clockwork

The entire mechanism inside a clock is called a clockwork . It ensures that the time is displayed correctly.

Other devices can also contain a clockwork, such as measuring recorders , short-term time switches , time fuses , exposure time switches , music boxes and others.

There are movements in purely mechanical and electromechanical form with more or fewer gears . Electronic clocks have no wheels and only a minimum of moving mechanical parts. Digital watches with an electro-optical numeric display (except for oscillating crystals ) no longer have any moving parts.

In the elementary watches as the hourglass , the sundial and the water clock , the term movement is not applied.

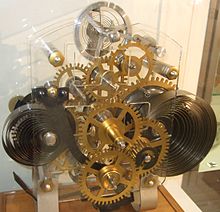

A purely mechanical clockwork is most clearly visible on a large historical clock . It ranges from the energy storage device (mostly a weight drive) to several gear transmission stages ( gear train ) and an escapement to the gear regulator (mostly a pendulum ). A branch leads from the gear transmission to the pointers located outside. With the exception of the hands, this so-called pointer mechanism is also located inside a watch, but is often - like the winding weights - not counted as part of the movement.

Mechanical clockworks

Mechanical clockworks are multi-stage gears whose wheels rotate at a constant angular speed . They get their drive energy from a mechanical energy store. The stored potential energy is released in a controlled manner and converted into a rotary movement of the display device (mostly pointer axes).

Components of the mechanical clockwork

Every mechanical clockwork consists of one or more gear trains. The main gear mechanism is called a mechanism that every clock mechanism must have. The clockwork can also have one or more additional wheelworks , but these are controlled by the movement .

- A walking frame consists of:

- Drive device with associated elevator ( spring mechanism , weight train)

- Display device with pointer or jumping numbers ( pointer mechanism )

- inhibition

- Oscillation system (rate control) by means of a balance wheel , recirculating ball , pendulum or rotary pendulum

- Additional gear trains (selection):

- Percussion

- Spielwerk

- Alarm clockwork

- Time switch

drive

Mechanical movements are driven as follows:

- with spring mechanism : winding by hand (with key or winding crown ), electromagnet or electric motor , in automatic watches with unbalance and movements of the wearer

- With weights: Winding by pulling on their chains, with ropes with a crank, with large clocks with an electric motor

To avoid overwinding, spring mechanisms often have a Maltese locking mechanism that limits the number of rotations. In contrast to the rest of the spring, which is made of hardened steel , the spring's start and end loops are soft-annealed - although breaking is normally only possible through the application of extreme force, older spring material tended to break in the area of the inner, smaller bending radius of the spring Transition to the hardened spring.

Automatic wristwatches have a spring bridle that lets the mainspring slip through when fully wound.

An atmospheric clock draws the winding energy for its spring mechanism from fluctuations in temperature and air pressure.

display

Simple movements only have an hour and a minute hand above a dial . In more elaborate movements, functions such as second hand , date display , day of the week , alarm functions , stop watch , moon phase, etc. are added. There are also other types of display, such as only one (hour) hand in the case of the single-hand watch or the display using rotating disks under a cutout in the case of the disk watch . Additional indications are achieved through the use of kadratures with additional complications .

Percussion

The striking mechanism is an independent mechanism in a wheel clock, with the help of which the time is also given acoustically. The acoustic signal is generated by means of a round gong, rod gong, church bell , whistle , gong or music box mechanism.

Alarm clockwork

The alarm function is set with another pointer (alarm pointer). In purely mechanical alarm mechanisms, the alarm pointer usually sits on a control disk (alarm dial). The hour tube has an additional elevation (alarm trigger cam) and is pressed forward against the control disk by a flat spring (alarm trigger spring). When the wake-up time is reached, the elevation of the hour tube falls into the associated depression of the control disc and the hour hand jumps visibly closer to the minute hand. This movement is caused by the alarm trigger spring. The loose end of the alarm trigger spring usually moves further than the hour hand itself due to the leverage and releases the alarm mechanism or triggers an electrical contact via this movement. Via a bevel on the alarm trigger cam or the recess of the alarm setting wheel, the hour tube is moved back into the normal position against the force of the flat spring as the movement of the hour hand progresses. With simple alarm clocks, this typically happens in 30 to 90 minutes. Only when the loose end of the alarm release spring blocks the alarm mechanism again, the alarm mechanism can be rewound without running down again immediately. Due to the fact that the hour hand rotates 360 ° in 12 hours, the alarm usually triggers twice in 24 hours. There are also seldom alarm clocks with a 24-hour alarm dial that only wake up once every 24 hours. With digital alarm clocks, the distinction is common after 24 hours.

In mechanical alarm mechanisms, the alarm mechanism spring with the associated spring wheel often acts on an alarm clock wheel. The alarm clock wheel causes the alarm clock anchor to move, which strikes a hammer against a bell or the housing of the alarm clock via a lever arm. The combination of alarm wheel and alarm armature often looks somewhat similar to the escape wheel and armature of a mechanical movement with pendulums, but has completely different optimization criteria. When the alarm mechanism spring runs out, it takes up more and more space in the clockwork and thus hinders the movement of the retaining lever, which often forms a single component with alarm clock anchor and hammer. If the movement of the alarm armature is impaired to a certain extent, the further process of the alarm mechanism is prevented and the alarm stops abruptly. This avoids a slow wake-up call.

Clocks with an alarm function usually have a second energy store (usually spring mechanism) for the alarm function. Special case is z. B. the use of a spring balancer both for the movement and for the alarm. This design is easily recognizable in that there is only one single elevator option, which simultaneously winds the movement and alarm mechanism.

Mechanical movements according to size

Watch movements (wrist and pocket watch movements)

Wrist watch movements are also called calibers . Except for the “big ones” in the industry (such as Montblanc , A. Lange & Söhne , Audemars Piguet , Blancpain , Breguet , Ebel , Glashütte Original , IWC , Omega SA , Patek Philippe , Rolex , Seiko , Zenith ) and a few small manufacturers (such as D. Dornblüth & Sohn, Lang & Heyne, Nomos Glashütte ), most watch manufacturers today use more or less processed foreign base calibers. These are manufactured and installed in millions, for example by ETA ( Swatch Group ) ( ETA2824, ETA2894, Valjoux7750 ) or Ronda (e.g. in Baume & Mercier , Breitling SA , Longines , Panerai, Sinn ). Many inexpensive mechanical watches also contain basic calibres from the manufacturers Miyota ( Citizen ) and Seiko .

In small, high-quality watch movements, precious stones are used as bearing stones for moving parts, as there is less friction between steel and stone than between two steel components. This reduces the wear and tear and increases the accuracy through even power transmission. Synthetic stones such as rubies are used today .

Miniature movement of a ladies' wristwatch

17 mm × 17 mm, lollipopAutomatic movement, caliber 2824-2, ETA SA

Wrist watch movement, chronograph, Tianjin Seagull

Clockwork of a carriage clock Friedberg local history museum

Large clockworks (living room and industrial clockworks)

In contrast to a small portable watch, the term “ large clock ” is a general term for all larger, stationary watches. Movements for such watches, depending on their function, can be quite different.

Clockwork of an astronomical grandfather clock ( Hüsgen clock in the Goethe House )

Weight-driven historical clockwork for roast spatulas at Chenonceau Castle

Clockwork of a parking meter from the Kienzle company

Movement of a clock

Tower clockworks

Movements for large public clocks on buildings such as town hall, schools, castles, churches or monasteries.

Movement for Nebelhorn

Tower clock mechanism with hourly reference mechanism

Astronomical clockwork Prague town hall clock

Clockwork in the clock tower of the Palace of Westminster in London

Electromechanical clockwork

Mechanical movements with electric winding

Among other things, electric motors or electromagnets were used for the automated winding of conventional clockworks, u. a. also for tower clocks .

Motor lift ( Diehl company )

Motor lift, tower clock movement JF Weule , 1877, Lüdenscheid church

Tower clock Villa Haas electromechanical elevator (Perrot)

Synchronous and stepper motor works

The clock generator of synchronous clocks is a synchronous motor that drives the display elements, numbered wheels or falling plates via a gear. The daughter clocks in clock systems work in a similar way, receiving impulses from a mother clock and thus driving a stepper motor or synchronizing their motor-driven hands. Energy- saving motors such as the Lavet stepper motor are used in battery-operated watches .

Synchronous clocks are also included in electromechanical timers designed as adapter plugs.

Synchronous clockwork with drop leaf display

Daily time switch with 10-stone balance movement and motorized winding for mains operation; Power reserve 50 h, 1987, VEB Uhrenwerke Ruhla

Lavet stepper motor as a movement of a daughter watch, T&N

Electronic clockwork

In electronic clockworks, a partial function or the entire function of the clockwork is implemented electronically.

While with a magnetic or motorized winding the power transmission in the clockwork, as in the conventional mechanical clock, is transferred from the energy storage via the pointer mechanism to the escapement (oscillation system) and thus very high demands are placed on the accuracy and strength of the gears, with direct electronic drive of the oscillation system this is the case Energy flow reversed. This made it possible to further simplify the gear train and save energy.

Different oscillation systems of electronic clocks

- mechanical vibrations

- an inductively excited tuning fork (frequencies between 300 and 720 Hertz ) for the tuning fork watch .

- a pendulum or a balance wheel, whereby these carry permanent magnets and are kept in motion electromagnetically by an electronic circuit, the blocking oscillator (the pendulum or balance wheel is the time base and itself causes the isochronous drive of the clockwork); before the introduction of the quartz clock, there were clocks that worked according to the electrodynamic principle, e.g. B. the ATO-MAT from Junghans

- an electrically excited quartz crystal . The oscillations of a specially designed clock crystal with a frequency of 32.768 kHz are passed through frequency dividers and then either counted or used directly to drive a Lavet stepper motor that moves a pointer ( dial display ). To display numbers , to display pointers on a liquid crystal display or to generate a clock signal , the vibrations are counted and processed with the aid of software . Most wrist and living room clocks today use oscillating crystals as clocks.

- Time signals

- Radio clocks receive electromagnetic waves from time signal transmitters ( DCF77 ).

- The time displays on cell phones or computers are synchronized with time signals transmitted via the cellular network or the Internet .

- Quantum transitions of an electronically excited substance

- Atomic clocks use energy differences in electron levels (for example the cesium atomic clock)

- Oscillation states of molecules (usually also called atomic clocks)

Tuning fork system, Bulova Accutron , Spaceview model 1971

First quartz wrist watch movement cal.35A, No. 00234 Seiko 1969, German watch museum

Radio controlled clockwork with alarm clock, ferrite antenna (bottom left) and battery compartment (top left)

Battery movements

Battery movements can be electromechanical as well as electronic. Today almost only quartz movements are used. The accuracy can be improved by integrating a radio clock , which is continuously synchronized with the signals from time signal transmitters .

Before it was possible to manufacture quartz movements inexpensively, there were processes such as blocking oscillators , which achieved acceptable running times and accuracy in a compact design and with battery operation.

Battery movements combined various advantages.

- The automated elevator, so that the spring mechanism no longer z. B. had to hold for a week, but possibly only a few minutes.

- This made it possible to simplify the movements and thus reduce the cost of the mechanical part.

- The battery change was less necessary than manually winding it.

- In many types of movement which is accuracy not completely decoupled from the drive force, therefore, reduced by the frequent electric lift and the clock error .

Battery movements thus offered comparatively good accuracy and comfort at low cost.

literature

- Literature by and about clockwork in the catalog of the German National Library

- W. Trylinski: clockwork gears. Precision engineering, July 1954

- Friedrich Assmus: Technical drives including clocks. Springer-Verlag Berlin, Göttingen, Heidelberg 1958

- Siegfried Hildebrand : Precision mechanical components. Hanser, Munich 1983; ISBN 3-446-13789-0

- Karl Hermann Ströde: Who uses which works and why. In: Uhren Magazin. Issue 7/8, 1994, pp. 42-46.

- Charles-André Reymondin: Theory of watchmaking. Association of Technical Schools, CADEV, Lausanne 2001; ISBN 2-940025-11-8

- Klaus Menny: The clock and its mechanics. Callwey, Munich 1994; ISBN 3-7667-1095-8

- Günter Krug: Mechanical watches. VEB Verlag Technik, Berlin 1987; ISBN 3-341-00356-8

- Günter Krug: Electric and electronic clocks. VEB Verlag Technik, Berlin 1987; ISBN 3-341-00190-5

- Franz Schmidlin: Electric + electronic battery clocks; Principle, function, repair. Edition Scriptar, Lausanne 1972

- Michael Arnold: Time signal and normal frequency reception; Propagation, sender, receiver, etc. Decoder. Franzis, Munich 1987; ISBN 3-7723-8171-5

- Hans Kocher: Automatic clocks. Publishing house of the Neue Uhrmacher-Zeitung, Ulm 1969

- Bernhard Schmidt: Tower clockworks - Part I. Georgsmarienhütte 2001; ISBN 3-9807704-0-0

- Bernhard Schmidt: Tower clockworks - Part II. Georgsmarienhütte 2004; ISBN 3-9807704-6-X

- Gottfried Mraz : The role of the clockwork in the imperial worship of Turks in the 16th century. In: The world as a clock. German clocks and automata 1550–1650. Edited by Klaus Maurice and Otto Mayr. Exhibition catalogs Bayerisches Nationalmuseum, Munich 1980, pp. 39–54.

- Klaus Maurice: The German wheel clock. Vol. 1., Beck, Munich 1976

- Klaus Maurice: The German wheel clock. Vol. 2., Beck, Munich 1976

- Ernst von Bassermann-Jordan , Hans von Bertele: watches. Klinkhardt & Biermann, Munich 1982; ISBN 3-7814-0205-3

- Ernst Matthäus Fürböck: Thoughts on the nature of the clock. DGC , Writings of the “Friends of Old Watches”, Book XVI, 1977, p. 14 f.

- Gisbert L. Brunner : The mechanical clockwork - a wonderful microcosm. In: The most beautiful watches. 1991, pp. 96-105.

- Helmut Kahlert , Richard Mühe , Gisbert L. Brunner: Wristwatches: 100 years of development history . Callwey, Munich 1990, ISBN 978-3-7667-0975-2 ; 5th, expanded edition, ibid. 1996, ISBN 3-7667-1241-1 (idea and conception: Christian Pfeiffer-Belli), pp. 24, 33–86, 100–115, 124 ff., Passim, and 504–506.

Web links

- Clockwork in UhrenLexikon

- Clockwork in Watch Wiki

- Volker Vyskocil: watch technology

- Siegfried Wetzel: clockwork technology and precision engineering

- Directory of movement manufacturers in TrustedWatch

- Easy to understand video from 1949 in Wimp (English, Adobe Flash )

- Animation of a simple clockwork - functions of the individual parts can be checked experimentally in scratch.mit (English / German, Adobe Flash )

Individual evidence

- ↑ Fritz von Osterhausen: Callweys lexicon. Munich 1999, ISBN 3-7667-1353-1 , p. 339.

- ↑ clockwork . In: Heinrich August Pierer , Julius Löbe (Hrsg.): Universal Lexicon of the Present and the Past . 4th edition. tape 18 . Altenburg 1864, p. 133 ( zeno.org ).

- ^ Johann Georg Krünitz: Clockwork in Economic Encyclopedia .

- ↑ Lukas Stolberg: Lexicon of the pocket watch. Carinthia Verlag, Klagenfurt 1995, ISBN 3-85378-423-2 , p. 238.

- ↑ Fritz von Osterhausen: Callweys lexicon. Munich 1999, ISBN 3-7667-1353-1 , p. 128.

- ↑ Tower clock . In: Heinrich August Pierer , Julius Löbe (Hrsg.): Universal Lexicon of the Present and the Past . 4th edition. tape 17 . Altenburg 1863, p. 572 ( zeno.org ).

- ↑ Fritz von Osterhausen: Callweys lexicon ; Munich 1999; ISBN 3-7667-1353-1 ; P. 337.

- ↑ Hartmut Wynen: Description of the technology of the ATO-MAT movement .

- ↑ Physikalisch-Technische Bundesanstalt: DCF77 transmitter .