The Industry Foundation Classes - IFC - are an open standard for building models. The IFC standard is registered under ISO 16739.

With the CAD system-neutral formats, only edge, surface and volume models can usually be transferred. The construction history is usually lost, so the transferred data is usually only partially suitable for further processing. CAD system-specific data formats enable the transfer of the complete CAD models, but they are only available for a few systems.

The so-called Gerber format and the newer Extended Gerber format are of great importance for the transfer of PCB data for the creation of exposure films for circuit boards (see photographic film ).

CAD in the individual industries

CAD programs are available for a wide variety of applications and industries. In contrast to office solutions, there are strong specializations in the CAD area. There are often national market leaders in areas such as electrical engineering, road construction, surveying, etc. See the list of CAD programs and the list of EDA applications .

Electronic circuits

Another area of application is the design of electronic circuits. Such programs are often under the terms eCAD and EDA summarized, particularly in applications in chip design , the circuit board design , the installation technology and microsystems technology .

Due to the special requirements, special areas with sometimes very different development methods have emerged. This applies particularly to the computer-based circuit design , i.e. the design automation (EDA) for analog or digital integrated circuits , such as ASICs . Related to this is the design of programmable devices such as gate arrays , GALs , FPGA and other types of programmable logic ( PLDs ) using, for example, VHDL and Abel . The automated layout creation for integrated circuits is often referred to as layout synthesis .

In the development of printed circuit boards first, the draft takes circuit in the form of a circuit diagram instead, followed by computer-aided layout design .

There are also numerous areas of application for software in classic installation technology , in particular in house installations for industry or public buildings or the design and implementation of PLC-based control systems.

In the field of microsystem technology , a particular challenge is to merge circuit data with mechanical product design data (CAD) and to produce microsystems directly with such data .

history

The term “Computer-Aided Design” came into being at the end of the 1950s in the course of the development of the APT programming system , which was used for computer-aided programming of NC machines.

At MIT showed Ivan Sutherland in 1963 with his sketchpad Development that it is possible to interactively to a computer-controlled radar screen (light pen, keyboard) simple sketches (English Sketch ) to create and modify.

In 1965, Lockheed (aircraft construction, USA) made the first attempts at a commercial CAD system for creating technical drawings (2D). This system, CADAM (Computer Augmented Design and Manufacturing) based on IBM - mainframes and special screens, and high costs, was later marketed by IBM and was, at least in aircraft, leading up to the 1980s. It is partially absorbed by CATIA . In addition, a PC-based version of CADAM with the name HELIX was developed and sold, but it has practically disappeared from the market.

At the University of Cambridge , England, the first research work began in the late 1960s to investigate whether it was possible to use 3D base bodies and use them to depict more complex assemblies (e.g. pipelines in chemical plant construction). This work resulted in the PDMS (Plant Design Management System) system, which is marketed today by Aveva, Cambridge, UK.

Also at the end of the 1960s, the French aircraft manufacturer Avions Marcel Dassault (now Dassault Aviation ) began to program a graphics program for creating drawings. This resulted in the CATIA program . The Mirage was the first aircraft to be developed with it. At that time, such a program still required the performance of a mainframe .

Around 1974, B-spline curves and surfaces were introduced for CAD.

The 1980s were dominated by the medium-sized data technology of the 32-bit super mini computers and workstations ( Digital Equipment Corporation , Prime Computer , Data General , Hewlett-Packard , Sun Microsystems , Apollo Computer , Norsk Data etc.) on which CAD Packages such as MEDUSA and CADDS from Computervision , for example , were running. Also ME10 and I-DEAS are to be mentioned.

After the first personal computers were installed in companies in the second half of the 1980s , CAD programs for them also came onto the market. During this time there were a variety of computer manufacturers and operating systems. AutoCAD was one of the first and most successful CAD systems to work on different operating systems. To enable data exchange between these systems, AutoDesk defined the DXF file format as a “neutral” export and import interface for its AutoCAD CAD system . In 1982 AutoCAD appeared for the DOS operating system . The construction procedure, however, remained almost the same as before with the drawing board. The advantage of 2D CAD were very clean drawings that could easily be changed again. It was also possible to draw different versions of a component more quickly.

In the 1980s, a CAD boom began due to falling workplace costs and improving software. The industry hoped that one system would be able to solve all of the pending drawing and construction tasks. However, this approach has failed. Today a special system with very powerful special functions is used for every special planning task. The step to the third dimension became affordable for smaller companies towards the end of the 1980s due to the increasing performance of the hardware . In this way, virtual bodies could be examined from all sides. It was also possible to simulate loads and to derive production programs for computer-controlled machine tools ( CNC ).

Since the beginning of the 2000s, there have been first attempts to make the drawings that were still essential until then disappear. In the more and more frequently available 3D models, all of the information required for production is incorporated into the dimensions, color and material. If the 3D model is expanded to include these additional, geometry-alien properties, it becomes a product model , supported for example by the STEP data format . The individual uniform volume objects become instances of different classes. This allows construction rules and references between individual objects (for example: window is anchored in the wall) to be implemented.

See also

Web links

- 3D model of a cylinder cover (PDF; 2 MB), interactive (Adobe Reader 8.1 or higher)

- CATIA SYSTEM picture gallery

- CAD in the Computer History Museum

- History of CAD (English)

Notes and individual references

- ^ Günter Spur, Frank-Lothar Krause: CAD technology. Text and workbook for computer support in construction, sacrifice and work planning. Hanser, Munich / Vienna 1984, ISBN 3-446-13897-8 , p. 16.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. Springer, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 1.

- ^ Gerhard Pahl: Constructing with 3D CAD systems. Basics, work technology, applications Springer, Berlin / Heidelberg 1990, ISBN 3-540-52234-4 , p. 5.

- ^ IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 24.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. Springer, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 6.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 46.

- ↑ Siegmar Haasis: Integrated CAD applications. Rationalization potential and future areas of application. Springer-Verlag, Berlin / Heidelberg 1995, ISBN 3-540-59145-1 , p. 2.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 434.

- ^ Gerhard Pahl: Constructing with 3D CAD systems. Basics, work technique, applications. Springer-Verlag, Berlin / Heidelberg, 1990, ISBN 3-540-52234-4 , p. 7.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 55.

- ↑ Siegmar Haasis: Integrated CAD applications. Rationalization potential and future areas of application. Springer-Verlag, Berlin / Heidelberg 1995, ISBN 3-540-59145-1 , p. 2.

- ^ Günter Spur, Frank-Lothar Krause: CAD technology. Teaching u. Workbook for computer support in construction and work planning. Hanser-Verlag, Munich / Vienna 1984, ISBN 3-446-13897-8 , p. 254.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 434.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 53.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 436.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 5.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 16.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 237.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 398.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , pp. 28,67.

- ↑ Siegmar Haasis: Integrated CAD applications. Rationalization potential and future areas of application. Springer-Verlag, Berlin / Heidelberg 1995, ISBN 3-540-59145-1 , p. 3.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 401.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 434.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 55.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 41.

- ↑ Siegmar Haasis: Integrated CAD applications. Rationalization potential and future areas of application. Springer-Verlag, Berlin / Heidelberg 1995, ISBN 3-540-59145-1 , p. 3.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 43.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 41ff.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 159.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 3.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 53.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 59.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 171.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 27.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 4.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 23.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 60.

- ↑ Process chain observation, FEM simulation and CAD. Retrieved October 15, 2018 .

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , pp. 131f.

- ^ Günter Spur, Frank-Lothar Krause: CAD technology. Teaching u. Workbook for computer support in construction and work planning. Hanser-Verlag, Munich / Vienna 1984, ISBN 3-446-13897-8 , p. 74.

- ^ Günter Spur, Frank-Lothar Krause: CAD technology. Teaching u. Workbook for computer support in construction and work planning. Hanser-Verlag, Munich / Vienna 1984, ISBN 3-446-13897-8 , p. 91.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 45.

- ↑ Hans-Joachim Bungartz, Michael Griebel, Christoph Zenger: Introduction to Computegraphik. Basics, geometric modeling, algorithms Vieweg-Verlag, Braunschweig Wiesbaden 1996, ISBN 3-528-06769-1 , p. 6f.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 170.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 437.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 161.

- ↑ Siegmar Haasis: Integrated CAD applications. Rationalization potential and future areas of application. Springer-Verlag, Berlin / Heidelberg 1995, ISBN 3-540-59145-1 , p. 50.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 170.

- ↑ Siegmar Haasis: Integrated CAD applications. Rationalization potential and future areas of application. Springer-Verlag, Berlin / Heidelberg 1995, ISBN 3-540-59145-1 , p. 50.

- ↑ Siegmar Haasis: Integrated CAD applications. Rationalization potential and future areas of application. Springer-Verlag, Berlin / Heidelberg 1995, ISBN 3-540-59145-1 , p. 51.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 171.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 442.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 159.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 442.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 175.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 442.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 176.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 443.

- ↑ José Encarnação, Wolfgang Straßer, Reinhard Klein: Graphische Datenverarbeitung 2. Modeling of complex objects and photo-realistic image generation. 4th edition. Oldenbourg-Verlag, Munich / Vienna 1997, ISBN 3-486-23469-2 , p. 19.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 177.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 47.

- ↑ Mustafa Celik: NX 9.0 for machine builders. Basics of technical product modeling. Springer Vieweg Verlag, Wiesbaden 2015, ISBN 978-3-658-07783-9 , p. 4.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , pp. 177f.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 47.

- ↑ José Encarnação, Wolfgang Straßer, Reinhard Klein: Graphische Datenverarbeitung 2. Modeling of complex objects and photo-realistic image generation. 4th edition. Oldenbourg-Verlag, Munich / Vienna 1997, ISBN 3-486-23469-2 , p. 19.

- ↑ See, for example, the applications Realize Shape at NX or Imagine & Shape at CATIA

- ^ Gerhard Pahl: Constructing with 3D CAD systems. Basics, work technique, applications. Springer-Verlag, Berlin / Heidelberg, 1990, ISBN 3-540-52234-4 , p. 52f.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 160.

- ↑ José Encarnação, Wolfgang Straßer, Reinhard Klein: Graphische Datenverarbeitung 2. Modeling of complex objects and photo-realistic image generation. 4th edition. Oldenbourg-Verlag, Munich / Vienna 1997, ISBN 3-486-23469-2 , p. 43.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 180.

- ↑ Martin Eigner, Daniil Roubanov, Radoslav Zafirov: Model-based virtual product development. Springer Vieweg Verlag, Berlin / Heidelberg 2014, ISBN 978-3-662-43815-2 , pp. 123f.

- ↑ Martin Eigner, Daniil Roubanov, Radoslav Zafirov: Model-based virtual product development. Springer Vieweg Verlag, Berlin / Heidelberg 2014, ISBN 978-3-662-43815-2 , p. 126.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , pp. 183f.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 51.

- ↑ Martin Eigner, Daniil Roubanov, Radoslav Zafirov: Model-based virtual product development. Springer Vieweg Verlag, Berlin / Heidelberg 2014, ISBN 978-3-662-43815-2 , p. 129.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , pp. 187ff.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 52.

- ↑ See the advantages of Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx für Ingenieure. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 186.

- ↑ See for example Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx für Ingenieure. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 189.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 193.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 55.

- ↑ Reiner Anderl, Ralf Mendgen: Modeling with constraints. Theoretical foundation and application. In: Computer-Aided Design. Vol. 28, No. 3, Elsevier Verlag, 1996, pp. 155-168.

- ↑ See for example Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , pp. 440f.

- ↑ Dieter Roller: CAD. Efficient adaptation and variant construction. Springer-Verlag, Berlin / Heidelberg 1995, ISBN 3-540-58779-9 , pp. 51-67.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 233.

- ↑ Dieter Roller: CAD. Efficient adaptation and variant construction. Springer-Verlag, Berlin / Heidelberg 1995, ISBN 3-540-58779-9 , p. 124.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , pp. 207ff.

- ↑ Dieter Roller: CAD. Efficient adaptation and variant construction. Springer-Verlag, Berlin / Heidelberg 1995, ISBN 3-540-58779-9 , p. 13.

- ↑ Dieter Roller: CAD. Efficient adaptation and variant construction. Springer-Verlag, Berlin / Heidelberg 1995, ISBN 3-540-58779-9 , p. 117.

- ^ Ronald List: CATIA V5 - Basic course for mechanical engineers. Component and assembly construction, drawing generation. 8th edition. Springer Vieweg Verlag, Berlin / Heidelberg 2017, ISBN 978-3-658-17332-6 , p. 125.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , pp. 458ff.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 172.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 50f.

- ↑ Ernst Beutner, Heiko Neukirchner, Gerhard Maas. In: IAV GmbH Ingenieurgesellschaft Auto und Verkehr (Ed.): Virtual product development. Vogel-Verlag, Würzburg 2013, ISBN 978-3-8343-3106-9 , p. 55.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 195.

- ^ Tamer MM Shahin: Feature-Based Design. An overview. In: Computer-Aided Design and Applications. Vol. 5, No. 5, 2008, pp. 639-653.

- ↑ Jami J. Shah, David Anderson, Yong Se Kim, Sanjay Joshi: A Discourse on Geometric Feature Recognition From CAD Models. In: Journal of Computing and Information Science in Engineering. Vol. 1, 2001, pp. 41-51.

- ↑ See comprehensively Jami J. Shah, Martti Mäntylä: Parametric and Feature-Based CAD / CAM. Concepts, Techniques, and Applications. John Wiley & Sons, New York / Chichester / Brisbane / Toronto / Singapore 1995, p. 122ff.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , pp. 179ff.

- ↑ Martin Eigner, Daniil Roubanov, Radoslav Zafirov: Model-based virtual product development. Springer Vieweg Verlag, Berlin / Heidelberg 2014, ISBN 978-3-662-43815-2 , p. 131.

- ↑ Ulrich Sendler: The PLM Compendium. Product Lifecycle Management Reference Book. Springer Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-87897-1 .

- ^ Gerhard Pahl: Constructing with 3D CAD systems. Basics, work technique, applications. Springer-Verlag, Berlin / Heidelberg, 1990, ISBN 3-540-52234-4 , pp. 186ff.

- ↑ Martin Eigner, Helmut Maier: Entry into CAD. Textbook for CAD users. Hanser Verlag, Munich / Vienna 1985, ISBN 3-446-14118-9 , pp. 200ff.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 192f.

- ↑ Dieter Roller: CAD. Efficient adaptation and variant construction. Springer-Verlag, Berlin / Heidelberg 1995, ISBN 3-540-58779-9 , pp. 73ff.

- ^ André Borrmann, Markus König, Christian Koch, Jakob Beetz (eds.): Building Information Modeling. Technological basics and industrial practice. Springer Vieweg Verlag, Wiesbaden 2015, ISBN 978-3-540-36038-4 , p. 195.

- ↑ José Encarnação, Wolfgang Straßer, Reinhard Klein: Graphic data processing 1. Device technology, programming and application of graphic systems. 4th edition. Oldenbourg Verlag, Munich / Vienna 1996, ISBN 3-486-23223-1 , p. 224ff.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 236ff.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , pp. 73f.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , pp. 75ff.

- ↑ Andreas Kalweit, Christof Paul, Sascha Peters, Reiner Wallbaum (eds.): Handbook for Technical Product Design. Material and manufacturing. Decision-making bases for designers and engineers. 2nd Edition. Springer Verlag, Berlin / Heidelberg 2012, ISBN 978-3-642-02641-6 , p. 463ff.

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Hanser-Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 410.

- ^ Sandor Vajna, Christian Weber, Helmut Bley, Klaus Zeman: CAx for engineers. A practical introduction. 2nd Edition. Springer-Verlag, Berlin / Heidelberg 2009, ISBN 978-3-540-36038-4 , p. 241f.

- ↑ Thomas Jedrzejas: Development of historical urban 3D scenarios for use under Google Earth, based on data from terrestrial laser scanning, photogrammetry and archive information. Diploma thesis at the HS Bochum. July 2008, 3.1.2.1., 3rd paragraph. ( hochschule-bochum.de ( memento from December 25, 2012 in the Internet Archive ), PDF; 7.80 MB)

- ↑ DXF internal

- ↑ autodesk.de ( Memento from December 18, 2012 in the Internet Archive )

- ^ Günter Spur, Frank-Lothar Krause: The virtual product. Management of the CAD technology. Carl Hanser Verlag, Munich / Vienna 1997, ISBN 3-446-19176-3 , p. 42.

- ^ Michael E. Mortenson: Geometric Modeling. 3. Edition. Industrial Press, New York 2006, p. 10.